Labeling Machine Parts: Everything You Need to Know

The labeling machine is the unsung hero in the packaging world. It works quietly to ensure that every product gets right and solid label.

But, have you ever wondered what are the key components that make a labeling machine shine? In this article, we'll introduce you to the 10 most important components of a labeling machine and show you how they work together to keep your labeling machine running smoothly.

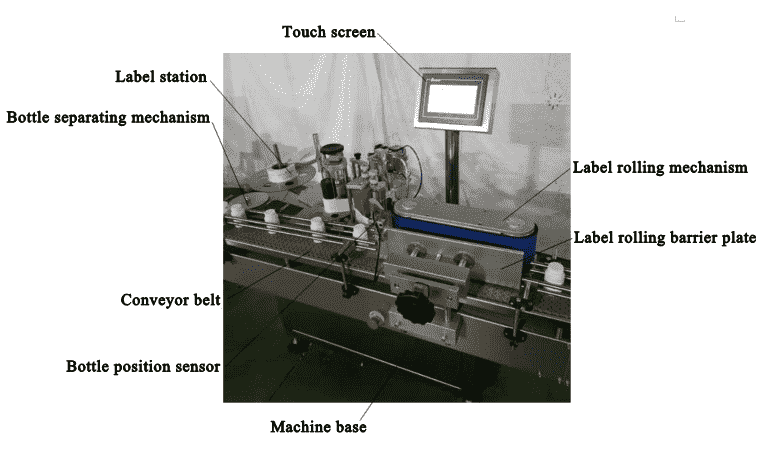

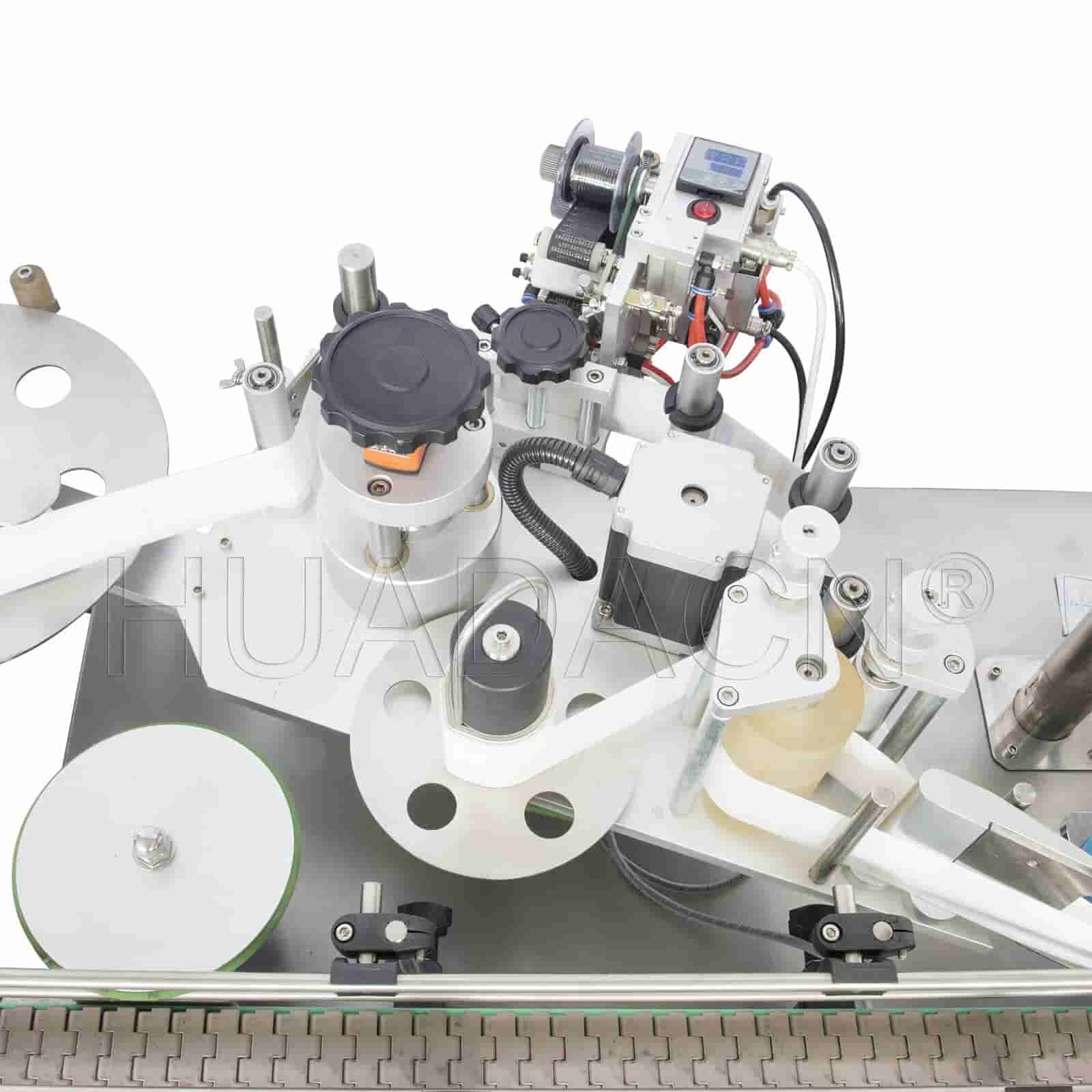

Basic Structure of a Labeling Machine

Before we delve into the specific components of the labeling machine, let's take a look at the picture below. It shows the basic structure of a labeling machine and how its main components arrange. With this picture in mind, it will be easier for you to understand what a labeling machine is and the detailed description of each labeler component later on.

10 Most Important Parts of a Labeling Machine

Different types of labeling machines may have some exclusive parts. However, the parts we are going to talk about are common to most labeling machines.

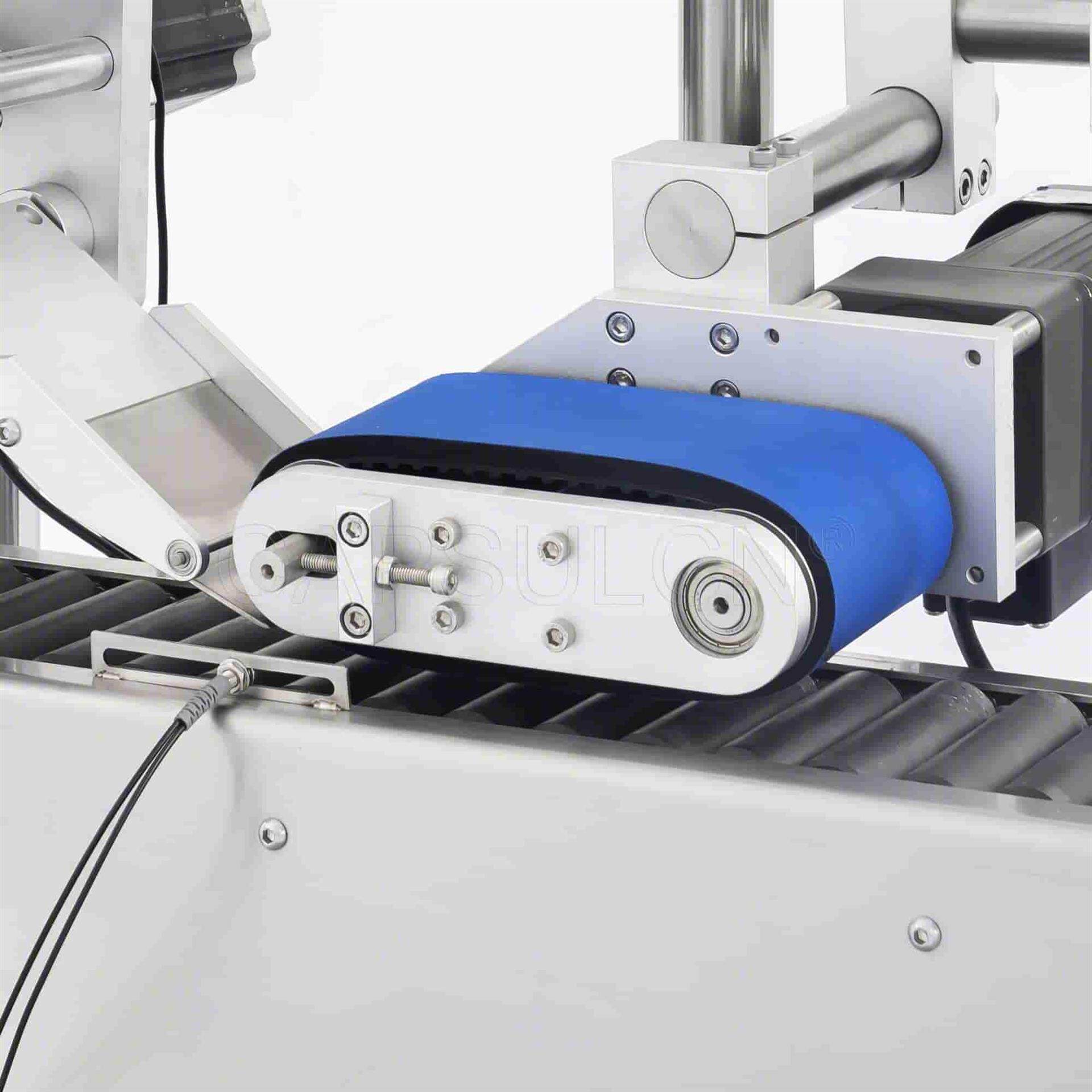

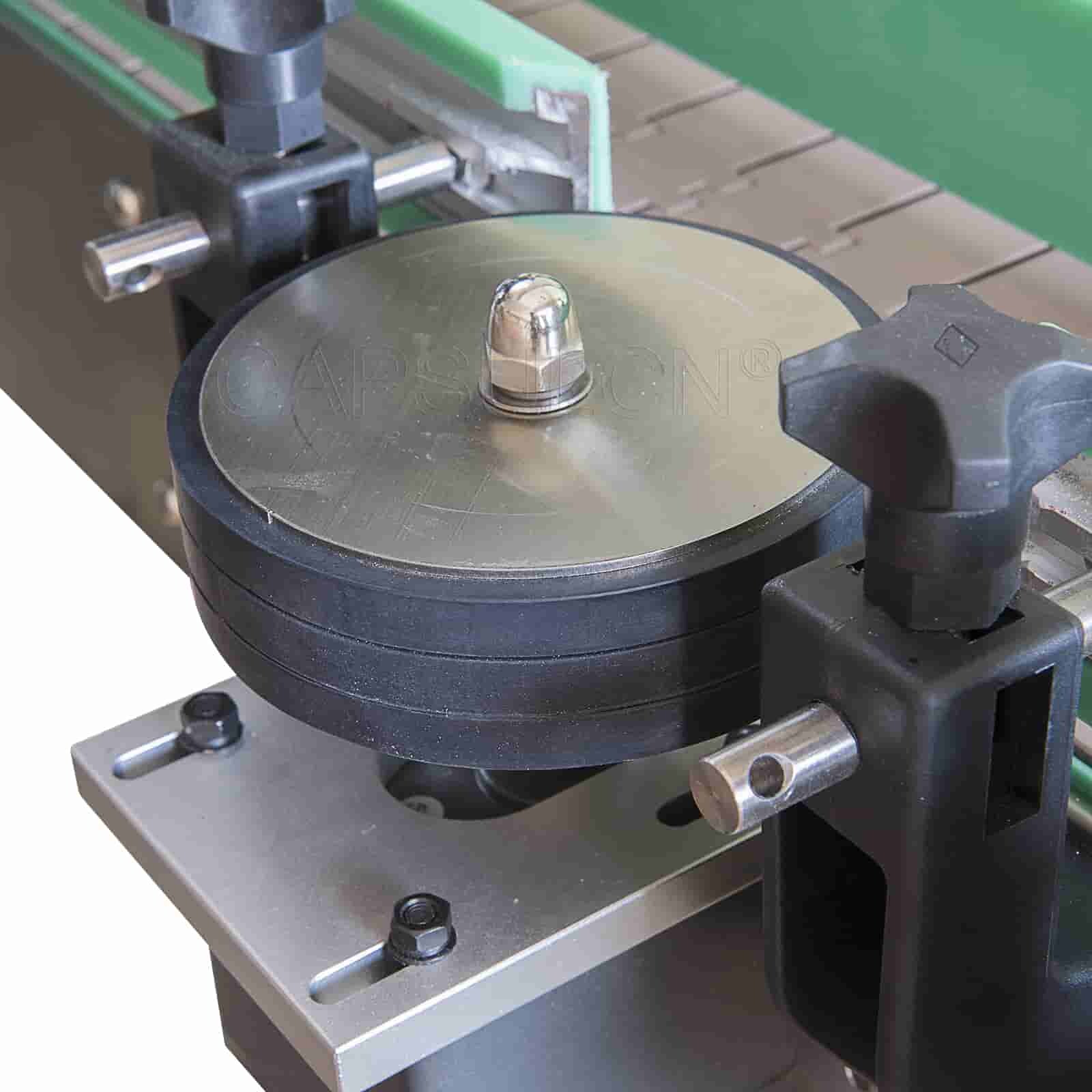

1. Conveyor Belt

A conveyor belt transports the product from the inlet to the labeling station and then to the discharge area. The speed of the conveyor belt can usually be adjusted to meet the desired production speed and ensure proper labeling.

In addition, labeling machines can be equipped with different types of conveyor belts depending on the shape and size of the product, such as flat belts, slat belts or roller belts.

Accuracy is critical in the labeling process. For this reason, some labeling machine conveyor belts also have guides to ensure precise product alignment. These kind of adjustable guides are usually located on both sides of the conveyor. They precisely guide the products to move forward smoothly.

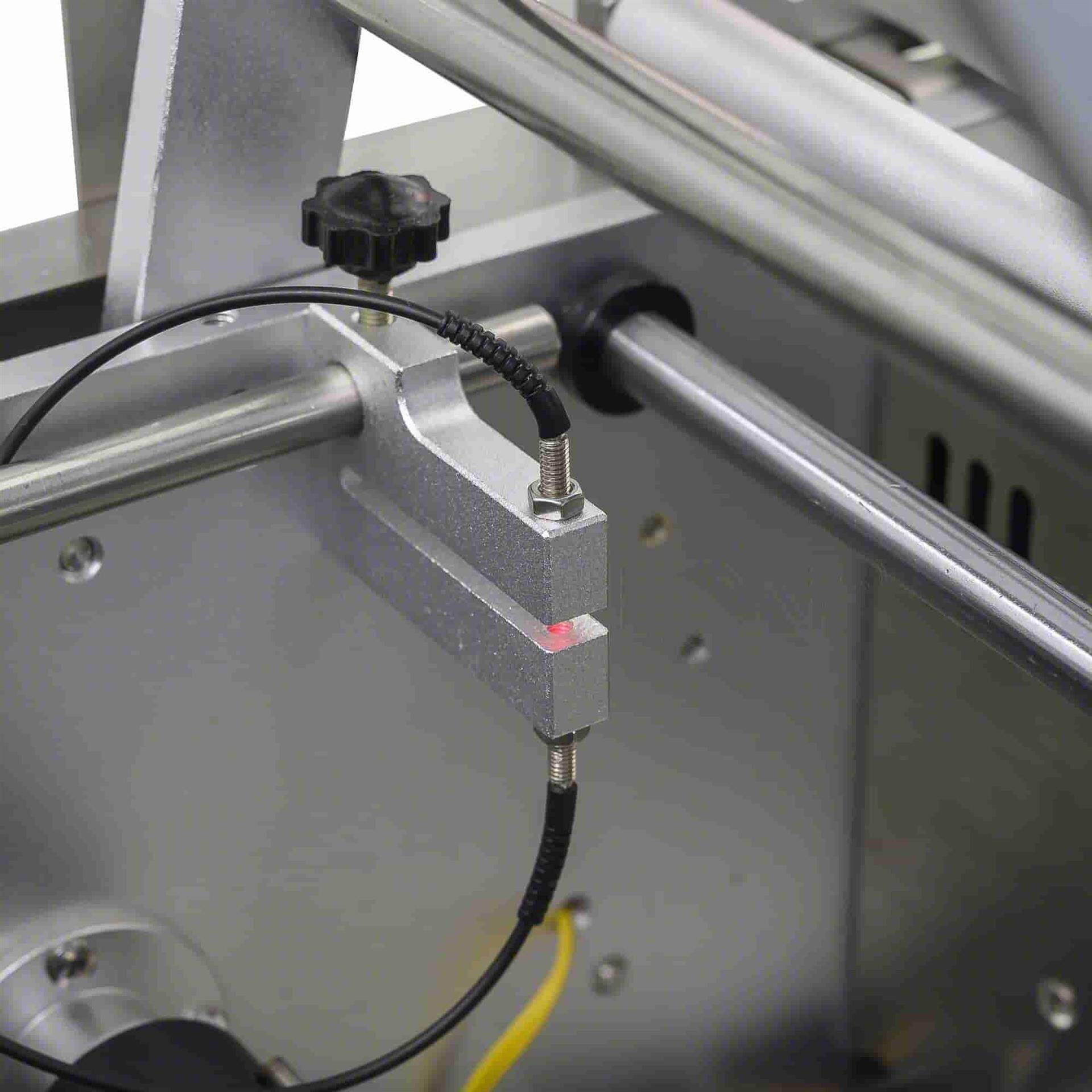

2. Product Sensor

In a labeling machine, a product sensor identifies the presence and specific location of the product when it enters the labeling zone. Depending on your product characteristics, labeling machines can use different types of sensors, such as photoelectric sensors, proximity sensors or vision systems.

The product sensor only triggers the labeling process when it detects a product. So, this can help avoid wasted labels and ensure correct label placement.

3. Label Unwind Stand

The label unwind stand holds the label roll securely and feeds it into the labeling head at a set speed.

In addition to feeding the label roll into the labeling machine, the label unwind stand also has a guiding function. During the unwind process, the guiding system of the unwind stand keeps the label rolls centered and aligned. This effectively avoids inaccurate labeling positions or even paper jams due to skewed labels.

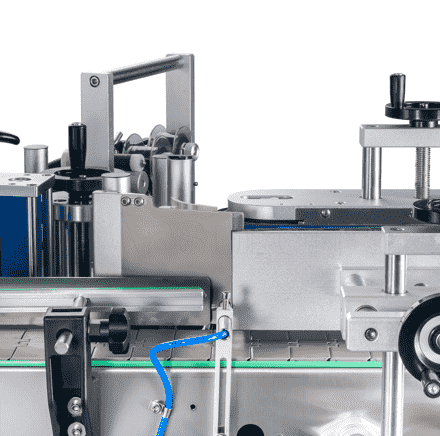

4. Label Dispenser

A label dispenser separates individual labels from a continuous roll of labels fed from an unwind rack. It uses tools such as peelers or vacuum systems to carefully separate labels without damaging them. The separated labels are then carried on a conveyor belt and placed exactly where the labeling head is ready to apply them.

5. Labeling Head

The conveyor belt delivers the product to the labeling station. Here, the labeling head grabs the label from the unwind stand via various mechanical devices such as vacuum pads, tamping pads or belt systems.

Then, the labeling head will accurately position the label in its designated location on the product. This kind of positioning accuracy of the labeling head ensures that every label is correctly aligned and applied.

6. Label Sensor

Similar to the function of a product sensor, the biggest use of a label sensor is to detect the presence of a label at different stages of the labeling process.

If it is before the product enters the labeling head, the label sensor can make sure that the label dispenser is ready for labeling and prevents the machine from triggering the labeling procedure without a label.

After the product leaves the labeling head, the label sensor can be used to confirm that the label has been successfully applied to the product. And, it can release a signal to the labeling machine which triggers subsequent operations, such as product unloading.

7. Control Panel

For an automatic labeling machine, the control panel is of great use. It provides the interface to start, stop and pause the labeling machine. The control panel allows the operator to set key parameters such as labeling speed, product feeding speed, labeling time and temperature settings for different labeling materials.

Some labeling machines control panels even offer various operating modes, such as manual, automatic and batch. You can choose the mode you like via a touch screen.

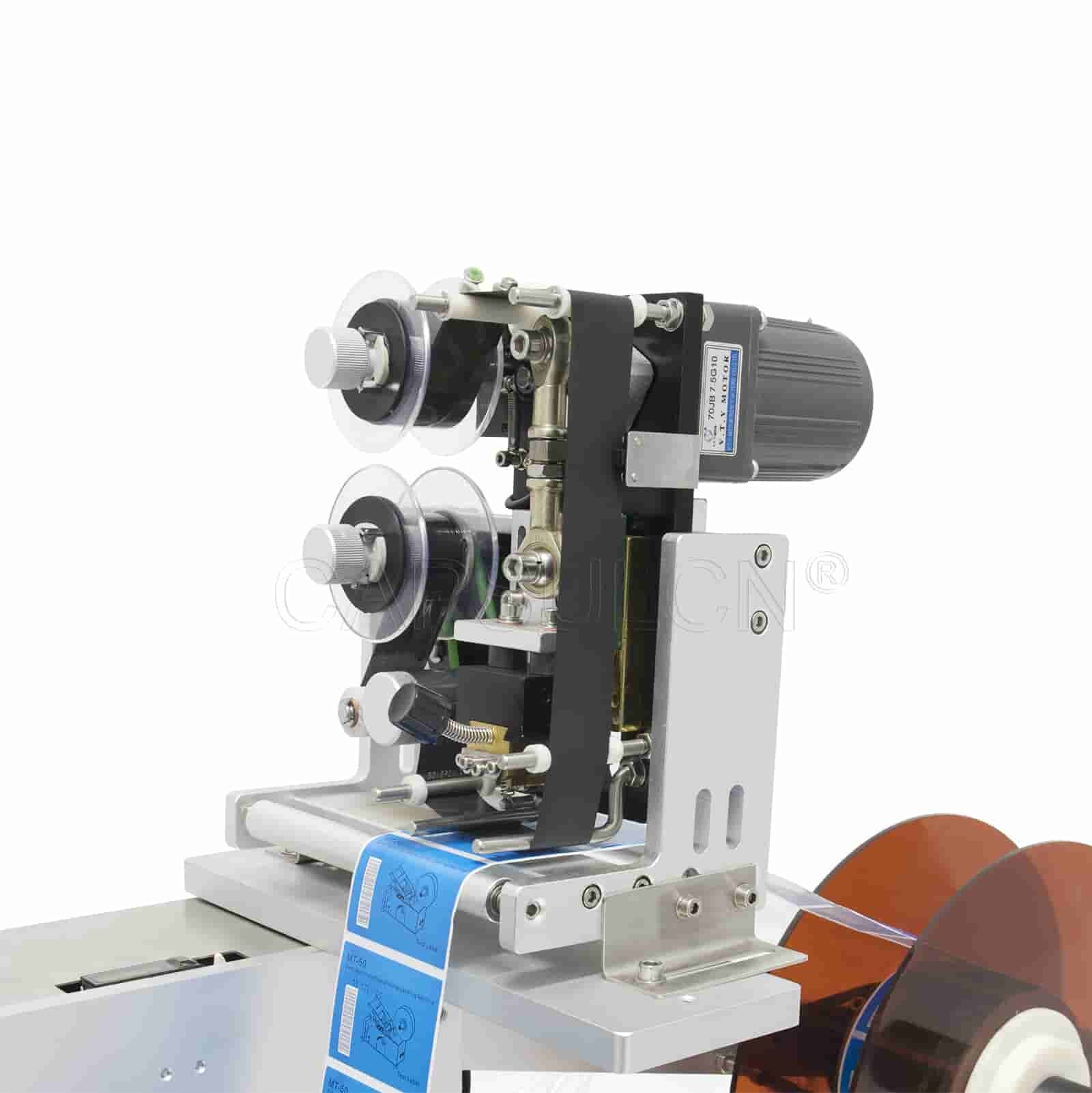

8. Printing Device (Optional)

Some labeling machines even have an integrated printing device. This device prints labels directly on the label roll as it passes through the labeler. This allows for variable data printing, and each label can be customized with unique product information, such as product name, batch code, or expiration date.

Typically, labeling machines can be equipped with many types of printing devices, including inkjet, thermal transfer or laser printers. Which printing device to choose depends specifically on the label quality, speed and resolution you need.

9. Rejection System

The rejection system is the gatekeeper on the conveyor belt of a label machine. It comes with a sensor to identify mislabeled and unlabeled products. Once detected, the reject device will remove the faulty product from the labeling line as soon as possible. It ensures only correctly labeled products move forward.

This reject device guarantees the quality of all final products are consistent, and prevents mislabeled products reaching the market.

10. Rewind Unit

The rewind unit brings an eco-friendly element to the labeling machine. This device can collect unused labels and effectively manage labeling wastes. This responsible rewind unit creates a cleaner work environment and reduces resource waste. More importantly, it makes the labeling machine become a sustainable labeling solution.

Wrapping Up

At the end of the day, the components of a labeling machine are not just individual parts, but a system that works together to maximize machine efficiency.

Therefore, if you want to achieve the best labeling results and maximize the value of your labeling machine, it's important to understand the importance of each component and maintain them properly.

Are you are looking for a high quality labeling machine? iPharMachine may be your right choice. Our labeling machines are top-notch in the whole industry. We use robust and durable components to make our equipment. And, no matter what type of product you have, we can customize a perfect labeling solution for you.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche