9 Major Manual Capsule Filling Machine Parts

Are you looking for the best manual capsule filling machine? As so many manual capsule fillers are available in the market, you could be confused about their differences.

Given this, this article has listed the 9 major manual capsule filling machine parts and the differences between the common parts and the quality parts.

Hopefully, it can help you understand their structure and working principle, and find the pill filling machine that suits you best.

What are the types of manual capsule fillers?

To learn the manual capsule filling machine parts, we have to first make sense of different manual capsule fillers available in the market since they consist of different parts.

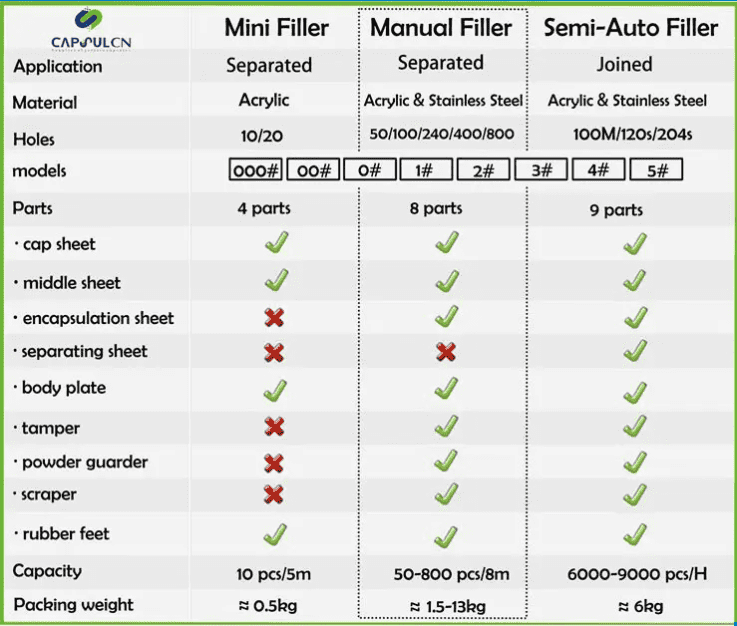

Check the chart below, and you will get a quick overview of the differences of their parts.

1) Filling separated or joined capsules?

According to the types of capsules they can fill, manual capsule fillers can be divided into:

1. Manual capsule filler (used to fill separated capsules)

2. Manual semi-auto capsule filler (used to fill joined capsules)

Generally speaking, the manual capsule filler used to fill separated capsules has a simpler structure than the second type. The reason is simple: They don’t need the part to separate joined capsules.

In comparison, a semi-auto one has a more advanced structure that allows users to load and separate capsules handily. You only need to push a button or pull a handle. Then the capsule filler will automatically load and separate hundreds of capsules at once.

2) For home use or commercial use?

According to the production capacity, manual capsule fillers can be divided into two types:

1. Mini manual capsule filler (10/20 capsules per cycle)

2. Manual capsule filler (50/100/240/400/800 capsules per cycle)

For home use or DIY, small-sized production is very suitable. And a cost-effective mini filler can well cater to the needs. It is portable and easy to use and only takes 5 minutes to fill 10 to 20 capsules.

Due to their simple structure, many of them can do without an encapsulation sheet (loader), separating sheet and powder guarder (used to avoid spillage). Some don’t have a tamper (used to compress powder) or a scraper (used to fill capsules evenly).

The reason is self-evident:

You only need to fill several capsules each time, so you don’t need a loader to collect and load them - you can use your hands to position capsules quickly.

On top of that, mini capsule fillers are often used to fill separated capsules, so they don’t have separating sheets either.

As for the filling process, you even don’t need a powder guard, for you only put a small spoon of powder, which is unlikely to cause spillage.

What are the manual capsule filling machine parts?

After learning the different machine types and the difference between their parts, it’s time to illustrate the details of manual capsule filling machine parts.

And if you want to learn their operating procedure, feel free to check this article, and you will learn how to use manual capsule filling machines.

1) Tamping tool (tamper)

For the accurate filling, a tamping tool or tamper is indispensable. Every time you use the scraper to fill capsules, you need to use the tamper to compress the powder as well.

By doing so, the capsule body can spare more space for filling, and you need to repeat the process several times until the bodies are fully filled.

A tamping tool of high quality is made of non-scratch, shatterproof acrylic with one layer structure. Yet, most tampers in the market are made with thin acrylic of the double layer structure.

In comparison, the double-layer acrylic is not as sturdy as the one-layer structure, and its screws are more likely to gather dirt.

As for the pegs used to compress powder, the ideal material should be stainless steel, while inferior products tend to use softer aluminium as their material.

2) Scraper (spreader)

To fill the bodies evenly, a scraper or spreader is necessary. As mentioned before, it is used together with tampers so that the capsule bodies can be fully filled. The ideal material of a scraper should be sturdy acrylic as well.

3) Encapsulation plate (loader)

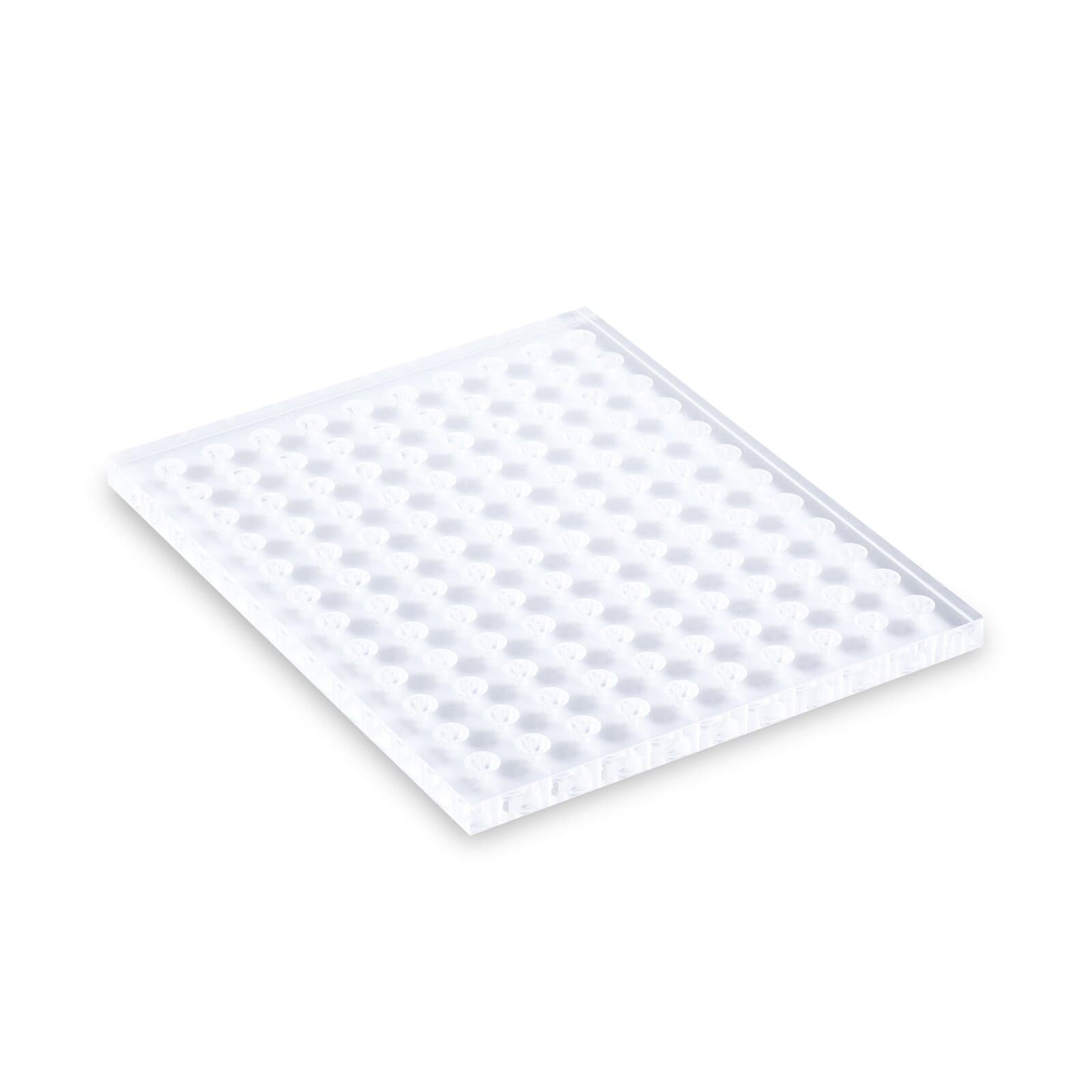

The encapsulation plate, also called the loader, is used to load capsules in bulk.

For a manual capsule filler used to fill separate capsules, you need to use the loader two times. With the aid of it, you can position the caps into the cap sheet and the bodies into the body sheet.

This type of loader tends to be made of acrylic.

For a manual semi-auto capsule filler, its loader tends to be made of stainless steel. After pouring a large amount of joined capsules, you only need to push a button, and then the capsules will fall through and sit in the holes waiting for the separation.

When selecting the encapsulation sheet, especially the one for a semi-auto type, you need to consider their designs. Is it convenient in terms of collecting and releasing capsules? An efficient encapsulation sheet can greatly improve the filling efficiency.

4) Powder guard

When it comes to filling over 50 capsules per cycle, a powder guard is significant. You surely want to avoid powder waste, as you have to pour a large amount of powder each time.

The ideal material of a quality powder guard should be acrylic as well, for it is sturdy and hygienic.

5) Cap sheet (cover plate)

As the literal meaning indicates, the word “cap sheet” is where the capsule caps locate. But for common manual capsule fillers and semi-auto types, the roles of their cover sheets are slightly different.

For manual capsule fillers used to fill separate capsules, you need to fix capsule caps onto the holes of cap sheets. And the capsule bodies will sit in the body sheet.

After filling, you should connect the cap sheet with the middle sheet, and then place them on the body sheet for capsule locking. So the role of the cap sheet in a manual capsule filler is more about loading caps.

While for manual semi-auto fillers, the cap sheet is not used to load caps. As you can see, after loading, the joined capsules will sit in the holes of the set (middle sheet + separate sheet + bottom sheet). And then, you will cover the cap sheet onto the middle sheet for separating and locking.

So the role of the cap sheet in a manual semi-auto filler is more about covering the caps but not loading.

The ideal material of a cap sheet should be acrylic. And it should adopt a one-layer design with its angle polished.

6) Middle sheet

For the manual type, the middle sheet connects the cap sheet and the body sheet, so it often sits between the cap sheet and the body sheet.

For the semi-auto type, the middle sheet is also where joined capsules sit, waiting for separation.

No matter what design is adopted, a middle sheet should have features that can avoid the breakage of capsules when joining them. And it is the biggest factor to consider when selecting middle sheets.

7) Separate sheet

A separate sheet is a part peculiar to the manual semi-auto type used to separate joined capsules. It is also the part that affects the production capacity like the loader.

When choosing a separate sheet, you should prioritise the separating speed. Does it take a lot of effort to separate capsules? Or do you just need to pull a lever and lift the middle sheet, and then you can get the caps and the bodies neatly?

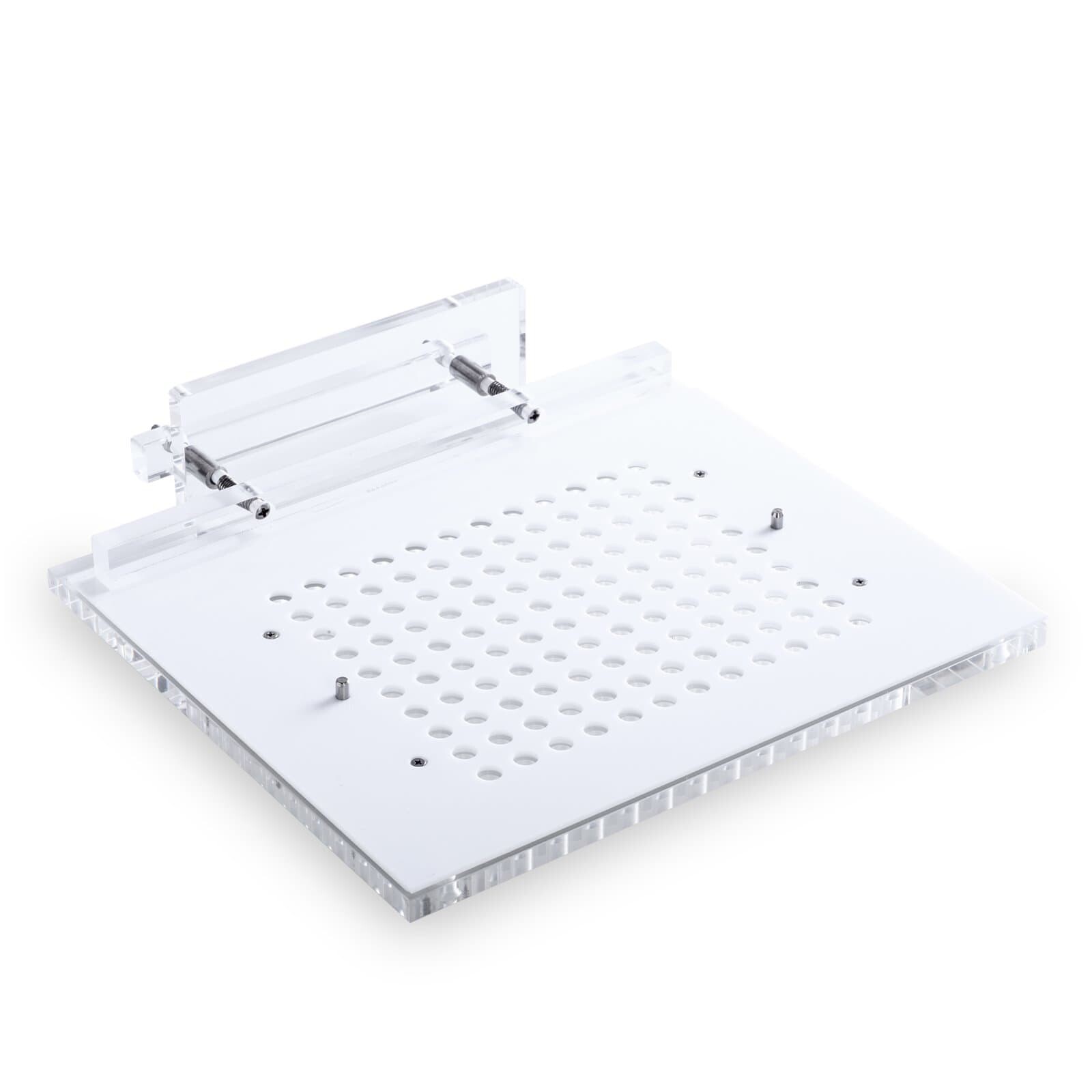

8) Body sheet (bottom sheet)

The body sheet is where the capsule bodies locate. Its structure is more complex than the cap sheet, for it has a two-layer structure linked by screws and springs. When locking capsules, the up layer will be pushed downwards so the capsules can connect properly.

When choosing body sheets, you need to consider two things: Are the screws easily movable so you can clean the machine handily? And are the screws and springs specially dealt with so they will make little noise when pressed downwards.

9) Other detached parts

Last but not least, for the benefit of shipment, some attached parts should be detachable, like the handle of the tamping pin and rubber feet for the bottom sheet.

Wrap-up

So this article has listed all the manual capsule filling machine parts. Hopefully, it has given you a clear view of the structure of a capsule filler.

For anyone who enjoys a mini filler, a manual filler or a manual semi-auto filler, iPharMachine has a broad product line that can meet all your production needs.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche