How does a Semi Automatic Capsule Filling Machine Work?

Are you considering purchasing a semi-automatic capsule filler to boost your business? Before diving into it, you may want to know how it works - the semi automatic capsule filling machine working principle.

For medium-size production, a semi-automatic capsule filler is an ideal choice. Compared with an automatic type, a semi-auto one is more cost-effective. Further, it is more efficient and accurate than a manual filler.

As the name indicates, a semi-automatic capsule filler involves both automatic and manual processes. On the one hand, it still needs extra personnel to manually load capsules and fillings and move the cap and body trays. But on the other, it can automatically separate, fill, lock and discharge the capsules.

To help you understand the semi automatic capsule filling machine working principle, this article has attached two videos and listed the four major filling steps.

Before learning how it works, you may want to be familiar with the parts of semi-automatic capsule filling machine and the top 5 manufacturers of semi automatic capsule fillers.

Step one: Loading capsules and fillings

First, you should check the capsule filler condition so that it can conform to the performance specifications.

Then pour the empty capsules and the fillings into their own hoppers - capsule hoppers and powder hoppers (Unfortunately, you have to do this manually).

It is noteworthy that the powder hopper has an auger powder feeder, which can keep the fillings loose enough for a consistent feed. And more importantly, it can control the filling speed.

On top of that, the size of the two hoppers will determine the number of capsules and materials you can fill at a time.

After pouring the capsules, key in the operating parameters at the PLC system. Then all the preparation is done.

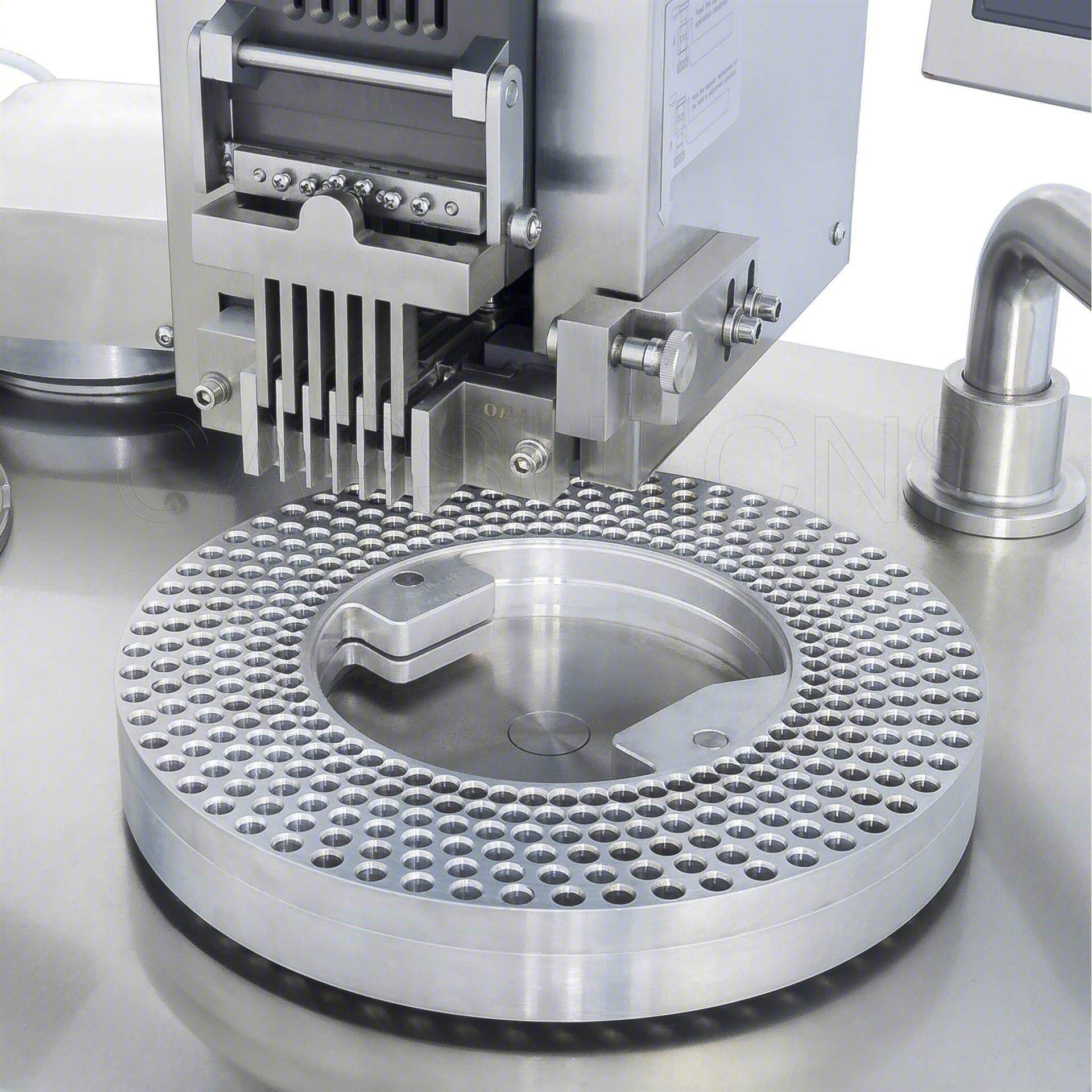

Now, the capsule sowing mechanism (or the delivery system) will deliver the capsules from the capsule hopper to the filling ring (or the capsule tray with two discs that hold capsule bodies and caps).

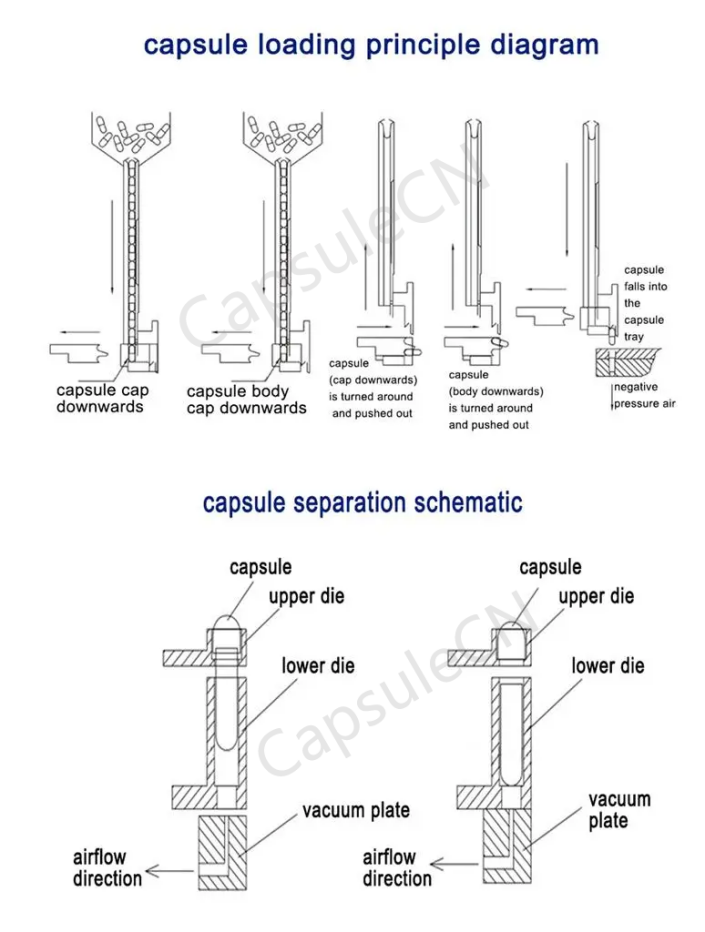

The most interesting is the direction of the capsules in the filling ring. You might think since you’ve poured the capsules randomly into the hopper, their direction should be random as well - either with their bodies downward or the caps downward.

Yet the truth is the opposite. Thanks to its unique structure known as the rectifier, the capsules will always be adjusted with their bodies downward. This is the beauty of machinery.

Step two: separating capsules

When all the capsules align at right angles in the filling ring, it’s time to separate them.

As the separation schematic shows above, the vacuum pump will extract air from the vacuum plate so that the bodies and the caps will be separated from each other.

And for complete separation, the filling ring should be rotated for 2 circles (manually or automatically, depending on the machine model).

Then the capsule caps will stay in the up ring while the bodies remain in the lower ring.

Step three: filling capsule bodies

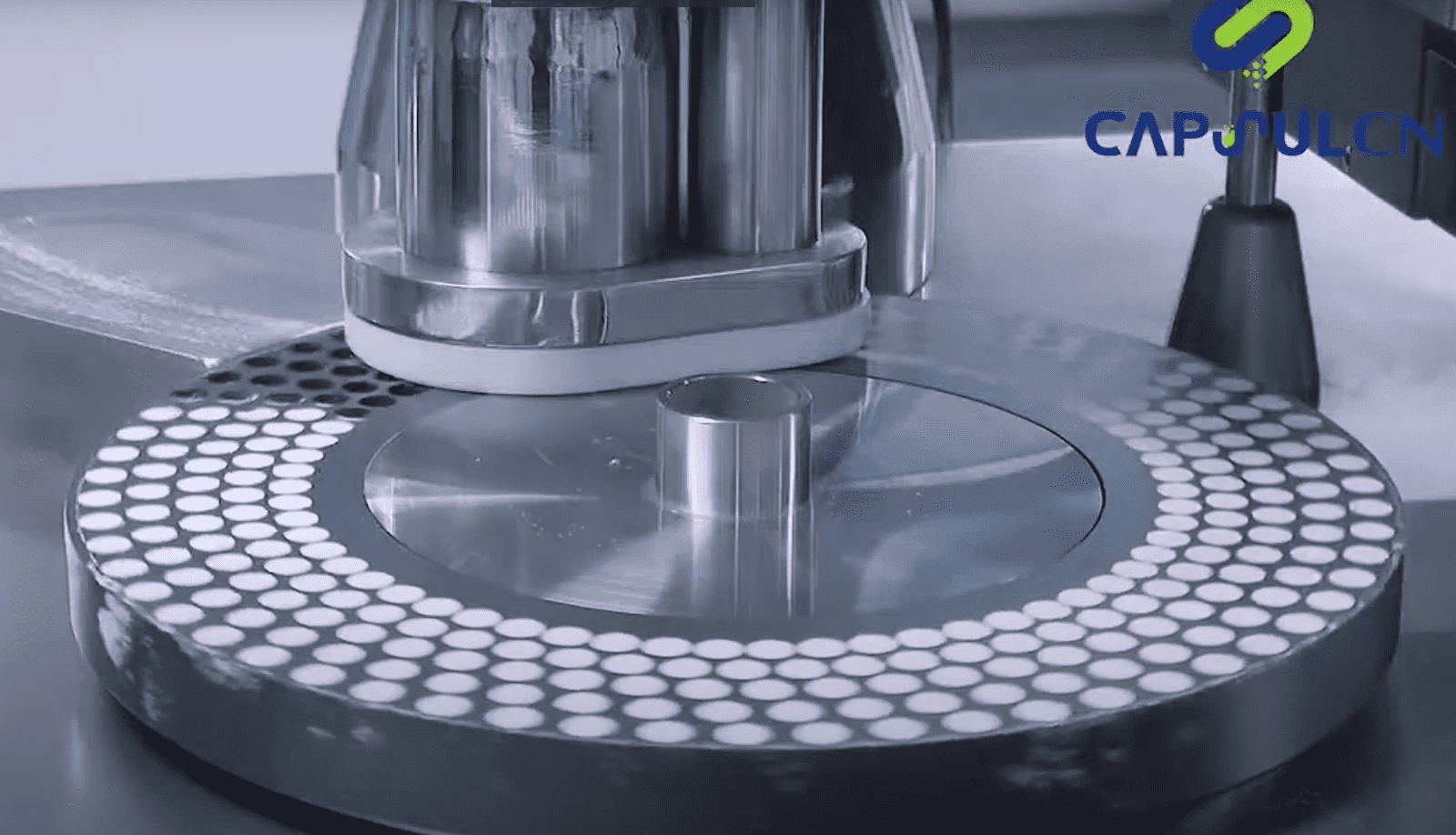

After separation, take the lower holding ring and fix it onto the rotary table, which is installed in front of the powder hopper.

Press the filling button, and the filling table will position the filling nozzles above the capsule tray (filling ring).

Then the rotary table will rotate in a circular motion as the fill materials flow into the bodies. During the filling process, the filling quantity and speed are controlled by the rotary table and the powder filling auger system.

Thanks to the accurate filling, the bodies will be precisely filled after rotating a circle. You don’t need to use a tamping tool to compress powder as you do in a manual capsule filler.

Step four: capsule locking

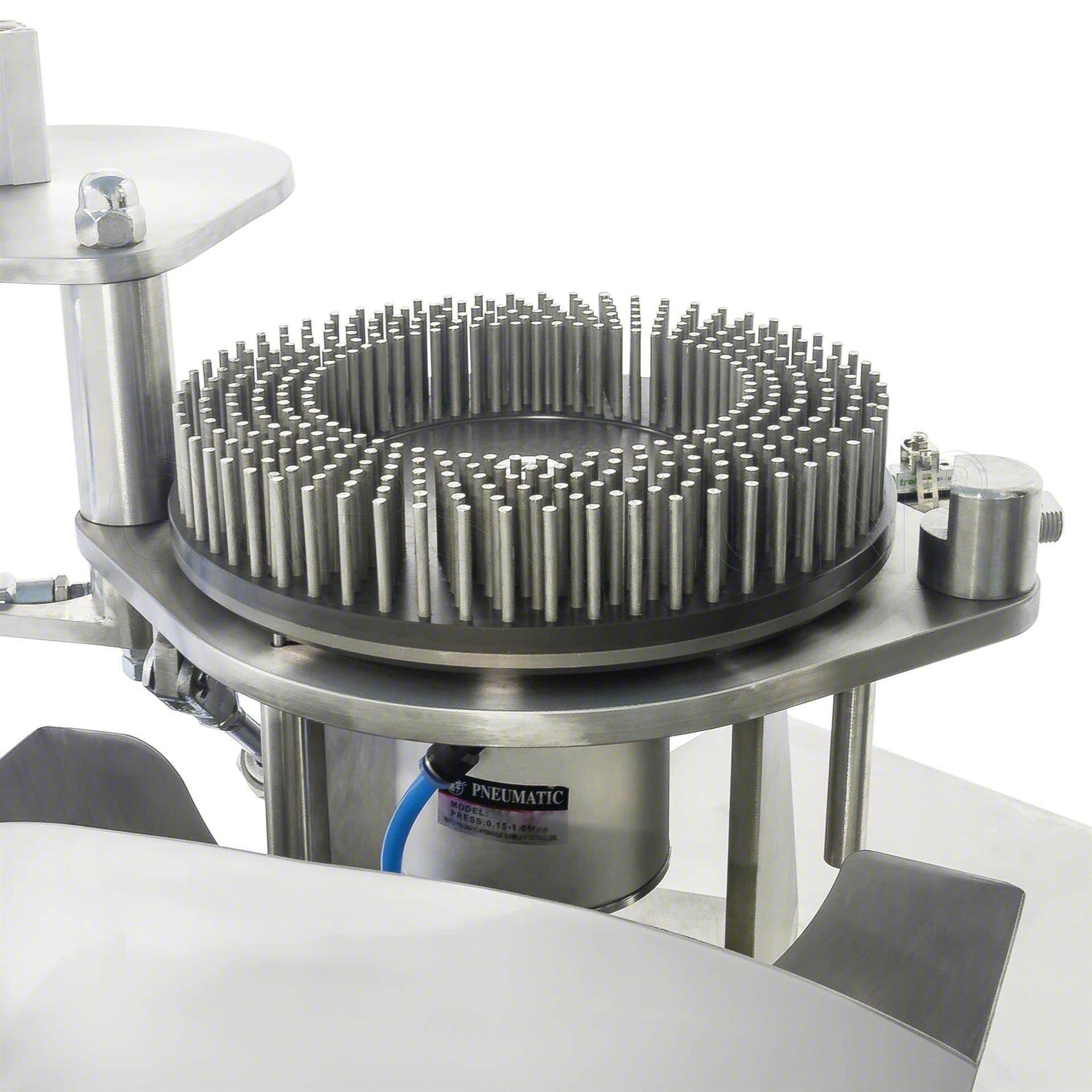

After filling, place the upper capsule tray on the lower capsule tray. Then put the whole capsule tray (filling ring) on the peg ring of the locking station. Ensure the ejector pins are inserted into the holes of the capsule tray.

Pull the top cover onto the capsule tray (some models need the operator to move, while advanced ones will pull the cover automatically).

After preparation, the pneumatic system linked to the locking station will help lock the capsules and push the fillings into the whole capsules.

Finally, the ejector pins will push all the finished capsules out of the locking station for further inspection and packaging.

Wrap-up

I’ve given you a walkthrough of the semi automatic capsule filling machine working principle. Generally speaking, the filling process above applies to all the semi-automatic fillers in the market.

Despite their similar working principle, their quality is not at the same level. As the pharmaceutical business does need reliable machines which can stand the test of time, I sincerely hope you can find a high-quality capsule filler.

At iPharMachine, our capsule fillers have never failed to meet customers’ expectations. To learn more about our proud work, feel free to visit our website. If you are curious about how efficient our JTJ-V semi-auto series are, you can check the video below, then you may understand why they are worth your money.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche