Soft Capsule Sizes: Find the Right Fit for Your Market

Softgels are a popular medicine type in the pharma industry. Many manufacturers make them for essential vitamins and supplements. If you also want to invest in this business, there is a must to have a thorough understanding of soft capsules. This post helps you get more involved in softgels and then make a wiser choice.

What Are Softgels?

Softgels are typically made of gelatin. They encase a liquid or semi-liquid substance, such as oils, suspensions, or emulsions. The gelatin shell can be augmented with other ingredients like glycerin or sorbitol. It helps increase flexibility and durability. This design makes softgels an ideal delivery system for oil-based or liquid supplements.

Softgels are often transparent or translucent, and sometimes the contents can be seen clearly. They feature a seamless design, ensuring content stability and uniform dosage. Also, the smooth texture and rounded edges make softgels easier to swallow.

Why Do Softgel Sizes Matter?

The size of a softgel capsule is a critical factor in its efficacy, manufacturing process, and user experience.

- Dosage accuracy. Correct sizes ensures the precise delivery of the intended dose. It is crucial for therapeutic efficacy and safety.

- Manufacturing efficiency. Different sizes require different production settings and machinery adjustments. This impacts the overall efficiency and cost of production.

- Consumer preference. The size influences the ease of swallowing and user acceptance. It is particularly important for pediatric and geriatric populations.

- Marketing and packaging. Proper sizing is crucial for product labeling, and packaging design. It ensures regulatory compliance and consumer appeal.

Sofgel Sizes Classification

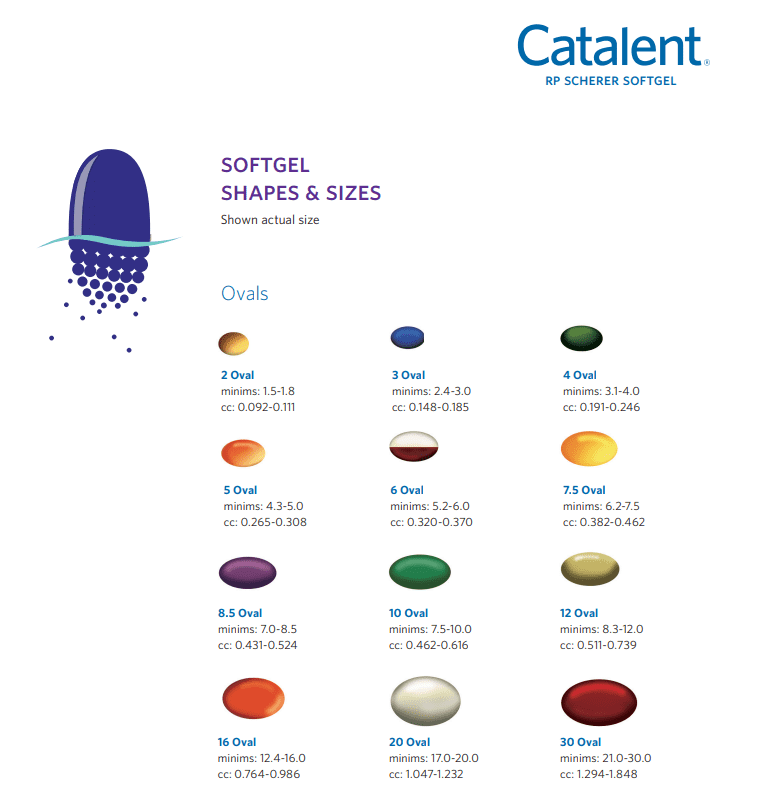

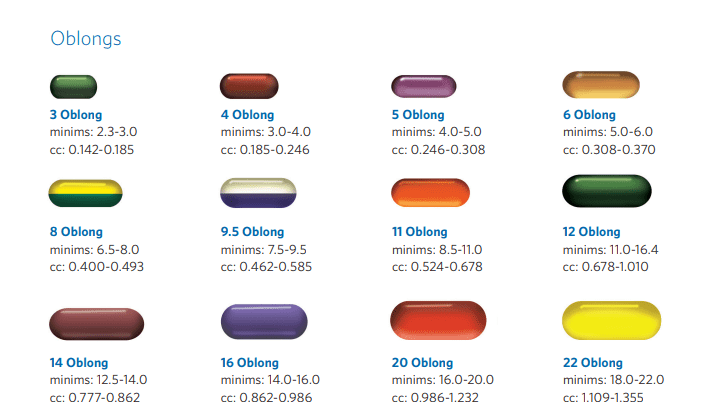

Softgel sizes are different from capsule sizes. They do not use a numbering system like #000, #00, etc. Instead, they are usually measured by volume in minims or cubic centimeters (cc). One minim is about 0.06161152 cubic centimeters. Softgel capsules come in various shapes. Common shapes include oval, oblong, and round. Each shape has its own range of sizes.

To distinguish different sizes and shapes of softgels, there is an established industry standard. Manufacturers add a number before the specific shape, like 2 Oval, 3 Oblong, etc. The larger the number, the bigger the size. This makes it easier and more efficient to produce soft capsules. It also ensures that the best size and shape can be chosen for optimal use and user experience.

Oval Softgel Sizes

As the most popular softgel shapes, oval softgels have a series of sizes to choose from. You can check the picture below to see the proper volume of every size.

Oblong Softgel Sizes

Oblong softgel capsules are slightly elongated. It provides wider options for customization than other shapes. For example, you can print eye-catching patterns or logos on the surface. In addition, this shape is able to hold higher volume fills. Here is the minims and cc for your reference.

Round Softgel Sizes

Round capsules feature the symmetrical shape. So they are easier to achieve even distribution of the drug during the filling process. Moreover, the design makes the mold design simpler. It makes the manufacturing cost is lower than other shapes. Round soft capsules also come in many sizes.

Sizes of Special Shapes

Besides the common shapes mentioned above, there are some special shapes on the market.

- Heart-shaped. This unique design adds more attraction. It is usually used for specific markets like children's or pet products.

- Animal-shaped. These are very fun and come in various shapes like bears, fish, cats, etc. This shape is mainly used for the children's market, such as children's vitamins.

- Customized shapes. If you want unique shapes to attract customers and promote your products, you can customize shapes. This may involve redesigning and molding, so the cost will be higher.

When it comes to sizes, special-shaped softgels usually do not have strict standards. The size is more often determined by the product's function, target market, and brand positioning. You can calculate the capacity based on the required dose of active ingredients, then design its size.

Take pet gummy softgels for example. The size depends on the pet's size and dosage. Vitamins for small pets may have a diameter of 10-12 mm, while fish oil gummies for large pets may have a diameter of 15-20 mm.

How to Choose Proper Softgel Sizes for Regular Shapes?

Determine Product Formula and Dosage

First, determine the total amount of ingredients in each softgel capsule. This will directly affect the size of the softgel needed, as different sizes can hold different amounts of material. If you want to make a large-capacity softgel, like 500 milligrams, you should consider a size around 10.

Customer Preference

If your target customers are mainly elderly people or children, you should choose smaller sizes. Because they are easier to swallow. If your target customers prefer high-dose supplements, such as athletes, you can choose larger softgels. Because they can provide more nutrients at once.

Cost

Another key factor to consider is production cost. If you want to make high-quality soft capsules, the raw materials can also be expensive. This is because their extraction and processing processes are more complex.

In addition, different sizes can significantly impact production costs. Larger softgels require more raw materials, increasing expenses for ingredients. Larger sizes might also need specialized equipment and longer production times, further raising costs.

Manufacturing Capabilities

You should ensure the chosen softgel size can be produced efficiently with your current equipment. Different sizes may require adjustments or specific settings on manufacturing machines. Larger sizes might need more precise control and higher capacity machinery.

Meanwhile, if you want to conduct mass production, assess your production line's flexibility and capabilities. In this way ,you can avoid unnecessary delays, and quality issues.

The End

By carefully choosing the shape and size of your softgels, you can ensure product efficacy and consumer satisfaction. Then it helps enhance your product's market competitiveness. Besides, a high quality softgel encapsulation machine is a must. If you don’t know how to choose, contact us to get more valuable information.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche