Exploring the Working Principle of a Rotary Tablet Press

Have you ever wondered how those tiny, perfectly shaped pills magically appear in your medicine bottles? It's like a mysterious transformation from a loose powder to a precisely compressed tablet. Well, get ready to uncover the mesmerizing working principle behind this pharmaceutical wizardry.

In the previous guide, we have introduced the types of tablet presses, providing a foundation for understanding of tablet presses. Now, let’s dive deep into the world of rotary tablet presses. By the time you finish reading, you will have an understanding of the rotary tablet compression machine and its functioning. Now, buckle up and come along with us on a journey of demystifying how a rotary tablet press works.

What Is A Rotary Tablet Press?

A rotary tablet press is a type of machine used in pharmaceutical and nutraceutical industries to compress powdered or granular materials into tablets. It is a key piece of equipment in tablet manufacturing processes.

Rotary tablet presses are designed to produce tablets at high speeds. They offer precise control over tablet weight, thickness, and hardness. These are critical factors for the final product. Additionally, modern rotary tablet presses often incorporate features like automated monitoring and data acquisition to maintain quality control and optimize production.

The specific features and configurations of rotary tablet presses can vary across different manufacturers and models. But the general working principles of these machines remain consistent.

How Does A Rotary Tablet Press Work?

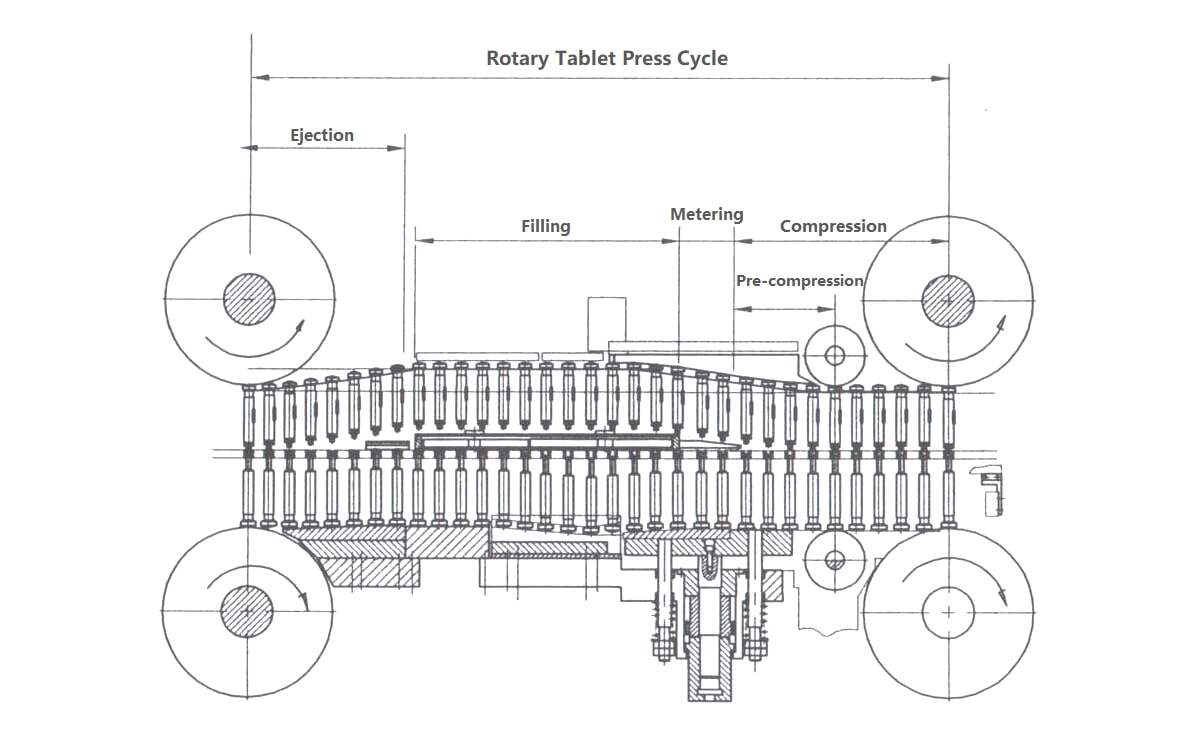

The rotary tablet press operates by using a rotating turret. The turret is designed to hold multiple punches and dies. These punches and dies are responsible for shaping and compressing the powder or granules into tablets of consistent size and weight. As the turret rotates continuously, the punches come into contact with the powder or granules in a specific sequence.

Here are several process stages based on the rotary tablet press principle:

1. Filling

(Image Source: I HOLLAND)

The filling stage is the initial step, where the powder or granules are loaded into the hopper of the tablet press. From the hopper, the material flows into a force-feeding device called a feed frame. The feed frame is responsible for evenly distributing the material into individual die cavities. It can ensure a consistent flow of the powder or granules, preventing overfilling or uneven distribution.

2. Metering

(Image Source: I HOLLAND)

Following the filling stage, the metering stage takes place. In this step, precise amounts of the material are measured and controlled while the excess material is removed from the turret. This process ensures accurate dosing of the material, which is crucial for maintaining uniform tablet weight and composition.

3. Compression

Once the filling and metering stages are complete, the compression stage begins. This stage can be further divided into two distinct steps.

a. Pre-compression

(Image Source: I HOLLAND)

In this step, the upper punch descends and applies a moderate level of pressure to the material within the die cavity. The purpose of pre-compression is to form a compacted mass known as a slug. The slug acts as a foundation for the subsequent main compression stage and helps eliminate any voids or air pockets within the tablet.

b. Main compression

(Image Source: I HOLLAND)

After pre-compression, the upper punch exerts a higher level of pressure on the slug. This further compacts the material and shapes it into the final tablet form. The force applied during the main compression ensures proper tablet hardness, thickness, and density. The dwell time—the duration that the punches remain in contact with the material—can be adjusted to control the tablet's characteristics.

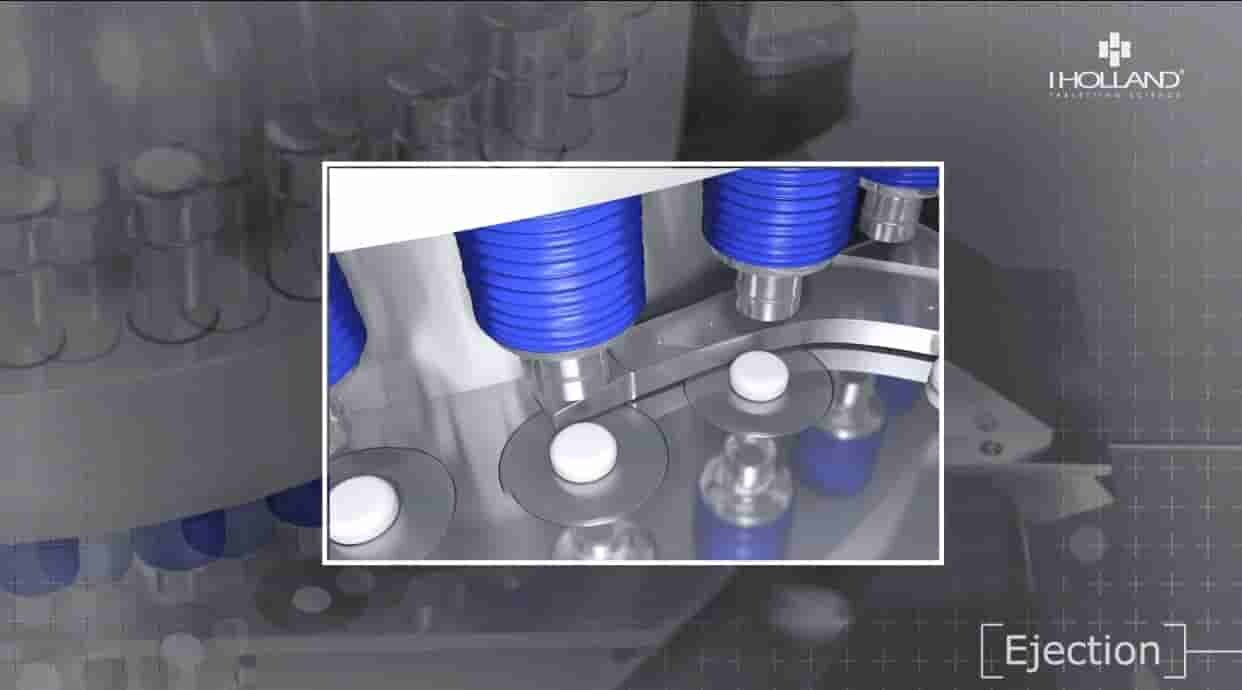

4. Ejection

(Image Source: I HOLLAND)

This is the final stage involved in the rotary tablet press principle. Here, the lower punch rises, pushing the formed tablet out of the die cavity. To facilitate the ejection process, the tablet press employs lubricants to gently guide the tablet out of the die. This helps to prevent the tablet from getting stuck or damaged during ejection. Moreover, some advanced tablet presses are equipped with a reject system to sort out the defective tablet during this step.

SOP For Operation Of Rotary Tablet Compression Machines

Ready to put the rotary tablet press principle into action? In this section, we'll guide you through a concise Standard Operating Procedure (SOP) for operating this powerful machine. Get ready to revolutionize your tablet manufacturing process and become a master of the rotary tablet press principle.

While specific SOPs may vary depending on the equipment and manufacturers, here's a general step-by-step instruction for the proper operation of the machine:

1. Machine Setup:

a. Thoroughly clean the machine before use to remove any residual material.

b. Confirm that all safety features are properly in place and functioning as intended.

c. Double-check that the machine is correctly adjusted to meet the desired tablet specifications.

2. Material Preparation:

a. Confirm availability and compliance of raw materials with required specifications.

b. Conduct essential inspections, including sampling and testing, to ensure material quality.

c. Prepare the material according to the specified formulation.

3. Machine Calibration and Configuration

a. Set the machine parameters, such as turret speed, tablet thickness, and compression force, based on the specific requirements for tablet production.

b. Perform necessary calibration procedures to ensure precision and accuracy in the machine's settings.

4. Machine Operation:

a. Switch on the machine and allow it to warm up, checking all components for proper functioning.

b. Load the material into the feed hopper and adjust the feeding rate as needed.

c. Monitor the machine's operation throughout production, including filling, metering, compression, and ejection.

d. Adjust the machine's settings as necessary during production to maintain tablet quality.

5. Cleaning and Maintenance:

a. Perform regular cleaning of the machine to prevent cross-contamination and maintain hygiene.

b. Follow cleaning procedures for different parts, such as the punches, dies, and cams.

c. Conduct routine maintenance, including lubrication and inspection of critical components.

6. Documentation and Record-Keeping:

a. Document all batch details, machine settings, and any adjustments made during production.

b. Record the parameters for tablet quality control, such as weight, hardness, and dimensions.

c. Maintain comprehensive batch records, including batch numbers, production dates, and material usage.

7. Shutdown and Shutdown Verification:

a. Proper shutdown procedures must be followed to ensure safety.

b. Conduct necessary checks after shutdown to confirm completion of all tasks.

The Bottom Line

The rotary tablet press principle is a process that involves the precise stages of filling, metering, compression, and tablet ejection. By adhering to the SOP for operating the machine, you can ensure consistent dosage accuracy and tablet quality.

The rotary tablet press plays a crucial role in the pharmaceutical industry, enabling the efficient production of medications. Embracing and understanding the rotary tablet press principle empowers you to deliver high-quality tablets and take your pharma business to the next level.

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche