Elevate Your Candy Business with a Semi-Automatic Gummy Machine

Do you want to launch a gummy business but lack the funds? Candy Expert! We are here to help take your sweet projects one step further! The gummy industry has seen tremendous expansion recently and these delectable treats have quickly become world favorites. Anyone with enough drive and an entrepreneurial mindset can enter this lucrative market without the need for rich investors or capital backing.

Semi-automatic gummy machines offer an economical yet efficient means of producing top-quality candies without breaking the bank. Join us as we investigate how these machines can turn your candy dreams into a reality!

What Are Gummies, and Why Have They Become So Popular?

Gummies are tasty candies made of gelatin, sugar and flavors/coloring agents. Their stretchiness comes from their rubbery composition which make it very appealing.

Gummies have long been enjoyed for several reasons. Not only do they taste amazing! Gummies also appeal to all age groups because of their chewy and sweet consistenc. Classic bear-shaped varieties to fruit-shaped versions and vitamin-infused options are just some of the many forms that people enjoy enjoying them in.

Gummy markets have seen explosive growth recently as people seek new snack ideas and ways to incorporate vitamins and minerals into their diets. Gummies offer both tasty treats as well as an effective method for supplementation - offering one easy, tasty solution!

What are Semi-Automatic Gummy Machines?

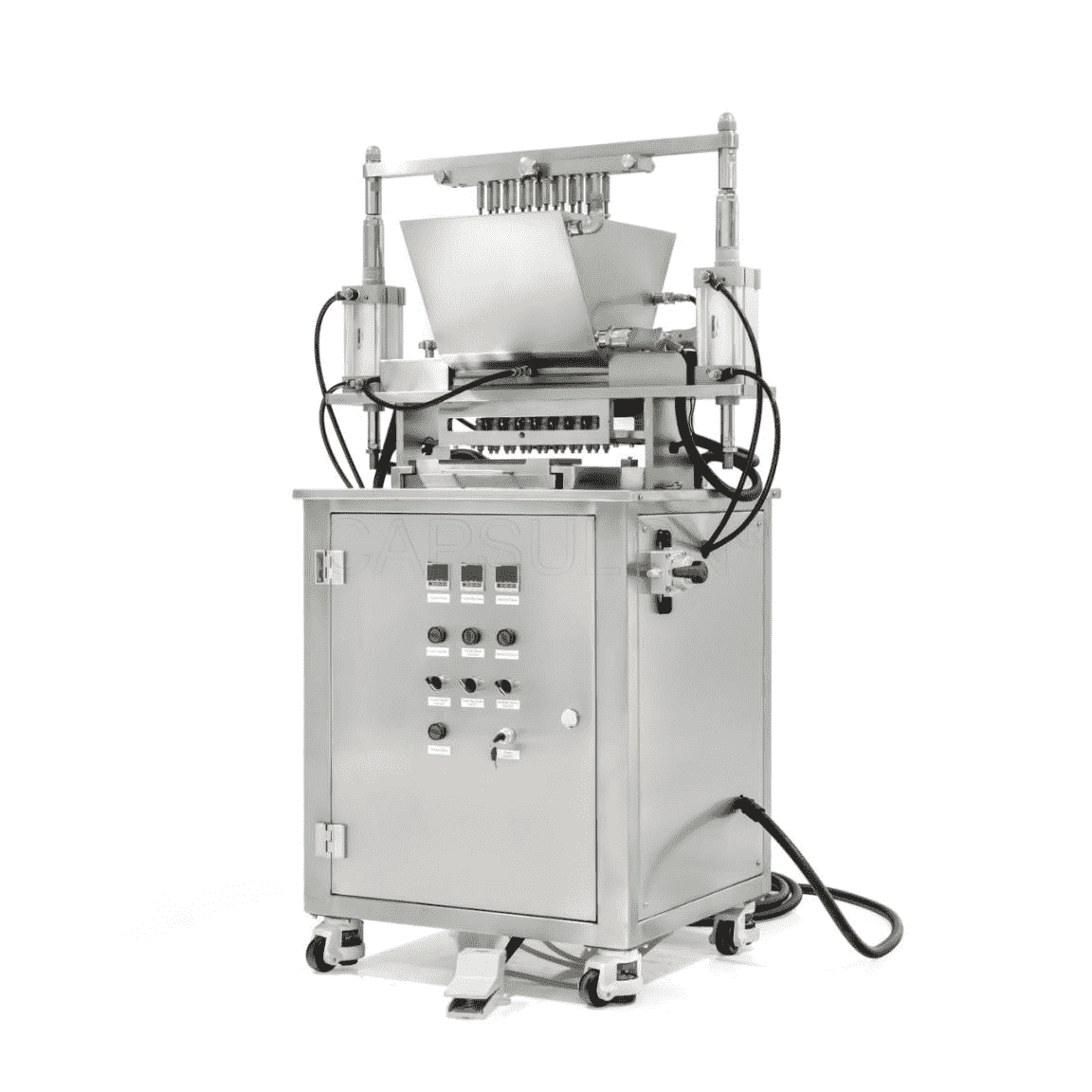

The semi-automatic gummy machine is a game-changer in candy-making. This new kit makes it easier to make gummy sweets, so you need fewer staff. It doesn't fully automate the process, but it does cut down on the manual effort needed.

The machine usually has a hopper, a mould and a cutting mechanism. The operator fills the hopper, inserts and removes the moulds, and cleans the machine. The machine heats the mixture, injects it into the moulds, and cools the gummies. Semi-automatic gummy machines are great for small to medium-sized businesses. They offer a good mix of automation and manual labor.

What are the Applications of Semi-Automatic Gummy Machines?

Semi-automatic gummy machines are versatile and can be used in many industries. Here are some ways these machines are making a big difference:

1. Nutraceutical Industry

People want more gummy vitamins, minerals, and other supplements. Semi-automatic gummy machines make producing consistent, high-quality products in large quantities easy.

2. Confectionery Industry

The confectionery industry uses semi-automatic gummy machines to make classic gummy bears and new shapes and flavours. These machines let you make great-looking, tasty gummy treats.

3. Pharmaceutical Industry

The pharmaceutical industry uses semi-automatic gummy machines to make pain relievers, anti-inflammatory drugs, and sleep aids. These machines ensure the right amount is dispensed and the product is always of a high standard.

4. Cosmetic Industry

The beauty industry has welcomed gummy products for skin and hair health. These products are made with semi-automatic gummy machines, which are fun and effective.

5. Veterinary Industry

Vets are using gummy supplements and medications to get pets to take their medicine. Semi-automatic gummy machines make it easy to make tasty and effective pet treats.

6. Stationery Industry

You can use semi-automatic gummy machines to make unique stationery items.

What are the Benefits of Semi-Automatic Gummy Machines?

Semi-automatic gummy machines help your candy-making business grow. Here are the main advantages:

- The semi-automatic gummy making machines are simple to use, even for those with limited technical expertise.

- These machines are made with top-quality stainless steel, so they're easy to clean and sanitize. Your products will always be hygienic and safe.

- The semi-automatic gummy machines are also affordable. They save small to medium-sized businesses money by reducing labor costs and increasing efficiency.

- These machines don't require a lot of manual labor, which helps reduce fatigue and injuries.

- Semi-automatic gummy machines can make all kinds of gummy shapes, sizes, and colors. You can customize your products any way you want.

- These machines make sure that every gummy meets the highest standards.

- There's minimal risk of contamination. The cleaning systems in these machines are pretty advanced.

What are the Components of a Semi-Automatic Gummy Machine?

A semi-automatic gummy machine is a complex system made up of several parts that work together to make gummy production happen. Let's look at the main parts:

1. Cooking Unit

- Cooking Tank - This tank is where you mix and heat the raw ingredients.

- Agitator - A motorized impeller mixes the ingredients to prevent sedimentation and ensure even mixing.

- Heating System - This system uses steam or electric heating elements to dissolve the ingredients and bring the mixture to the right temperature.

2. Depositing Unit

- Hopper - This part stores the cooked gummy mixture, so there's always a steady supply of the depositing nozzles.

- Nozzles - These nozzles can be adjusted and used to dispense the mixture into moulds with precision, allowing you to control the volume and flow rate.

- Moulding System - This system holds the moulds in place and ensures they are filled accurately.

3. Cooling Unit

- Cooling Tunnel - This chamber is where the gummies are cooled and solidified.

- Conveyor Belt - This belt transports the molds through the cooling tunnel.

- Cooling System - This system maintains the low temperature necessary for rapid solidification.

4. Demoulding Unit

Demoulding Mechanism - This gets rid of the solidified gummies from the moulds, getting them ready for the next stage of processing. It's often pneumatic or mechanical.

How Does a Semi-Automatic Gummy Making Machine Work?

The gummy machine has a set process for making high-quality gummies. Here's what happens:

Step 1 - Cooking

We prepare the gummy mixture. Next, we add the ingredients to a heated cooking tank. The mixture is heated to 108-110°C to make sure all the ingredients are dissolved. The prepared mixture is transferred to a storage tank.

Step 2 - Depositing

The mixture is transferred to a depositing unit. The operator puts molds into the machine and the machine fills them with a precise amount of mixture. Once filled, the molds are removed and a new set is placed.

Step 3 - Cooling

Then, we move the filled moulds to a cooling tunnel. This cools and solidifies the gummies.

Step 4 - Polishing (Optional)

If you want, you can add a layer of sugar or oil to the surface. This gives these gummy candies a shiny finish.

Step 5 - Drying

At last, we dry the gummies to get rid of any excess moisture. We will put them in a drying chamber. This can make gummies last longer and keep them in the right texture.

Are There Any Differences between Semi-Automatic and Fully automatic Gummy Machines?

The choice between semi-automatic and fully automatic equipment is important in gummy production. Each type of equipment has different advantages and disadvantages. Here is a table showing the difference between these two types of gummy machines.

|

Feature |

Semi-Automatic Gummy Machine |

Fully Automatic Gummy Machine |

|

Human Involvement |

Requires manual intervention for tasks like loading ingredients and removing molds. |

Minimal human intervention; primarily for monitoring and maintenance. |

|

Production Capacity |

Lower production capacity, suitable for smaller-scale operations. |

Higher production capacity, ideal for large-scale industrial operations. |

|

Ingredient Handling |

Manual ingredient loading. |

Automated ingredient loading. |

|

Flexibility |

More flexible for customization and recipe changes. |

Less flexible for frequent recipe or product changes. |

|

Consistency and Quality |

Potential for variations due to human factors. |

Consistent product quality due to automated processes. |

|

Cost |

Lower initial cost. |

Higher initial cost but potential for long-term savings. |

How to Prolong the Service Life of Your Semi-Automatic Gummy Machine?

Keep your semi-automatic gummy machine in good shape to make it last longer and work better. Here are some tips:

- Wipe down daily. Wipe the machine with a damp cloth to get rid of spills or residue.

- Wash the hopper and any removable parts with warm soapy water.

- Rinse and dry thoroughly to prevent water damage.

- Take the nozzles and molds apart and clean them regularly to get rid of any sugar buildup.

- Use a gentle cleaning solution to clean the inside of the machine, paying special attention to areas that may collect residue.

- Check the machine for wear and tear.

- Lubricate moving parts as recommended.

- Calibrate the temperature and timing settings for smooth, consistent operation.

For more thorough cleaning, use Cleaning-In-Place (CIP) and Sterilisation-In-Place (SIP) systems. These automated processes use cleaning and steam solutions to clean and sanitise the machine.

CIP and SIP are great for your gummy products:

- They get rid of harmful bacteria and microorganisms, so your products stay clean.

- They save you time and money on cleaning, so you can focus on making great products.

- They keep your products pure and fresh, so your customers love them.

- They help your machines last longer, which saves you money.

The Bottom Line

A semi-automatic gummy machine can help any business make candy more efficiently. Knowing the key parts, what they do and how to look after them will help you decide if this machine is right for you. A well-maintained machine improves efficiency and product quality. Invest in a reliable semi-automatic gummy machine and watch your business thrive.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche