The Ultimate Guide to Buying a Pill Counter Machine in 2024

Packaging is an indispensable part of the modern pharmaceutical manufacturing process. Making sure each package contains the correct number of pills is vital yet challenging. That's where counting comes in handy. If you want to count tablets or capsules precisely and efficiently, it's time to embrace some advanced tools. Pill counter machines are exactly what you're looking for!

Pill counter machines are also known as tablet counters, drug counters, or tablet counting machines. No matter what you call them, they're built to elevate your pharmaceutical production to a whole new level. Thinking about investing in a tablet counting machine for the year 2024? Look no further! We've assembled this ultimate buying guide to help you navigate the abundance of options available. So, shall we dive in?

Different Types of Pill Counter Machines

When it comes to tablet counters, you've got three main types of counting machines to choose from, including manual, semi-automatic, and fully automatic machines. Each of them is designed to suit different production needs.

- Manual Pill Counter:

Let's start with the basic ones. Like those trusty old pharmacy pill counting trays, manual pill counters are usually made of plastic or stainless steel. Some are just flat square plates, some come in a triangle shape, while others have a bunch of evenly spaced holes.

Now, if you've got one of those flat square plate ones, you'll need to keep an eye on the pills and count them using a spatula.

Triangle trays are printed with a scale, which includes row and tablet counts. When tablets arranged in the tray reach a specific row mark, you will know how many tablets are on it. This manual counter is ideal for counting round tablets.

Compared to the former two pill counters, the holey kind makes counting a bit easier. You just need to shake the tray to allow the pills to sit snugly in those holes. The number of holes represents the tablet count.

|

|

These manual counters are great choices when you prefer hands-on counting. But, fair warning, they do take more time and effort since you're doing all the counting yourself. However, they can be budget-friendly if your business isn't churning out tablets by the truckload.

- Semi-Automatic Pill Counter Machine:

Semi-automatic tablet counting machines – they're kind of like a mix of automation and manual work. These counters typically come in tabletop versions. You can either use them alone or slot them into your existing tablet production line. For integration, go for the model featuring customization or compatibility.

|

|

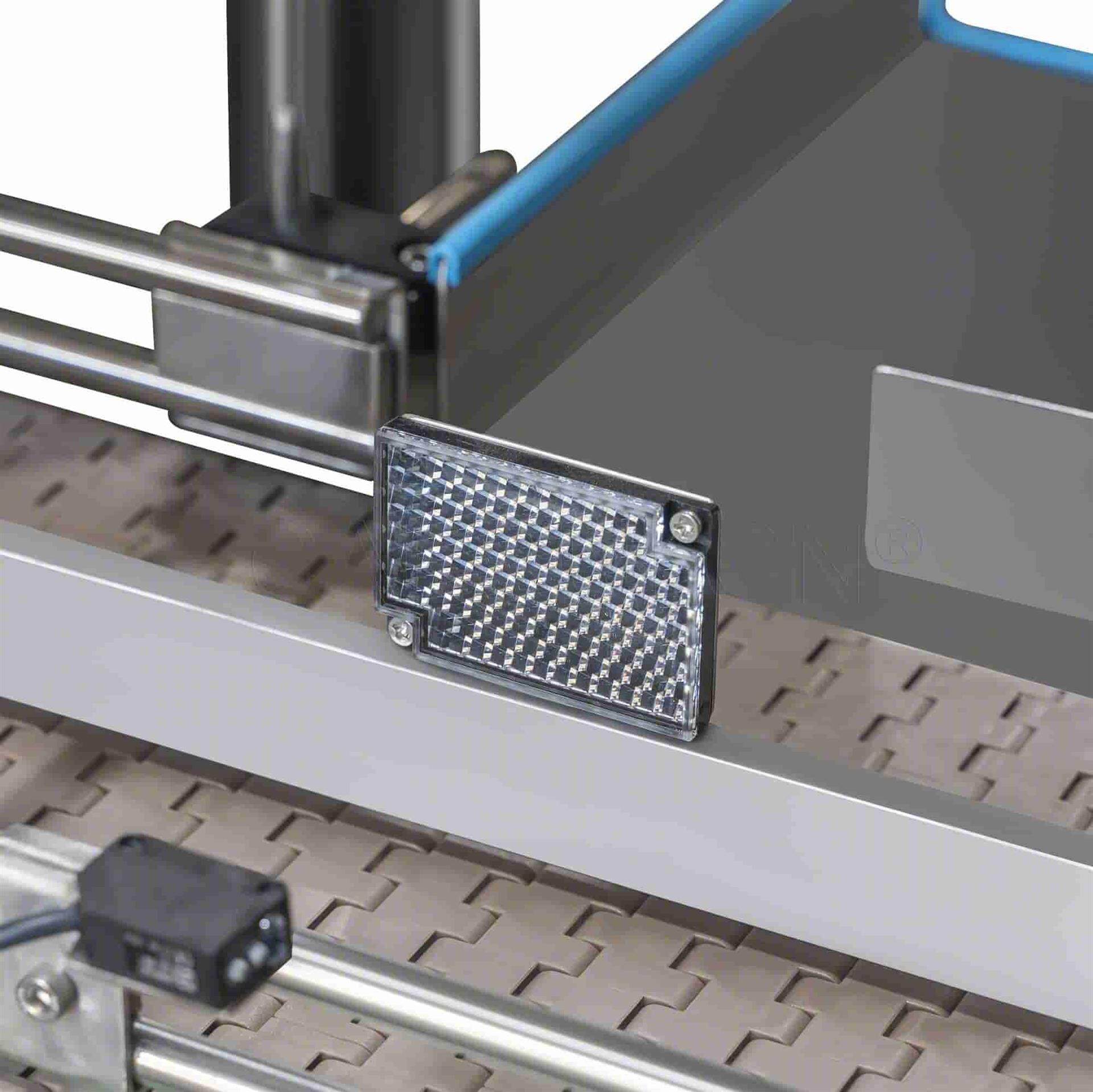

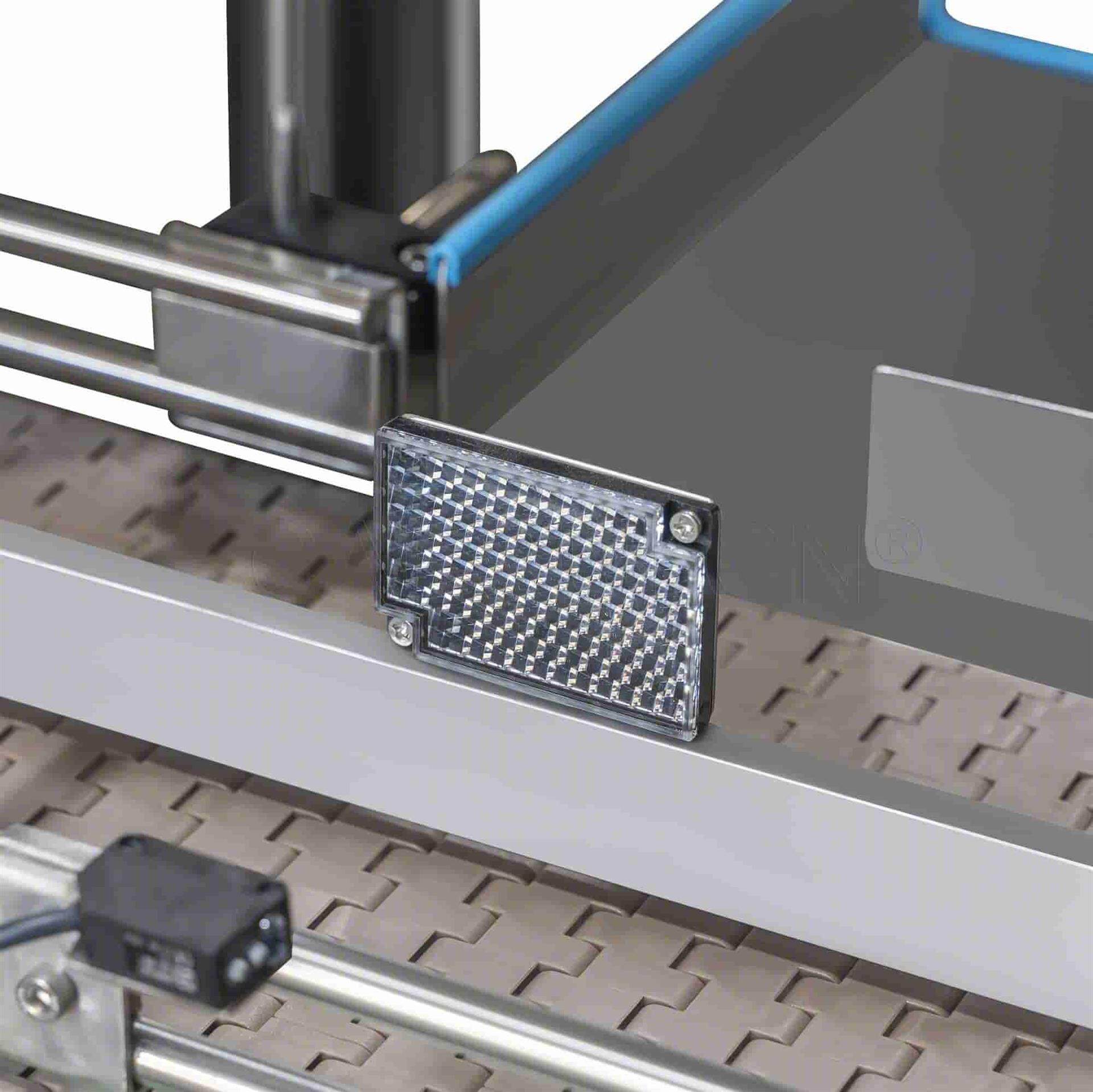

When working with one of these semi-automatic counters, you'll have to load tablets and place bottles where they need to be, all by hand. The cool part is these pill counters are packed with photoelectric sensors. This speeds up counting compared to doing it all manually.

The best thing about semi-automatic pill counter machines is that they seriously up your game in terms of counting accuracy and efficiency. Plus, they're pretty flexible – you can adjust them to handle different tablet shapes, sizes, and formulations. That's why they're a popular choice for those small to mid-sized pharmaceutical operations out there.

- Automatic Pill Counter Machine:

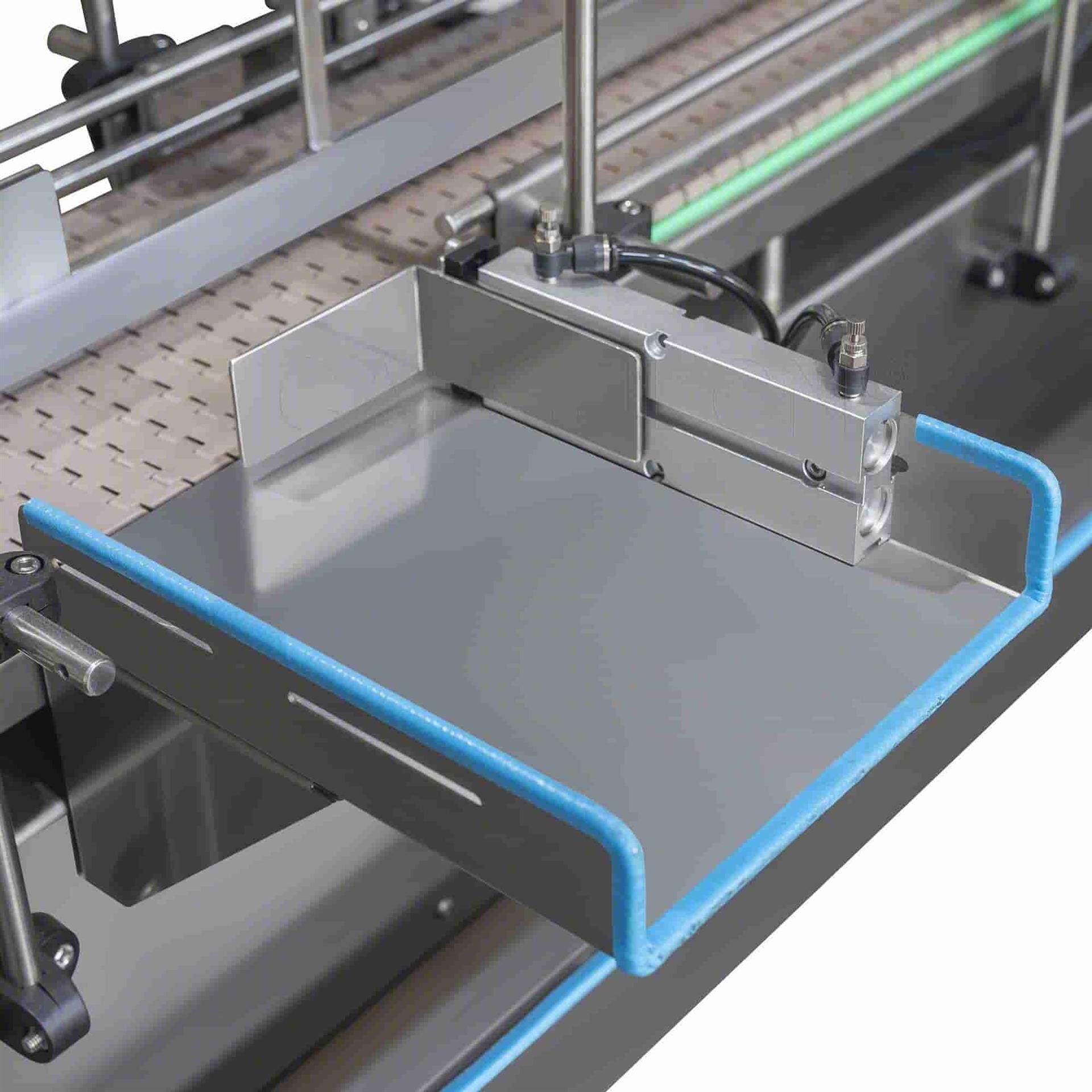

Fully automatic tablet counting machines are pretty high-tech. They come loaded with photoelectric sensors, conveyors, and all sorts of automated systems. All of that fancy tech ensures you get super precise counts at an incredible rate.

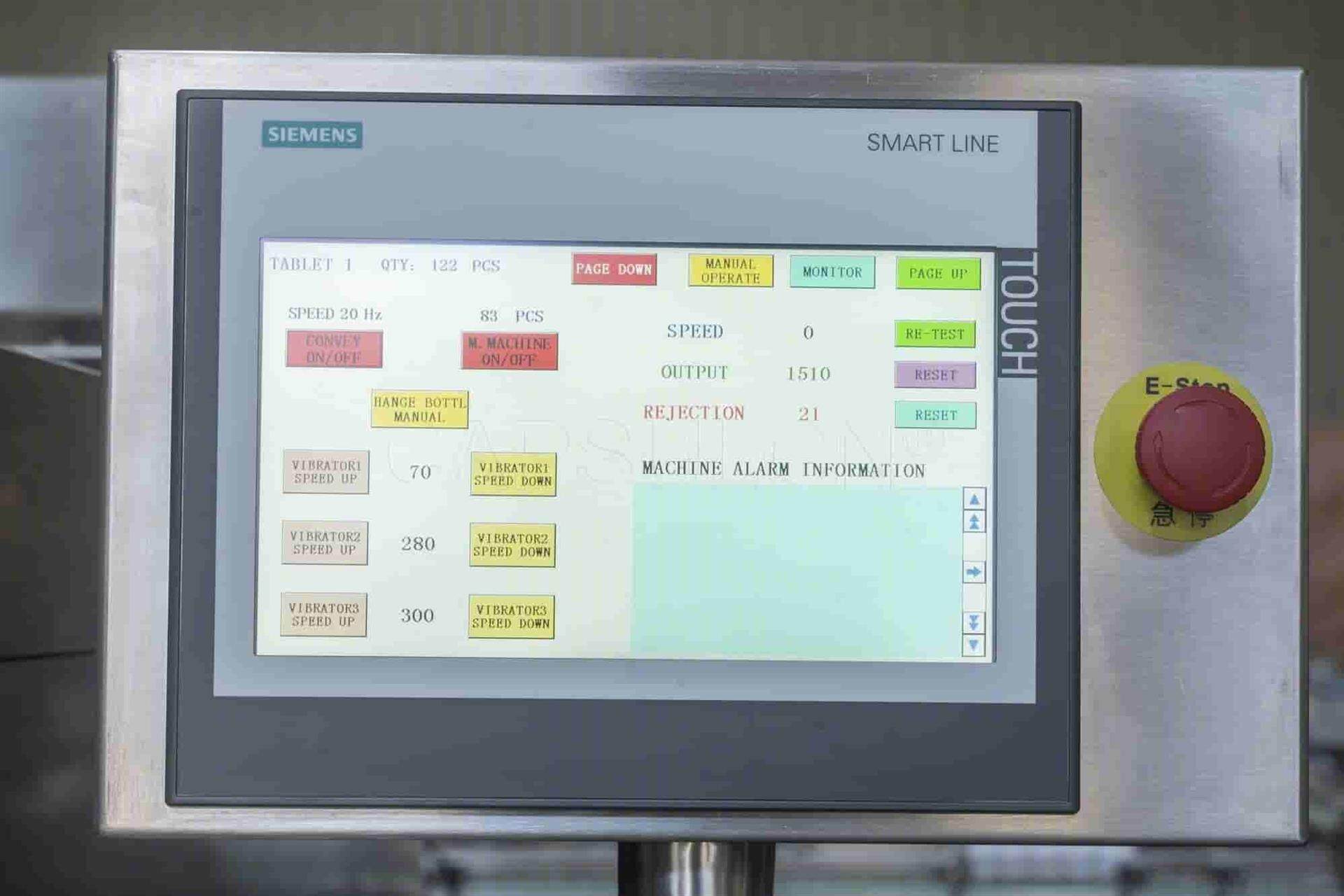

Most of these automatic tablet counting machines boast a user-friendly PLC-based touchscreen. You can easily set up the counting parameters, monitor the counting process, and tweak settings if necessary. They can also be equipped with a dust extraction system. This component helps create a dust-free working environment when dealing with uncoated tablets.

|

|

Now, here comes the highlight – these machines are designed to handle the entire process. They do everything from feeding tablets to counting them and filling up those bottles. With such a high level of automation, you can count and fill a boatload of tablets in no time. This makes them the go-to choice for pharmaceutical giants dealing with massive production volumes.

Read More:

Basic Tablet Counting Machine Parts You Should Know

How Does a Tablet Counting Machine Work

What Features to Look for When Buying Pill Counter Machines?

Before adding a pharmacy pill counting machine to your production flow, whether manual, semi-automatic, or automatic, there are several key features to consider in choosing the right one.

- Manual Pill Counter:

Construction Quality: Firstly, pay attention to the quality of construction. Manual pill counters on the market are typically made of hard plastic or stainless steel. Remember to check if the materials are durable and reliable. This is crucial as manual operation places demands on the pill counter. Plus, a robust construction can increase the longevity of the counter.

Tray Size: Secondly, check the size of the counting tray. If you pick a flat-plate style, ensure it's ample enough to arrange and organize the pills you intend to count. If you choose the holey kind, check if the hole size fits your tablets or capsules.

Ease of Cleaning: The pill counter should be easy to clean. Opt for a well-designed pill counter without dead corners to avoid getting powder or pills stuck. Ensure the materials of the counting tray are allowed to be cleaned with a mild detergent and water. This helps to prevent cross-contamination.

Accuracy: Don't overlook accuracy, even with manual counters. Look for a pill counter with designs or features that help minimize counting errors and enhance precision.

- Semi-Automatic Pill Counter Machine:

Speed and Capacity: Counting speed and capacity should be important considerations. Generally, these machines can achieve a production output ranging from 500 to 4000 pills per minute. Look for a semi-auto pill counter that efficiently handles your daily counting needs.

Accuracy Enhancement: Whether electronic or mechanical devices, semi-automatic pill counter machines enhance accuracy compared to manual counters. Look for models featuring optical sensors or other technologies that reduce errors.

User-Friendly Interface: Machines are made to make work easier. Intuitive controls, whether a touchscreen or a control panel, can simplify operation. Also, they help reduce the learning curve for new operators. Look for the feature to ensure improved efficiency.

Customizable Settings: Now that you're considering a semi-automatic machine, why not pick a flexible one? Choose a machine compatible with a wide range of pill sizes and types, providing versatility in your operations. You can also go for the custom ones that can be integrated with other equipment to streamline the production process.

- Automatic Pill Counter Machine:

Precision Sensors: Sensors play a key role in automatic tablet counting machines. These sensitive components mimic human eyes to monitor every single stage of the production process. From counting to filling, advanced optical sensors bring impeccable accuracy.

Space and Noise Considerations: With multiple mechanisms, an automatic tablet counting machine occupies more space than other types. Check if your production facility can accommodate the machine. Plus, pay attention to noise levels. Ensure it operates within acceptable noise levels for your environment.

Detection and Rejection: Look for automatic pill counters equipped with detection and reject systems. These systems can flag errors in tablet counts and bottle filling. This helps to maintain product consistency and regulatory compliance.

Data Logging: Most automatic tablet counting machines can record the data of the counting and filling process. Consider a machine with data logging functions. These help you control quality and optimize the process.

How to Clean and Maintain Pill Counter Machines?

Cleaning and maintaining pharmacy pill counter machines are essential to ensure accuracy and efficiency. Here are some tips to help you properly maintain different types of pill counters.

Manual Pill Counter:

Manual Pill Counter:

Before Use

- Wash your hands thoroughly.

- Check that the counting tray is clean and free from contaminants.

After Use

- Clean the tray with a cloth or wipe.

- Inspect for spills, stains, or damage.

- Store it in a clean, dry place.

Cleaning

- Wipe down the tray after every use.

- Use a mild detergent if needed.

- Pay attention to corners and counting slots.

Regular Maintenance

- Inspect for wear, damage, or calibration issues.

- Ensure counting holes are clear.

- Replace damaged parts promptly.

- Keep a maintenance log.

Semi-Automatic Pill Counter Machine:

Before Use

- Check for any foreign objects in the feeding hopper and turntable.

- Carefully inspect the connecting bolts and nuts for any signs of looseness.

- Verify if the two pads under the vibration bracket (used during transportation to prevent vibration) have been removed.

- Reset all buttons on the control panel to the default positions.

- Inspect the power supply and power cord for any damage.

- Ensure proper grounding of the machine.

After Use or When Changing Materials

- Disinfect the hopper and turntable and wipe them dry with a soft cloth.

Cleaning

- Clean the hopper and turntable with alcohol to ensure they are clean and contaminant-free.

- Unscrew the hand-tightened nuts and clean the material passage with alcohol.

- Gently wipe the photoelectric sensors with a dry, soft cloth.

Regular Maintenance

- Periodically check for any looseness in the height adjustment hand-tightening screws on the hopper.

- Perform regular maintenance on the photoelectric sensors.

- Keep a maintenance log.

Automatic Pill Counter Machine:

Before Use

- Check for stray tablets, capsules, or foreign objects in the machine.

- Tighten all connections and fasteners.

- Verify HMI control panel settings for the task.

- Inspect the power supply and cables for damage.

- Ensure proper grounding of the machine.

After Use

- Clear any remaining pills or debris.

- Examine the machine for wear and tear.

- Reset HMI control panel settings to default or manufacturer recommendations.

- Power off and unplug the machine.

Cleaning

- Use a suitable cleaning agent to wipe down machine surfaces.

- Clean feeding and counting channels thoroughly.

- Use a soft, lint-free cloth for sensitive components and screens.

- Disassemble and disinfect parts in contact with medications.

- Avoid abrasive materials and harsh chemicals.

Regular Maintenance

- Establish a maintenance schedule (monthly or quarterly, depending on usage).

- Inspect and lubricate moving parts as per manufacturer recommendations.

- Check and clean sensors and photoelectric eyes.

- Calibrate the machine for precise tablet counting.

- Promptly replace worn or damaged components.

- Maintain a maintenance log to track activities.

Specifications of Popular Pill Counter Machines

Here's an array of iPharMachine semi-automatic and automatic pill counter machines that are well-received by customers. You can explore these models to find the one that best suits your needs.

Take a look at the specifications of these machines for your reference.

|

Model |

Output |

Tablet Size |

Capsule Size |

Container Size |

Weight |

Dimensions |

|

iPharMachine Semi-Automatic Tablet Counting Machines |

||||||

|

CDR-3A |

800-1200 pcs/min |

Ф5mm-25mm |

#00-#5 |

15-500ML |

55kg |

830x820x350mm |

|

CDR-5A |

300-1500 pcs/min |

Ф3mm-13mm |

#00-#5 |

15-500ML |

22kg |

400x360x550mm |

|

YL-4 |

2000-4000 pcs/min |

Ф6mm-23mm |

#00-#4 |

15-500ML |

75kg |

980x790x930mm |

|

YL-4B |

1000-4000 pcs/min |

Ф5.5mm-18mm |

#00-#5 |

15-500ML |

65kg |

920x780x930mm |

|

iPharMachine Automatic Tablet Counting Machines |

||||||

|

PBDS-8 |

10-50 bottles/min |

Ф5.5mm-22mm |

#00-#4 |

Dia.: 20-100mm |

280kg |

1600x1500x1600mm |

|

PBDS-12 |

20-55 bottles/min |

Ф5.5mm-22mm |

#00-#4 |

Dia.: 20-100mm |

300kg |

1600x1500x1600mm |

|

PBDS-16 |

60-100 bottles/min |

Ф5.5mm-22mm |

#00-#4 |

Dia.: 20-100mm |

360kg |

2600x1600x1600mm |

|

PBDS-24 |

80-150 bottles/min |

Ф5.5mm-22mm |

#00-#4 |

Dia.: 20-100mm |

580kg |

4200x1800x1600mm |

Takeaways

When you're on the hunt for a pharmacy pill counting machine in 2024, keep the features mentioned earlier in mind. Then, make sure this machine fits your budget, too. Don't forget to check if it comes with good customer support and a solid warranty. Oh, and reading the reviews left by other buyers. Lastly, ensure the machine complies with the regulatory standards in your region. We're hoping that our guide will help you make an informed decision. Good luck with your pill counting!

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche