Introduction

CTG-LD20 Semi-auto Lab Candy Depositing and Forming Set is a semi-automatic candy production equipment that integrates high efficiency, energy saving and space saving. It is especially suitable for pharmaceutical companies or investors new to the candy manufacturing business. It is easy to operate and requires moderate maintenance, and can realize the continuous production of candies of different specifications with low labor costs.

The processing line is an advanced and continuous plant for making different sizes of candies. It is an ideal equipment that can produce good quality products with the saving of both the manpower and the space occupied.

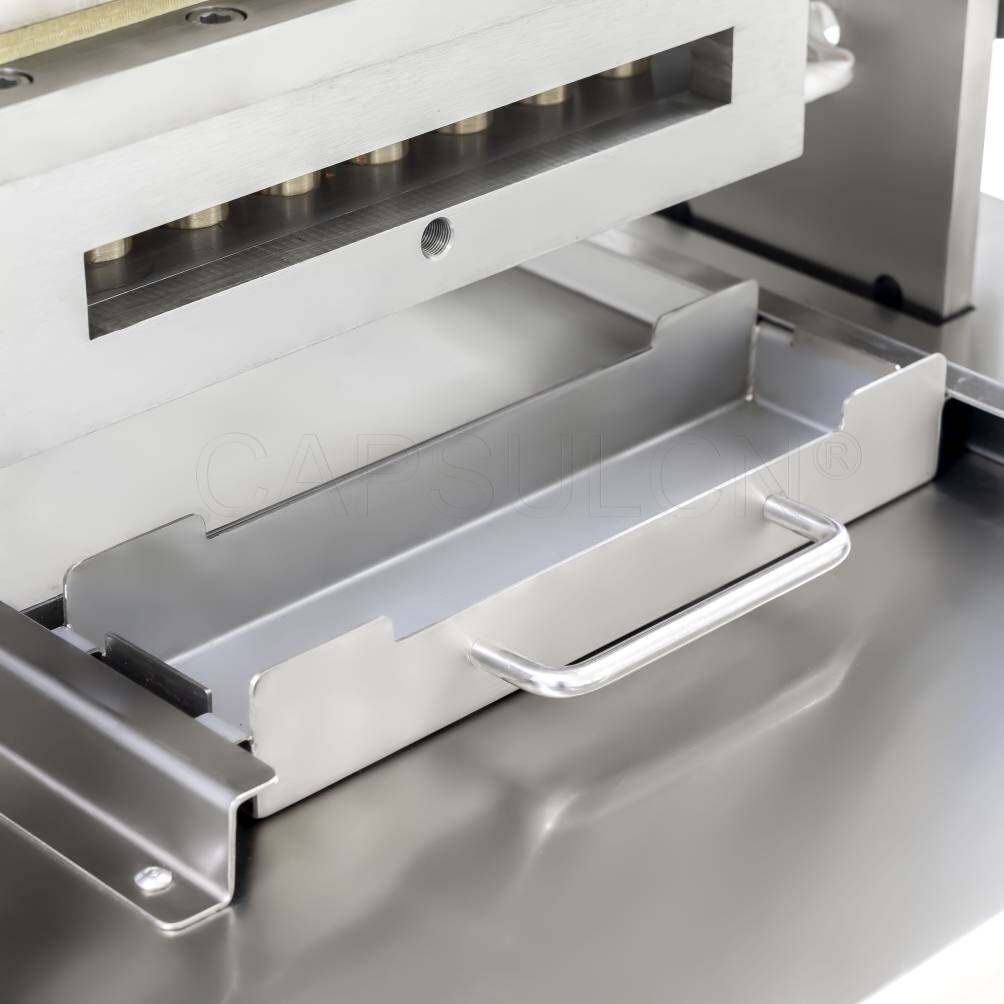

Detail Images

Specifications

| Model | CTG-LD20 |

|---|---|

| Capacity | 1-20 pcs/time (gummy quantity can by customized) |

| Depositing speed | 10-30 times/min |

| Power supply | 3.2KW |

| Air pressure | > 0.4 MPa |

| Weight | 120kg |

| Dimensions | 800*800*1700mm |

Feature

- Efficient and energy-saving: low energy consumption design reduces operating costs and conforms to modern environmental protection concepts.

- Intelligent control: built-in PLC program logic controller, which can preset multiple process parameters and simplify operating steps.

- High safety: equipped with multiple protection mechanisms, such as emergency stop button, overload protection, etc., to ensure the safety of operators.

- Quality Assurance: Strictly follow international food safety standards to ensure reliable product quality.

- Customized services: Personalized customization can be carried out according to customer needs and the most suitable solutions can be provided.

Advantages of peers

Compared with other brands, CTG-LD20 has the following significant competitive advantages:

- Higher cost performance: Provide a more competitive price while ensuring the same or even better performance.

- Stronger technical support: A professional team provides comprehensive after-sales service and technical guidance to help customers solve problems encountered during use.

- Faster service response: With service outlets all over the country, we can solve problems for customers in the shortest time and ensure the normal operation of the production line.

- Strong flexibility: Not only suitable for laboratory environments, but also easily integrated into small production lines, suitable for diverse application scenarios.

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Related products

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche