12 Questions for Choosing a Labeling Machine

In the world of packaging, labels can be considered the face of a product. They play a big part in the identification, information, instructions for use, branding, warning, and tracking of products. This makes the labeling process one of the essential steps in packaging operations. But how do you apply a high-quality label to your product? I bet you've guessed it already. Yes, a labeling machine can do the job for you.

If you take a look around the labeling machine market, you will find there is a multitude of options available. So, how do you go about choosing the best labeling machine? We can help! Below are a few useful questions that can guide you to the best label applicator to help make a difference in your business.

6 Questions You Will Get Asked by Labeling Machine Suppliers

During a buyer's consultation, label applicator suppliers might ask you a bunch of questions. Your answers will provide them with effective information about your demands. With this information, the suppliers can recommend the most suitable labeling machine to you. Meanwhile, this helps you to compare these potential suppliers to make a better purchase decision.

#1 What type of products do you want to label?

Why: Labels are typically applied to product packaging, including primary, secondary, and tertiary packaging. They can be attached to various packages for different purposes. Understanding the type of your product allows the supplier to have an idea of the shape, size, and material of your product. Even if you want to label a unique product, this question allows the supplier to determine if they can take the project in the first place. Here are some examples.

|

|

|

|

Bottles and Jars |

Cartons and Boxes |

|

|

|

|

Bags and Pouches |

Cans and Tins |

|

|

|

|

Tubes and Squeeze Bottles |

Trays and Clamshells |

#2 What are the sizes and shapes of your product?

Why: Standard labeling machines may not work for some products with irregular shapes. In addition, labeling machine configurations such as conveyor belts, product carriers, and label applicators can vary depending on the product's specifications. Knowing the shapes and sizes of the product to be labeled helps the supplier find a machine that can handle your product more efficiently.

#3 What is the material of your product packaging?

Why: Product packaging can be made from paperboard, plastic, glass, or metal. Some labels don't work well on certain materials. For example, some adhesive labels might not be able to offer optimal adhesion to your product. So, this question helps the supplier determine which label type is best for you.

#4 What labels do you need for your product?

Why: Based on purposes, labeling methods, or other standards, labels can be classified into many types. Understanding your labeling requirements allows the supplier to recommend the right equipment. Let's take a look at some of the major label types.

|

|

TYPES OF LABELS |

|

|

BY PURPOSE |

1. Brand labels |

|

|

2. Descriptive labels |

|

|

|

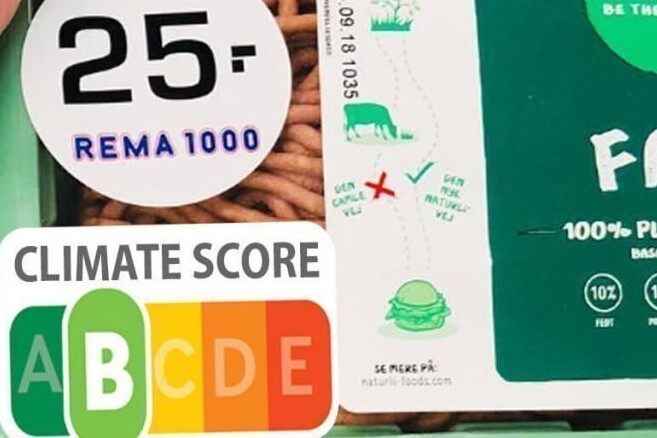

3. Informative labels |

|

|

|

4. Grade labels |

|

|

|

BY LABELING METHOD |

1. Pressure-sensitive labeling |

|

|

2. Shrink sleeve labeling |

|

|

|

3. Cut-and-stack labeling |

|

|

|

4. In-mold labeling |

|

|

|

BY APPLICATION METHOD |

1. Wrap-around labeling |

|

|

2. Front & Back labeling |

|

|

|

3. Top & Bottom labeling |

|

|

#5 What is your expected labeling speed and production volume?

Why: Labeling machines are available in semi-automatic and fully automatic operations. So, labeling speeds and production capacities can vary depending on the machines you select. Knowing your production requirements helps the supplier recommend the labeling machine to meet your production targets effectively.

#6 How much room does your facility have for a labeling machine?

Why: Label machines come in tabletop, standalone, or modular designs. Each option requires a space of different sizes. In addition to the room for the machine, there must be sufficient space for operators to move around. Knowing your facility's available space helps the supplier recommend a labeling machine that fits seamlessly into your workspace.

6 Questions to Ask When Buying a Labeling Machine

So, now you know the common questions from labeling machine suppliers. It's your turn to ask questions. Here are a couple of frequently asked questions that will help you make a smarter purchasing decision.

#1 What labels can the machine handle?

Why: Labels are available in different materials, sizes, and shapes. Based on your product to be labeled, you need to know if the machine is compatible with your labeling needs. If you're labeling more than one product, ensure that it can effectively label each specific product, no matter the material, size, or shape.

#2 What is the machine's labeling speed?

Why: Even when you choose the same type of labeling machine, such as a tabletop or integrated option, these machines run at different speeds. The labeling speed determines the production volume. Figuring out the machine's speed helps you assess its capability. An overcapacity machine can cause unnecessary costs. Of course, if you have a scale-up plan, choose the machine available for speed upgrade.

#3 What type of products can the machine label?

Why: Asking this question to see if the machine can handle your product. Having a clear understanding of the product types the machine can label helps you assess if it is flexible and versatile enough to fit with your diverse product range. After all, a flexible label applicator is always a go-to option.

#4 What is the labeling method of the machine?

Why: This is another way to identify if the machine matches your labeling needs. Many labeling machines are not all-around players. Some work better on flat packaging, while some are more suitable for curved surfaces. Understanding the labeling method of the machine allows you to determine if it's capable of handling your product precisely and effectively.

#5 Can the machine be integrated into an existing production line?

Why: This question is essential if you intend to invest in an automatic labeling machine. Automatic labelers can be either standalone or integrated with other packaging equipment. If the machine is used to boost the efficiency of your existing packaging line, confirm that it can fit seamlessly into the current workflow.

#6 Do you offer customization for the machine?

Why: All labeling machines package products with labels off the shelf. But what if your product requires unique prints or other labeling requirements? Asking the supplier whether the machine is customizable, such as adding a print and label system, allows you to evaluate if the supplier can provide diverse labeling solutions.

Examples of Labeling Machines

At iPharMachine, we have provided our customers with a wide range of labeling solutions. The following two labeling machines are popular among them. If you've not decided yet, these two models might be the ones you're looking for.

|

|

|

|

|

Model |

||

|

Applications |

Bottles and jars |

Bottles and jars |

|

Level of Automation |

Semi-automatic |

Automatic (integrated solution) |

|

Maximum Labeling speed |

25-50 pcs/min |

120 pcs/min |

|

Label size |

30-280 mm (L) x 20-130 mm (W) |

25-200 mm (L) x 25-90 mm (W) |

|

Product size (diameter) |

Φ20-120 mm |

50-500 ml |

|

Voltage |

220V 50HZ/110V 60HZ |

AC220V/50HZ |

|

Dimensions (L x W x H) |

820x340x545 mm |

2000×1150×1650 mm |

|

Weight |

29 kg |

300 kg |

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche