Introduction

The CGF-B2S semi-automatic powder filling machine is designed for the food, pharmaceutical and chemical industries. It is made of stainless steel to ensure durability and easy cleaning. It can achieve accurate filling through weight feedback tracking, and is suitable for a variety of powder and granular materials and packaging containers. It is equipped with a quick-release hopper and servo motor, which is flexible and accurate in operation, and provides 10 recipe memory functions. The built-in intelligent control system supports automated operation processes and has safety features such as overload protection and emergency stop. The low-energy design conforms to the concept of green production and is an optimal solution for high efficiency and easy maintenance.

Specifications

| Model | CGF-B2S |

|---|---|

| Work Mode | Powder rotation filling traced by weight feedback |

| Filling Weight | 10g - 5000g (With different powder tooling) |

| Filling Accuracy | Weight:≤ 100g, error:≤±2%; Weight:100g – 500g, error:≤±1% Weight:>500g, error:≤±0.5% |

| Screw Diameter | Ø19,Ø 24,Ø 28,Ø 34,Ø 38,Ø 41,Ø 47,Ø53 (Depends on different filling weights) |

| Filling speed | 40– 120 Units/Min |

| Power supply | 3PAC208V-415V 50/60Hz |

| Total Power | 1.4Kw |

| Total Weight | 260kg |

| Overall Dimensions | 1140×970×2030mm |

| Hopper | 50L |

Feature

- High-precision filling: supports weight control with a minimum error of ±0.5%.

- Flexible and adaptable: customized production can be carried out according to customer needs to meet the needs of special materials.

- High degree of automation: integrated intelligent control system, which can automatically complete a series of processes such as feeding, mixing, and filling.

- Good safety performance: equipped with complete protection mechanisms, such as overload protection, emergency stop button and other functions.

- Energy saving and environmental protection: low energy consumption design reduces power consumption, which is in line with the concept of green production of modern enterprises.

Compared with other brands, CGF-B2S has the following significant competitive advantages:

- Higher cost performance: Provide a more competitive price while ensuring the same or even better performance.

- Stronger technical support: A professional team provides comprehensive after-sales service and technical guidance to help customers solve problems encountered during use.

- Faster service response: With service outlets across the country, we can solve problems for customers in the shortest time and ensure the normal operation of the production line.

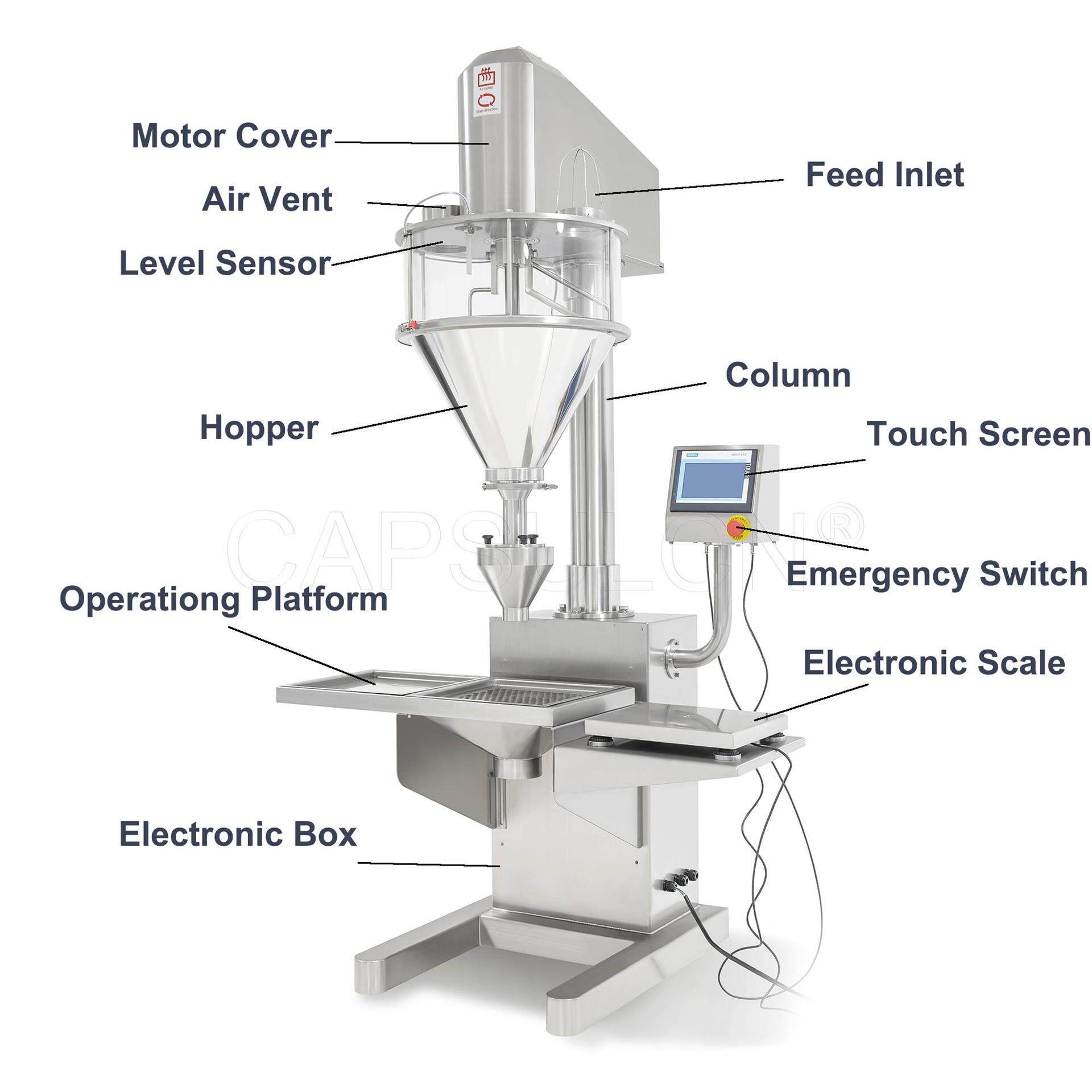

Structure

Write your own review

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche