Introduction

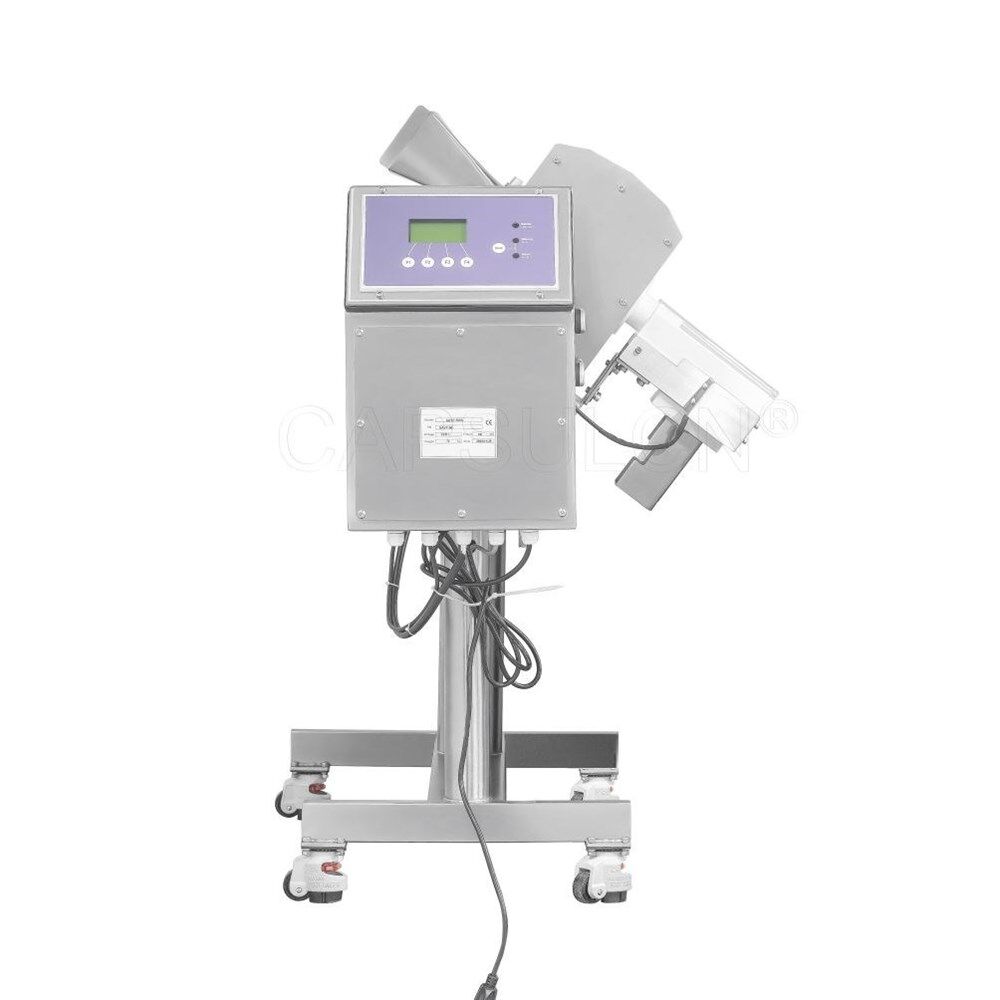

The metal separator is mainly used for the detection and separation of metal impurities in gravity feed granular materials in plastic chemical industry as well as other similar industries.

It can detect all magnetic and nonmagnetic metal impurities (e.g.: steel, stainless steel, aluminum, etc.). Even if encapsulated, these metal impurities can still be detected and then separated by the rejecting unit.

Main Application

Applied in the pharmaceutical industry, health care product industry, food industry, chemical industry and other industries. Metal detectors are mainly used to detect metal impurities mixed into tablets, capsules, candies and other products during the production or processing process.

Specifications

| Model | SAYP700S-50 | SAYP700S-80 | SAYP700S-100 | SAYP700S-120 | SAYP700S-150 | SAYP700S-200 |

|---|---|---|---|---|---|---|

| Inlet Size | Φ50mm | Φ80mm | Φ100mm | Φ120mm | Φ150mm | Φ200mm |

| Detection accuracy (empty machine) | Fe 0.4mm NOFe: 0.5mm SUS 0.7mm |

Fe 0.6mm NOFe: 0.8mm SUS 0.9mm |

Fe 0.8mm NOFe: 1.0mm SUS 1.2mm |

Fe 1.0mm NOFe: 1.2mm SUS 1.5mm |

Fe 1.2mm NOFe: 1.35mm SUS 1.6mm |

Fe 1.5mm NOFe: 1.7mm SUS 1.8mm |

| Maximum production volume | 2000L/H | 8000L/H | 12000L/H | 16000L/H | 25000L/H | 44000L/H |

| Working voltage | 220/110VAC(+10%,-15%) | |||||

| Compressed air | 5-8bar | |||||

| Net weight of equipment | about 35kg | about 39kg | about 50kg | about 55kg | about 70kg | about 75kg |

Feature

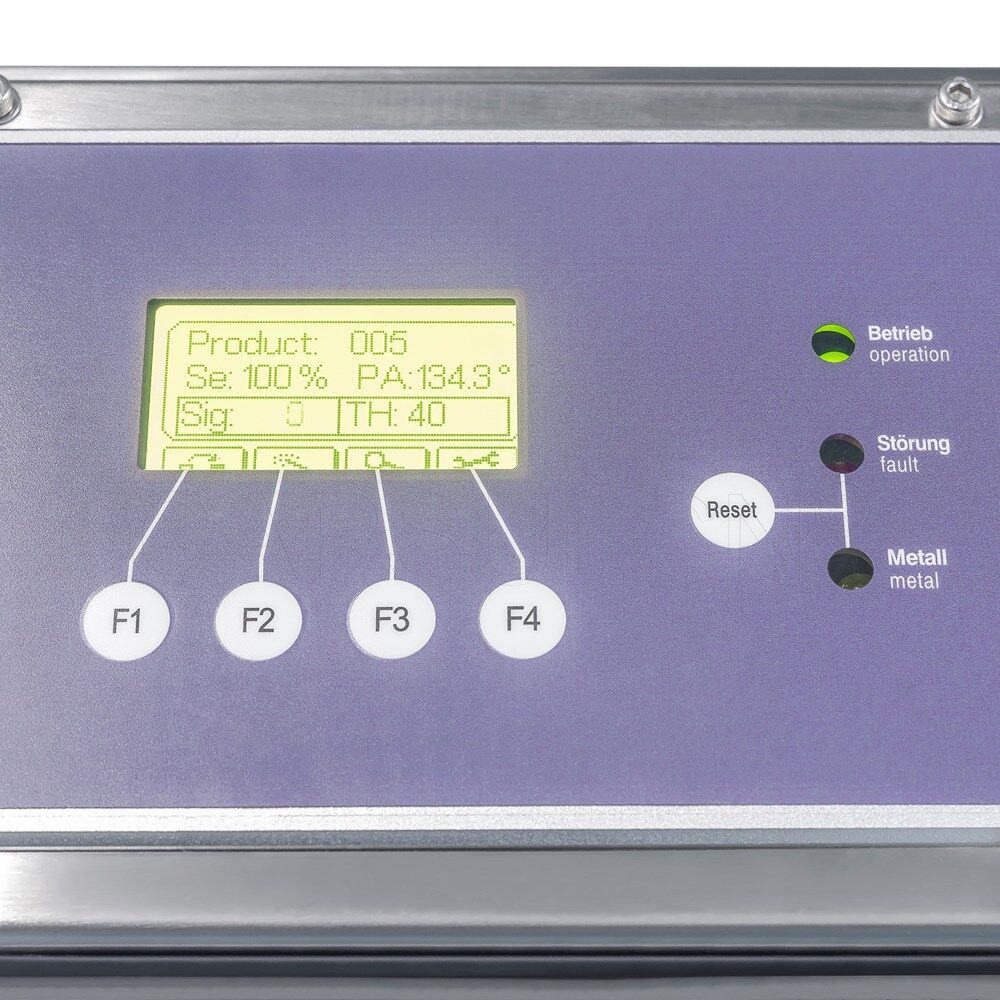

1. Special design effectively avoids interference from vibration, noise and product effects.

2. German technology, ultra-high precision, metal detector designed specifically for pharmaceuticals and health products.

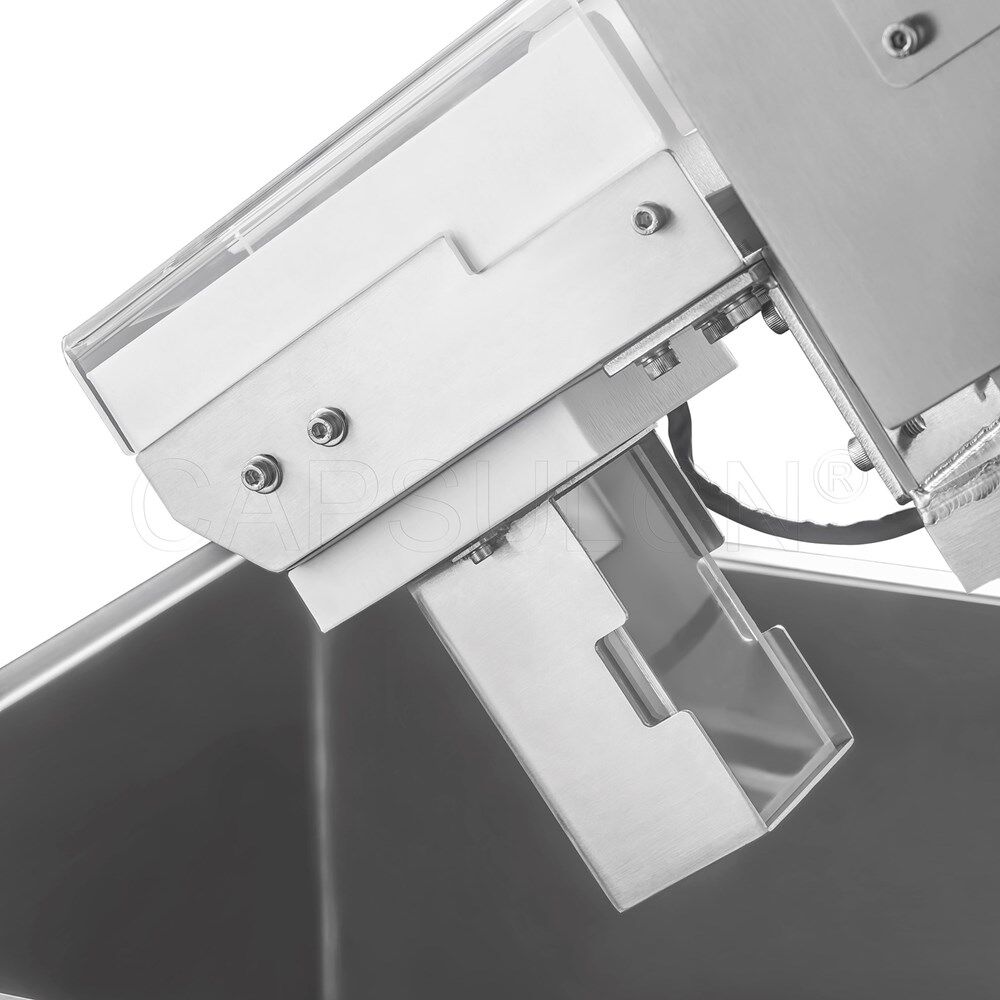

3. Flake and long fiber products do not block the rejection equipment.

4. Ultra-high frequency ensures the best detection accuracy and performance.

5. Specially detect and separate magnetic and non-magnetic metals in flakes, powders, fibers and wet materials.

6. A variety of calibers are available to meet various application requirements.

7. Equipped with 316 stainless steel rejection device, easy to disassemble and wash, in line with FDA and USDA certification.

8. Online impurities are removed to ensure the operation of the production line. Manually adjust the height and angle, easy to move and clean.

9. Accurately detect tiny metal objects in medicines, with a processing speed of 15,000 particles per minute.

10. Comply with HACCP, GMP, GAMP, FDA, IFS, ISO9001 and other standards.

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche