Rotary Tablet Press ZPW17/19D Installation

ZPW17/19D Rotary Tablet Press and powder-sucking auxiliary machine are installed in two wooden cases separately to avoid being damaged by impact during transportation.

The transportation and installation of machine must comply with the following rules:

The rules of transportation and loading /unloading

The marks on wooden cases are made according to “GB191 Indication Mark of Packaging and Transportation”. The machine should be lifted with a crane or handled according to the designated position marked on wooden case when lifting with a crane and it should be kept in vertical position and handle with care.

Unloading and restore

When opening wooden case, the top board and side board should be torn off firstly. When the machine is completely uncovered, two bucket and bucket rack have to be torn down, then use a crane to hook the top ring bolts. Prior to lift, the bolt connecting the machine with base foot of wooden case. The first lift should be 400mm far from the ground, tear off the base holder of wooden case, then use a spanner to tear down the corner-iron slips embedded on the baseboard of machine, finally, lift the machine to the designated position.

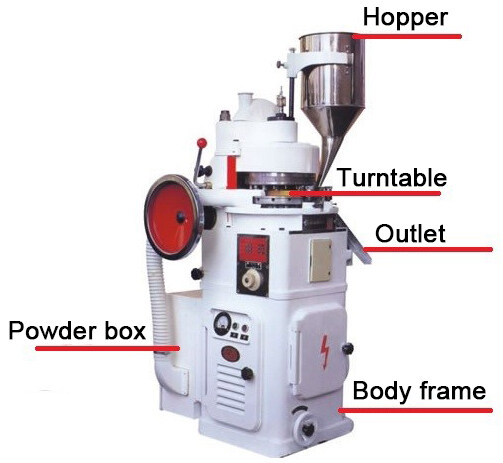

Machine structure diagram

The standard of leveling for the installation of Rotary Tablet Press is the plane of rotary table.

There must be enough space to be left between the main unit and wall for the leaf of organic glass window to open

The base foot of this machine is shockproof rubber cushion, it is not necessary to equip with subfloor bolt.

Electric installation

The working voltage of frequency converter in this machine is 1 phases 240 V AC voltage. If the power supply and voltage in your region is not the same as that of our machine, please contact us immediately. The power supply system of this machine is TN-S system, that is to say the inlet line of power is 3 phases 4 wires system (middle wire is marked at the line end). There is a grounded screw beside the plug-ins of the power system, and the grounded screw must be grounded securely to ensure the safe operation. The total consumption of power is 2.2kw, the section of inlet conducting wire should be more than 1mm².

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche