Introduction

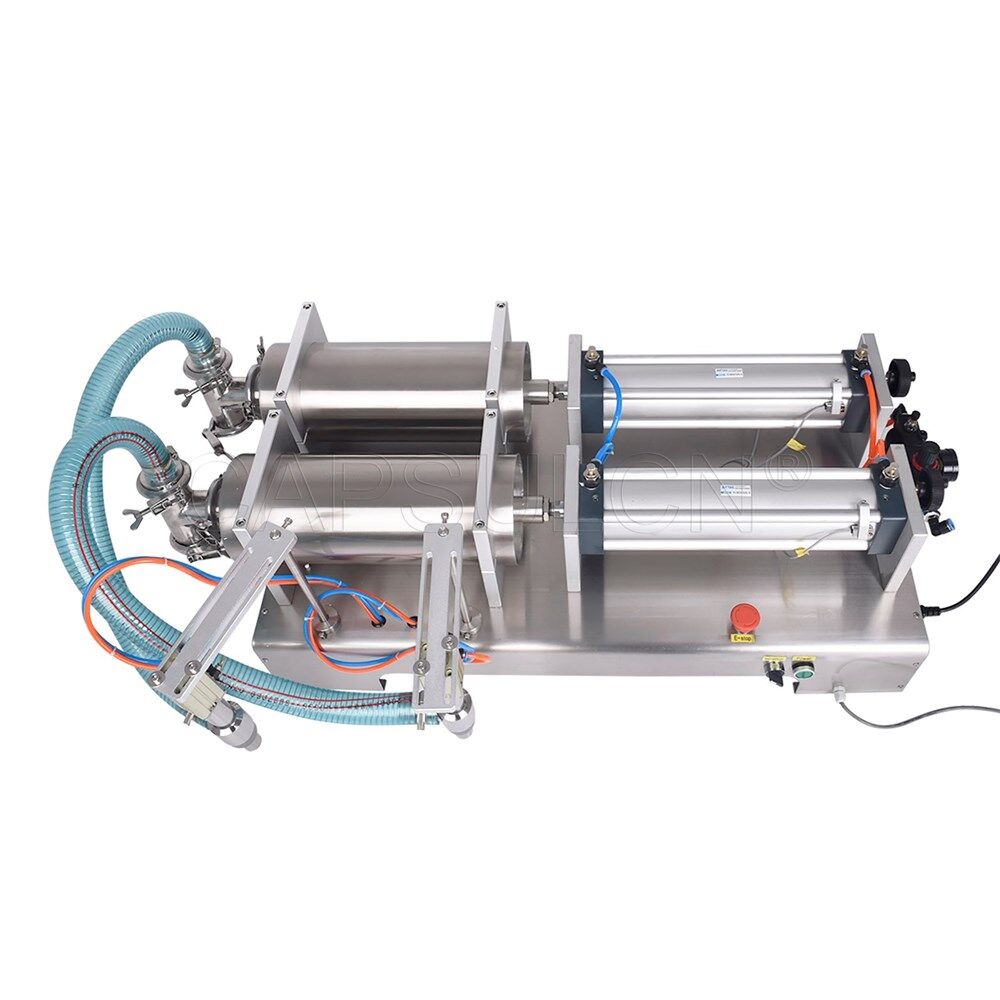

The machine is to operate and is well-designed, easy to disassembly and to be washed, and has higher filling accuracy. The parts in contact with the material are made of 304 stainless steel (316L can be customized), which meets the requirements of GMP. The sealing parts are all made of PTFE and silicone materials, which have the advantages of corrosion resistance, aging resistance, high temperature resistance, and good sealing. It is an ideal choice for filling equipment in food, pharmaceutical, chemical, daily chemical, oil, pesticide and other industries.

Feature

- Easy to operate, disassemble, and wash.

- It has high filling accuracy and is made of 304 stainless steel (with an option for 316L) to meet GMP requirements.

- The sealing parts are made of PTFE and silicone for corrosion resistance, aging resistance, high temperature resistance, and good sealing.

- This machine is suitable for filling equipment in various industries such as food, pharmaceutical, chemical, daily chemical, oil, and pesticide.

Specifications

| Model | C1WY |

|---|---|

| Input Voltage | 220V±5V 110V±5V |

| Current | 1A |

| Power | 10W |

| Air pressure | 0.4-0.6MPa |

| Filling Speed | 10-30 bottles/ min with one outlet; 20-60 bottles /min with two outlets |

| Filling Accuracy | ±0.5%-±1% |

Specifications

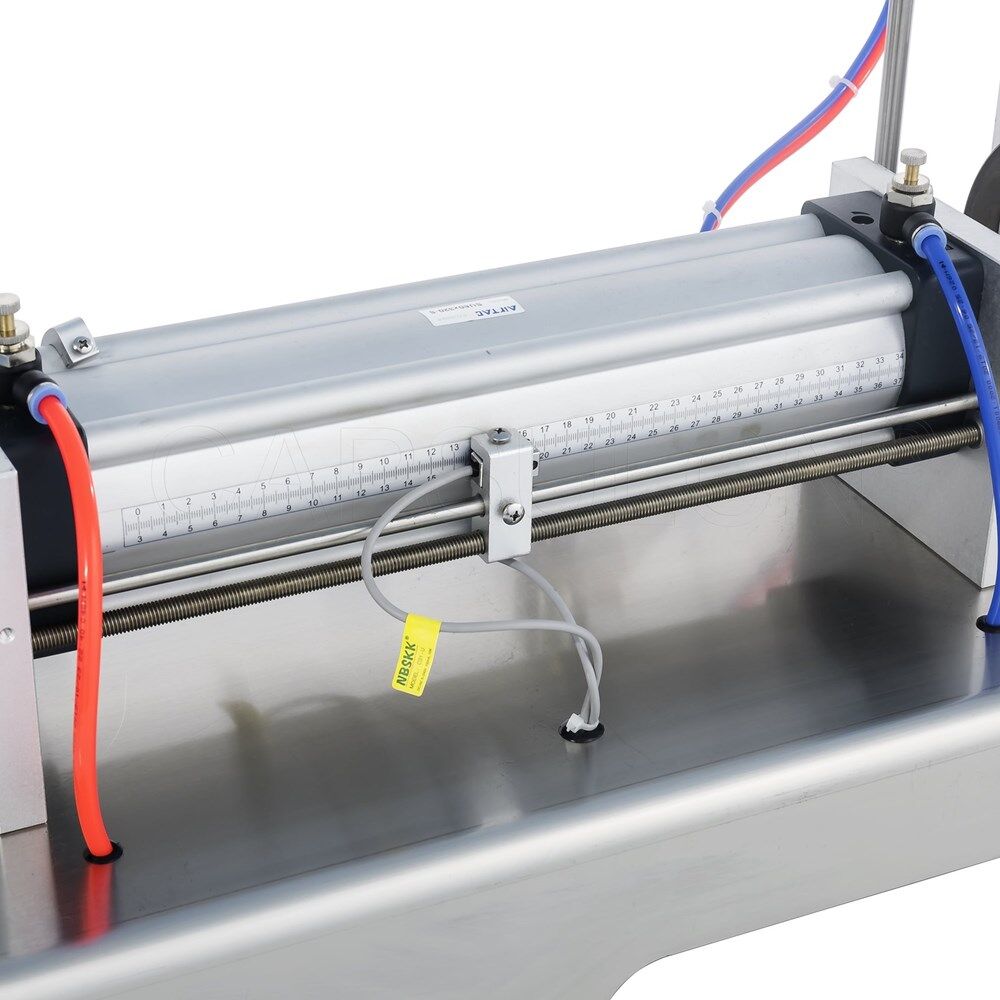

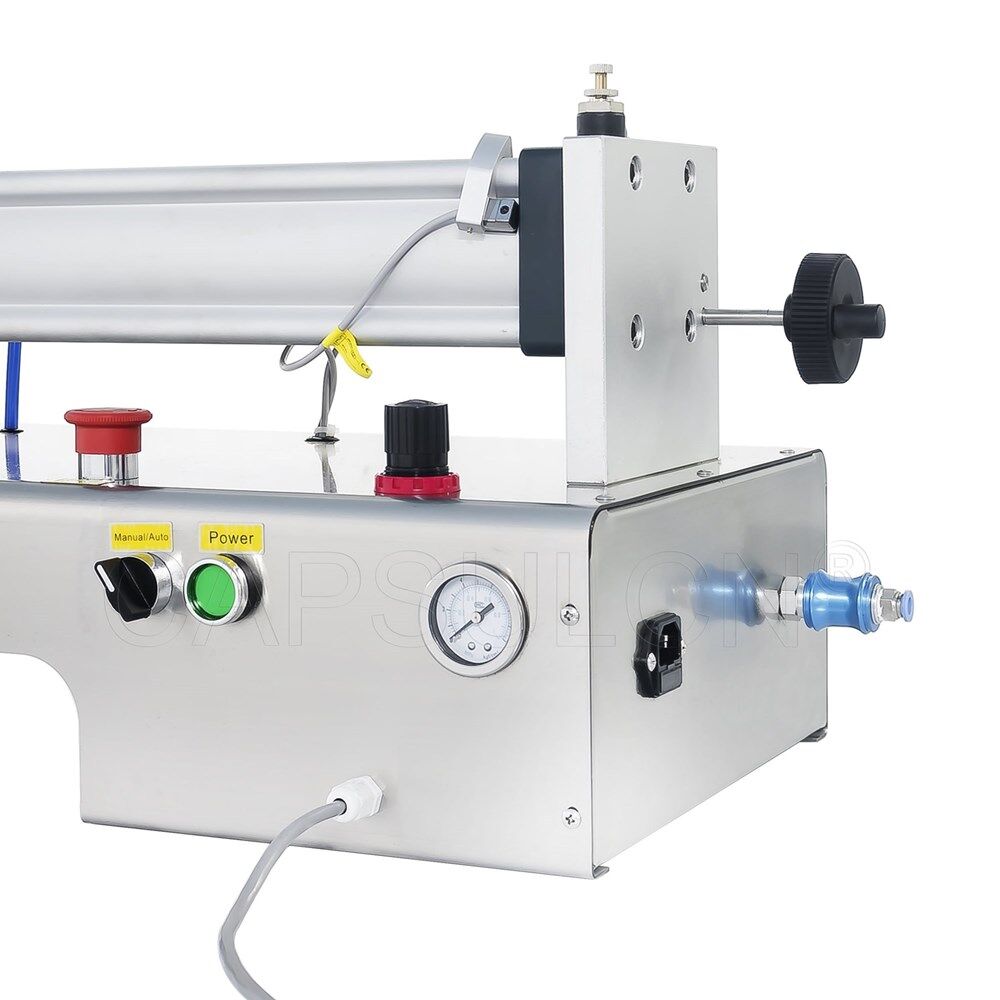

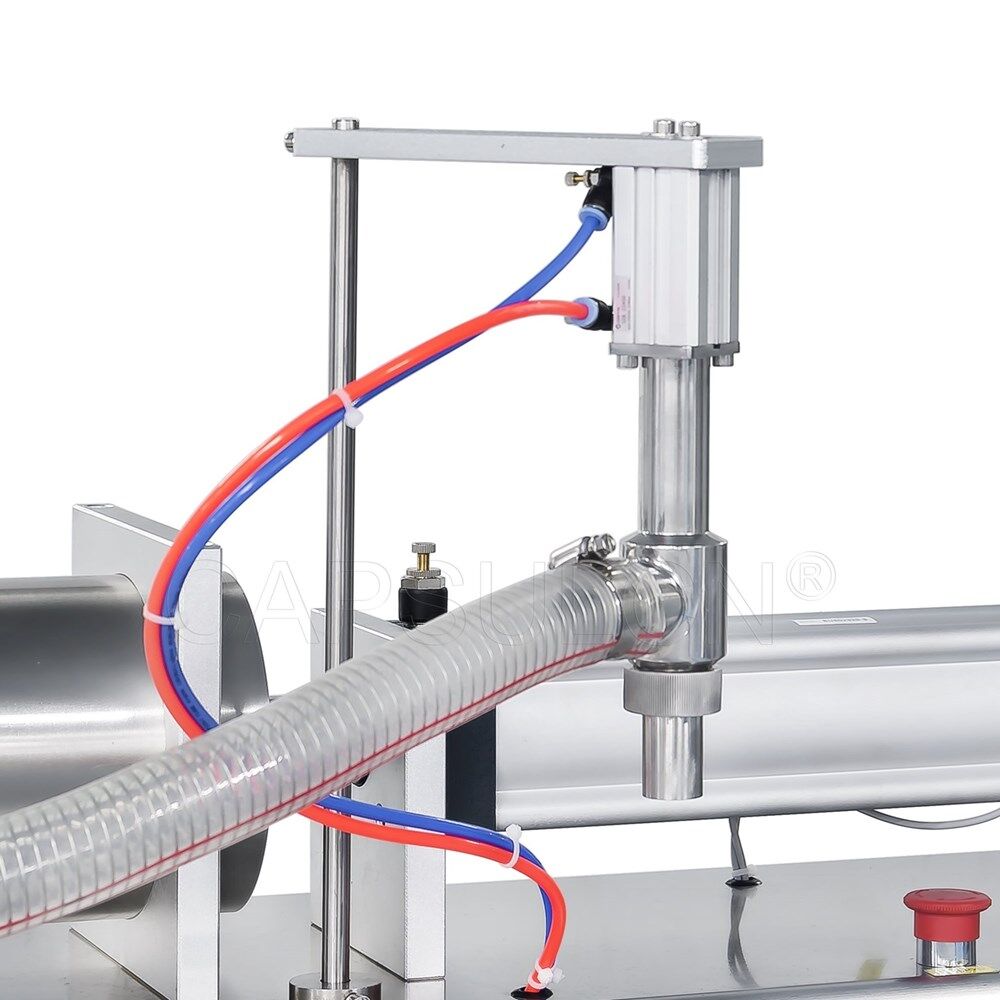

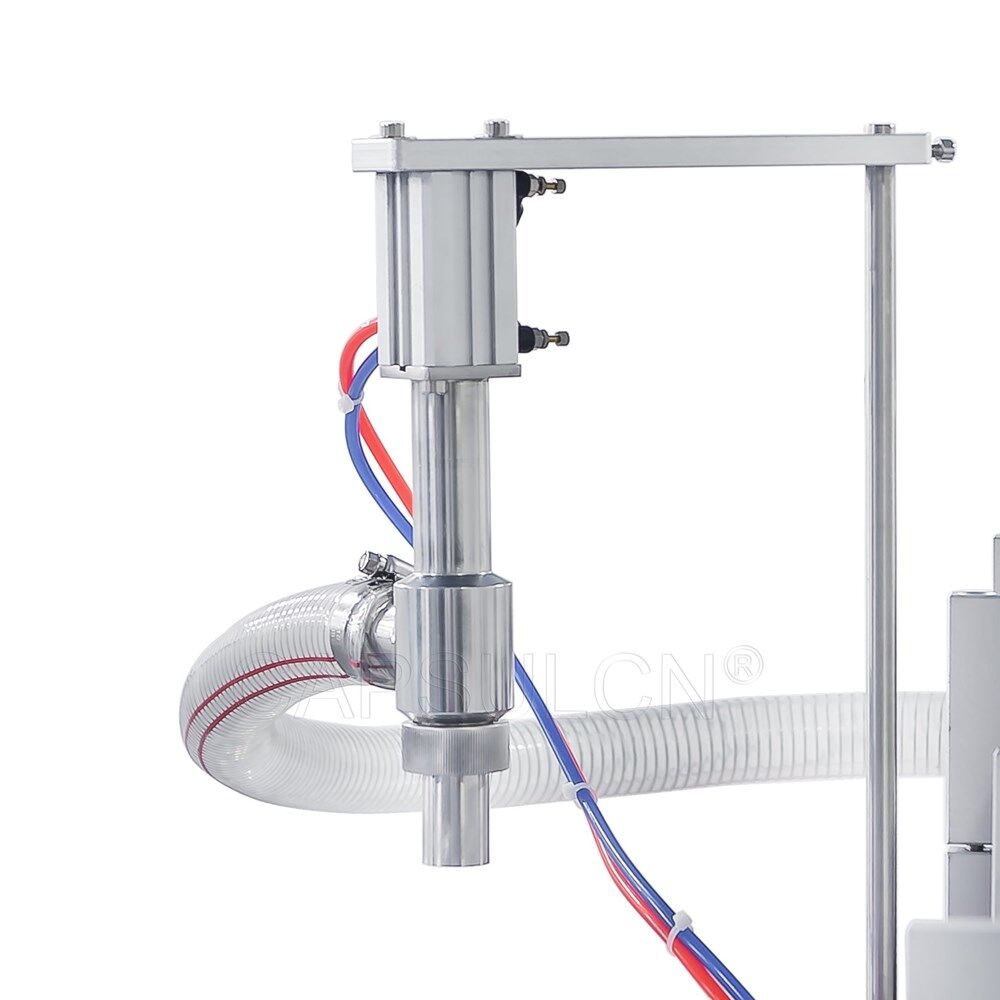

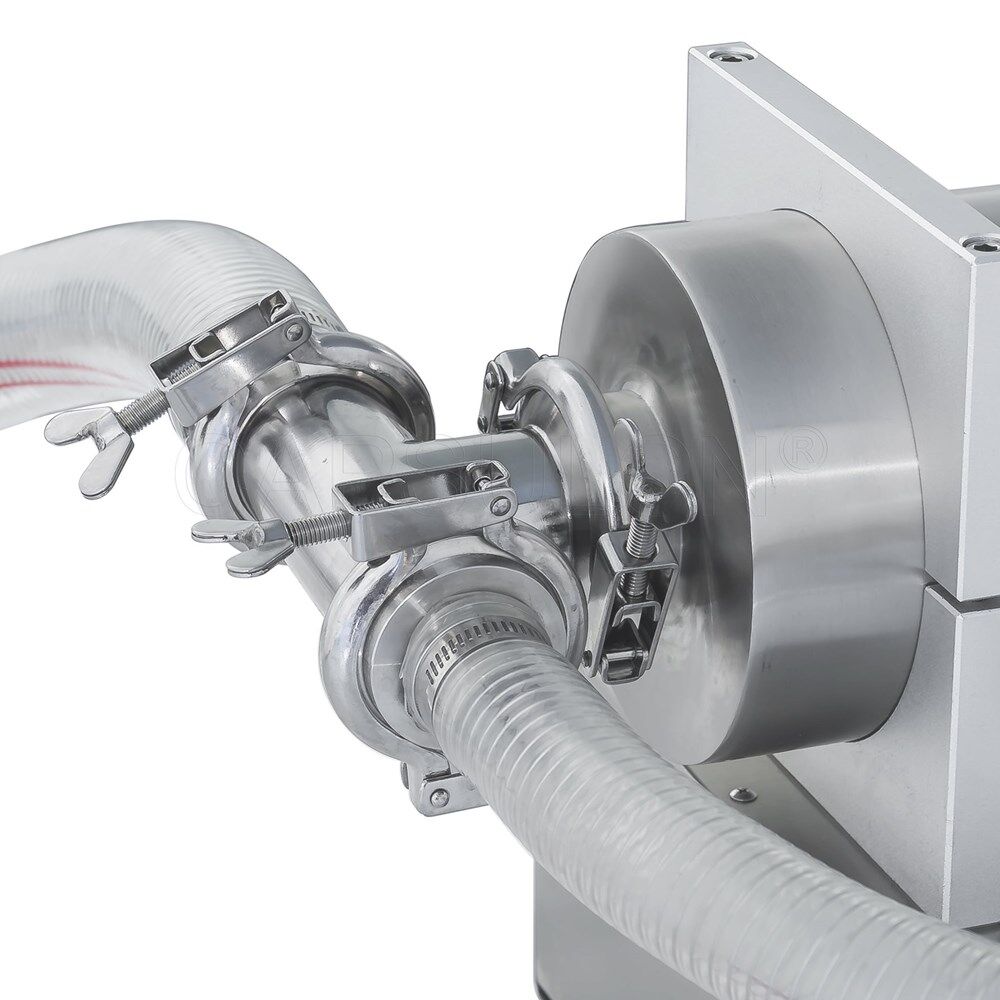

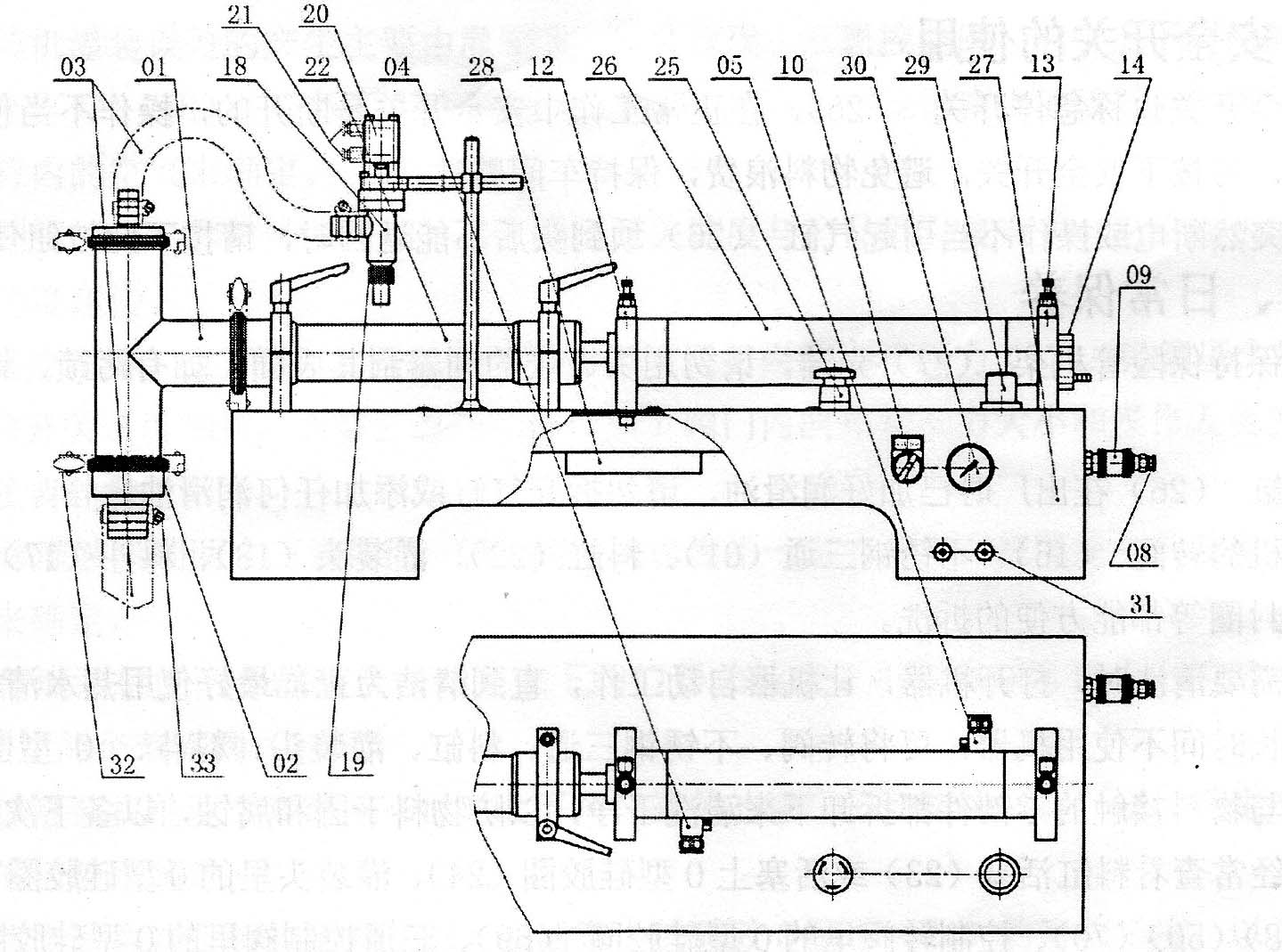

(01) three-way control valve(02) feeding joint (03) tube (04) movable magnetic switch (05) fixed magnetic switch (06) power line (07)power switch (08) air source quick-installation socket (09) air source switch (10) selector switch (11) safety seat (12) speed-adjusting throttle valve (13) time gap-adjusting throttle valve (14)hand wheel (15)U-shaped three (16)Rotary valve (17) hopper (18)filling head (19)changeable nozzle (20) thin cylinder (21)thin cylinder throttle valve (22) material cylinder (23)material cylinder piston(24) piston O-shaped Silicone sealing ring(25) emergency Stop (26) Cylinder (27) machine body (29) press-adjustment filter (30) barometer (31) foot switch line (32) clamp (33) tube buckle

Remarks

The machine is only suitable for filling liquid. To ensure safe production, read carefully about the precautions:

1. Use air source and power complying with this machine (Referring to the specifications of this manual). Make sure the stability of the air source when the machine is continuously working.

2. Do cut off air source and power before disassembling and washing this machine.

3. Electrical control elements are built in the rear part (close to the control button) of the machine. Do not wash the machine with water at any circumstance in case of electric shock and damage to controlling elements.

4. A reliable earth wire should be ensured by providing a socket with an earthing line.

5. Plug out when repairing the circuit as voltage may still be in the circuit of power control even when the power is off.

6. Do not put your eyes close to the filling head when the machine is working, pay attention to personal safety.

7. Do not put your hand on the center shaft of the cylinder in case of being clamped.

8. Before filling, it is best to use detergent to clean the machine first, and then clean it with water. It is to avoid oil stains or foreign objects mixed with materials, resulting in waste of materials and damage to the machine.

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche