7 Questions To Answer Before Requesting A Blister Packaging Machine

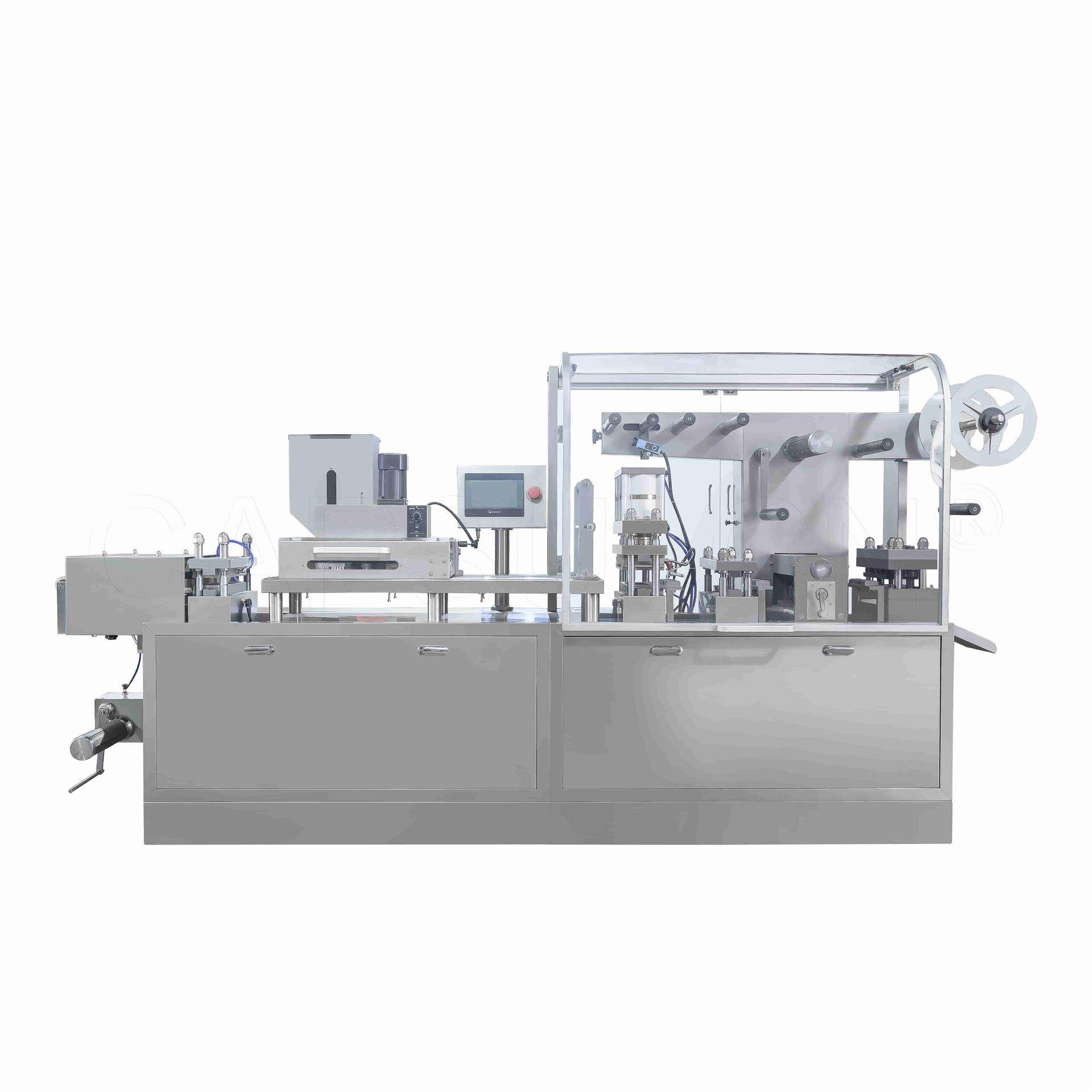

An equipment used in the packaging business to create blister packets is referred to as a blister machine or blister packaging machine. Small consumer goods, medications, and medical equipment are frequently packaged in blister packs.

Typically, a blister pack consists of a hole or pocket made of clear plastic, known as a blister, which firmly retains the product, and a backing card or foil, which acts as a protective covering.

The blister machine makes it easier to create the blisters, place the product inside, and seal them with the backing material.

Since you have an idea of what a blister pack and a blister packaging machine is, let’s delve into the striking questions to answer before requesting a blister packaging machine that you must keep in mind.

1. What is the production requirement? How many blister packs do you need to produce per day, week, or month?

The production requirement for blister packs can vary significantly depending on the specific product, industry, and market demand. The number of blister packs needed per day, week, or month is determined by factors such as:

- Market Demand: The demand for the product packaged in blister packs is a key consideration. This can be influenced by factors like consumer demand, seasonality, market trends, and the product's shelf life.

- Production Capacity: The capacity of the blister machine and the overall production line determines the maximum output that can be achieved. The production capacity can vary based on the machine's speed, efficiency, and downtime for maintenance or changeovers.

- Lead Time and Inventory: The desired inventory levels and lead times also impact the production requirement. For example, if a tablet production company aims to maintain a certain level of safety stock or meet specific customer orders within a defined timeframe, it will influence the production quantity.

- Production Efficiency: The efficiency of the blister machine and the production process can affect the number of blister packs produced. Factors such as machine uptime, cycle time, operator skill, and Overall Equipment Effectiveness (OEE) play a role in determining the production output.

Given these factors, it is challenging to specify the precise number of blister packs that must be manufactured each day, week, or month without first understanding the context and specifications of a given product or sector.

Depending on the amount of production and consumer demand, each situation's production requirement will be different and may range from hundreds to thousands or even millions of blister packs every day or month.

2. What is the budget? How much are you willing to spend on a blister packaging machine?

The budget for a blister packaging machine can vary significantly depending on several factors. Machine type and complexity of the blister packaging machine influence its cost. Manual or semi-automatic machines are generally less expensive compared to fully automated or high-speed machines.

Another thing to note is production capacity. Machines with higher production capacities often come with a higher price tag. Higher capacity machines can handle larger volumes and offer greater efficiency but can also be more expensive.

Furthermore, features and functionality play an important role. Additional features and functionalities, such as advanced controls, monitoring systems, integration with other equipment, or special customization options, can increase the cost of a blister packaging machine. This is why iPharMachine blister packaging machines’ are recommended if you are on a budget.

Quality and durability cannot be overemphasized. The quality, reputation, and durability of the machine and the manufacturer can affect the price. Renowned manufacturers or brands with a history of producing reliable and high-quality machines might come at a premium.

3. What type of blister packaging do you need?

There are many different types of blister packaging, including clamshells, blisters with peel-off lids, and blisters with push-through lids.

Face sealed blisters, clamshell packaging, sliding blister packaging, blister packs with peel-off lids, blister packs with push-through lids, and child-resistant blister packaging are some of the several forms of blister packaging.

Face sealed blisters entail sealing the item inside the blister cavity and enclosing it in foil or backing card.

Clamshell packaging encloses the product safely with two hinged sections. A sliding cardboard sleeve or cover is attached to a blister cavity in slide blister packaging.

A plastic blister chamber is sealed with a lid that can be easily peeled off in blister packs with peel-off lids. Push-through blister packs have a plastic blister chamber that is sealed with a push-through lid.

Special features are incorporated into child-resistant blister packaging to keep toddlers from accessing the contents.

The needs for the product, desired level of protection, visibility, and industry-specific restrictions all play a role in the blister packaging option.

4. What size blister packs do you need?

Blister packs come in a variety of sizes, from small to large.

Blister packs come in various sizes to accommodate products with different dimensions. The individual product being packaged, its dimensions, and the desired presentation all influence the size of blister packs that are needed.

Blister packs may have compact dimensions for smaller objects like tablets, capsules, or small consumer goods to securely keep the product and create an aesthetically pleasing display. These blister packs are made to be as effective and resource-conserving as possible.

On the other hand, larger products or those with unusual designs can need blister packs that are larger in size.

These blister packs offer enough room for the product to fit firmly inside the hollow, guaranteeing adequate protection throughout handling, shipping, and storage.

5. What materials do you need the blister packs to be made from?

Blister packs can be made from various materials, including plastic, paper, and metal.

Each of the materials frequently used to make blister packs—plastic, paper, or metal—has advantages of its own.

Plastic is excellent for a wide range of products because it offers transparency, toughness, and versatility. Paper blister packs offer a flexible, lightweight, and environmentally responsible packaging option.

Products are shielded from oxygen, light, and moisture by metals with outstanding barrier qualities, such as aluminum foil.

Product features, packaging requirements, and environmental issues all play a role in the choice of blister pack material. So, before you choose the blister packaging machine, note this well.

6. What features do you need the blister packaging machine to have?

Apparently, some blister packaging machines have features such as automatic loading and unloading, as well as the ability to print on the blister packs.

Multiple features on blister packaging machines can improve the packaging procedure. Numerous blister cavities for high-volume production, automatic loading and unloading for greater efficiency, direct labeling printing capabilities, temperature and pressure control for secure sealing, quality control and inspection systems, and changeover flexibility to meet the needs of various products are a few of these.

The best characteristics for a blister packing machine can be chosen by analyzing particular requirements and communicating with manufacturers.

7. What is the level of automation required?

Some blister packaging machines are fully automated, while others require some manual intervention.

The amount of automation needed for blister packaging relies on various elements, including labor costs, process complexity, production volume, and efficiency objectives.

There are three basic levels to note; fully automatic, semi-automatic, and manual. Compared to semi-automatic devices, hand packaging requires a lot of manual labor.

Fully automatic machines are excellent for high-volume production and require little operator input.

The level of automation used depends on particular requirements as well as elements like resource availability and desired efficiency.

How To Buy A Blister Packaging Machine

The dependable blister packaging machines from iPharmachine will improve your packaging procedure.

A broad variety of choices are available, including manual, semi-automatic, and completely automatic types.

Our customized equipment ensures a perfect fit for your unique requirements. Experience outstanding quality, reasonable pricing, and top-notch customer service. Improve your product appeal and packaging effectiveness.

Get in touch with iPharmachine right away for your blister packaging needs.

Conclusion

In conclusion, before requesting a blister packaging machine, there are seven important questions to answer. Consider the production requirement, budget, type of blister packaging needed, size of blister packs, materials for blister packs, desired features in the machine, and level of automation required. These factors will help you make an informed decision when purchasing a blister packaging machine.

For reliable and customized solutions, iPharmachine offers a range of manual, semi-automatic, and fully automatic blister packaging machines. Contact iPharmachine immediately to enhance your packaging process with quality equipment and excellent customer support.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche