Introduction

The line of semi-automatic auger fillers is the ultimate in operator convenience. The innovative design and PLC-based controls make each filler an affordable, reliable auger filler with the same rugged construction.

It is the ultimate in operator convenience – precision engineered for time saving, cost cutting performance.

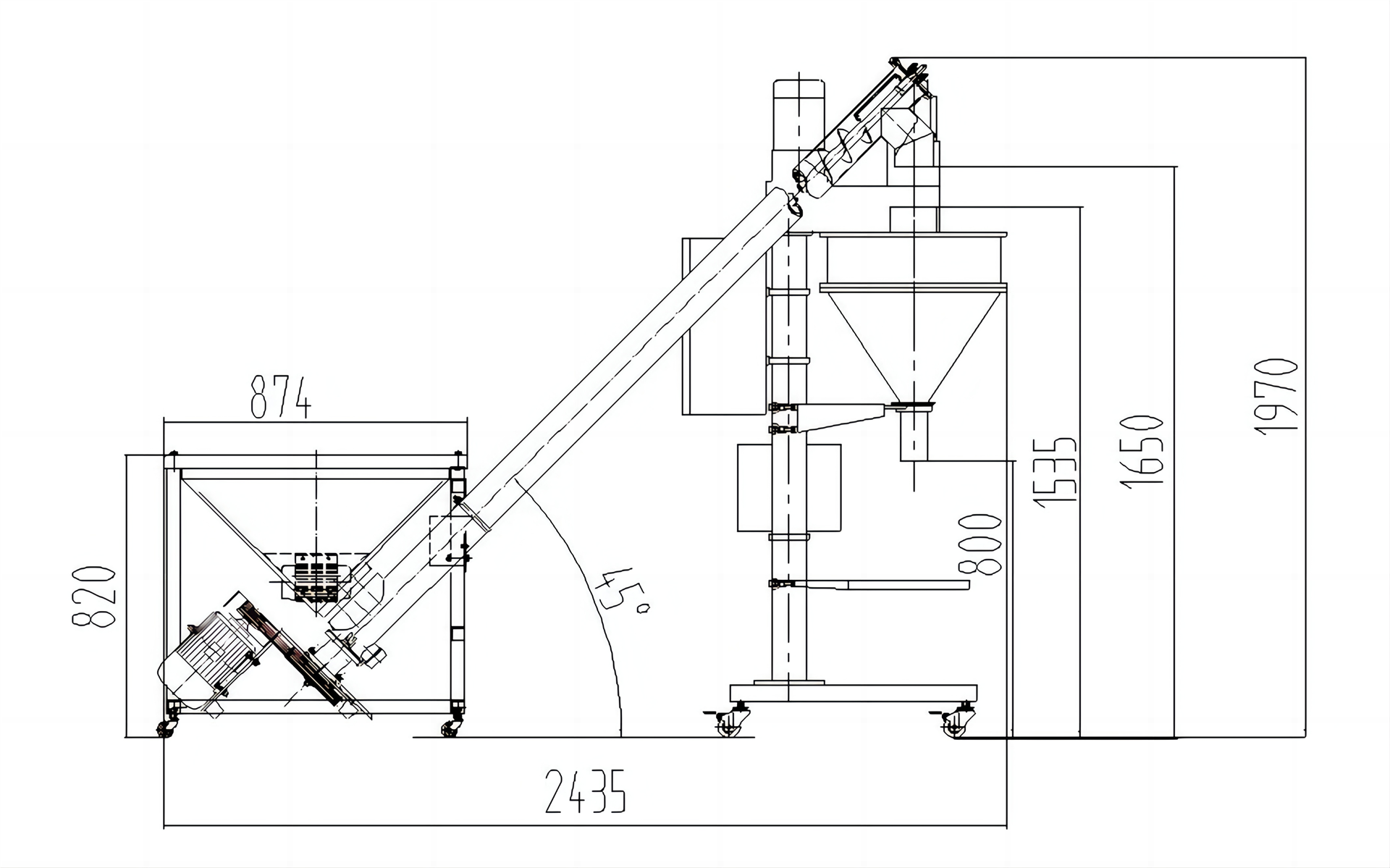

Specifications

| Model | HZSL-B |

|---|---|

| Feeding height | 1600mm |

| Volume | 120L |

| Voltage | AC220V, 50/60HZ |

| Power | 1.8KW |

| Dimensions | 2200mm*900mm*2050mm |

| Machine package dimensions | 1140mm*1030mm*1180mm |

| Feeder package dimensions | 2450mm*240mm*500mm |

| Machine package weight | 147kg |

| Feeder package weight | 40kg |

| Model | CN-HZFC |

|---|---|

| Filling container | wild-mouth bottle |

| Filling specifications | 10g-5000g (Replace the screw part) |

| Filling accuracy | 1% |

| Input voltage power | AC220V 50Hz 1000W (Without feeding machine) |

| Filling speed | 10-40 bottles/min (depending on the material quality, filling specification, professionism of operators) |

| Suitable bottles | diameter of bottle body 20-150mm; bottle height 60-300mm |

| Total Wt | 360kg |

| Overall dimension (L*W*H) | 2000*980*2000mm |

Remarks

- Reduce dust, reduce labor intensity - improve labor efficiency; the material mouth is a round material mouth, and there is no dead angle for cutting.

- Wide range of applications - This product is mainly used for powder and pellet loading, and is suitable for equipment loading in industries such as food, chemical, building materials, plastics and packaging.

- Wide range of applicable materials - capable of handling a variety of powder materials, storage tanks and spiral conveyor tubes are made of stainless steel;

- The vibration amplitude is adjustable - the vibration amplitude of each switch of the feeding motor and the vibration motor is adjustable, and the whole spiral can be easily disassembled and cleaned.

- Easy to disassemble - soft connection between storage bin and screw conveyor, easy to disassemble;

- Convenient cleaning - the lower end of the storage bin has a discharge port and a positive and negative switch for easy cleaning;

- Convenient feeding - the storage tank is equipped with a vibration motor, so that the material passes through the spiral conveying pipe to the discharge port.

Structure

review(s)

good auger filler

I have been using it to fill our products, working with my assembly line, very efficient

From: Guest | Date: 9/19/2019 5:00 AM

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche