Everything You Need To Know About Softgel Drying Process

Do you have any idea how softgels are made? Have you ever seen the softgel manufacturing process? You don't think that you can get the final product after the soft gelatin capsules are sealed, do you?

Indeed, the process has not yet come to an end when the capsules come out of the softgel encapsulation machine. To ensure you get the end product right, drying the softgels is also a critical stage of the manufacturing process.

But how do you dry softgels? What method can be used for drying soft gelatin capsules? This article will take you through everything you've ever wanted to know about the softgel drying process. Let's get started!

Why is the softgel drying process necessary?

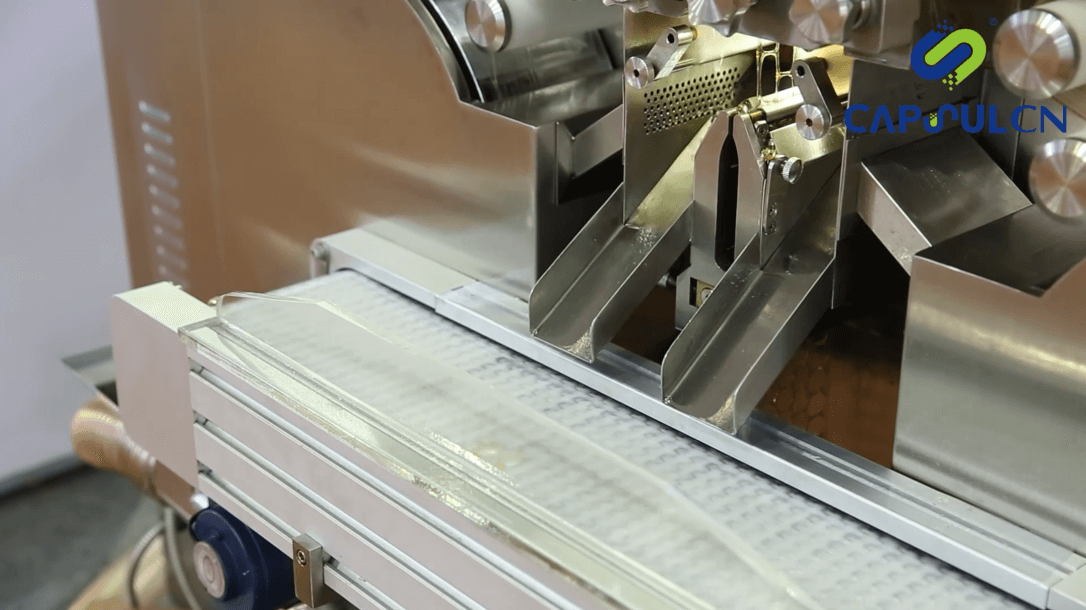

Following encapsulation, all the finished softgel capsules fall onto a conveyor belt. The softgels are tacky and moist at this time due to the inner fill material, outer shell material, and lubricant used during the manufacturing process.

So, prior to further treatments, including polishing, final packaging, and shipping, they need to be transferred by the conveyor to the next stage - Softgel Drying.

What equipment should you use to dry soft gelatin capsules?

As you can see, the softgel drying process is very important because it matters to your product's final quality. There are three essential tools that can make the process much easier and more efficient: tumble dryers, softgel drying trays, and drying tunnels.

Tumble dryer

After the soft gelatin capsules are formed and leave the encapsulation machine, they fall onto a conveyor belt. The conveyor plays the role of transferring these softgels to a tumble dryer.

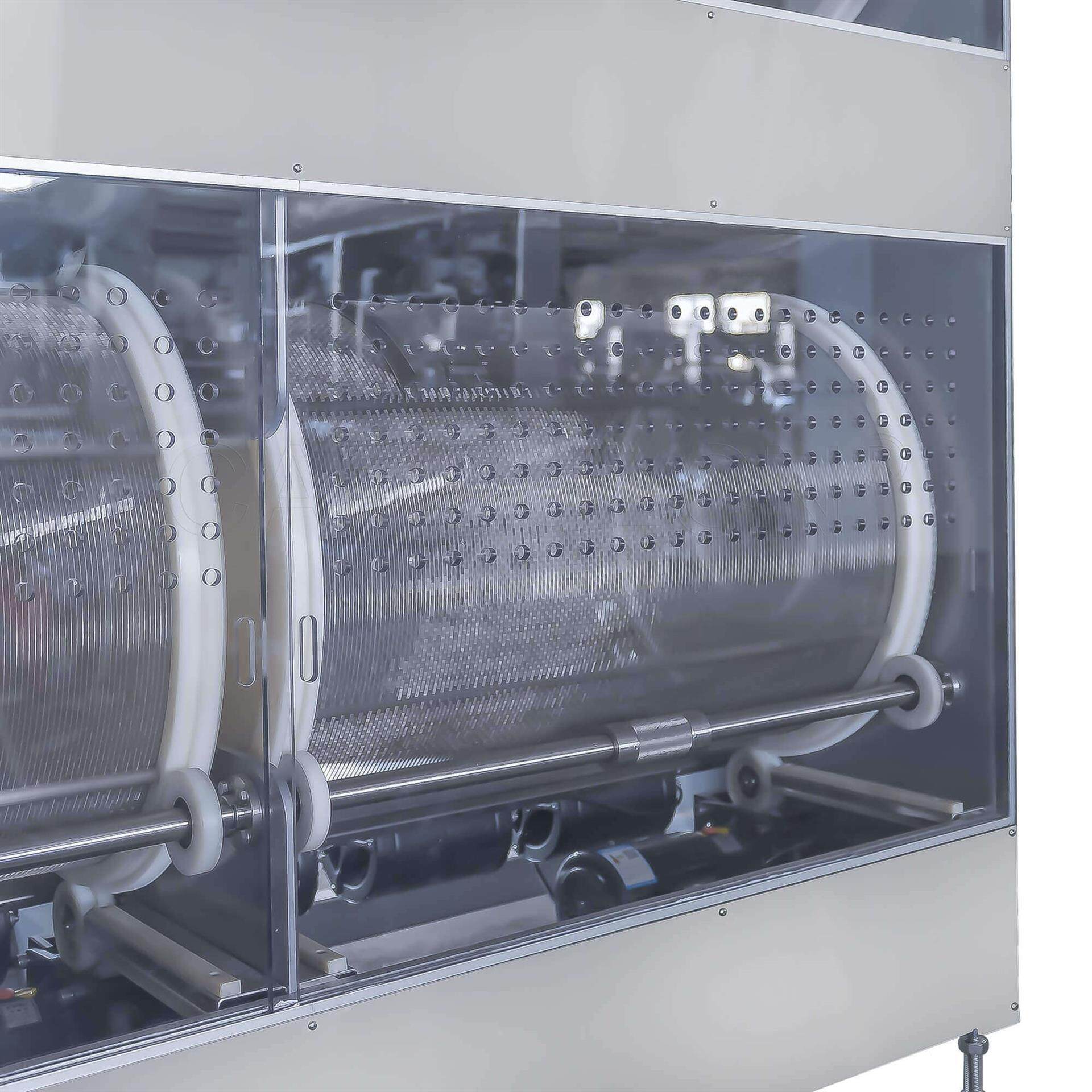

The tumble dryer is a device designed and constructed to support your softgel encapsulation production line. The entire softgel drying process takes place in a drum mounted in a housing with a safety guard.

The drum is a large compartment in the dryer that holds and spins the softgels. It's fully perforated and comes in a cGMP-compliant stainless steel construction.

So, how does the tumble dryer work? The principle is quite simple.

Driven by an electric motor, the tumble dryer starts to rotate. The formed softgel gelatin capsules are fed into the tumble dryer by the conveyor.

Typically, these softgels are tumble dried in a plurality of perforated drums. Heated air is continuously pumped into these drums at a temperature of less than 35℃. The drying air penetrates the gelatin shell and allows it to dry from the inside by pushing the moisture outward to the surface of the softgel.

The tumble dryer is equipped with a heater that works to heat the air. Also, the dryer comes with a thermostat that maintains the temperature inside the drum at a desired setpoint.

At the same time, the electric motor enables multiple blower fans to circulate heated air through the drums. The circulating drying air causes a large proportion of the moisture from the softgels to evaporate.

Some tumble dryers also place lint-free towels in the drum to help remove excess moisture on the soft gelatin capsules faster.

Lastly, the heated, moist air is pumped out of the drum by the tumble dryer directly through a flexible hose fitted into an external vent. The soft gelatin capsules exit the first stage of the drying process.

Softgel drying trays

After the soft gelatin capsules are discharged from the tumble dryer, they move to softgel drying trays for the second stage of the drying process.

The softgel drying trays are specifically designed to allow softgels to harden at room temperature. There is a variety of softgel drying trays made of metal, plastic, or fiberglass blend out there.

If you're looking for quality softgel drying trays, go for those featuring contoured edges and rounded corners. These softgel drying trays can prevent the buildup of moisture or residue to avoid contamination and marking.

Also, choose the trays that allow easy stacking under heavy loads without warping or distorting. Plus, they should be easy to clean and comply with GMP/cGMP regulations.

Drying tunnel

As the soft gelatin capsules come out of the tumble dryer, they are spread on the softgel drying trays. These trays are pushed into drying tunnels to complete the final stage of the softgel drying process.

(Image Credit: ACIC Machinery)

Trays are stacked inside the drying tunnels, where air with a controlled temperature and low relative humidity is continuously circulated.

The softgel drying process typically takes 16 to 24 hours, but it may be a little longer if the softgels are larger than 20 minims or formulated with a non-oily liquid base.

It's worth mentioning that depending on the gelatin and fill formulation used, the fill and shell materials of softgels contain 6–10% water after drying.

Important things impacting the softgel drying process

If you're looking to maximize the efficiency of the softgel drying process, there are a few things you have to be careful about.

1. Gelatin preparation

The shell of the softgel is typically made of gelatin that can affect drying. If you want to get a stable final product, your gelatin must be properly prepared from the very beginning.

The incorrect gelatin-to-liquid ratio will lead to improper drying of your softgels, regardless of whether the ingredient ratio in your original formulation is too low or too high.

2. Equilibrium moisture content

Temperature and relative humidity are two environmental factors that have an impact on the equilibrium moisture content of the shell of the soft gelatin capsule.

Softgel capsules should typically be stored at 20-30℃ and 30-50% relative humidity. Maintaining proper environmental temperature and humidity control is crucial to reduce the moisture exchange with the environment during softgel post-drying handling stages, such as packaging, shipping, or storing.

Manufacturing softgels in a temperature- and humidity-controlled environment can help mitigate risks to ensure consistent, high-quality batches.

3. Equipment condition

Defective softgels could be caused by malfunctioning tumble dryers during the drying process. As a result, you can never get a high-quality, desirable product if your drying systems aren't running at the proper speed or temperature.

To prevent equipment breakdown, you need to clean and inspect your drying system on a regular basis. Get your machine serviced as soon as you spot a problem. Buying new drying equipment if your machine is outdated and beyond repair.

The bottom line

Softgel drying is a critical link in the softgel manufacturing process. Good equipment can help prevent your soft gelatin capsules from sticking, tearing, and breakage. At iPharMachine, we offer high-quality softgel encapsulation machines and drying systems to have all your production needs covered. Contact us anytime.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche