Upgrade Your Perfume Business with 5 Machine Types and Practical Tips

Nowadays, more people invest in perfume packing machines. Because wearing perfume is widely popular among daily life. Manually packaging perfume bottles can be time-consuming and labor-intensive. A perfume packaging machine is more chosen. It can integrate filling and packing. It improves efficiency and productivity greatly. In addition, in the competitive perfume market, product packaging plays a critical role in attracting customers. A good perfume packaging machine ensures every bottle has the same and precise shapes and labels.

If you are also interested in this machine, you’d better know the follow.

- What are perfume packing machines?

- What are common types of perfume filling machines?

- What should be considered when choosing one?

- How to start a business with perfume packaging machines?

What Are Perfume Packing Machines?

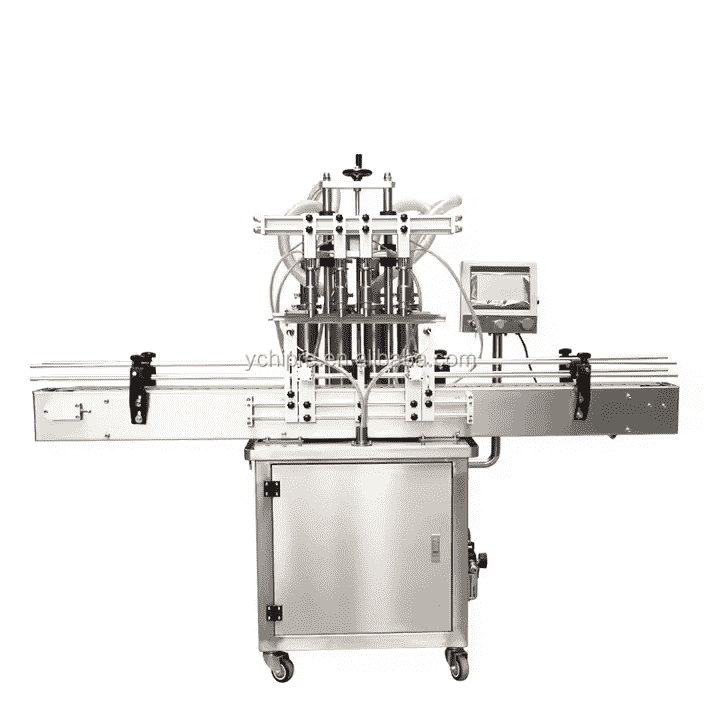

Perfume packing involves a series of equipment to finish the whole process. It includes liquid filling, bottle sealing, capping, cartoning and labeling. Each step requires a machine to complete the task. So many perfume manufacturers would integrate these machines into one production line for more efficiency. During operation, filling machines would dispense the perfume into containers like bottles according to the required amount. Then, the opening is sealed by sealing machines to prevent leakage.

Compared to other containers, perfume packing always use crimp nozzles. So it doesn’t use aluminum foils for sealing but relies on the tight fit between the nozzle and the bottle neck. Next, caps are placed securely to protect the sealed opening. Finally, labels are applied for key information like brand name and volume.

Five Common Machine Types for Perfume Filling

Nearly every machine could be divided into manual, semi and fully automatic models. For perfume filling, there are also other popular types of liquid filling machines you should know.

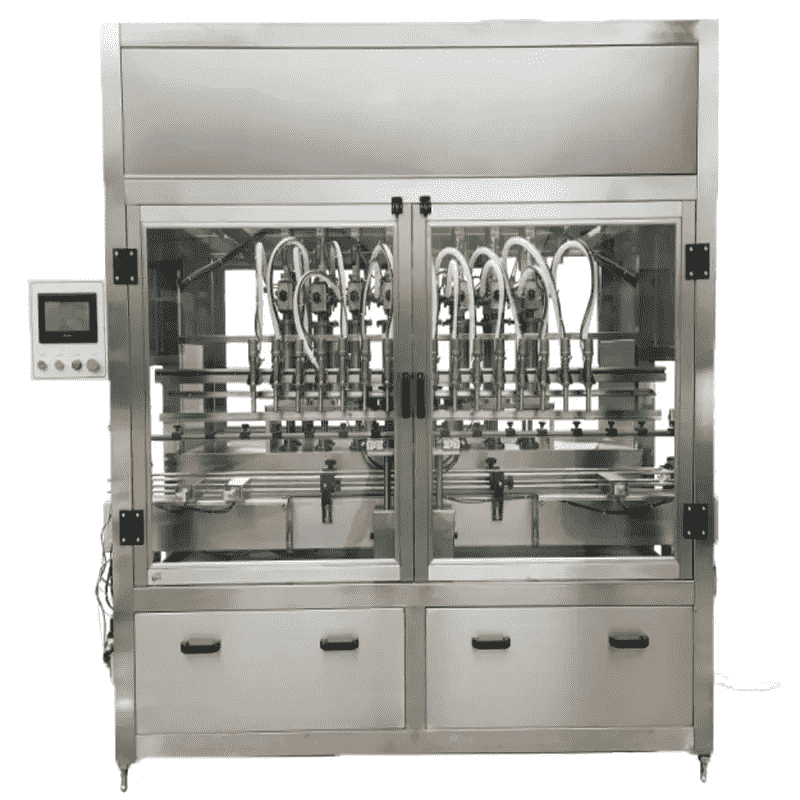

Volumetric Fillers

Volumetric fillers are a popular choice due to their speed, accuracy, and efficiency. They can fill a large number of bottles per minute. The volume and filling speed could be adjusted to meet your production needs. Besides, it could suit different sizes of containers. This machine operates by measuring a precise volume of liquid to dispense. This could be usually conducted by 2 mechanisms.

- Piston fillers. A piston moves within a cylinder, drawing in a specific volume of perfume and then dispensing it into the bottle.

- Gear pumps. They involve intermeshing gears to rotate. It creates a cavity that draws in and transfers a precise volume of liquid.

Volumetric filling machines are suitable for those with lower viscosities, such as alcohol-based or oil-based formulations. They could provide uniform filling and maintain the product's quality without compromising speed or precision.

Gravimetric Filling Machines

These machines use weight as the primary measure. They have built-in scales to ensure that the exact weight of liquid is dispensed into each container. These scales are highly sensitive to monitor the weight and stop filling when the set amount is reached. This type features high precision, even for small quantities. So it is ideal for filling high-end, or expensive perfumes where accuracy is crucial. In addition, they’re great for both thick and light perfumes, such as alcohol-based fragrances.

However, gravimetric fillers are not as fast as other filling methods, like volumetric fillers. Because their primary focus is precision rather than speed. Tthey need to weigh each bottle individually. It takes slightly longer compared to systems that require continuous flow to measure volumes.

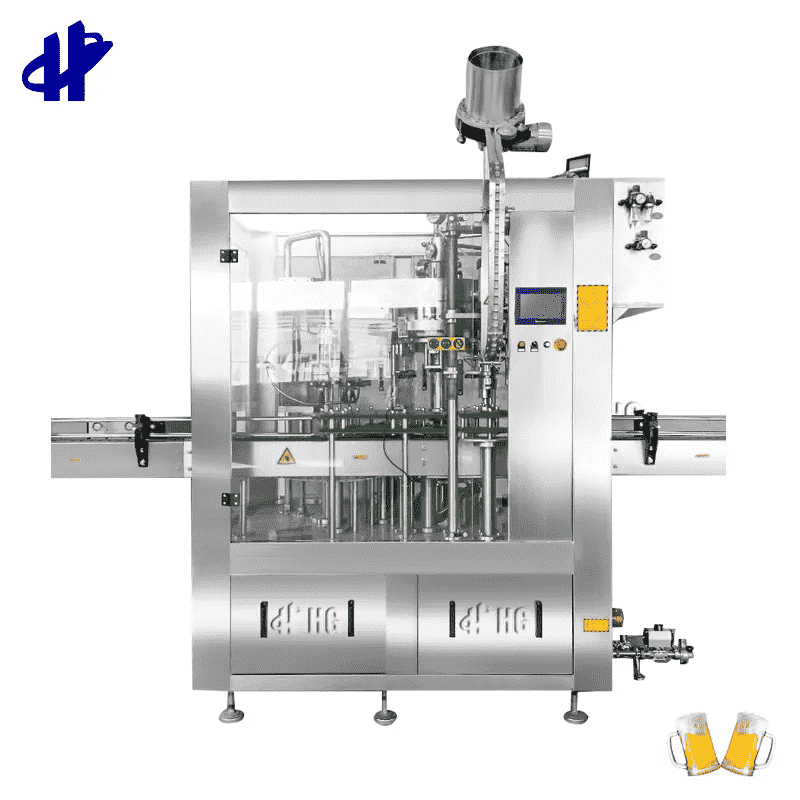

Gravity Fillers

These machines works best with low-viscosity liquids like water-based perfumes. They rely on the natural force of gravity to fill bottles. Liquid flows from a tank into containers below, and it stops when a specific volume is reached. It features high efficiency and easy operation, but the precision is much less than gravimetric fillers. So it is more suitable for larger production batches.

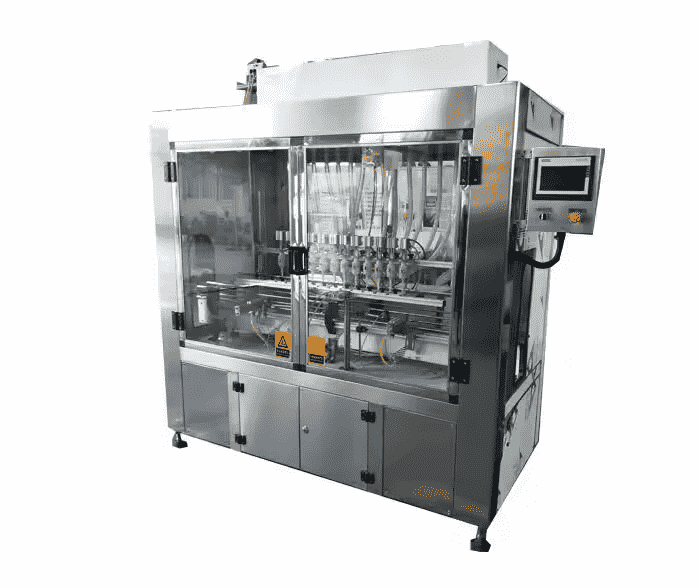

Vacuum Filling Machines

During filling process, this machine creates a vacuum inside the perfume bottle. Then it gently draws the liquid in, usually low-viscosity perfumes, until it reaches the desired amount. This method ensures precise filling without spillage or overfilling. So this machine is perfect for delicate perfumes, especially those in unique or irregularly shapes like stars. It could maintain consistent fill levels, even when bottles vary slightly in size. High-end fragrances always choose vacuum fillers to get more attraction in their packaging.

Overflow Fillers

Similar to vacuum fillers, overflow fillers also aim to achieve consistent fill levels. But they have totally different working principles. They work mainly through pumps and nozzles with a return pathway. The nozzles has an adjustable overflow tube that determines the desired fill height. Once the liquid reaches this set height by nozzle filling, any extra liquid flows back into the reservoir through the return tube. And these liquids could be reused for next filling.

This machine is perfect for low-viscosity perfumes like floral or citrus fragrances. Also, it is more suitable for transparent bottles. Because clear and consistent fill levels play a key role in these containers.

How to Choose A Good Perfuming Packing Machine?

Compatibility with Bottle Sizes and Shapes

Before buying a perfume packing machine, especially liquid fillers, you should make sure it can handle the sizes and shapes of your perfume bottles. Some bottles, especially unique designs, may require specific nozzles or adjustments. For example, if your bottles are asymmetrical designs, you might need a machine with adjustable clamps to hold and fill them securely. So it won’t cause spills or uneven filling.

Perfume Types

Different perfumes have unique properties that can influence the filling process. Most perfumes are watery and low in viscosity, so they work well with overflow or gravity fillers. However, if your perfume is oil-based or much thicker, you’d better choose a machine designed for higher-viscosity liquids. In addition, if your perfume contains delicate ingredients, the machine should be able to handle liquid gently. It prevents loss of fragrance quality or contamination.

How to Start Perfume Business for Newbies?

If you want to join in perfume business, the following tips are for your reference.

Find A Reliable Supplier

A good supplier is the base of high-quality machines. You can find them in many online websites, such as Alibaba and Made-in-China. When searching, you’d better check their profiles. You can ask them some questions to judge if they have enough experience in your area, or if they have good after-sales support to back their products. Also, don’t forget to compare prices among different suppliers. You can negotiate with them for the best deal that meets your budget.

If you find it struggling to find a reliable manufacturer in such a big market, you may directly contact iPharMachine. We focus on various machine manufacturing for different industries, like pharma and cosmetics. We have helped 30,000 clients to get their satisfying equipment. Whatever you want fillers, cappers or cartoners, just tell us your requirement in detail, and we’ll match the most suitable one based on your needs. Moreover, you can ask us to take photos or a video about how the machine works. We have a professional technical team to help you understand it thoroughly.

Maintenance and Troubleshooting for Long-Term Use

To keep your machine running smoothly, you can learn how to maintain your shipping, such as regular cleaning, checking for loose parts, and lubricating moving components, etc. This prevents breakdowns and extends the machine’s lifespan. In addition, you should know how to troubleshoot machines for quick fixes, like dealing with clogs or misaligned parts. You can these troubleshooting tips in the manual guide.

Arrange Shipping

When you buy machines from other countries like China, shipping is a big factor you should consider. It refers to which shipping mode suits you best. Air shipping is the fastest but the most expensive. Sea shipping is more cheaper but takes longer shipping days. Also, you need to know how to conduct customs clearance for your goods to your country. If problems occur, it may cause loss for your business.

So if you are not experienced enough, you’d better find a freight forwarder. He can help you arrange shipping from port to your designated place. For customs clearance, a forwarder is also OK to do it if you require. Or you can find a customs broker to help you smooth the process.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche