Primary and Secondary Packaging: Protecting Your Pharmaceuticals

We all know packaging is just packaging, right? Wrong! It’s actually a crucial part of ensuring that your medicines are safe and effective.When it comes to pharmaceutical packaging, there are two main types: primary and secondary. These protective layers work together to keep your medicines in top condition from the moment they're produced until they reach your medicine cabinet. Let's look at how they work and what really sets them apart.

What is Primary Packaging?

The main purpose of your medication's packaging is to keep it safe and secure! It's the first line of defence, touching the drug directly. It could be anything from a simple blister pack to a complex vial or syringe. The primary packaging is super important because it stops contamination and keeps the drug strong. It's designed to protect the medication from things like light, moisture, and oxygen, which can make it less effective.

The main purpose of your medication's packaging is to keep it safe and secure! It's the first line of defence, touching the drug directly. It could be anything from a simple blister pack to a complex vial or syringe. The primary packaging is super important because it stops contamination and keeps the drug strong. It's designed to protect the medication from things like light, moisture, and oxygen, which can make it less effective.

What is Secondary Packaging?

Secondary packaging is just the outer layer of protection on top of your primary packaging. It's like a sturdy cardboard box that holds your medication bottle. It doesn't touch the drug itself, but it's super important in keeping your product safe on its journey from the manufacturer to your medicine cabinet.

Secondary packaging is just the outer layer of protection on top of your primary packaging. It's like a sturdy cardboard box that holds your medication bottle. It doesn't touch the drug itself, but it's super important in keeping your product safe on its journey from the manufacturer to your medicine cabinet.

Secondary packaging protects the primary container from physical damage, moisture, and light. It also provides essential information about the product, such as dosage instructions, expiration dates, and manufacturer details.

What Materials are Used for Primary and Secondary Packaging?

Primary Packaging Materials

You'd be amazed at how important the material used for primary packaging is! It comes into direct contact with the drug product, so it's really important to get it right. The material needs to be inert, compatible with the drug and able to provide the necessary barrier properties to protect the medication from external factors. The most common materials used in primary packaging are:

- Glass: It's great at keeping out light, oxygen and moisture, so it's perfect for storing sensitive drugs.

- Plastic: It's really versatile and cost-effective, and you can get it in different types (HDPE, PET, PVC, etc.) with different properties.

- Metal: You can use it for specific drug formulations, like aluminium for blister packs or stainless steel for ampoules.

- Paper and Cardboard: You can use it for specialised drug delivery systems like inhalers and pre-filled syringes.

Secondary Packaging Materials

Secondary packaging is there to keep your medicines safe and sound during their journey to you! The choice of materials is often down to a few different things, like the weight of the product, where it's being sent and how it's going to affect the environment. Some of the most common materials used are:

- Corrugated Cardboard: It's great for absorbing shocks and is a popular choice for shipping cartons.

- Paperboard: It is another great option! This lovely, thin and light material is perfect for smaller boxes and folding cartons.

- Plastic: It's great at keeping moisture out and you can even mould it into all sorts of shapes. However, it's worth noting that it's not always the most environmentally friendly option out there.

- Wood: It is a great material for making strong and durable pallets and crates.

What are Different Functions of Primary and Secondary Packaging?

Functions of Primary Packaging

When we say 'primary packaging', we mean the first container you see for the pharmaceutical product. Its main job is to:

- Keeping the product safe and secure: It keeps the drug in a particular form (solid, liquid, or gaseous).

- Product protection: It keeps the drug safe from things like external contaminants, light, moisture, oxygen, and physical damage.

- Preservation of product integrity: It makes sure the drug stays potent, pure, and stable over time.

- Delivery system: For certain products, the primary packaging itself acts as a delivery system (e.g., inhalers, pre-filled syringes).

- Patient convenience: It makes it easy for the user to administer the drug.

Functions of Secondary Packaging

Secondary packaging is what you find on the outside of the primary package, protecting it. Its main functions include:

- Grouping products together: It puts together several primary packages into one unit to make handling and distribution more efficient.

- Product protection: .It makes sure the original packaging stays in one piece, free from damage, contamination, and the effects of the environment while in transit and storage.

- Product ID: It also gives you all the product info you need, like the brand name, product description and batch number.

- Marketing and branding: It gives the product a visual identity and gets key marketing messages across to consumers.

- Making life easier for the consumer: It makes it easier to handle and display the product at the point of sale.

What Kinds of Packaging are Typically Used in the Pharmaceutical Industry?

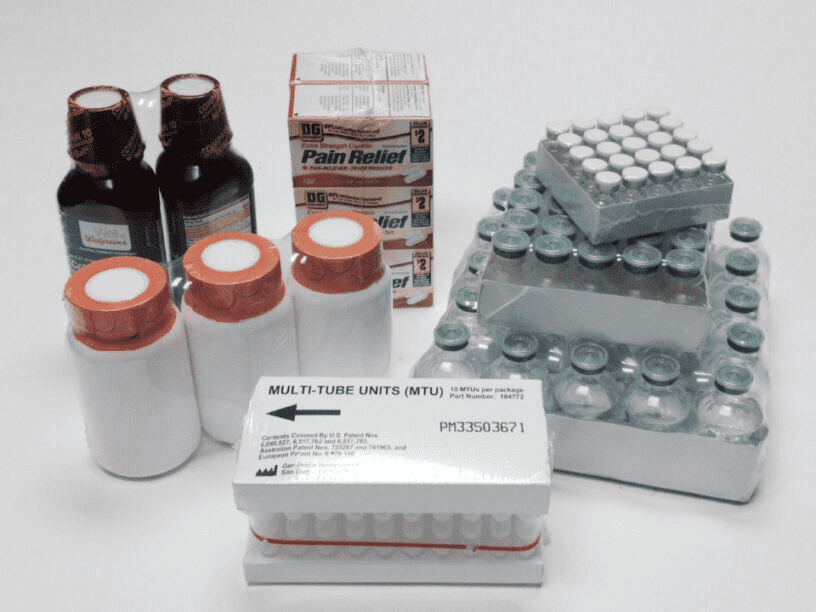

I've put together a few examples of primary packaging for you:

- Blister packs: The medication is supplied in single-dose packages, sealed in plastic.

- Vials: Glass or plastic containers with a rubber stopper, used for storing liquid or powdered medications.

- Ampoules: These are sealed glass containers for single-dose medications.

- Bottles: Plastic or glass containers with different types of lids for oral medications.

- Tubes: We also have flexible containers for creams, ointments and pastes.

- Sachets: Single-use packets for powdered or liquid medications.

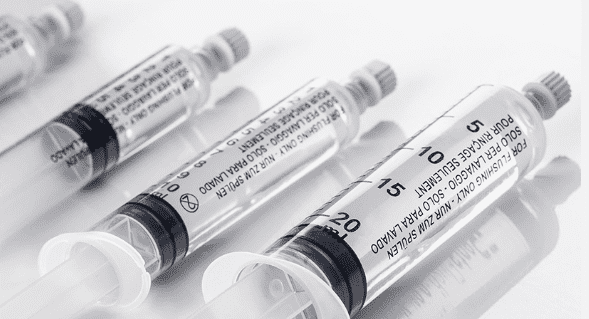

- Pre-filled syringes: These are ready-to-inject syringes that already contain the medication.

Here are some examples of secondary packaging:

- Cartons: Boxes made from cardboard that can hold several primary packages.

- Boxes: Similar to cartons, but often with different shapes or materials.

- Shrink wraps: It's plastic film that wraps around the main package to give it an extra layer of protection.

- Clamshell packaging: It's a rigid plastic container with a hinged lid, which is often used for blister packs.

- Pallets: These are wooden or plastic platforms that are used for transporting multiple secondary packages.

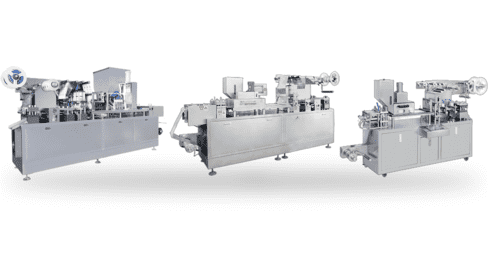

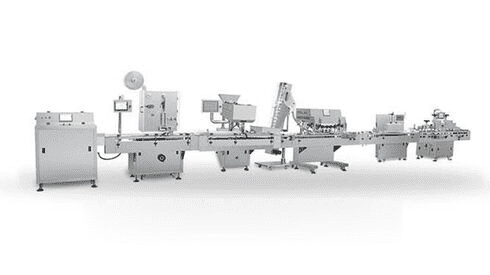

What are the Machinery Behind Primary and Secondary Packaging?

The packaging of pharmaceuticals involves specialised machinery. These machines are the backbone of the pharmaceutical packaging industry. They ensure product quality, safety, and efficiency.

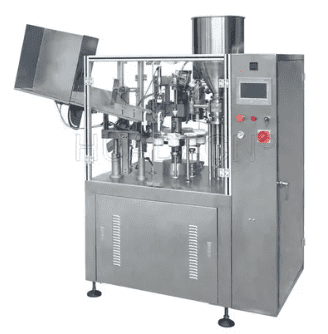

Equipment Used to Create Primary Pharmaceutical Packaging

The packaging that comes into contact with the drug must be precise and sterile. Key machines in this category include:

- Blister packaging machines: These form plastic or aluminum foil cavities, fill them with medication, and seal them.

- Bottle filling and capping machines: These fill liquid or solid products into bottles and seal them.

- Vial filling and sealing machines: These are used for injectable medications.

- Tube filling and sealing machines: These fill and seal tubes with creams, ointments, or pastes.

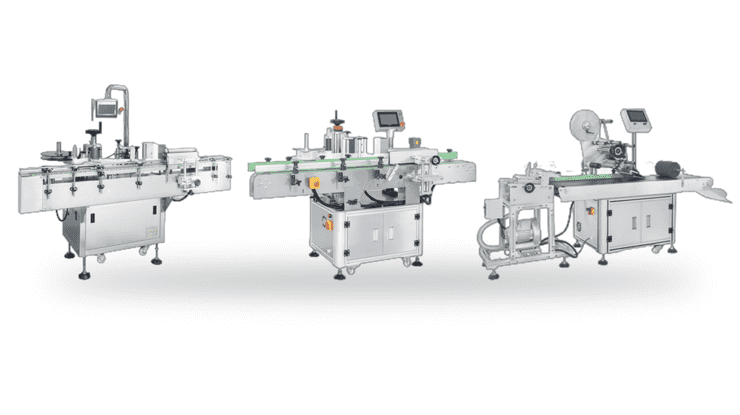

Equipment Used to Create Secondary Pharmaceutical Packaging

Secondary packaging protects and transports products after primary packaging is complete. Key machines in this category include:

- Cartoning machines: Make cardboard cartons to hold multiple packages.

- Case packing machines: Pack cartons into larger shipping cases for efficient transportation.

- Shrink wrapping machines: Add plastic film to packages for protection and to show if they have been tampered with.

Labeling machines: Add product labels to cartons or cases.

The Bottom Line

From the carefully crafted blister pack to the solid cardboard box, both the primary and secondary packaging are key to getting your medication to you safely. The primary packaging keeps the drug safe, and the secondary packaging makes sure it reaches you in one piece. This teamwork, with the help of cutting-edge machinery, gets your medicine to you when you need it.

I know it can be tricky to get your head around the different roles of primary and secondary packaging, so I've put together this handy summary table to help you out!

|

Feature |

Primary Packaging |

Secondary Packaging |

|

Purpose |

Directly interacts with the drug, maintains product integrity and sterility |

Protects the primary package, facilitates distribution and marketing |

|

Materials |

Typically glass, plastic, or metal |

Primarily cardboard, but can include plastic, wood, or metal |

|

Examples |

Blister packs, vials, ampoules, bottles, tubes, pre-filled syringes |

Cartons, boxes, shrink wrap, pallets, crates |

|

Equipment |

Blister packaging machines, bottle filling and capping, vial filling and sealing, tube filling and sealing, sterilization equipment |

Cartoning machines, case packing, palletizing, shrink wrapping, labeling machines |

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche