Top 3 Things You Need to Know About Liquid Packaging

Packaging liquid formulations can sometimes be a challenge. Liquids move easily and can spill easily too. They also require careful temperature control and an understanding of how thick or thin they are. To get your product to market successfully, you need to learn everything about the equipment, materials, capacities, and uses of liquid packaging.

Starting a liquid packaging business may seem overwhelming. But with some planning, you can make this process easier. Liquid products are in high demand in many industries, like pharmaceuticals, food, and beverages. This has made liquid packaging more important.

This blog will give you some helpful tips to ease your way into liquid packaging. We'll talk about top three things for anyone working with liquid packaging. We want to equip you with tools you need to make this process more smooth.

1. Keep an Eye on the Temperature

You have to keep an eye on the temperature to make sure your liquid products stay effective from start to finish. This is especially important if you're moving, shipping, or storing products because changes in temperature can mess up the product.

For example, medicines often have strict temperature requirements. Some meds are sensitive to temperature changes, and they are also known as "cold chain" medications. Thus, they need to be stored within specific temperature ranges, usually between 2°C and 8°C. If exposed to temperatures outside this range, they might not work properly or even become dangerous.

Besides, temperature control is crucial for keeping perishable food and drink products safe and quality. When it's too hot, microbes can grow faster. Then, the food might go bad, have bad flavors, and make people sick.

So what can you do to regulate the temperature?

Insulated Packaging - You can use insulated packaging materials, like those made from Polylactic Acid (PLA). They keep products at the right temperature while they're being shipped. Plus, PLA keeps things cool for a long time, which helps keep temperatures steady.

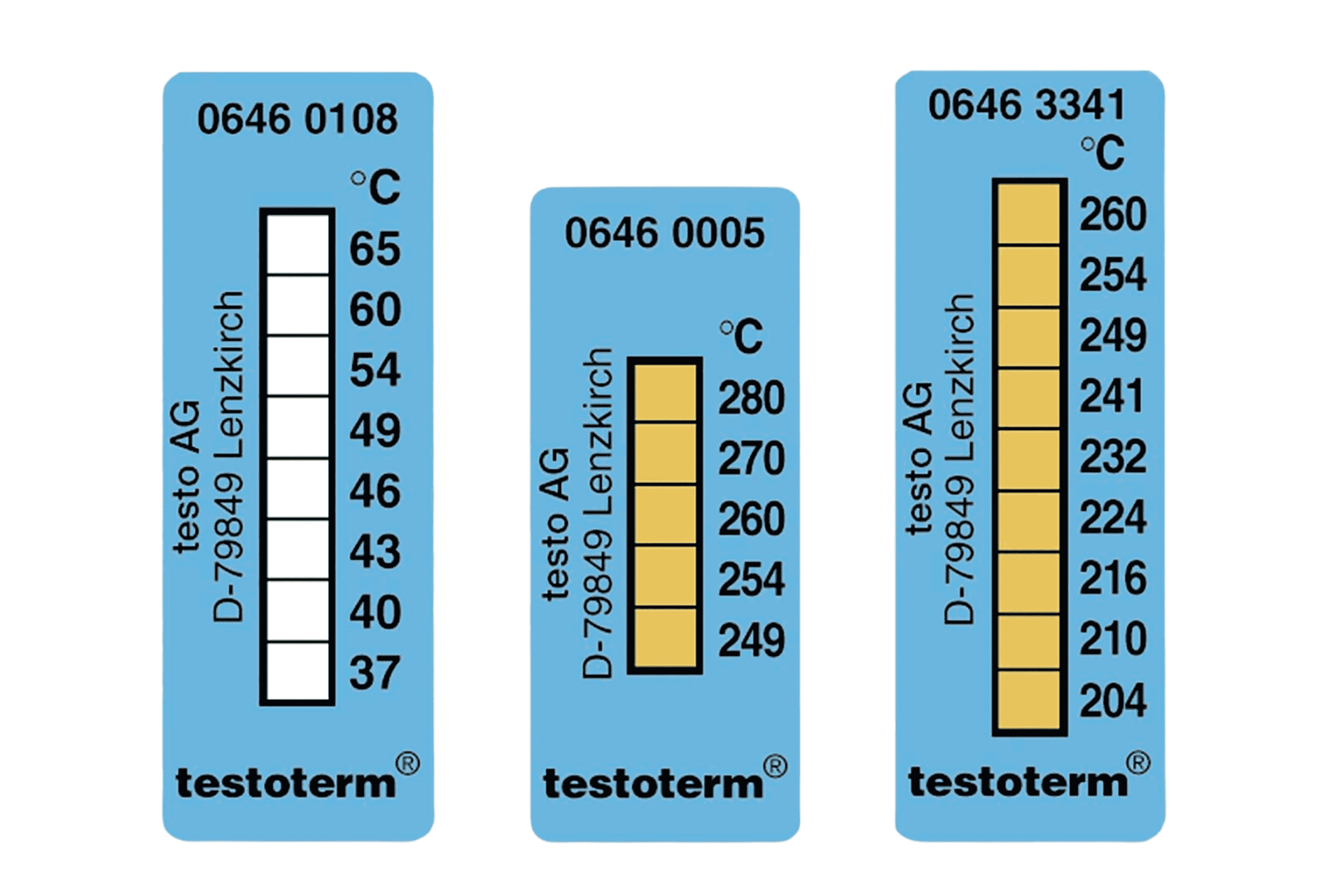

Temperature Indicators - Get high-tech, color-changing temperature indicators to help you keep track of the temperature. These indicators show the temperature in real-time. And they will alert the operators to any deviations from acceptable ranges.

Temperature-Controlled Packaging Equipment - Invest in liquid packaging machinery with advanced temperature control functions. This can ensure that the temperature is always consistent throughout the liquid packaging process.

To show how important temperature control is, check out the table below. You'll see the best temperatures for different types of products:

|

Product Category |

Ambient Temperature |

Refrigerated Temperature |

Freezing Temperature |

|

Medicine |

15°C - 25°C |

2°C - 8°C |

Below 0°C (-15°C to -40°C) |

|

Food |

15°C - 25°C |

2°C - 4°C |

Below 0°C |

|

Nutraceuticals |

15°C - 25°C |

2°C - 8°C |

Below 0°C |

|

Cosmetics |

15°C - 25°C |

2°C - 8°C |

Below 0°C |

2. Get to Know Liquid Particle Size

Liquids often contain particles of different sizes, from tiny to big. For instance, things like suspensions, where bigger particles are mixed with a liquid. And products like condiments and salad dressings have a bunch of different particles in them. Particles can mess up the filling process. If they're too big, they might block up the filling nozzles. So, you should know the size distribution of the particles in a liquid. That way, you can select the right liquid filling equipment and get the most out of the packaging process.

Look at the table below to better understand the different types of particles you can find in liquid formulations.

|

Category |

Particle Size |

|

Solution |

Less than 1 nm |

|

Colloid |

1 nm - 100 nm |

|

Suspension |

Greater than 100 nm |

|

Granules |

Greater than 1000 µm |

|

Coarse Particles |

100 µm - 1000 µm |

Piston fillers are often an effective choice for products with larger particles, such as the containing granules or coarse particles. They use a special filling nozzle that can handle viscous materials and products with larger particle sizes. This makes them well-suited for filling products like salad dressings, jams, and other foods with particles.

When you fill it, make sure you spread the particles around evenly. You can do this by stirring the mixture constantly. This stops the particles from sinking to the bottom of the container, so the product is filled evenly.

Now what can you do to solve the particle size challenges?

It can be difficult to work with liquids that have particles of different sizes. But some pretty advanced technologies can handle that just fine.

- Homogenization - Techniques include cone milling, rotor-stator mixing, and high-pressure homogenization. They use forces like shear, impaction, or cavitation to make the particles smaller and spread them out more evenly.

- Emulsification - Specialized equipment can make stable dispersions with small, separated drops in emulsions(mixtures of two liquids that don't mix well together).

3. How Liquid Viscosity Relates to Its Packaging?

Viscosity is how we measure a fluid's resistance to flow. It's a way to measure how thick a liquid is. This internal friction within the fluid directly influences how easily it moves and behaves during the packaging process.

High-viscosity liquids, like honey or thick sauces, don't flow as easily. Because of their higher internal friction, they can make filling operations more challenging. This can mean higher pressures and slower production lines. On the other hand, low-viscosity liquids, like water or thin oils, flow more easily and usually require less force for packaging.

How can we measure viscosity?

We usually measure viscosity with special instruments called viscometers. These instruments are designed to measure the viscosity of Newtonian fluids, which stay the same no matter how much shear stress is applied.

We also use rheometers, which are more advanced instruments. Rheometers measure non-Newtonian fluids. Their viscosity changes depending on the shear stress that's applied to them. You might have used them to measure things like ketchup, sauces, or certain paints.

Below is an equation for measuring viscosity:

Viscosity (μ) = Shear Stress (τ) / Shear Rate (γ)

The unit of viscosity is usually written as centipoise (cP). For reference, the viscosity of water at room temperature is about 1 cP, while honey has a viscosity of around 10,000 cP.

So how liquid viscosity impacts the packaging?

High-viscosity liquids take longer to flow through the filling lines. This may slow down production speeds. Packaging lines might need stronger pumps to deal with high-viscosity liquids. Plus, the type of packaging you use (e.g. bottles, pouches, cans) can depend on how thick the liquid is.

Finally, how to handle those super thick liquids?

- Change the temperature. Heating the product can often reduce its viscosity. High temperature will make the liquids flow smoothly, and improve the processing efficiency.

- Mix and agitate. Use the right tool, such as an anchor impeller for thick liquids. Also, setting correct mixing time helps to dilute the mixture and make it more stable.

Final Takeaways

We hope you now get a better idea of the three important things about liquid packaging- temperature control, particle size distribution, and viscosity. If you are a manufacturer, they will help you enhance your production and the quality of your products.

At iPharMachine, we are dedicated to offering highest-quality liquid filling machines and services. Our team of experts can help you choose the best packaging for your specific needs. Contact us now to discover how we can help you achieve your production goals.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche