Introduction to the Pharmaceutical Sifting Process

The sifting process in the pharmaceutical industry involves the separation of particles of different sizes. It is essential to the pharmaceutical industry's drug manufacturing process. However, the sifting process is not limited to pharmaceuticals; it is used in food processing, chemical production, cosmetics, and many other industries.

There are three primary classifications of sifting machines, namely

1. A vibratory sifter uses circular or linear motion with a vertical component.

2. The centrifugal sifting machine uses force and rotary motion.

3. The gyratory sifting machine makes use of circular horizontal motion.

What is a Vibro sifter?

A Vibro sifter can also be called a vibrating sifter or Vibro sieve. It is an important machine used for many years in many industries, including pharmaceutical, chemical, and food, for scalping, grading, and separating materials. It is a vibratory sifting machine that grades or separates materials based on their particle size.

What are the uses of a Vibro Sifter?

The Vibro sifter is energy-efficient machinery built with high-grade stainless steel and has a compact and portable design. Some of the primary uses of the Vibro sifter include:

- Sifting or rebolting

- Scalping

- Proof sifting

- Screening or grading

Read more: List of Top 5 Vibro Sifter Machine Manufacturers

How does a Vibro sifter work?

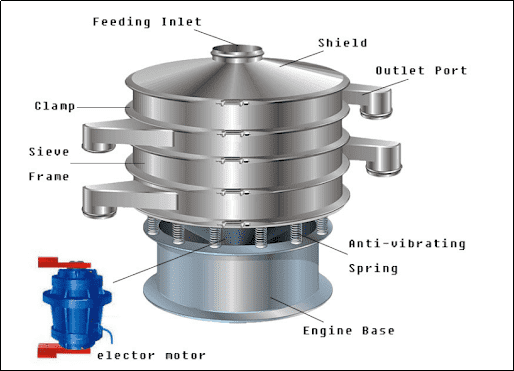

To understand the machine principle entirely, you need to know the vibro sifter parts and how they function.

What are the parts of a Vibro sifter machine?

1. Vibratory electric motor

The vibratory electric motor is responsible for the vibratory motion of the Vibro sifter. The movement increases the rate at which the material passes through various sieves.

2. Screen structures

The screen structures are the fundamental components of the machine that differentiate the materials processed in their particle size and shape. They consist of the filter screen and wire mesh screen ring. The filter screen is made of wire mesh that facilitates the smooth surface finish of materials during processing. It also prevents the leakage of materials.

The wire mesh screen ring attaches the wire mesh to the ring supported by glue. The bonding of the mesh to the ring maintains the screen during the material processing, especially during high-intensity vibration, and also increases the lifespan of the mesh.

The direction of the device's vibration could be horizontal or vertical; however, the screen structures are secured tightly to facilitate the easy movement of the materials in the order of the vibration.

You can modify the motion of the screens to fit the desired performance, depending on the type of material to be processed. Therefore a Vibro sifter can produce both gentle and aggressive product separation. The screen structures have FDA-approved seals to prevent the cross-contamination of materials across different sieves.

3. High-quality springs

The springs are structures of the Vibro sifter that suspend the screens within the machine's interior. It facilitates hydraulic movement of the device, free vibration of the machine's upper part, and restricts vibration transmission to the floor. It is also known to reduce power consumption.

4. Outer casing

The casing of the vibrating sieving machine is usually made from stainless steel. It keeps the materials process in a particular size. The outer structure of the Vibro sifter has nylon casters for easy transportation.

5. Hopper lid/Cover lid

The hopper lid is the cover of the Vibro machine; it is made from metal and protects the materials in the upper section of the device from dust and contamination. The cover lid prevents the processed materials from falling off while vibrating. It is connected to the machine by a clamping ring.

6. Oversize material outlet.

The part of the Vibro sifter where the oversized materials are discharged. It is placed at the upper part of the device for easy and complete discharge of the materials.

7. Screen materials outlet.

It is where the screen and graded materials are discharged from the machine. It is located at the lower part of the device for easy and complete discharge of the processed materials.

8. Control panel

The control panel consists of buttons used for operating the device.

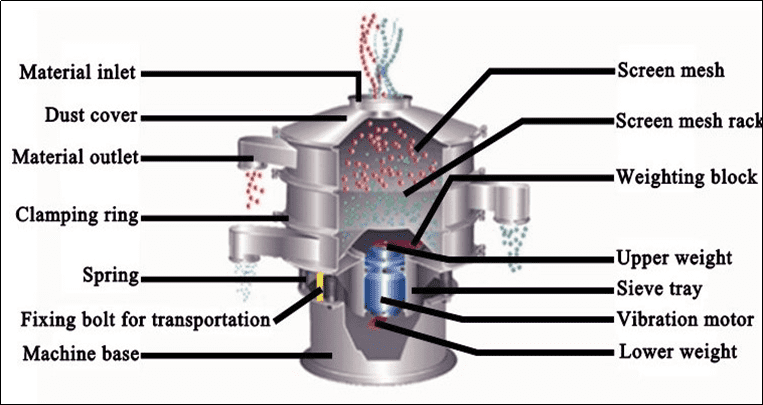

What is the working principle of a Vibro sifter?

The working principle of a pharmaceutical Vibro sifter is based on gyratory vibrations. Therefore, it is also known as a gyratory Vibro sifter. A centrifugal force is created by a gyro motor placed at the bottom of the device.

The vertical vibration motor of the Vibro sifter serves as the existing force source, with the eccentric weights installed at the upper and lower ends of the engine transforming the rotary motion of the motor into horizontal, vertical, and sloping three-dimensional action. Then, the vibratory movement is transmitted to the sifter surface for sieving.

The moving track of the materials on the sifter surface can be modified by adjusting the phase angle of the upper and lower ends to fit the desired performance.

The image above shows a powder sifter machine's structure and working principle

SOP for the Sieving process

The standard operating procedure for the sieving process of a Vibro sifter machine is explained below.

- The materials to be processed are fed through the hopper at the top of the Vibro sifter.

- Confirm that the screen structures, base frame, and cover lid are tightly secured before turning the device on.

- After connecting it to the primary power source, power the machine through the control panel.

- The out-of-balance assembly of the sifter machine will cause the vibrating motor to be energized by vibratory motion.

- The vibratory motion of the machine causes the screen structures and sieve to vibrate as the materials pass across, depending on the particle size.

- The materials pass through the screen structure in a controlled pathway and exit the system through the discharge system.

For multi-deck sifter machines, the sieving process in pharmaceuticals is used for classifying particles, while single-deck sieving machines are used for scalping or sifting.

Product introduction

iPharMachine is an expert in the pharmaceutical and pharmaceutical packaging industry that produces and supplies a quality and reliable series of Powder Sifter Machines, including the Powder Sifter Machine SY-450 and Powder Sifter Machine SY-200 and SY-300.

The Powder Sifter Machine SY-450 produced by iPharMachine is a high-efficient, silent vibrating screening filter. This series of powder sifter machines can be used in laboratories and scientific research departments such as medicine, agriculture, geology, cement, national defense industry.

The SY-450 type has both multi-layer powder or liquid filtration and single-layer screening and filtration used for processing materials with low production vowels and few impurities.

The technical specifications of SY-450 include

- 400 sieve size

- One layer of the sieve

- 1460 times/min Vibration frequency

- 1-4 mm Vibration amplitude

- 2.5kN exciting force

- 0.2kW motor power

- 1400 r/min motor rotation speed

- 220V input voltage

- 500 x 500 x 600mm Overall dimension (length x weight x height)

The Powder sifter machine SY-200/SY-300 produced by iPharMachine is a vibrating sieving machine with numerous advantages, including stable performance, low noise, compact size, simple structure, and convenient operation and maintenance.

The parts in contact with the materials are made of stainless steel, making them suitable for light, agriculture, chemical, medicine, and other industries.

The technical parameters for SY-200 include

- 200mm sieve frame diameter

- 2~5 layers of sifter layer

- 1400 times/min frequency of vibration

- 1~4 mm Amplitude

- 1.5kN exciting force

- 0.1kW Motor power

- 1400 r/min motor speed

- 220V supply voltage

- 330 x 360 x 360mm overall dimension (length x weight x height)

The SY-300 technical specifications include

- 200mm sieve frame diameter

- 2~5 layers of sifter layers

- 1400 times/min frequency of vibration

- 1-4 mm Amplitude

- 1.5kN exciting force

- 0.18kW motor power

- 1400r/min motor speed

- 220V supply voltage

- 480 x 420 x 370mm overall dimension (length x weight x height)

SOP for the Vibro sifter cleaning procedure

The standard operating procedure for cleaning a Vibro sifter machine is as follows.

There are two categories of cleaning a Vibro sifter, which are

- Dry cleaning is also known as batch-to-batch cleaning or TYPE ‘A’ Cleaning. This cleaning is usually done between batch-to-batch changeovers, before wet cleaning, or at the end of the day's operations.

Procedure for dry cleaning; the power source must be switched off before cleaning. Take out the last batch's labels, materials, and containers from the sieving area. Use a vacuum machine to remove materials from the outer surface of the sieving machine. Use a dry lint-free cloth to wipe out the attached powder from the outer surface of the sieving machine.

- Wet cleaning, also known as product-to-product cleaning or TYPE ‘C’ Cleaning. It is usually done between product-to-product changeovers, after six to eight days of continuous production of the same product, during a major breakdown of the machine, or after the device has been idle for 30 days.

Procedure for wet cleaning; Ensure the machine is powered off and all electric points are covered with a polythene bag. Take out the last batch's labels, materials, and containers from the sieving area. Disengage the upper and lower clamps of the sieving machine, remove the upper lid, top hopper, sieve, and bottom hopper, and unscrew the bolts to remove the gaskets. Take the disassembled part to the washing area for proper washing.

Conclusion

iPharMachine is a world-renowned pharmaceutical company committed to producing and supplying quality pharmaceutical machines. With a vast experience of 30 years, the team at iPharMachine has provided solutions for numerous pharmaceutical and health companies across the globe. Engage our team today at iPharMachine to purchase your quality powder sifter machines.

Read more:

Mixing process in the pharmaceutical industry

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche