How Do Powder Mixers Improve Your Pharma Business?

In the pharmaceutical industry, blending plays a key role in production. It mixes different ingredients evenly. This highly relates to effectiveness and safety of medicine. If you want to mix your materials, a blender is a must. This post helps you get more necessary information of blenders and make a wise choice for your business.

What is a Blender in Pharma Industry?

This machine is used to mix powders and other solid materials like granules for further processing. The main purpose of these blenders is to ensure that all ingredients are evenly mixed. This even mixing is important because it ensures that each dose of medicine has the correct amount of each ingredient.

Pharmaceutical powder blenders are especially useful when a product contains multiple ingredients. This includes APIs, fillers, binders, and other excipients. Without proper blending, it may lead to poor product quality. Because even a small difference in ingredient amounts can impact the effectiveness of the final product.

Blenders also feature high efficiency. Compared to manual mixing, they can process large batches and requires less time. In addition, you can adjust the speed, time settings, and load capacities for your desired materials. Blenders are often made of materials like stainless steel. It makes them easily cleaned to avoid contamination between batches.

Five Type of Blenders

Powder blenders come in different types. Each is designed to handle specific blending tasks. The right blender type depends on the materials being mixed and the final product requirements. Here are some common types of blenders for your reference.

V-Blenders

This machine is named for the unique V-shaped mixing chamber. This chamber consists of two connected cylindrical tubes that form a "V." These tubes can rotate to mix materials. It causes the powders inside to tumble and mix as they fall back and forth. This gentle tumbling action helps mix the powders evenly without high energy or intense mechanical force.

One of the main benefits of V-blenders is that they are very efficient at mixing dry powders and granules. They are especially good at mixing free-flowing powders with similar particle sizes and densities. Since their gentle tumbling, they are also perfect for materials that are fragile or prone to breaking.

Another benefit is that they are easy to load and unload. This design allows for smooth powder flow, reducing the risk of clumping or leftover material. V-blenders are also easy to clean. It helps prevent contamination between different ingredients used.

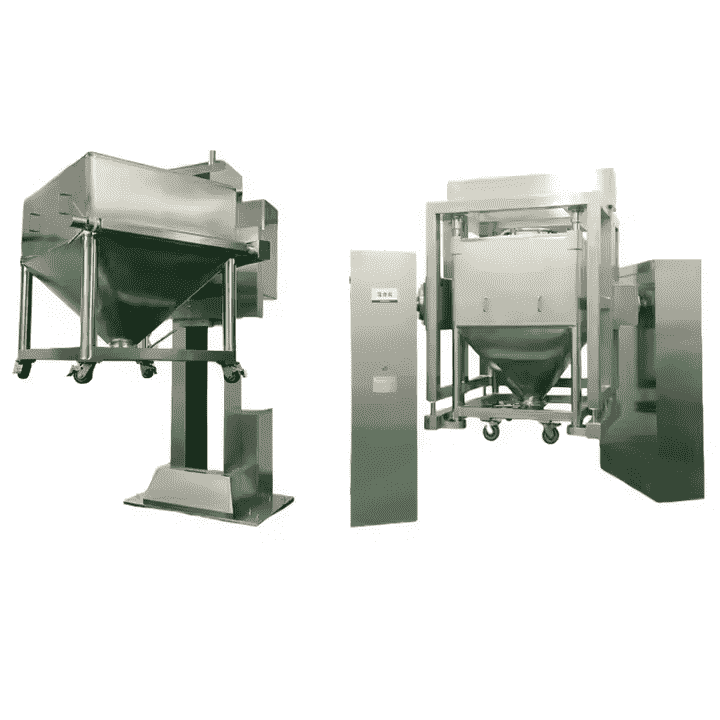

Bin Blenders

Compared to V-blenders, bin blenders use a detachable bin to hold the powders. It rotates in different directions to mix the contents. Then you can remove the bin after blending and transport the mixed material for further processing. Bin blenders feature great flexibility. It allows manufacturers to change different containers for different batches. So they don’t need to clean the entire blender each time. This reduces downtime and makes it easier to switch between products. It is especially useful when producing multiple types of medicines.

Bin blenders are typically used in larger pharmaceutical manufacturing. They are great for handling large quantities of powder. Because the container can hold a big load. The closed bin system also helps prevent contamination and keeps the mixing environment dust-free. It is important for maintaining a clean production process.

Ribbon Blenders

Ribbon blenders are designed with a long and horizontal mixing chamber. It contains a ribbon-shaped blade inside. The ribbon moves the powders in two directions. The inner ribbons push the material outward, while the outer ribbons push it inward. This creates a very thorough mixing that ensures all the powders are evenly blended. Because of the strong and continuous movement, ribbon blenders can handle powders with different particle sizes or densities. They are commonly used to mix powders with liquids. Also, they are used to blend powders that require a more intensive mixing process.

The design of the ribbon blender allows it to work quickly and operate in large scale. However, the machine can be more difficult to clean compared to other blenders. To avoid contamination, you’d better conduct regular maintenance.

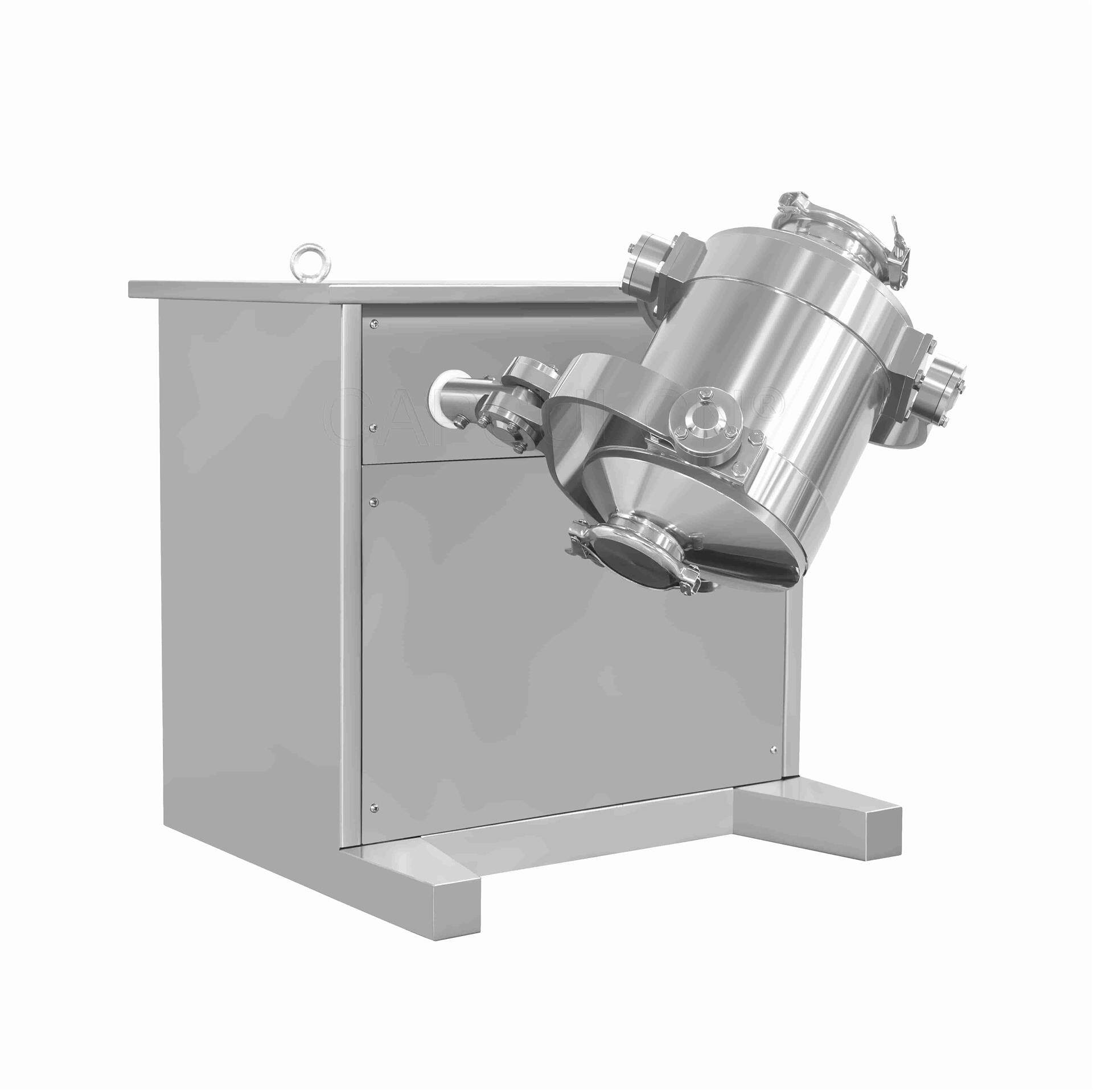

3D Powder Blender

A 3D powder blender is also known as a multi-directional motion blender. It mixes powders by rotating in multiple directions. The container is through bearings for connection with the equipment. With the support of the bearings, the container can rotate along several axes, including left and right, up and down, and front to back. This type of movement ensures that the powders are thoroughly mixed. Because the materials inside are constantly shifting and tumbling, the blending process is more efficient and uniform.

One of the main benefits of the 3D powder blender is that it produces a very even mix highly efficiently. Take mixing a heavy powder with a lighter one for example. They can often result in the heavier material settling at the bottom. But the 3D motion helps prevent this. These blenders are also helpful when dealing with delicate powders. These materials could be damaged by harsher mixing methods. 3D blenders offer smooth and gentle motion. It reduces the risk of breaking down the powder particles.

Cone Blender

Cone blenders are divided into single and double ones. Double mixers are more popular in the market. They consist of two cone-shaped containers connected together, forming a symmetric double-cone shape. This design makes the mixing more even. Because the materials tumble between the two cones during rotation, and expose more surfaces for better mixing. This also reduces the chance of the materials sticking to the walls or forming clumps. Cone blenders are also known for efficiently mixing dry powders and granules.

The cone blender’s gentle mixing process helps prevent the powders from breaking down. So it is greatly suitable for fragile or sensitive materials. Cone blenders are available in various sizes. They can be used for both small and large batches of products. In addition, the cone shape makes it easy to discharge the mixed materials after blending. The design also makes cleaning the blender relatively simple, which helps maintain hygiene standards in pharmaceutical production.

How to Maintain a Blender in Daily Use?

Equipment always require maintenance to ensure its longevity, efficiency, and safety. Here are some tips about how to keep a blender run well.

Regular Cleaning

Besides cleaning after every use, you should make a through cleaning for the whole device. If it is equipped with removable parts like the container and blades, disassemble them to clean. After washing, rinse all parts with clean water to remove any detergent. You should make sure everything is completely dry before reassembling the blender. Because moisture could lead to contamination or rust.

Inspect for Wear and Tear

Over time, seals and gaskets may wear out, leading to leaks. You should pay more attention to key parts like bearings and motors. If you notice unusual noises or excessive vibrations, they may wear out and need replacement. Besides, it is necessary to look for any scratches, cracks, or other damage on the container. This more important if the blender is used for abrasive or hard powders. A damaged container could affect the blending process and lead to contamination.

Lubrication

A regular lubrication for moving parts and bearings is a must. When applying lubrication, you’d better follow the guidelines in technical book. Proper lubrication ensures smooth operation and prevents mechanical issues.

The End

Powder mixers play a vital role in medicine, food or cosmetic making. They all require accurate ingredient blending for creating safe and effective products. Though there are many types of blenders to choose from in the market, you should choose one based on your production needs. With regular maintenance, you can get a more smooth and effective production.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche