Sugar Stick Packaging Machine: Features, Working & Buying Guide

As a popular packing type, sugar sticks are widely used in many occasions, such as in coffee shops, restaurants, supermarkets, etc. They pack sugar into small, single-use stick-shaped packets. This provides a convenient way for customers to add sugar to beverages. So more sugar suppliers choose sugar stick packing equipment to advertise their sugar. If you’re also involved in the sugar business, it is necessary to know

- What is a sugar stick packing machine?

- How does a sugar stick packing equipment work?

- How to choose a good one for your sugar business?

What is a sugar stick packing machine?

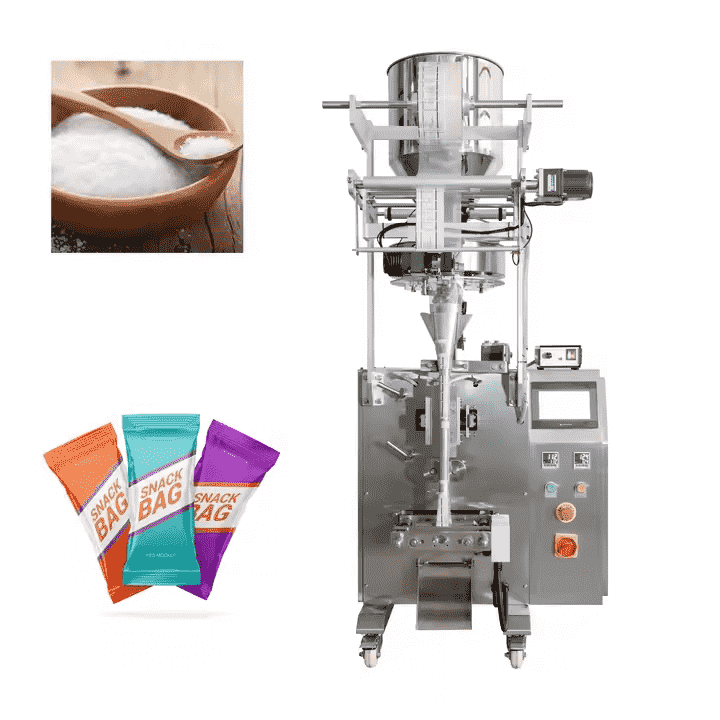

This equipment is used to fill and seal sugar into various types of sticks. It operates from forming the stick pack to accurately filling it and sealing it to maintain freshness. The machine ensures that each packaged sugar stick has a consistent weight, and a secure seal. Moreover, it provides a convenient way to carry and use sugar.

This equipment is popular in the food and beverage industry. Businesses prefer them over traditional sugar dispensers or bulk sugar packets. Because they help reduce waste and ensure product consistency. In addition, sugar stick packaging enhances branding appearance. An eye-catching packing would attract more customers and let your products stand out in the market. So many companies customize the packets with logos, colors, and promotional designs.

Sugar types used in the machine

A sugar stick packing machine is suitable for various types of sugar. Below are some common types.

- Granulated white sugar. This is the most common type of sugar. It features uniform granules, ideal for sweetening coffee, tea, and other beverages.

- Brown sugar. Because it contains molasses and has higher moisture content, special moisture-resistant packaging materials are always required to prevent clumping.

- Rock sugar granules. They are often used for specific beverages such as herbal tea and medicinal drinks.

- Sweeteners. Common types include xylitol, erythritol, and aspartame. These are mainly used in low-sugar or sugar-free products, especially in the health food industry. When packing them, a dust-proof design is necessary.

- Blended sugar. Examples include coffee sugar and vanilla sugar. When you fill them, precise mixing is required to ensure consistent composition in each sugar stick.

How does a sugar stick packing equipment work?

Film feeding and bag forming

The machine starts with a roll of packaging film. It is typically made of food-grade paper, plastic, or aluminum foil. At first, the film unwinds and passes through a forming collar. The machine seals the film along its vertical edge to create a continuous stick-shaped tube.

Sugar dosing and filling

Next, a precise dosing system measures the exact amount of sugar for each stick pack. The machine always uses the following common dosing methods.

- Volumetric cup filler. It uses cups of fixed volumes, ideal for free-flowing sugar.

- Auger filler. It is used for powdered sugar or sugar mixed with other ingredients.

- Electronic weighing system. It is a widely used dosing method in many machines like VFFS machines. This ensures highly accurate filling.

At this stage, the sugar is dispensed into the formed tube at a controlled rate. Once the filling amount is achieved, the filling stops. It maintains consistent weight in each pack.

Sealing and cutting

After filling, the machine seals the top of each pack with heat sealing or ultrasonic sealing. A tight sealing makes the sugar stay fresh and moisture-free. Then, the continuous tube of filled packs moves forward. The machine cuts between each portion, creating individual stick packs.

Discharge and collection

Finally, the finished sugar stick packs are discharged onto a conveyor or into a collection bin. They can then be further processed, such as boxed, stored, or shipped for distribution.

How to choose a good powder stick packing machine?

You may find it is challenging to select the right sugar stick packing machine. It refers to various factors you need to consider.

Production needs

You should clearly understand your production requirements. It helps determine the machine's speed, automation level, and investment cost. For small-scale businesses or startups, single-lane sugar stick packing machines are more recommended. They are compact, entry-level machines designed for businesses with lower production needs. This equipment operates with a single packaging line. So it features low production. Its output is 30–50 sticks per minute. Many newbies choose this machine because it requires low-cost investment and a small workplace.

For a large-scale sugar business, a multi-lane stick pack machine is a good choice. It operates multiple packaging lanes simultaneously. The more lanes there are, the more the production volume is. Its production speed could be up to 100–500 sticks per minute. This significantly increases production speed. Moreover, a multi-lane stick pack machine can produce different stick sizes across multiple lanes. It offers great pack size flexibility. However, this equipment requires a great deal of investment cost and a large work area.

Powder properties

If you pack free-flowing powders like fine sugar, you can choose volumetric cup fillers. They measure powder based on volume rather than weight. This makes free-flowing powders move easily under gravity. So they don’t clump or stick together.

For non-free-flowing powders like brown sugar, you’d better use a rotating auger. It can force the powder downwards in a controlled manner. This is because non-free-flowing powders have fine, sticky, or irregular particles, and tend to clump or bridge together. This machine can apply force and prevent clogging during operation.

Packing materials

The packing material plays a key role in keeping sugar packing attractive and the product freshness. Different packaging films provide different benefits, such as moisture resistance, environmental sustainability, and cost-effectiveness. When selecting a sugar stick packing machine, you need to see what type of film best suits your product and target market. If you have no good idea, here are some common materials for your reference.

Plastic films

They are popular types to make sugar stick packing. Common materials include PET, PE, etc. Plastic films feature low cost, good durability, and high strength.

Paper with PE coating

If most of your clients prefer an eco-friendly option, you can make your stick packs with paper and apply PE coating. It reduces plastic waste and provides a natural, premium look. It is especially ideal for organic and high-end products.

Aluminum foil

This material creates a strong barrier against air, moisture, and light. It suits sugar products that require high protection in the environment. This packaging also extends shelf life, keeping sugar fresh for longer. But it is more expensive than standard plastic or paper-based films.

The end

As a necessary packing machine in sugar production, you’d better have a careful selection for the equipment. It not only improves production efficiency but also ensures accurate filling, and high-quality packaging. VFFS machines belong to one type of sugar stick packing equipment. If you need it, just contact iPharMachine. We have helped hundreds of clients to get good sugar packing. Our professional team also helps you design and customize machine parts to meet your needs.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche