Introduction

PBGZ-160 is designed in strict accordance with pharmaceutical GMP standard and technological requirements. The whole machine is easy to operate. It is equipped with automatic stop system for bottle lacking, jamming and feeding. In addition, it is suitable for bottles of different sizes or shapes without replacing parts.

Feature

- In line with national GMP standards and process requirements, fully automatic packaging equipment is designed and manufactured.

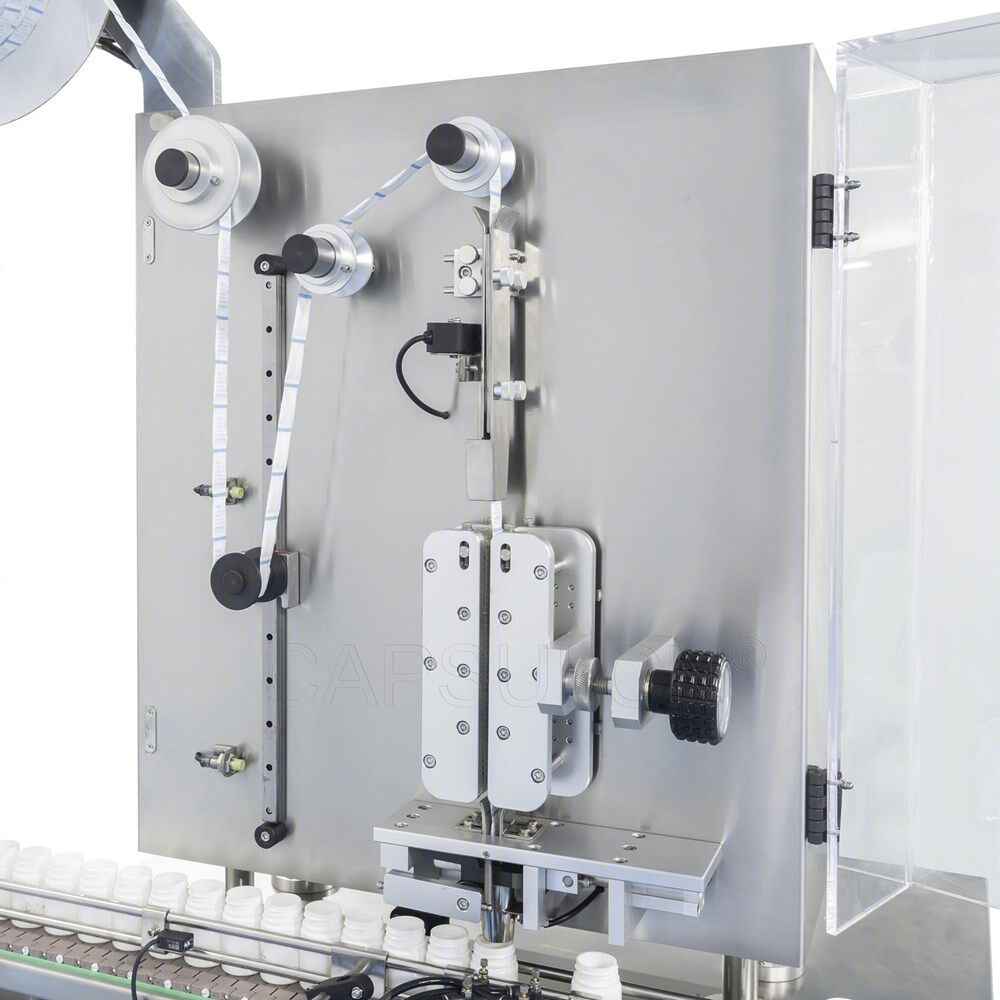

- Providing the best, most reliable plug desiccant work at the highest operational efficiency.

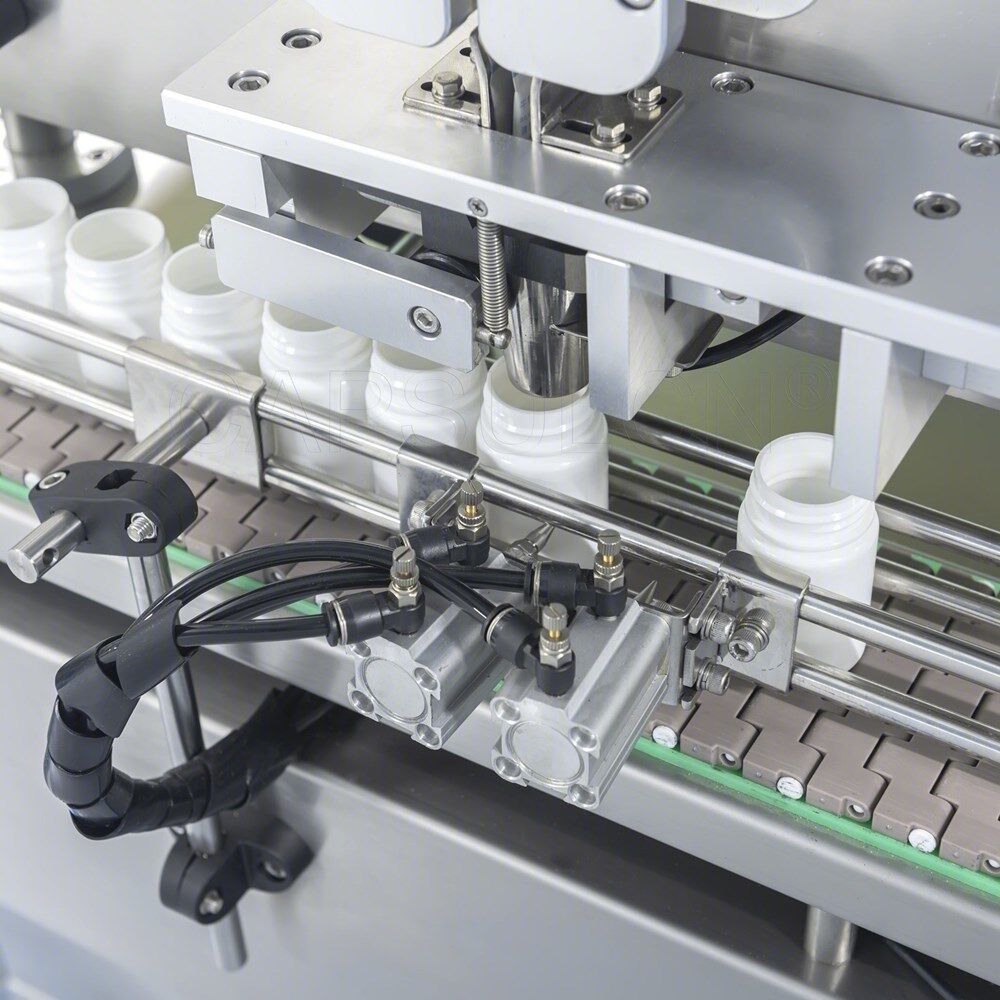

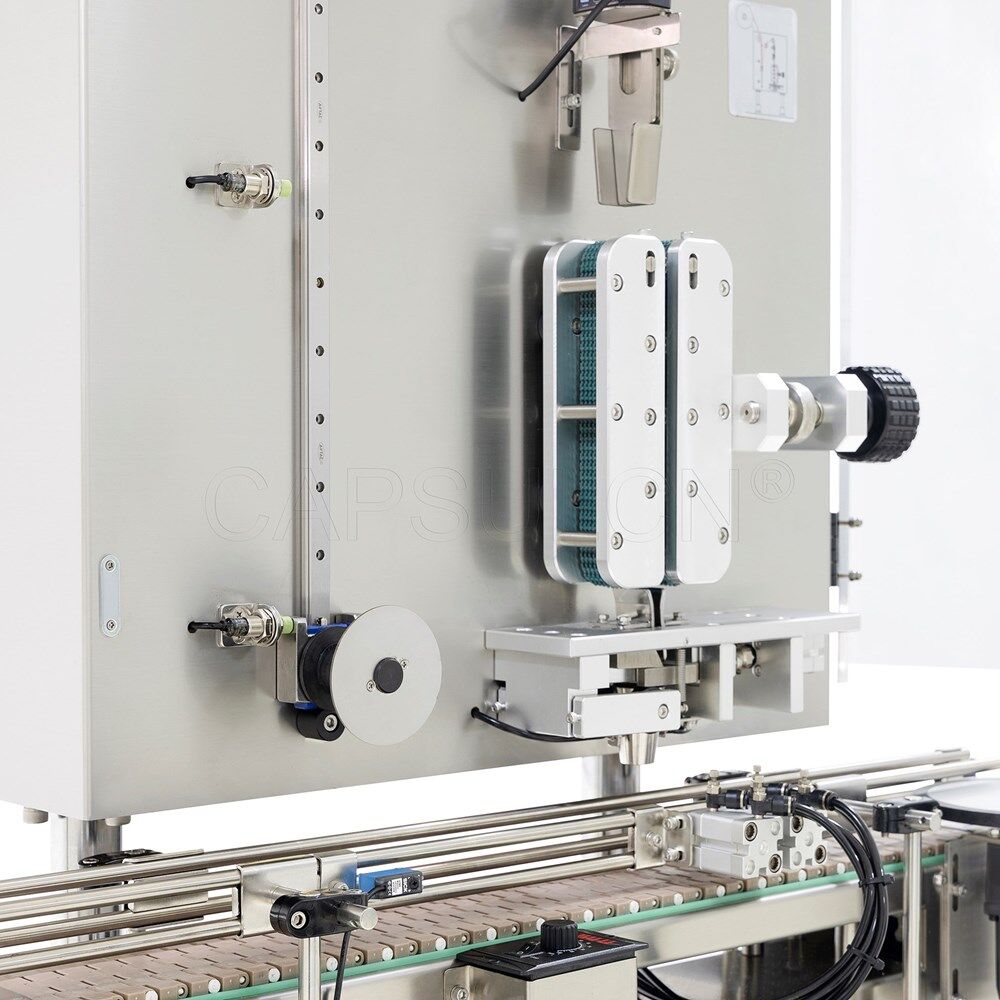

The transmission is simple and equipped with a variety of safety protection devices, such as shutdown without bottle, startup with bottle and shutdown without desiccant. - It adopts pneumatic bottle clamping mechanism, which works stably and reliably.

- It is suitable for bottles and desiccants of different specifications, and only needs to make appropriate adjustments to individual parts.

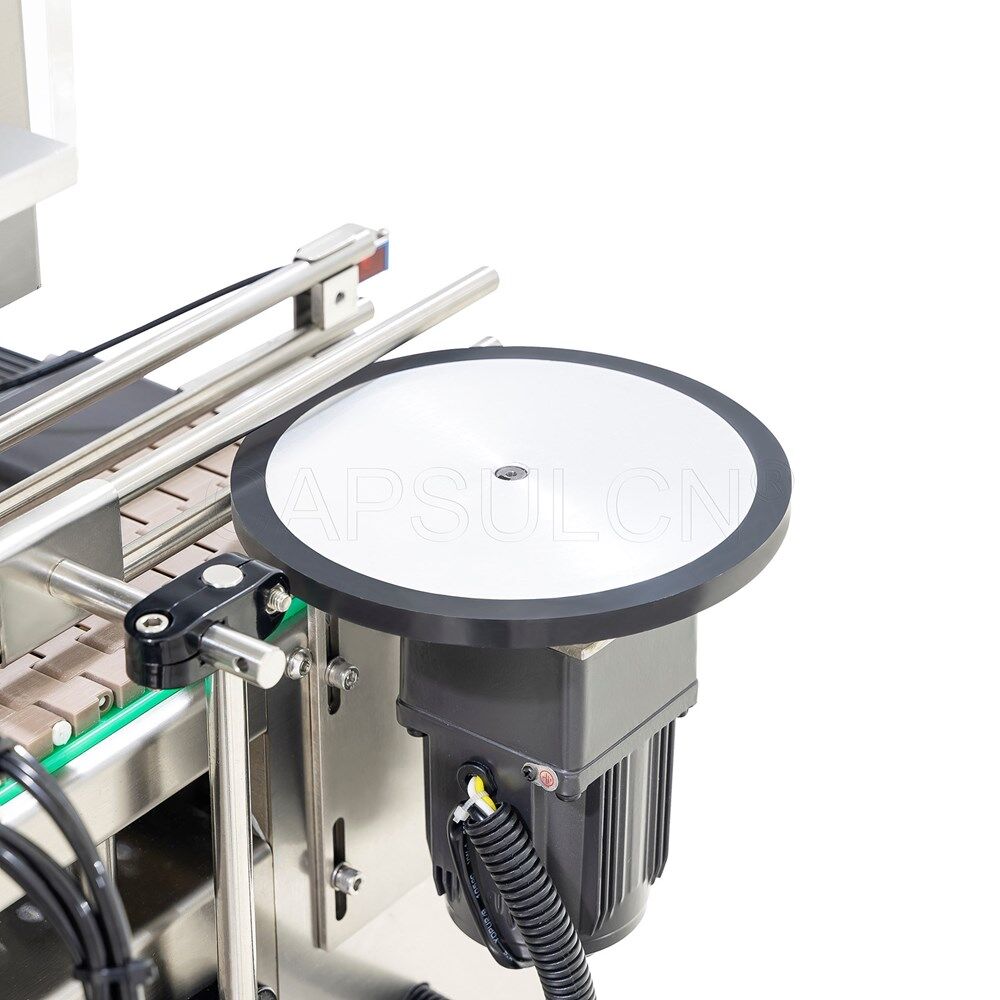

- The main motor adopts servo motor, and users can freely set the production volume, providing more convenience.

- PLC programmable controller is used to control the operation of the whole machine.

- It has a wide range of applications, is easy to operate, runs smoothly, is easy to clean and repair, and is durable.

Structure

Specifications

| Model | PBGZ-160 |

|---|---|

| Output | 20~130 bottles/min |

| Bottle Size | 15~300ml |

| Voltage | 220V 50/60Hz, single-phase |

| Power | 0.5 KW |

| Air Consumption | 0.4 Mpa / 0.3m³/h |

| Dimension (L*W*H) | 1600*750*1800 mm |

| Weight | 280 KG |

Remarks

-

When moving the machine, the forklift should lift the center of machine’s gravity and avoid to damage the machine. After opening the wooden case, please do as below.

-

Environment temp.: between 5~40℃ no matter whether the machine works or not Moisture: between 20~85%

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche