JF-24 Pill Counting Machine: Operation

Description of all function keys on the touch screen is shown as below:

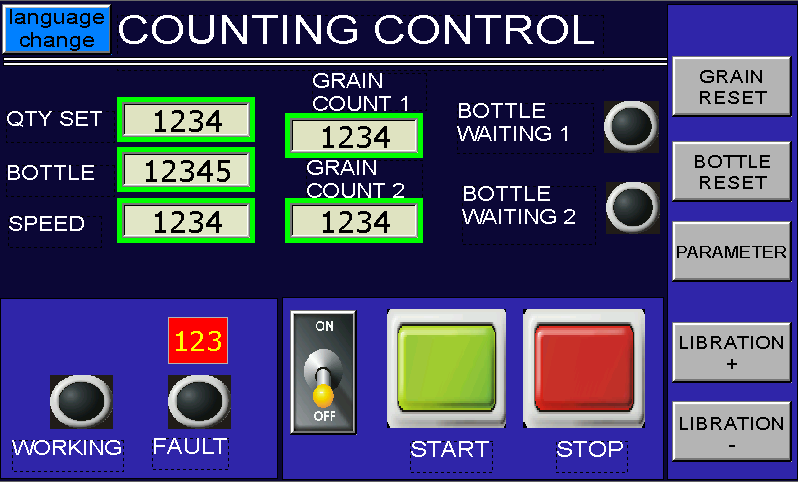

I. Plug in power, turn on the power switch and the following main screen displays:

Note: first, hit this icon to the ON![]() , so that the conveyor belt running, and then touch the right side of the start button.

, so that the conveyor belt running, and then touch the right side of the start button.

- Qty set: 0001-9999(eg.0020)

- Bottle: 0001-9999(0000) (real-time recording of bottling quantity)

Clear of number of bottle (individual clear): Touch “stop” key and then touch “Bottle reset” key. - Speed: 01-99 (00) bottle (bottles)/min

- Grain Count 1: 0001=1-9999 (0000)

Clear of Grain Count 1 (individual clear): Touch “stop” key, and then touch “Grain Reset” key. - Grain Count 2: 0001-9999 (0000)

Clear of Grain Count 2 (individual clear): Touch “stop” key, and then touch “Grain Reset” key. - Start: Start working

- Stop: Stop working

- Libration+: Micro-adjustment of speed, synchronously increasing vibration of the first grade and the second grade.

- Libration-: Micro-adjustment of speed, synchronously reducing vibration of the first grade and the second grade.

- Working: If the machine works in normal condition, indicator light is red.

- Fault: If the machine works in abnormal condition, the indicator light is on. And corresponding fault number displays. (101-112 and 201-212 shows there is failure in channel. For example, 101 shows that there is failure in the first channel; 80 shows there is failure in communications; 81 shows that the warehouse stock exceeds the set value)

- Bottle waiting 1: If there is no bottle below first track, indicator light is red, and the machine doesn’t work; if there are bottles, indicator light is green and the machine starts working.

- Bottle waiting 2: If there is no bottle below second track, indicator light is red, and the machine doesn’t work; if there are bottles, indicator light is green and the machine starts working.

Parameter

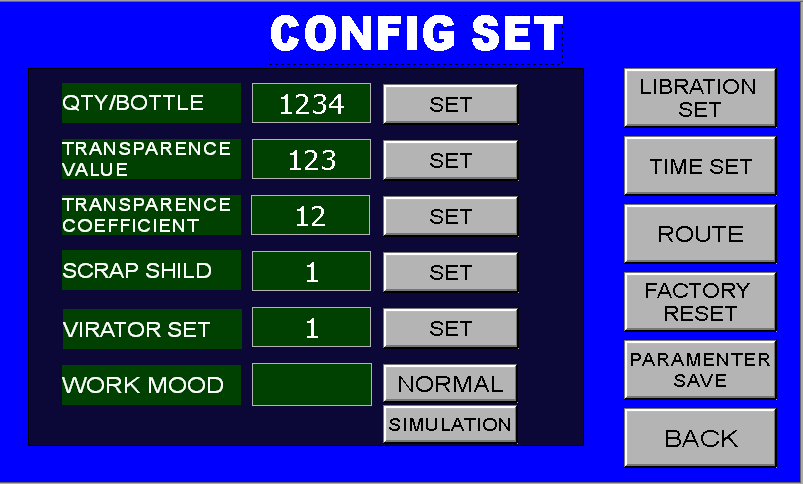

Touch “Parameter” key, the following picture frame displays

A. Qty/Bottle: 0001-9999(0020) The parameter adjusts the number of bottles.

B. Transparence value:001-250 (210). The value is used to set the maximum sensitivity of each photo-electricity eye and corresponding change in a certain range. If it is beyond the value, the alarm will remind.

C. Transparence coefficient: 1-20 (1) If transparent medicine is long, the high value should be set. The function has conflicted with maximum filtering length. Close the function of filtering bits for transparent medicine (Maximum filtering length is set as 001). Set 1 for the opaque medicine.

D. Scrap shield: 1-7 (eg. 1) When the JF-24 pill counting machine counts the particles, shield the medicine with particles, so the counter will not count. The value is bigger, filtered fragment length is larger. However, there is possibility for error. Close the function of transparent medicine in this condition (Set sensitivity of transparent medicine as 1)

E. Vibrator set

Display 1: Shows that when the particle counting is 90%, vibration becomes slow (Debugging value is 70% now).

Display 2: Shows that vibration didin’t becomes slow.

F. Work mode: Shows whether the machine is in normal or simulated state.

F1. Normal mode: Selection mode of normal particles counting.

F2. Simulation of medicine prescription: Select the mode in test-run of the machine to test whether all aspects can work normally. (When the counting is normal, switch from simulation of medicine prescription into normal operation mode, or the counting can’t be normal)

G. Libration set

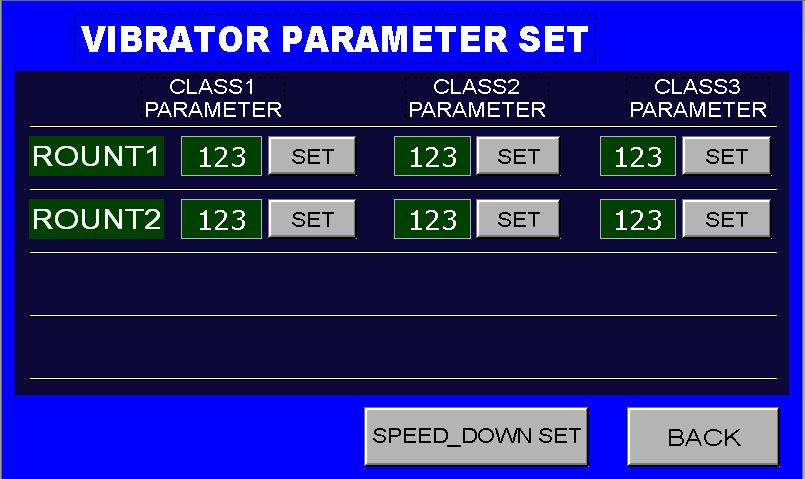

Touch “Libration set” key, the following picture frame displays:

- Class 1 parameter: 1-100 (50) Adjust the vibration of first grade.

- Class 2 parameter: 1-100 (50) Corresponding adjust second channel of vibration.

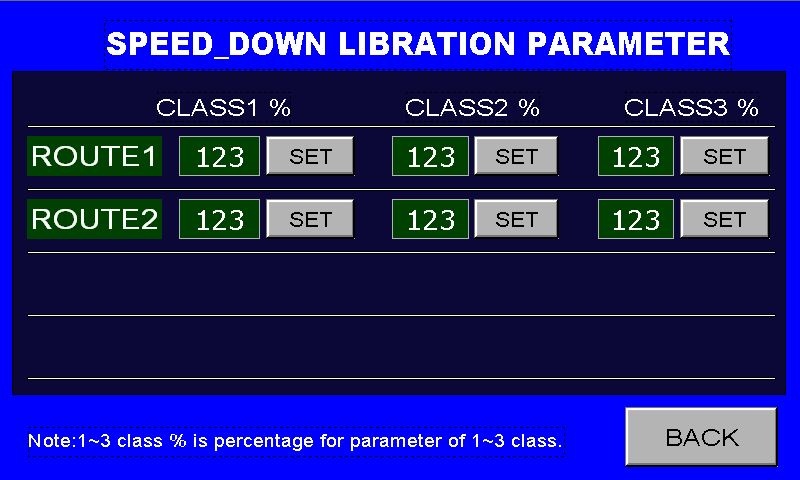

- Speed-down set:

Adjust according to the percentage of normal value.

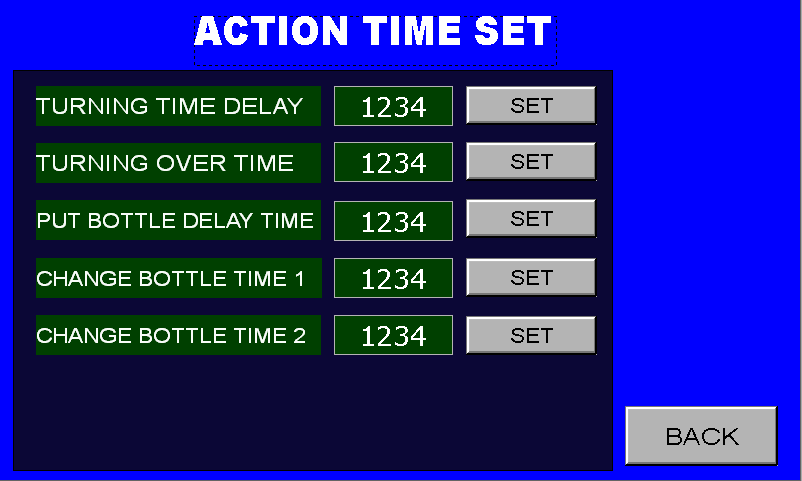

H. Time set

Touch “Time set” Key, the following picture frame displays:

- 1: Turning time delay: 001-100 ms (035)

The time will has effect on the accuracy of bottle separation. If the medicine drops smoothly in the channel, there are many bottles in the front, which means that the value is bigger; if there is only a few bottles in the front, which means the value is smaller; in addition, if the value is inappropriate, the medicine may fall in plate turning - 2:Turning over time: 001-500ms (350).

Time for plate turning is also used for precise counting which should be set as proper number, yet shouldn’t too small. - 3: Put bottle delay time: 001-500 ms (500)

If the setting number is too small will cause bottles pass away and medicine still in the medicine bucket; the number is too big will slow down the overall speed. - 4:Change bottle time 1: 0-2000ms(120)

Refers to the size of the bottle, to set the first channel and second channel cylinder’s delay time. - 5:Change bottle time 2: 0-2000ms(120)

Refers to the size of the bottle, to set the third channel and fourth channel cylinder’s delay time.

Note: The above data is based on the transparent drug debugging data before leaving the factory.

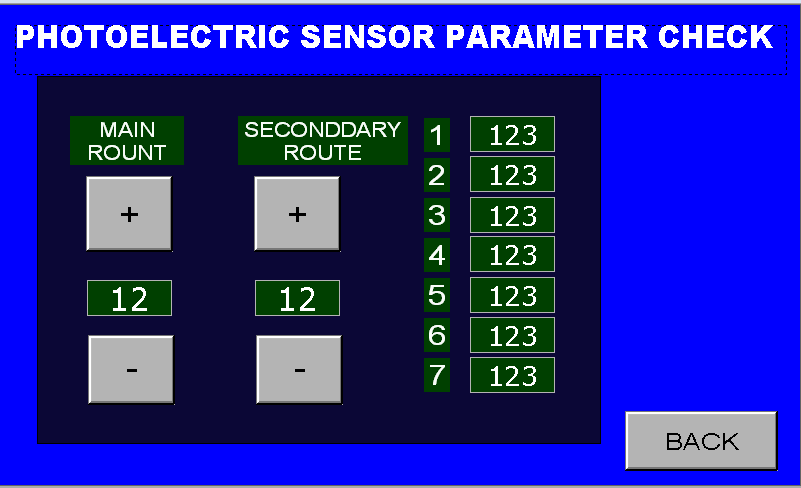

I. Channel

Observe the value of photo-electricity eye in the secondary route, the value displays the sensitivity of photo-electricity eye. The smaller the value is, the higher the sensitivity is.

J: Factory reset: Touch the key to recover original factory set.

K:Parameter save: Save the parameter after each adjustment.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche