Understanding the Rotary Tablet Press Machine Parts

In the world of pharmaceutical manufacturing, there's a remarkable machine called the rotary tablet press. It does something incredible—it turns powders into tablets! But have you ever wondered how it gets the job done? Well, get ready to uncover the secrets! Let's take a closer look at the important parts that make this machine tick.

This blog post will discover the crucial rotary tablet press machine parts. These components play a vital role in transforming simple granules into perfectly shaped tablets. If you are curious about the process of turning powders into tablets, understanding the parts and working principle of a rotary tablet press machine is key. Now, let's dive into the amazing inner workings of a rotary tablet press and unravel the mystery behind this essential tool in the realm of pharmaceutical manufacturing.

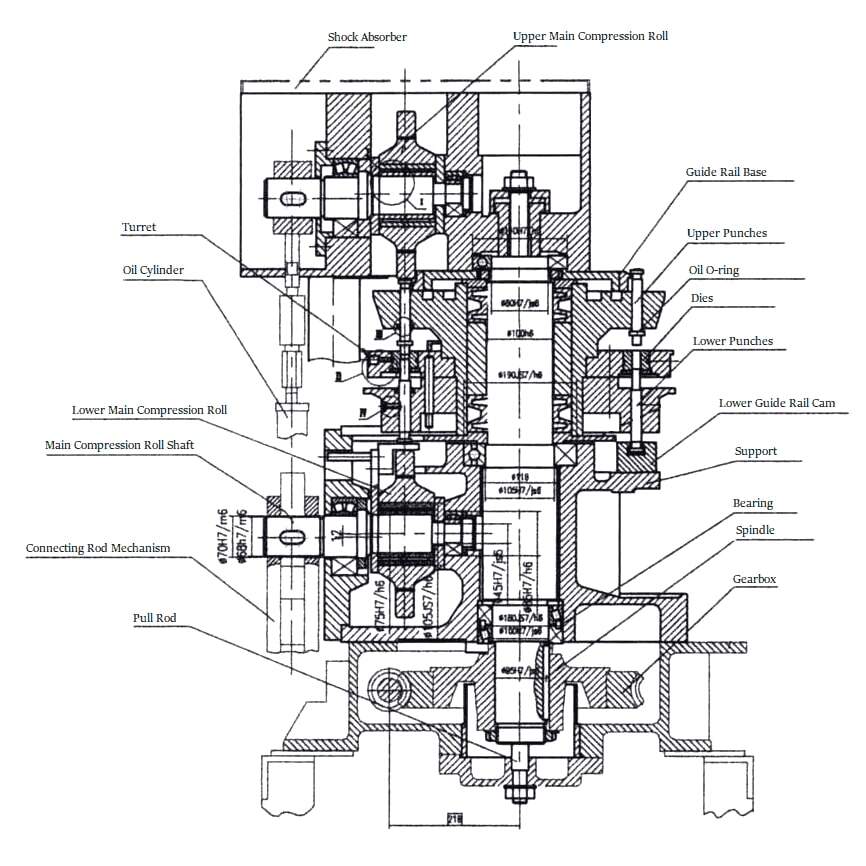

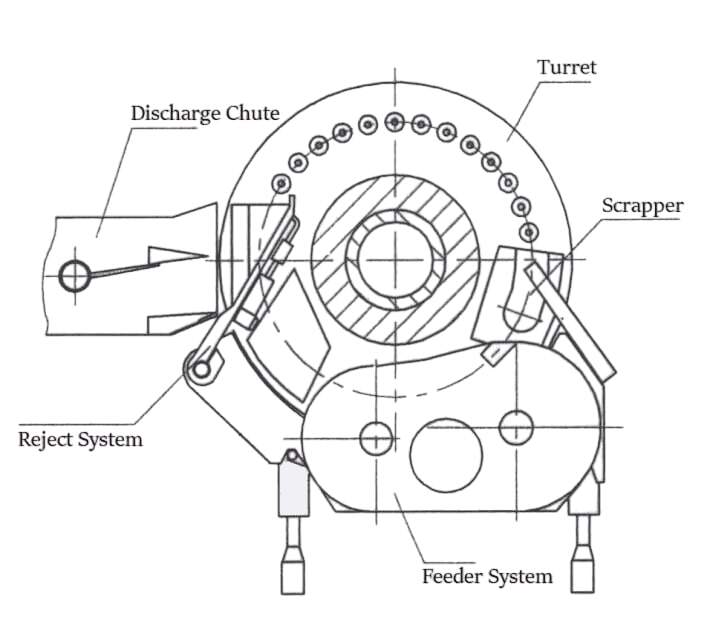

Rotary Tablet Press Diagram

Before delving into the major parts of the machine, you might want to get a rough idea of what the equipment looks like. This diagram visually represents the key components and their arrangement within the machine.

With the aid of the rotary tablet press diagram, the complexity of this machine becomes more accessible, paving the way for a deeper understanding of its essential functions. So, let's check out the rotary tablet press diagram.

(Main Structure of Rotary Tablet Compression Machine)

(Top View of Rotary Tablet Compression Machine)

What Are the Critical Rotary Tablet Press Machine Parts?

A rotary tablet press consists of several key components, each playing a crucial role in the tablet manufacturing process. Understanding these components is essential to comprehend how the machine transforms powders into tablets. So, let's explore each component in detail to help you optimize the performance of your machine.

1. Main Drive System

The main drive system is one of the most important rotary tablet press machine parts. This system is responsible for providing power and controlling the movement of the machine. It consists of an electric motor, a main drive shaft, a gearbox, and a set of gears or belts.

The main drive system also controls the speed and rotation of the turret. It determines the timing and position of each stage of the tablet production process, including filling, compression, and ejection. An efficient and reliable main drive system can maintain consistent tablet production and overall machine performance.

2. Hopper

The hopper in a rotary tablet press works to store and provide a continuous supply of the powder or granular material used in tablet production. The material can be fed into the hopper manually or using automated equipment.

Located at the top of the machine, the hopper is designed to hold a specific volume of the material. It features a vibratory feeder or an auger to regulate the flow. These components can ensure a controlled and steady material feed into the tablet press. The hopper is typically made of stainless steel to minimize cross-contamination.

3. Feeder System

The feeder system of a rotary tablet press is designed to deliver the powder or granular material into the die cavities for tablet formation. It may come in different mechanisms based on the machine models. There are two primary types of feeding mechanisms:

a. Force Feeder. The force feeder is used in most modern rotary tablet presses. This feeder features one or more paddle wheels in design. It applies additional force to ensure a regulated and consistent material flow into the die cavities. This component works well to overcome poor flow properties or material bridging. It assists in achieving uniform tablet weight and quality by controlling the material feed.

b. Gravity Feeder. The gravity feeder relies on the force of gravity to guide the material from the hopper to the die cavities. This feeding mechanism comes in a multi-chamber feed frame to allow for a controlled flow of the material under the influence of gravity.

4. Punches

Punches are part of a tooling set customized to meet specific tablet sizes, shapes, and imprints. They are integral rotary tablet press machine parts for compressing powder or granular material into tablets. The tooling consists of upper and lower punches made of durable tool steel. These punches are meticulously designed with specific tips or heads that match the desired tablet shape and size.

During compression, the punches exert pressure to compact the material within the die cavity, forming tablets. After compression, the punches retract, allowing the finished tablets to be ejected from the die cavities. Punches require regular cleaning and maintenance to prevent cross-contamination.

5. Dies

Dies are also crucial for shaping powder and granular material into tablets. Made of high-quality tool steel, dies consist of upper and lower punch holders that form the die cavities where tablet compression occurs. The machining of die cavities determines the tablet's shape, size, and thickness.

When the material is fed into the die system, the upper and lower punches compress it in the die cavities to create tablets. The dies are designed to withstand high compression forces and require regular maintenance to ensure consistent tablet quality.

6. Turret

The turret is one of the vital rotary tablet press machine parts. It rotates and accommodates the punches and dies during the tablet compression process. The turret is made of high-quality tool steel. It consists of multiple die pockets evenly distributed around its circumference.

The turret's rotation is synchronized with the tablet press operation. This allows the die pockets to move through different stages of tablet production, including filling, compression, and ejection. The turret design enables quick changeover between various tablet configurations, providing flexibility in tablet manufacturing.

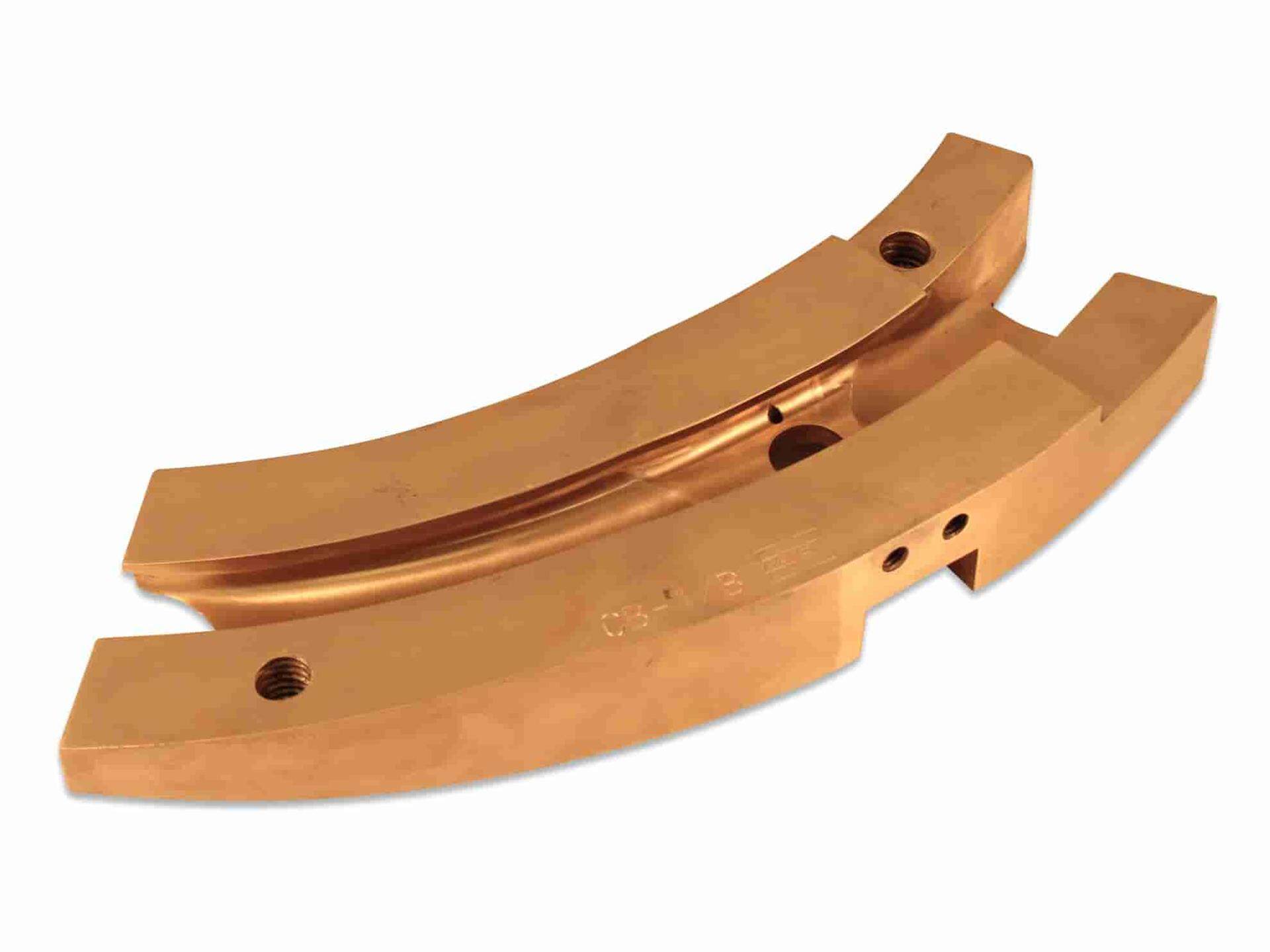

7. Cam Tracks

Cam tracks are curved or spiral-shaped grooves that guide the movement of upper and lower punches. Made of durable tool steel, cam tracks are designed to ensure precise and synchronized motion of the punches throughout different stages of tablet production.

Filling: Cam tracks raise the upper punches to allow the powder or granule material to flow into the die cavities.

Filling: Cam tracks raise the upper punches to allow the powder or granule material to flow into the die cavities.- Compression: During this stage, the cam tracks move the lower punches upward to contact the upper punches to compress the material in the die cavities.

- Ejection: During the ejection stage, the cam tracks guide the lower punches downward, retracting them from the dies and enabling smooth tablet removal.

8. Compression Rolls

Compression rolls are cylindrical rollers that play a crucial role in tablet compression. They can be divided into pre-compression rolls and main compression rolls.

- Pre-compression Rolls: Perform initial compression on the material before it enters the main compression area. They work to remove air in the material flow and die cavities to ensure uniform die fill.

- Main Compression Rolls: Exert higher pressure on the material within the die cavities. They compact the material to form solid tablets with the desired density, hardness, and thickness.

Both types of compression rolls may have adjustable settings to control the force applied during the compression stage. This allows for customization and optimization of tablet quality.

9. Tablet Ejection Mechanism

Tablet ejection is completed by a range of components. These components work together to remove the compressed tablets from the die cavities smoothly and efficiently. The mechanism can adjust the ejection force, speed, and timing to accommodate different tablet formulations.

- Ejection Cam: Pushes the lower punches upward and dislodges the tablets from the dies.

- Take-off Blade: Guides the finished tablets to the discharge chute.

- Discharge Chute: Provides a proper pathway for the tablets to exit the tablet press for collection or downstream processing. It's worth mentioning that certain advanced tablet presses have a discharge chute with a split design. This design is meant to sort out the good tablets and reject the defective ones to ensure quality control.

10. Dust Extraction System

The dust extraction system is one of the indispensable rotary tablet press machine parts. This system is used to capture airborne dust particles generated during tablet compression. It helps to maintain a clean and dust-free environment for operator safety and product quality.

11. Hydraulic System

The hydraulic system in a tablet press provides controlled force during the tablet compression process. It uses a hydraulic pump to pressurize hydraulic fluid. The fluid then actuates hydraulic cylinders to apply force to the compression rolls or other components. The system includes a control system to regulate the force, ensuring precise tablet compression.

12. Lubrication System

Tablets can sometimes stick to either the punch faces or the die cavities. To prevent this, tablet presses should include an automated lubrication system. This system can reduce friction and improve tablet release by applying a thin layer of lubricant to the punches and dies.

The Bottom Line

Understanding the major rotary tablet press machine parts is essential for running your machine smoothly and efficiently. From the powerful main drive system to the automated lubrication system, each component has a crucial role to play. By gaining knowledge about these parts, you can optimize the manufacturing process and achieve consistent tablet production.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche