Ribbon Mixer Working Principle: A Complete Guide

A pharmaceutical blender is a very important device in the drug-production industry. There are different types of blenders in pharmaceuticals - although they are similar in function. This article focuses on one type of pharmaceutical blender – the ribbon blender. You will get to know what is a ribbon mixer, the details about this device, the benefits you stand to gain, and some of the variations available.

What is a ribbon blender?

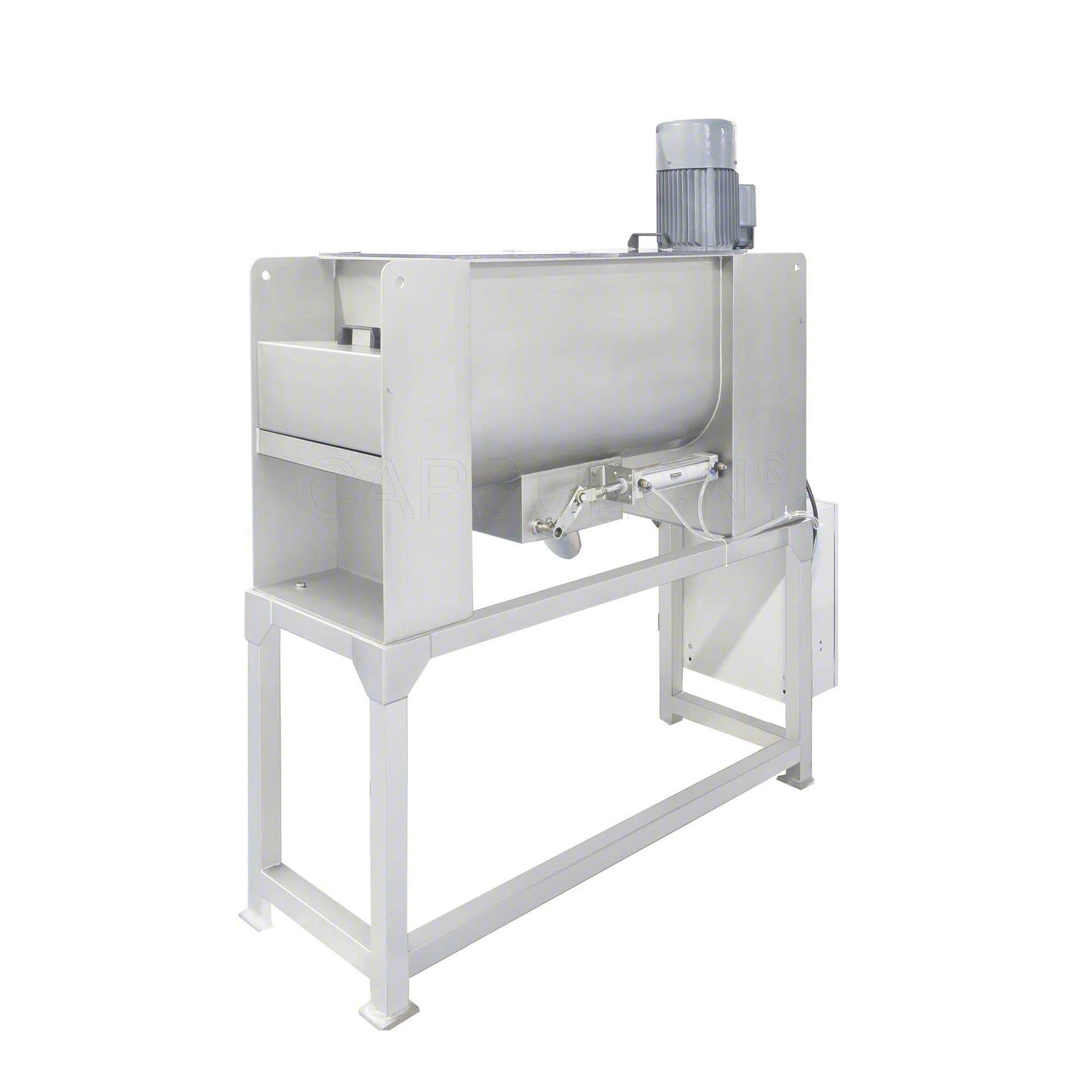

The ribbon blender also doubles as a mixer. It is used to mix dry solid and semi-solid raw materials such as powders, pastes, and dried granules. It is an efficient and versatile light-duty machinery used in various sectors, including the pharmaceutical, chemical, cosmetics, food, and agricultural industries.

The ribbon blender mixer is a type of connective mixer. It has a thin mixing blade that ensures that the raw materials are mixed through controlled motions. The mixing blades are fully sealed at each end to avoid leakage, making them appropriate for dry powders and semi-liquid materials.

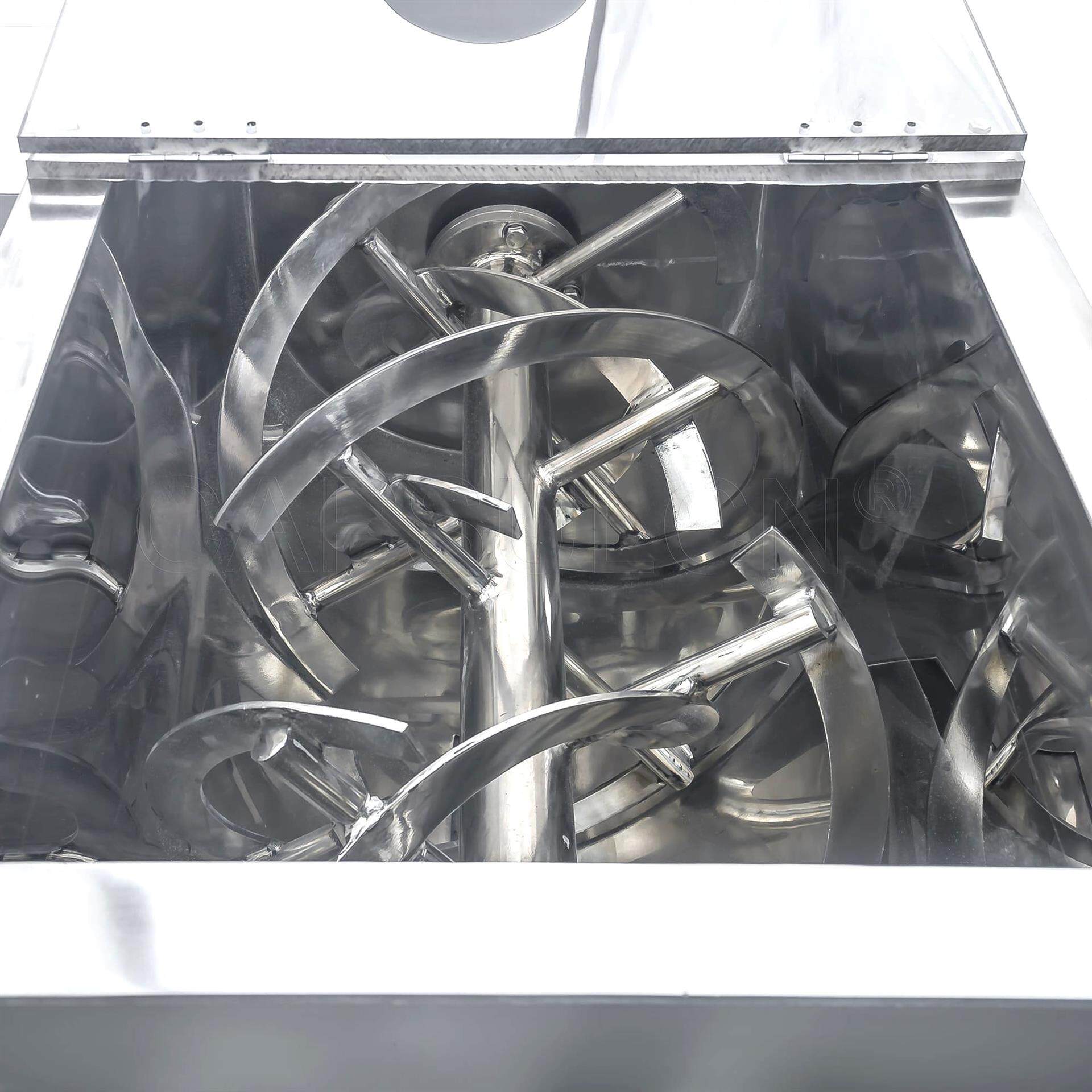

The image above shows a ribbon blender mixer

How does a ribbon blender work?

To fully understand the ribbon mixer’s working principle, we must first discuss the design, construction, and parts of the ribbon blender mixer machine. When choosing the right machinery, selecting equipment capable of mixing, vacuuming, and filling the materials is essential.

How is a ribbon blender designed?

The horizontal ribbon mixer consists of a transmission part, a U-shaped barrel, and a double-layer ribbon mixer. The shell of the ribbon mixer blender is designed in a U shape, with a rotating agitator located in the center of the shell. The bulk materials are efficiently mixed in two directions via a convective movement aided by the agitator's double helix design.

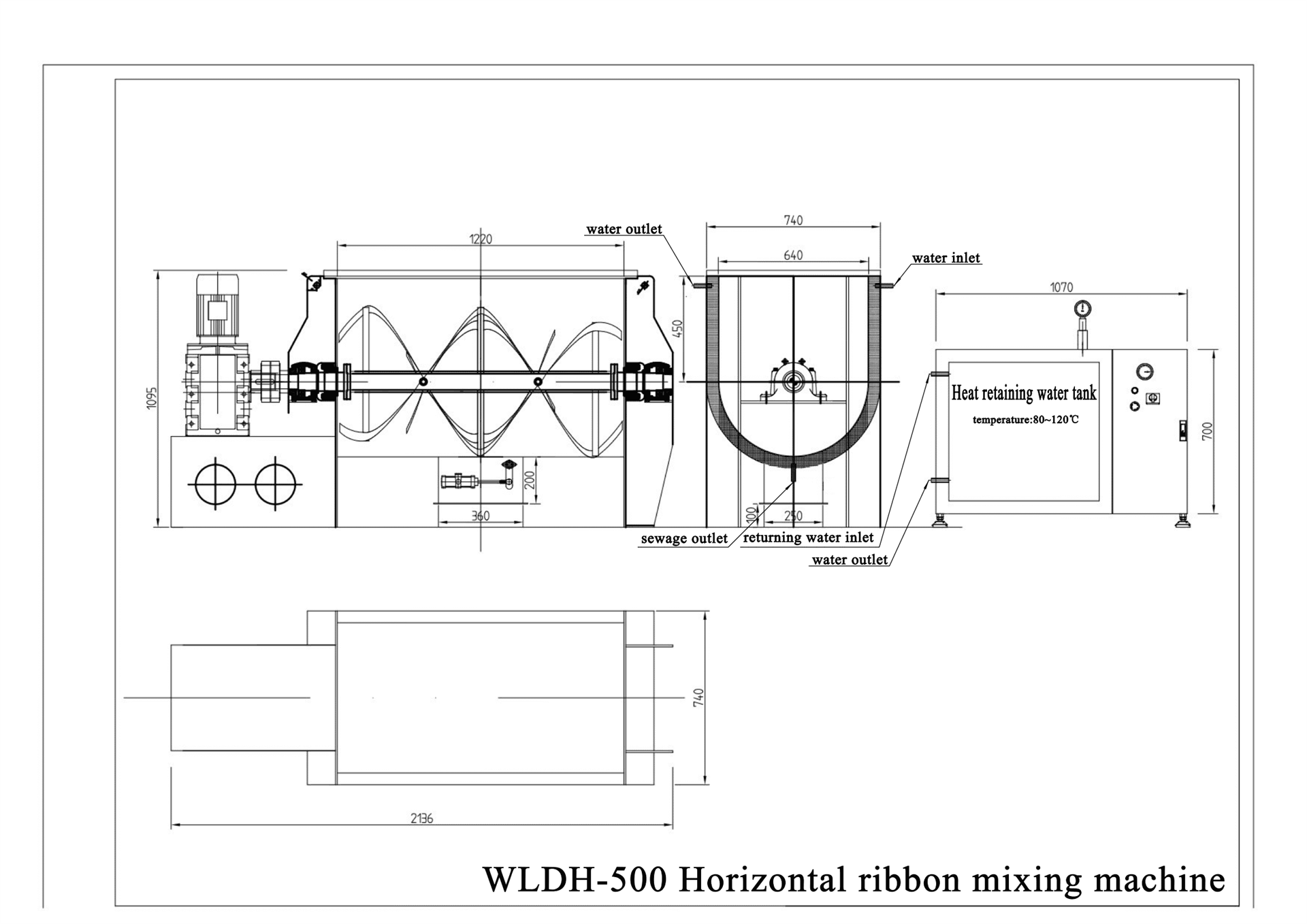

The image above shows the design of WLDH-500 Ribbon Mixer

How is the ribbon blender constructed?

The dimensions and layout of the ribbon mixer are precisely designed, arranged, and constructed to achieve an ideal homogenous product through the rapid and effective mixing and blending of the raw materials.

The construction of the different parts of the machine is carefully carried out with consideration to the features that are exposed to the materials. This helps to reduce the level of contamination of the product. The main parts of the ribbon mixer are constructed with stainless steel, which undergoes refining methods such as polishing, mirror polishing, sandblasting, and wiredrawing.

iPharMachine offers ribbon mixer series made of quality and durable materials that have been approved per the Good Manufacturer Product as well as other international certifications. We also boast of machines that can withstand atmospheric pressure imbalance while working.

The image above shows the details of the construction of WLDH-100L Ribbon Mixer

What are the parts of the ribbon blender?

The ribbon blender parts include:

- Mixing vessel

The mixing vessel is the part of the ribbon mixer where the blending and mixing of the raw materials occur. It occupies the most significant space of the machine; the rotating agitator is also placed in the mixing vessel.

It is designed in a U shape and is usually made with stainless steel; sometimes carbon steel and special alloy can be used for constructing the mixing vessel.

Materials that can be mixed in the mixing vessel include solid or powdered materials or a mixture of solid, semi-solid, and liquid.

- Discharge valve

The discharge valves of the ribbon mixer are well-fitted with a seal to prevent material wastage during discharge. There are three forms of drive mechanisms for the discharge valves, electric, manual, and pneumatic.

Different types of discharge valves can be used depending on the material being processed; butterfly valves, spherical valves, and rotatory ball valves, among many others.

- Agitator element

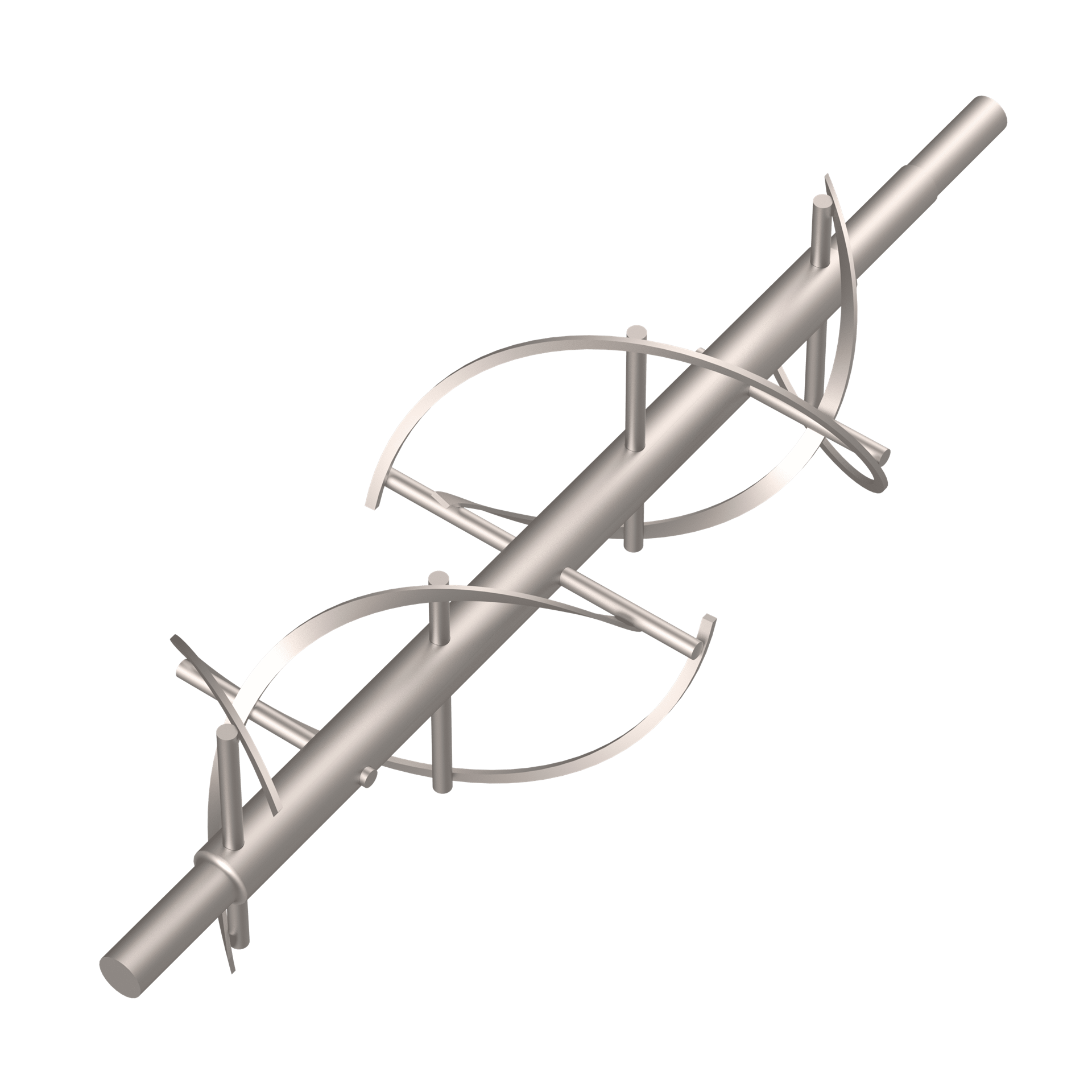

The agitator element is a double helical structure with inside and outside ribbons.

- Flat top cover

A ribbon mixer has a solid tight-fitting flat top cover that can be left open occasionally during operation. It is usually made from stainless steel, which aids easy cleaning of the mixing vessel and loading of raw materials.

- Rotating shaft

The rotating shaft is found in the mixing vessel of the ribbon blender. It is a horizontal shaft that rotates the agitator at a very high speed to ensure the effective blending of the materials.

The speed of the shaft is usually 80 to 100 meters per minute.

- Control shaft

The control shaft is the most critical part of the ribbon blending machine. It consists of the main power switch, safety limit switches, emergency stop buttons, and a fuse.

All the sections of the control system have to work together in good condition to ensure a productive output.

- Drive mechanism

The drive mechanism comprises a wide range of motors, including general motors, variable frequency motors, explosion-resistant motors, high efficiency, and energy-saving motors, this part of the ribbon mixer machine is crucial for the smooth running of the device.

The drive mechanism, output seed, and power consumption of the machine can be modified to fit the kind of material and the processing method of production.

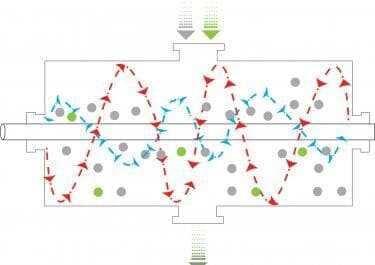

What is the working principle of the ribbon mixer?

The ribbon mixer works with a triple-action technique. The double helix structure of the agitator of the ribbon mixer, which includes the inner and the outer ribbon, works in a reverse direction. The counter-motion plays an essential role in the successful working of the machine.

The outer ribbon is coiled to transport the raw materials from both ends of the mixing vessel to the middle, while the inner ribbon takes the materials from the center of the mixing vessel to the opposite ends. The opposing angles and directions of the double helix make the materials flow in a different direction, causing continuous convection circulation and shear blending.

The ribbons rotate at a very high speed causing a radial motion- the fusion of the countercurrent and radial motion results in the speedy production of a smooth homogenous mixture. The estimated mixing time is about 15 to 20 minutes.

However, it is subject to some factors, such as the size and substance density of the raw materials, which also affect the quality of the blended mixture.

The filling factor is the ratio of the volume of materials loaded into the mixer in each batch to the total volume of the mixer vessel when the mixer is in operation. To derive the best mixing tie, uniformity, and effect, the loading coefficient of the ribbon mixer should be approximately 60 to 65 percent. If the mixing vessel is overloaded, it could result in mechanical damage to the mixer; also, if the material is not filled to the optimum, it could cause uneven mixing with a long mixing time.

The discharge process is activated after the completion of the blending process. The blended mixtures are ejected through the discharge valve at the bottom of the trough. It could be discharged manually, electrically, or pneumatically.

It is advised to avoid watery, diluted, semi-liquid materials when using the ribbon mixer blender. It reduces the lifespan of the machine.

iPharMachine Ribbon Mixers Series

iPharMachine supplies a series of ribbon mixer blenders comprising five high-performance trough format mixing machines. They are used for mixing powders or pastes into a homogenous end product.

The sizes of the Ribbon Mixer Series range from about 100 liters to 5000-liter capacity.

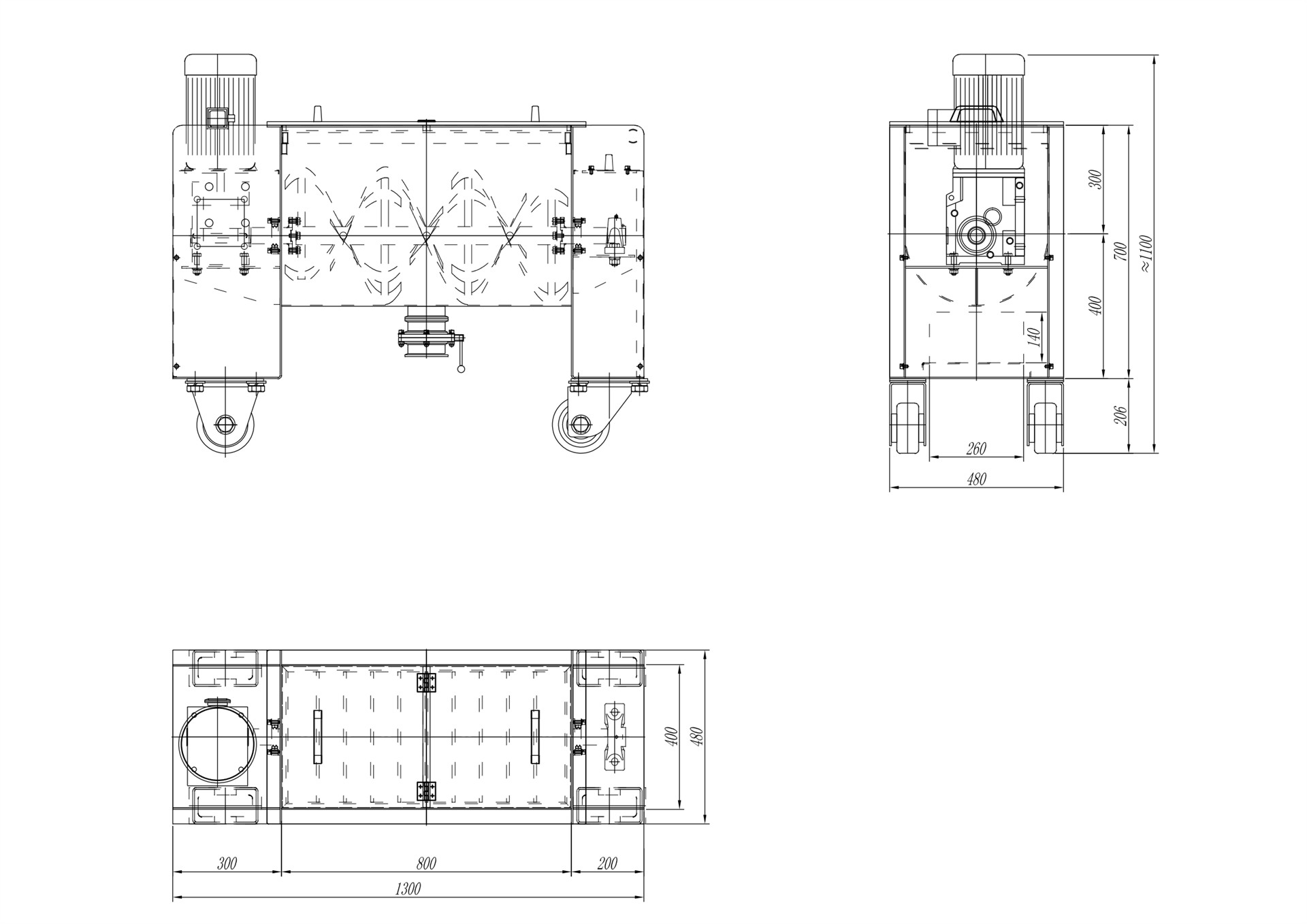

The specifications of the Ribbon Mixer WLDH-100L include:

- 3KW three-phase 380V/50HZ motor

- KC-57 gear speed reducer

- 60 minutes of direct output rotation

- Overall dimension; 1300x480x850 (Length x width x height)

- 40-60kg/once production capacity

- DN-120 pneumatic discharge valve

- The controlling unit has an intermediate relay, air switch, contactor, thermoelectric protection

- Electrical box

- 5mm 304 stainless steel mixing main shaft

- Seven 304 stainless steel hybrid countershaft

- 3mm 304 stainless steel mixing tank

- 6mm 304 stainless steel mixing passle

- Two 6mm 304 stainless steel side plate

- 6mm 304 stainless steel motor plate

- Four 6mm 304 stainless steel stiffener

The Ribbon mixer WLDH 200L weighs 382kg and has the following features:

- 3KW three-phase 380V/50HZ hybrid motor

- K-77 hard gear surface transmission hybrid speed reducer

- Two 2mm SUS304 stainless steel mixing tank cover

- 3mm SUS304 stainless steel mixing tank plate

- 5mm SUS304 stainless steel mixing main shaft

- 6mm SUS304stainless steel mixing paddle

- Production capacity of 80-120kg/h

- Overall dimension; 1800 x 650 x 1100 (length x width x height)

- Pneumatic discharge valve

- Two 6210 UCP Main shaft bearing

- Two sealing PTFE packing the main shaft

- CHNT electrical parts

The Ribbon mixer WLDH 500l has the following specifications:

- Overall dimension; 2100 x 750 x 1300 (length x width x height)

- Production capacity of 200-300kg/h

- Three-phase 380V/50HZ hybrid motor

- Hard gear surface transmission hybrid speed reducer

- 4mm SUS304 stainless steel mixing tank plate

- 3mm SUS304 stainless mixing tank cover

- 5mm SUS304 stainless steel mixing main shaft

- Pneumatic discharge valve

- CHNT electrical parts

- Two sealing PTFE packing main shaft

- Two 6210 UCP main shaft bearing

What are the benefits of a ribbon blender?

Some of the benefits of the ribbon blender are listed below:

1. The pharmaceutical ribbon blender can mix a large mass of dry solids, cosmetics, chemicals, and drugs. It is also used to mix ingredients in a capsule.

2. The ribbon blender mixer saves time and space and combines efficiently to produce a smooth homogenous product.

3. A ribbon blender machine is not restricted to pharmaceutical industries; it is applied in agriculture, chemicals, food, detergent, and soap industries.

4. The ribbon blender mixer uses a triple-action mixing technique, making it more efficient and speedy.

5. It has an independent control panel, making it easy to use. Reproduction is also possible as the machine can continuously make batches through the control unit.

6. Discharging materials through the valve is straightforward and user-friendly.

Conclusion

With 29 years in the pharmaceutical industry, iPharMachine boasts of being one of the best pharmaceutical companies producing and supplying quality pharmaceutical machinery.

iPharMachine supplies a series of efficient ribbon mixer blenders known for their high uniformity and loading coefficient, as well as low energy consumption, pollution, and crushing. We are also available for after-sale services, including installation, lubrication, maintenance, and consultation on product design specifications.

Wait no longer! Contact iPharmachine today for your quality and reliable Ribbon Mixer Blender series.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche