Introduction

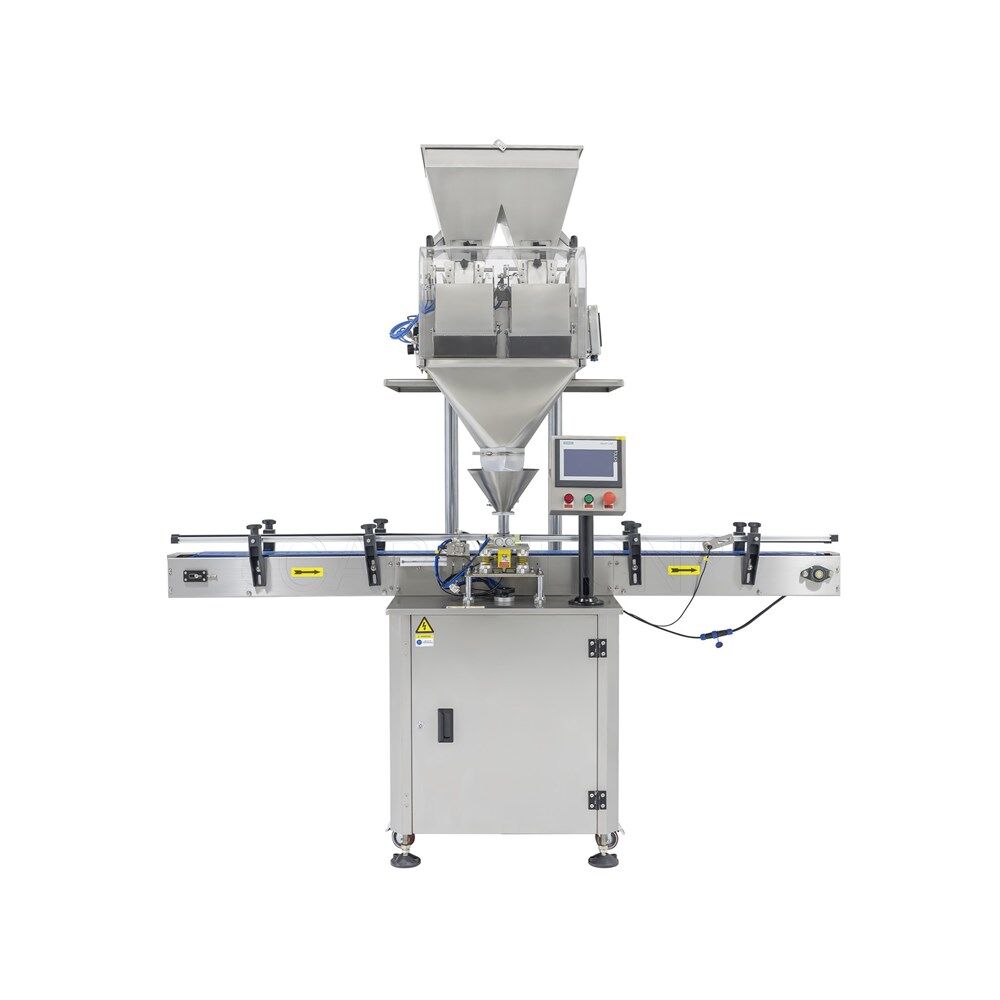

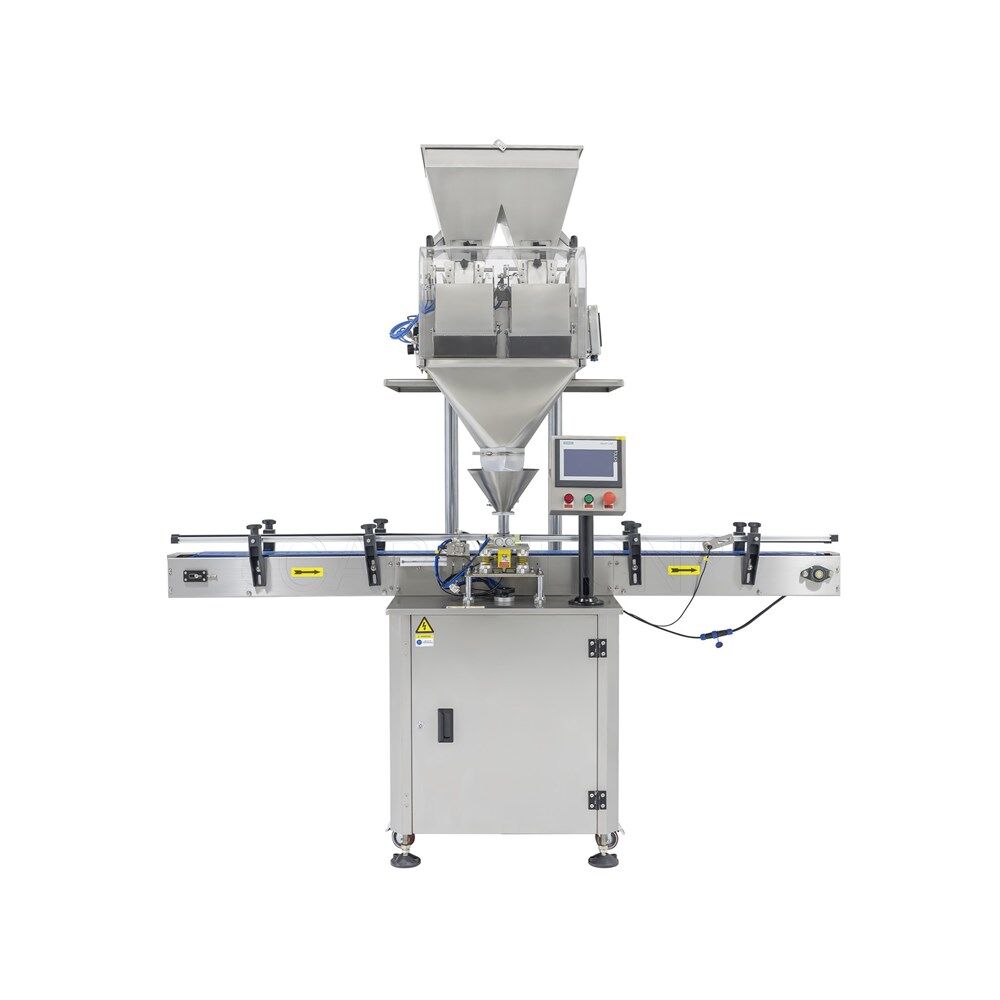

The machine collects the weight of the material in the weighing hopper in real time, and after analysis and processing, changes the working amplitude of the wire vibrating machine, thereby controlling the feeding speed of the wire vibrating plate, so that the weight of the material in the weighing hopper approaches the target weight, and achieves the target weight. The purpose of material weighing and subcontracting.

Application

all kinds of small granular

Specifications

| Model | CN-X2-2-1 |

|---|---|

| Max Outputange | 32ppm |

| Accuracy | 1-3% depending on product size /machine speed. |

| Single Weighing Range | 50-3000g |

| Hopper Volume | 4.5L |

| Parameters Press No. | 20 |

| Max Mixing Products | 2 |

| Power | 800W |

| Voltage | 220V/50/60HZ/4A |

| Packing Dimension(mm) | 685(L)*814(W)*971(H) |

| Weight | 130KG |

Details Images

- Copy 1.png)

.png)

.png)

Remarks

-

No bumping or strong pressure on weigh hoppers.

-

Check and empty the rest products inside the machine before running.

-

Press “ZERO” to make empty and zeroing before the first running.

-

Turn off the power before repairing and cleaning the machine.

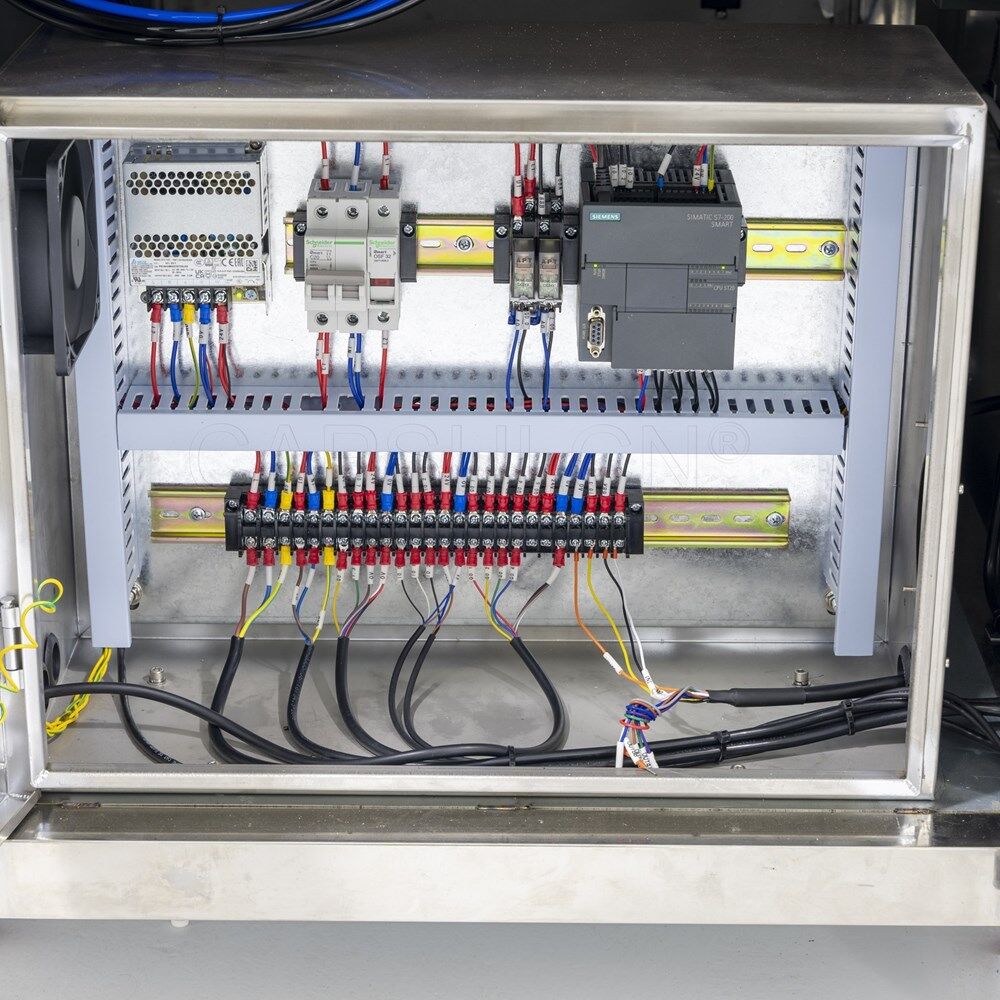

-

When electronic part is failed, non-electronic engineer is prohibited to repair the machine.

-

Be careful when cleaning and repairing the machine, since there is a certain distance from the ground when the weigher is installed above the packaging machine.

- The DC voltage of the signal connected to other equipment (such as packaging machines, conveyors, etc.) should not exceed 30V, and the load current should not exceed 100mA.

- It is strictly forbidden to touch the hopper when the machine is running.

- When using an air compressor, the air pressure must be stable, not less than 0.5MPa, and use a dryer to keep the cylinder dry.

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

Multi- Heads Linear Weigher

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche