Small Capping Machines: A Must-Have for Small-Scale Operations

Capping machines are widely used in various industries, such as pharma and food. Some people may require small capping machines because of budget and working space. This post helps you know more about small capping machines. And then you can decide if it suits your business or not.

What is a small capping machine?

This equipment can put caps on bottles quickly and tightly. It is small in size and easy to use. This makes them perfect for companies with limited space or resources. A capping equipment can handle various types of caps, such as screw caps. When dealing with bottle packaging, manufacturers choose this machine to cap bottles much faster and securely. It saves much time and effort. More importantly, this capping machine is easy to use, even for people without technical training. Their compact size makes them ideal for small work areas, like home-based businesses.

How to operate a small capping machine?

Small capping machines mainly includes manual and semi-automatic models. Fully automatic ones always need a larger area. So here are operation process of manual and semi-automatic capping machines for your reference.

Working process of a manual capping device

Step1

When fill your containers like bottles with products, place the cap on top at first. You should make sure the cap is properly aligned with the bottle opening.

Step2

You need to attach the chuck to the capping device, and make sure the inner plug is fixed tightly. Then you can put bottles under the device stably. Before capping, you should check if the capping head match the size of the cap you are using. Also, you need to keep the capping machine and the cap aligned vertically for processing.

Step3

Next, turn on the power switch, and the device will press down and screw the cap. Once the cap is tightened, the head will stop spinning automatically. Then, you can move on to the next cap. After capping, you can check the bottle to make sure the cap is tight and aligned. Here is a video to see the whole process.

Working principle of semi-automatic capping equipment

This model combines human work and automation. The process are as follows.

Step1

The operator should put the cap on the bottles with contents at first. Then, place it in the middle of the positioning fork.

Step 2

In this step, the operator could pull down the toggle switch for the manual mode. It needs to press the foot switch to screw the bottle cap tight.

Step3

On the other hand, if the operator is skilled, the automatic mode is also ok. This doesn’t need extra human effort to cap bottles. The machine would conduct it tightly. The operator just need to replace capped bottles with uncapped ones. You can see the video to see how it works.

What cap types can be used in the capping machine?

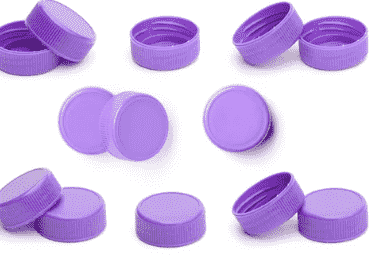

Screw caps

Screw caps are lids with spiral grooves. They fit onto bottles with matching threads. They are twisted onto the bottle, creating a tight seal to prevent leaks and keep contents fresh. Screw caps are easy to open and close. It makes them ideal for products that need to be opened multiple times. Screw caps are widely used in water bottles, soft drinks, sauces, and medicine containers. They also help maintain hygiene by keeping contaminants out.

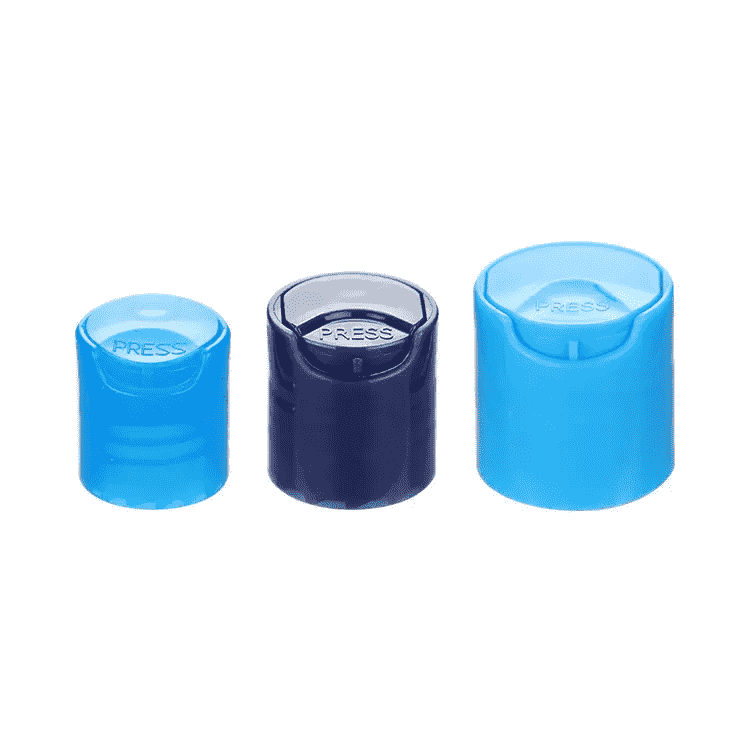

Press top caps

These caps are also called disc top caps. When you press one side of the cap, the other side pops up. This creates an opening to pour out the product. This design is mainly used for personal care products like cream and shampoo.

Sports caps

These caps work like screw caps but have a small nozzle on top. To open, you pull the nozzle. Many of these caps also have a plastic cover to protect the lid. They are often used for beverages, especially sports drinks. This design makes it easy to drink quickly while exercising.

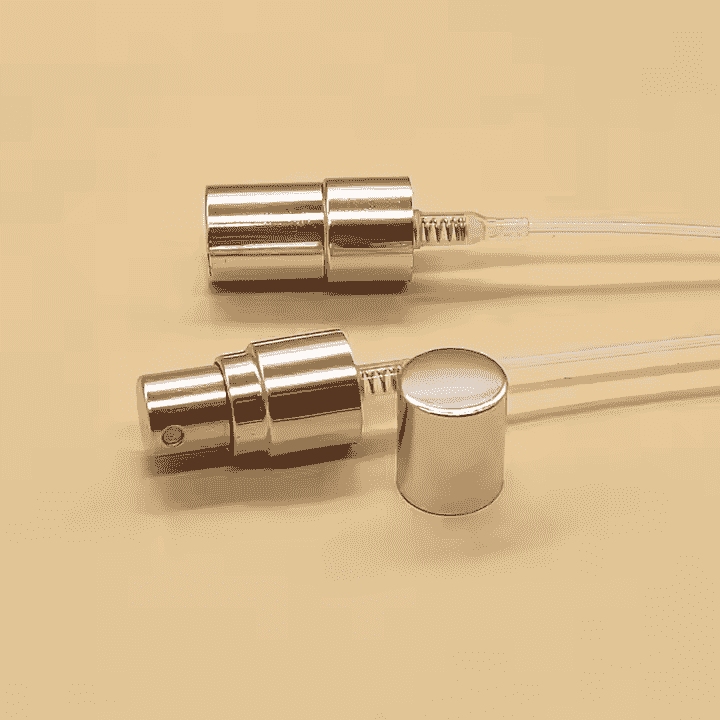

Spray caps

These caps are often used to store liquids like perfume, disinfectants, and hair spray. You just press the cap with your thumb, and it sprays out a fine mist. Most spray caps are made of plastic, but some high-end perfume brands use metal to make them shiny and more attractive. To prevent accidental spraying, spray caps usually have an outer protective cover.

Trigger caps

These caps also spray liquids, like spray caps, but you need to twist the nozzle before using them. The nozzle shape and color can be customized, and you can also choose the trigger length based on your needs. Trigger caps are used for products like cleaners, cooking oils, lubricants, and body mists.

Child-resistant caps

Child-resistant caps are specially designed to prevent children from opening bottles easily. To unlock these caps, it always needs some combined actions. For example, you need to press down and turn at the same time to open the bottle. Child-resistant caps are commonly used for medicines, cleaning chemicals, and other hazardous materials. They help keep children safe from accidental swallowing.

How to choose a small capping machine?

Product type

The packaging type and material determine if a capping machine can work effectively. For instance, glass bottles require more careful handling compared to plastic ones. Because they are heavier and more fragile. Similarly, the machine must be designed to handle specific cap types, such as screw caps. If the machine isn’t compatible, it may damage the packaging or fail to seal it properly.

Cost

When considering budget, you’d better balance cost with features. A lower-cost machine may save money at the beginning, but it could result in higher long-term costs because of repairs or limited functionality. Also, you need to consider shipping fee when buy one from other countries. Sometimes the machine price is low but the shipping cost is very high. So you can compare these factors to calculate if you can get the profit.

The end

Small capping machines help a lot in efficiently packing containers. When choosing one, you can think about what works best for your needs. If you’re just starting, a simple and affordable machine can save you time and reduce mistakes. If you have questions to find a reliable one, iPharMachine is your good help. We offer a wide range of machines, including various types of capping equipment. You can tell us your requirements and we’ll quickly match the machine that suits you best.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche