Streamline Your Production with the Right Pharma Checkweigher

In the pharmaceutical industry, precision is everything. Medicines need to be produced with exact measurements to ensure they are both safe and effective. Even small differences in the amount of a drug can affect its performance. Therefore, manufacturers must maintain strict control over the weight of each product.

A pharmaceutical checkweigher is designed to help with this task. A pharmaceutical checkweigher is designed to help with this task. So manufacturers can make sure their products meet the required weight standards. Then only products with the correct weight are packaged and sent to customers.

What Is A Checkweigher?

This device can check the weight of various items, such as tablets, capsules, or packaged medicines. It is equipped with advanced sensors. They can monitor products on the production line in real-time. They detect the weight of each product as it passes through the checkweigher. If products don’t achieve the required weight, they remove the products instantly. This efficient detection helps reduce errors. It also ensures that only correctly filled products can be processed further.

Moreover, many regulations like FDA also poses strict requirements to medicine weight. Pharmaceutical companies must meet these standards to sell products. A checkweigher guarantees that all products within a batch are uniform. This consistency improves the overall quality and effectiveness of the product. It helps reduce the chances of complaints or recalls.

Pharmaceutical checkweighers integrate seamlessly with other equipment on the production line. For example, they can be connected to packaging machines, labeling systems, or metal detectors. This integration ensures that the entire production process is efficient and streamlined. By working with other machines, checkweighers enhance the overall automation and improve efficiency.

Five Types of Checkweigher in Various Application

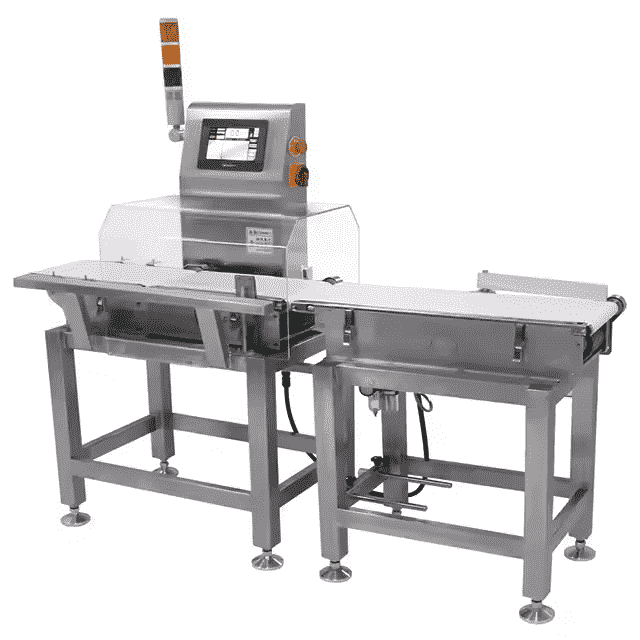

In-Motion Checkweighers

In-motion checkweighers weigh products as they move along a conveyor belt without stopping. This type is popular in food production or pharmaceutical packaging. they both require speed and efficiency. In-motion checkweighers are equipped with sensors that detect the product’s weight on the fly. If the item is under or overweight, it’s automatically rejected or sorted for further inspection. This ensures consistent product quality and prevents underfilled packages from reaching consumers. They are highly efficient for high-speed production lines and reduce manual labor.

Static Checkweighers

Unlike in-motion systems, static checkweighers require the product to stop before weighing. These are typically used in slower production lines. It ensures that external factors like vibrations do not interfere with the measurement. In this way, even the slightest weight difference could be detected. It guarantees that each item is within strict weight range.

These machines are flexible in the operation. Some models are designed for manual use. It is common in small production or when dealing with delicate products. Others are automated to make products stop and weigh. Static checkweighers are also used in laboratories or quality control processes for high-value items. They can handle a wider range of products compared to in-motion types.

Metal-Detection Checkweighers

This equipment is also popular in pharma industry for weight and contamination control. This type combines traditional checkweighing with metal detection technology. It simultaneously check the product’s weight and scan for metal contaminants. Products that fail either test are automatically rejected. This ensures product safety and compliance with health regulations. The integration of metal detection with checkweighing streamlines the quality control process. It also reduces the need for separate inspection stations on the production line.

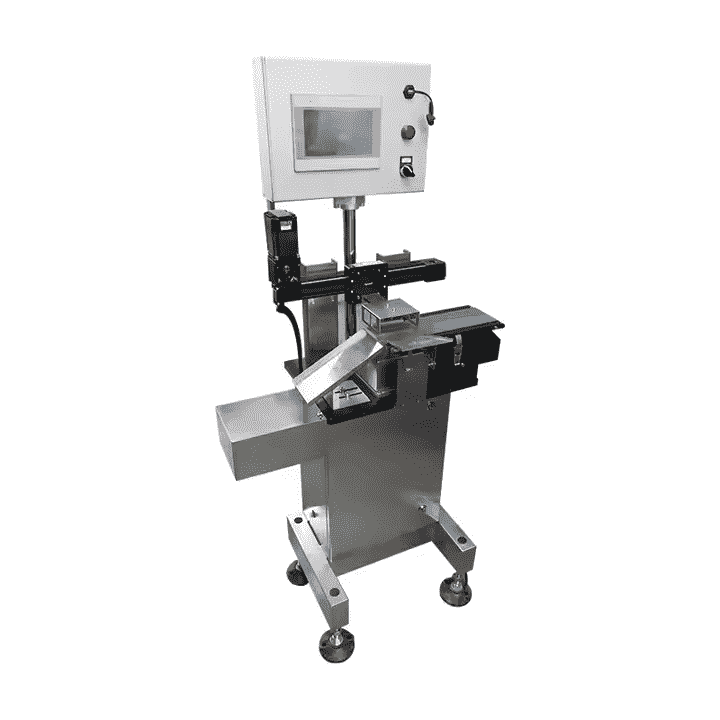

Compact Checkweighers

Compact checkweighers are used for production lines with limited floor space. They can offer high standards of quality control and compliance with regulatory requirements. They are ideal for pharmaceutical applications that involve smaller batches, research, and development. They can be used to weigh products like blister packs, bottles, or cartons of medications. Compact checkweighers feature high portability and ease of integration. So they are a good choice for businesses to optimize space without sacrificing performance.

High-Speed Checkweighers

Compared to other checkweighers, high-speed checkweighers are less commonly used in pharmaceutical production. They are usually useful in certain pharmaceutical applications. It includes large-scale operations or packaging lines for blister packs or bottles. These products are already verified for dosage accuracy and need to be checked for final packaging weight compliance.

In these cases, high-speed checkweighers ensure that packaging remains within weight limits. They also guarantee that products are complete. For example, products hold the correct number of tablets or capsules. However, if you require extreme precision for tablets, more sensitive checkweighers are preferred.

How to Choose A Checkweigher for Your Pharma Business?

Accurate Precision

Accuracy is critical in pharmaceutical production. Checkweighers vary in precision, from ±0.01g to ±10g. So you should choose the most suitable one based on the product requirements. Because incorrect dosages can compromise product safety and efficacy. Besides, sensitivity is especially important for weighing small items like tablets, capsules, or vials. You’d better choose checkweighers with high-precision sensors to ensure compliance and quality.

Product Types

You should consider the types of products you are producing. Different checkweighers are designed for various forms and packaging. Whether for pills, or liquid vials, you need to ensure the checkweigher can handle them. It means delicate items won’t be damaged and the packaging process won’t be disturbed, either. For example, blister packs require specialized handling, while vials need careful positioning to avoid spills.

Production Speed

Your production volume and speed will influence the type of checkweigher you choose. If your business involves high-speed packaging, an in-motion, or high-speed checkweigher is ideal. On the other hand, if precision is more important, such as in clinical trials, a static checkweigher may be better.

The End

Checkweighers play a crucial role in medicine making. You should have a thorough understanding of various types. Therefore, you can select the best one for your business. It not only guarantees product safety but also helps prevent costly errors or regulatory issues. Besides, regular maintenance and proper staff training are also needed. It can further ensure the checkweigher operates efficiently.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche