A Complete Guide To Softgel Encapsulation Machine Parts

Softgels are one of the most common and popular oral dosage forms used in the pharmaceutical and nutraceutical industries. A softgel is a type of capsule that consists of a gelatin-based shell encasing a liquid fill.

Since liquids are not easy to be filled manually, softgel manufacturing is typically automated. So, you need to possess a softgel encaspulation machine to ensure precise fill dosage of softgels.

If you are thinking about incorporating softgel manufacturing into your business or simply want to know how to make softgel capsules, let's start with the softgel encapsulation machine parts.

What Are Softgel Encapsulation Machine Parts?

Below is an array of essential parts and components of a softgel encapsulation machine. Read on to find out what they are and their roles in softgel manufacturing process.

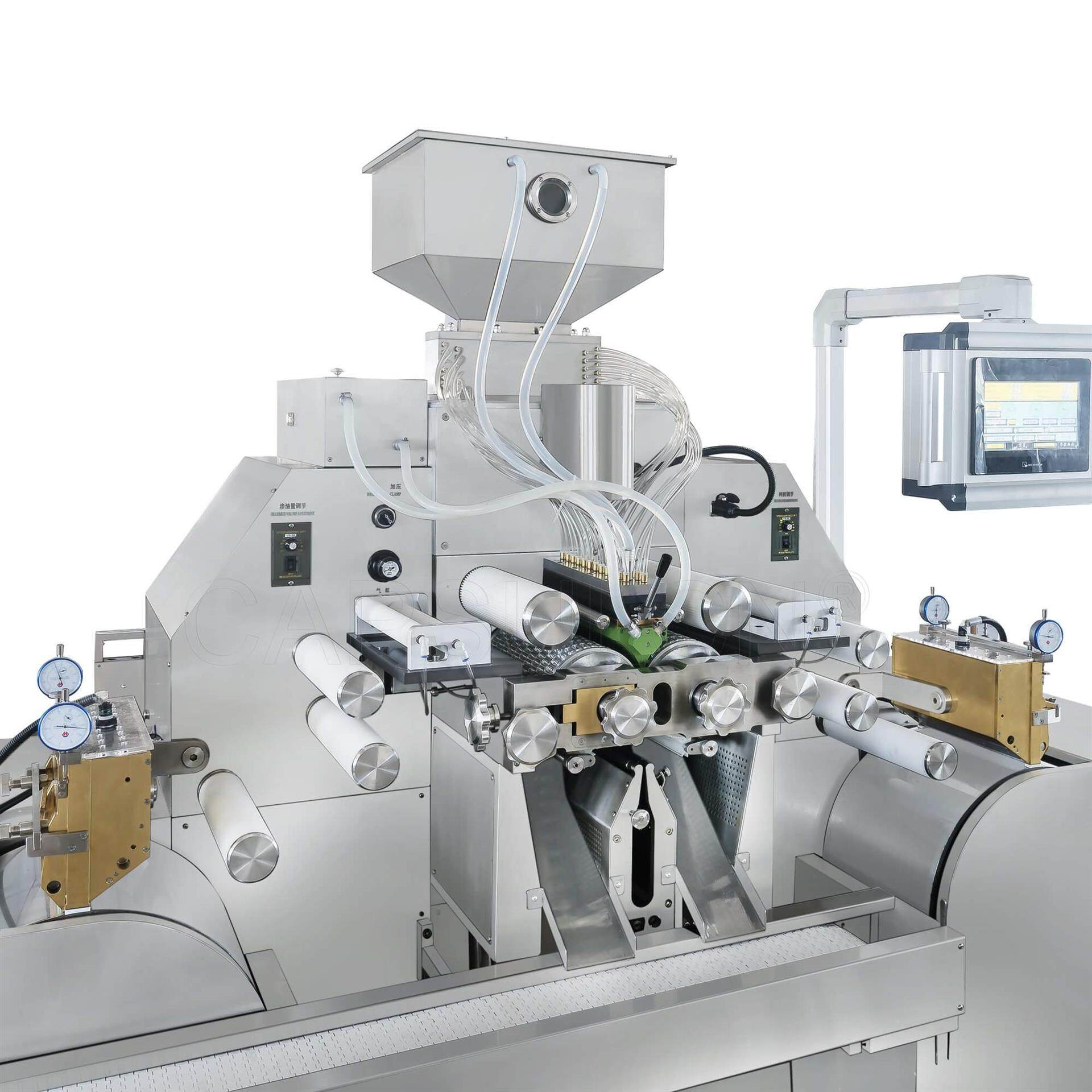

(Image Source: CapPlus Technologies)

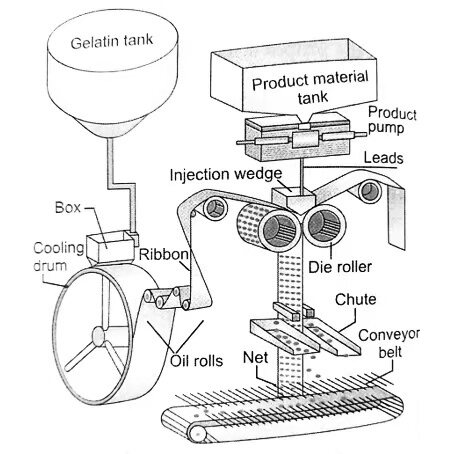

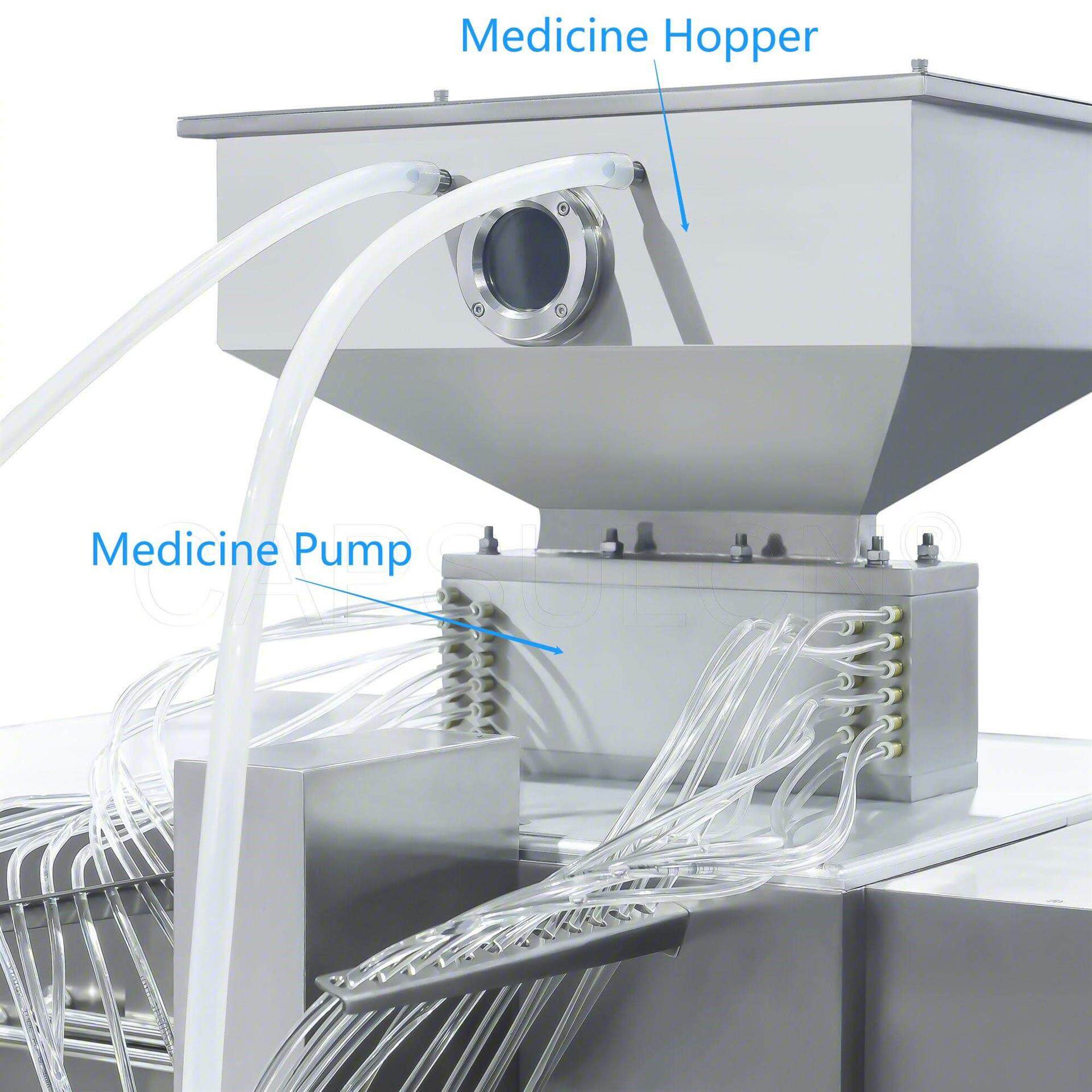

1. Medicine Hopper and Medicine Pump

The medicine hopper and medicine pump can be seen as a whole. The hopper is used to store the liquid formulations to be filled in the softgel capsules. It features a sight glass, allowing the operator to observe the level of liquids. Also, it's well designed to ensure liquid fills flow smoothly into the feeding pump.

The medicine pump is installed underneath the hopper. It works to deliver metered formulations to the injection wedge while allowing the excess liquids to flow back to the hopper through the return tubes. The pump pressure can be regulated depending on your manufacturing needs.

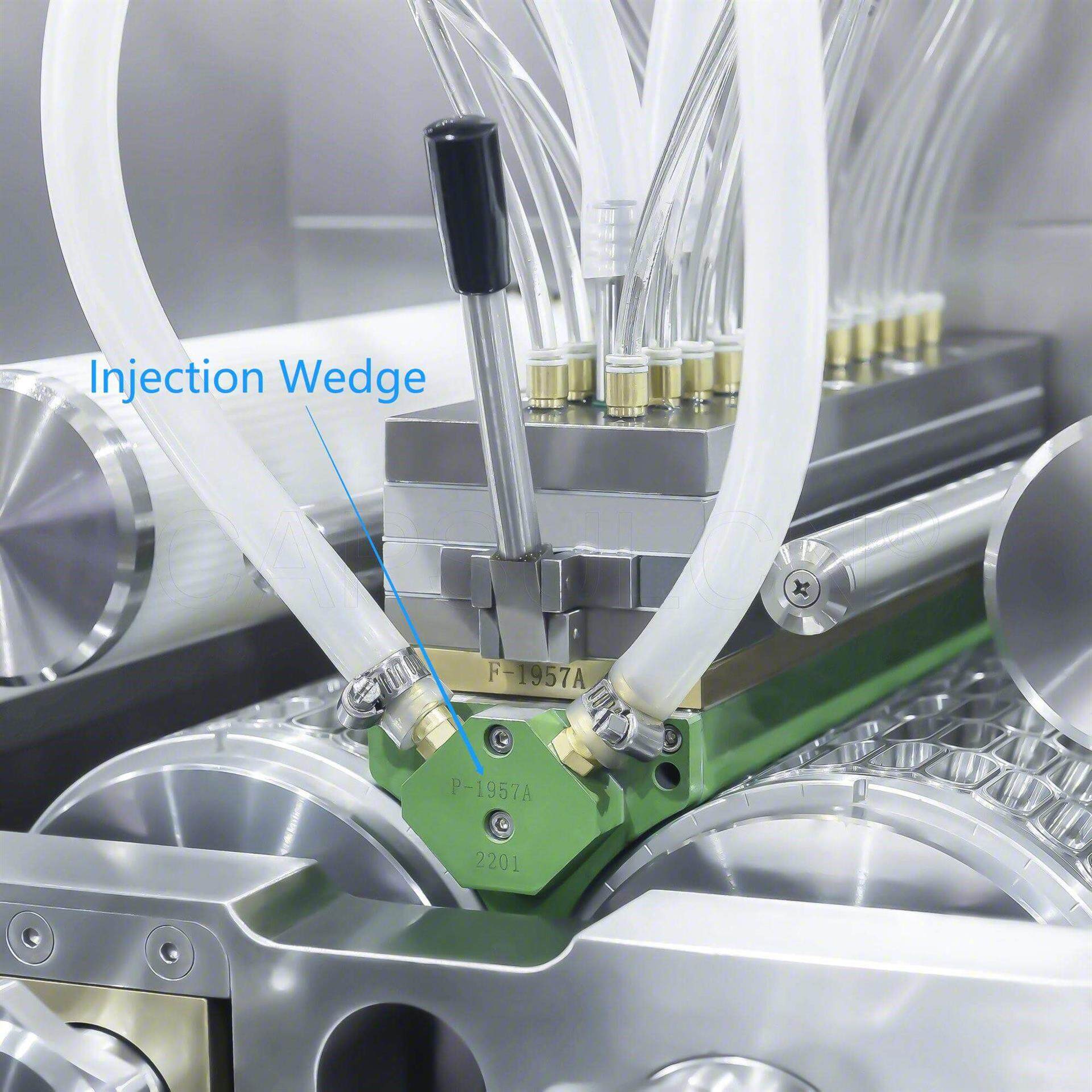

2. Injection Wedge

As its name implies, the injection wedge is a metal segment with dosing channels that inject the liquids into the soft gelatin capsules. Typically, the wedge is electrically or water heated to pretreat the gelatin ribbons before softgel formation. Simply put, the injection wedge is one of the most important softgel encapsulation machine parts since it plays a big part in the accuracy of softgel manufacturing.

3. Gelatin Melting Tank

This tank is a stainless steel storage container used to melt the gelatin and keep it at the desired temperature for soft gelatin capsule manufacturing. It comes in a variety of capacities to meet different production needs.

4. Gelatin Service Tank

This container helps control the gelatin temperature precisely and transfers the fill material to the softgel encapsulation machine from the melting tank.

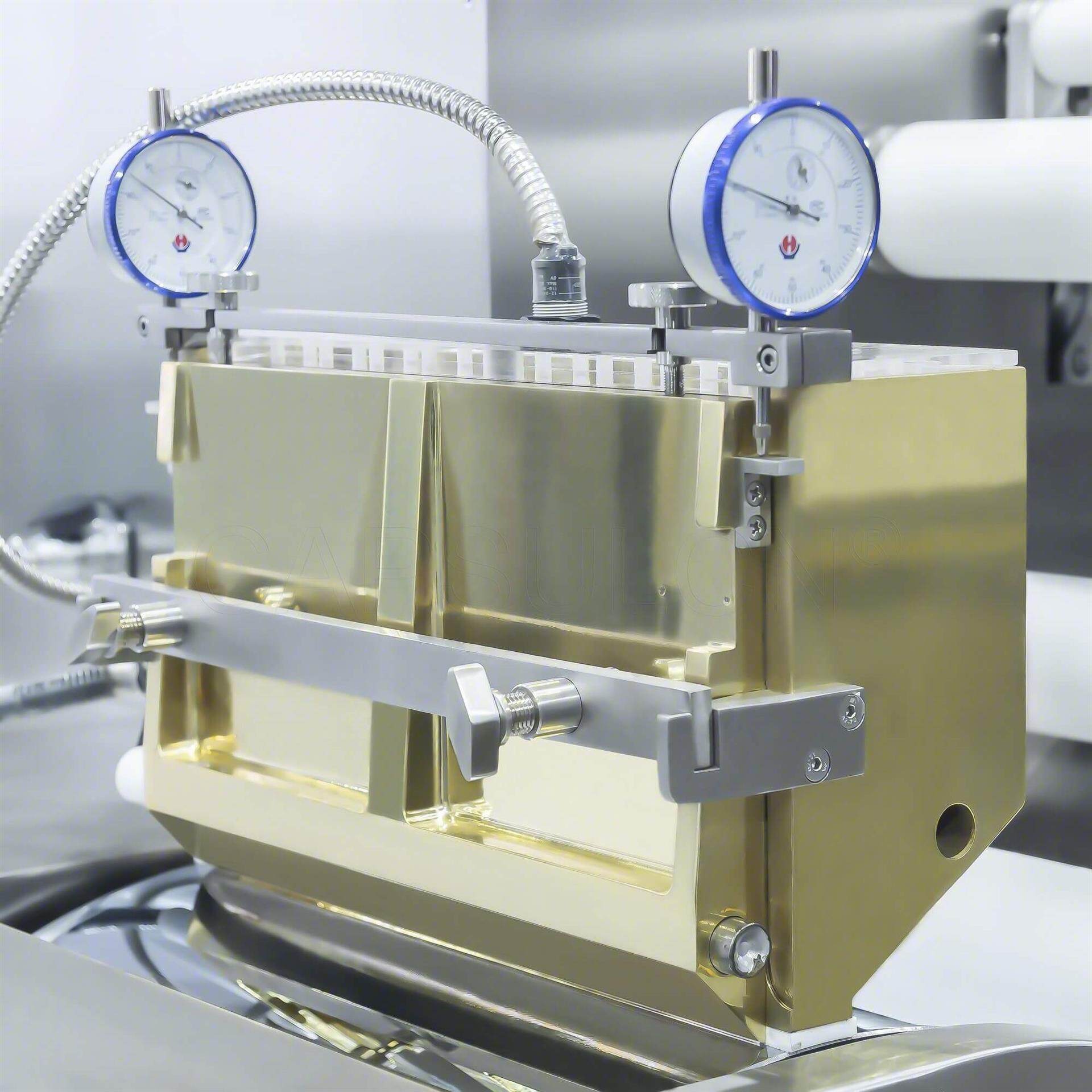

5. Spreader Box

When the gelatin flows into the encapsulator, the first stop it reaches is the spreader box. This unit is used to store the gelatin and spread it onto a casting drum to form a ribbon. The thickness and width can be adjusted as and when required.

Softgel encapsulation machines are generally designed with two spreader boxes on both sides. They create a ribbon respectively at the same time. The two ribbons finally meet at the injection wedge and fill the cavities of die rolls to form a complete capsule.

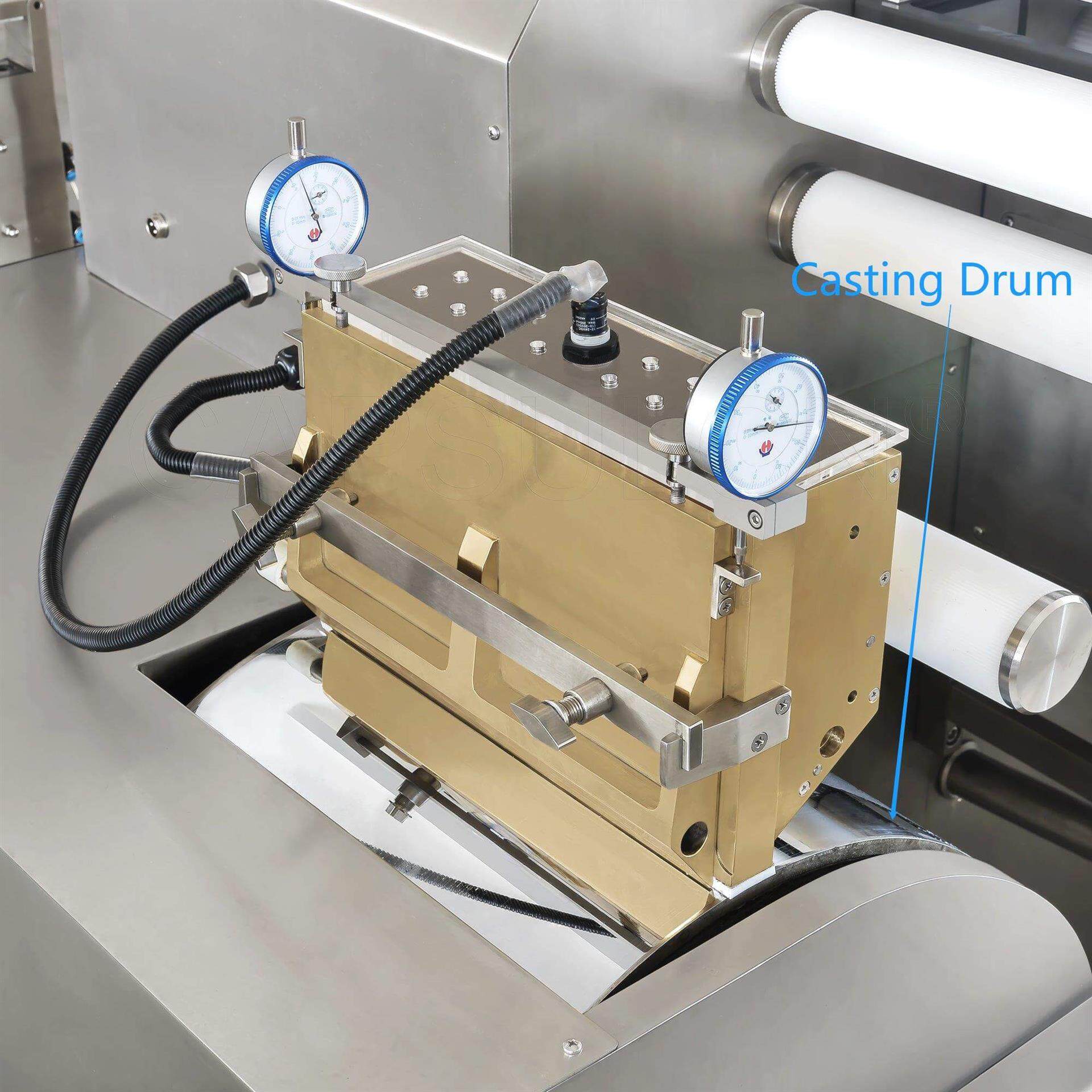

6. Casting Drum

The casting drum is mounted underneath the spreader box. The gelatin is spread onto the drum to form a flat ribbon. And then, the drum cools and solidifies the ribbon during rotation. So, the casting drum is also known as the cooling drum. Of course, there are two casting drums fitted underneath the spreader boxes.

Today, most softgel manufacturing machines boast a built-in cooling system or an external water chiller to perform the function.

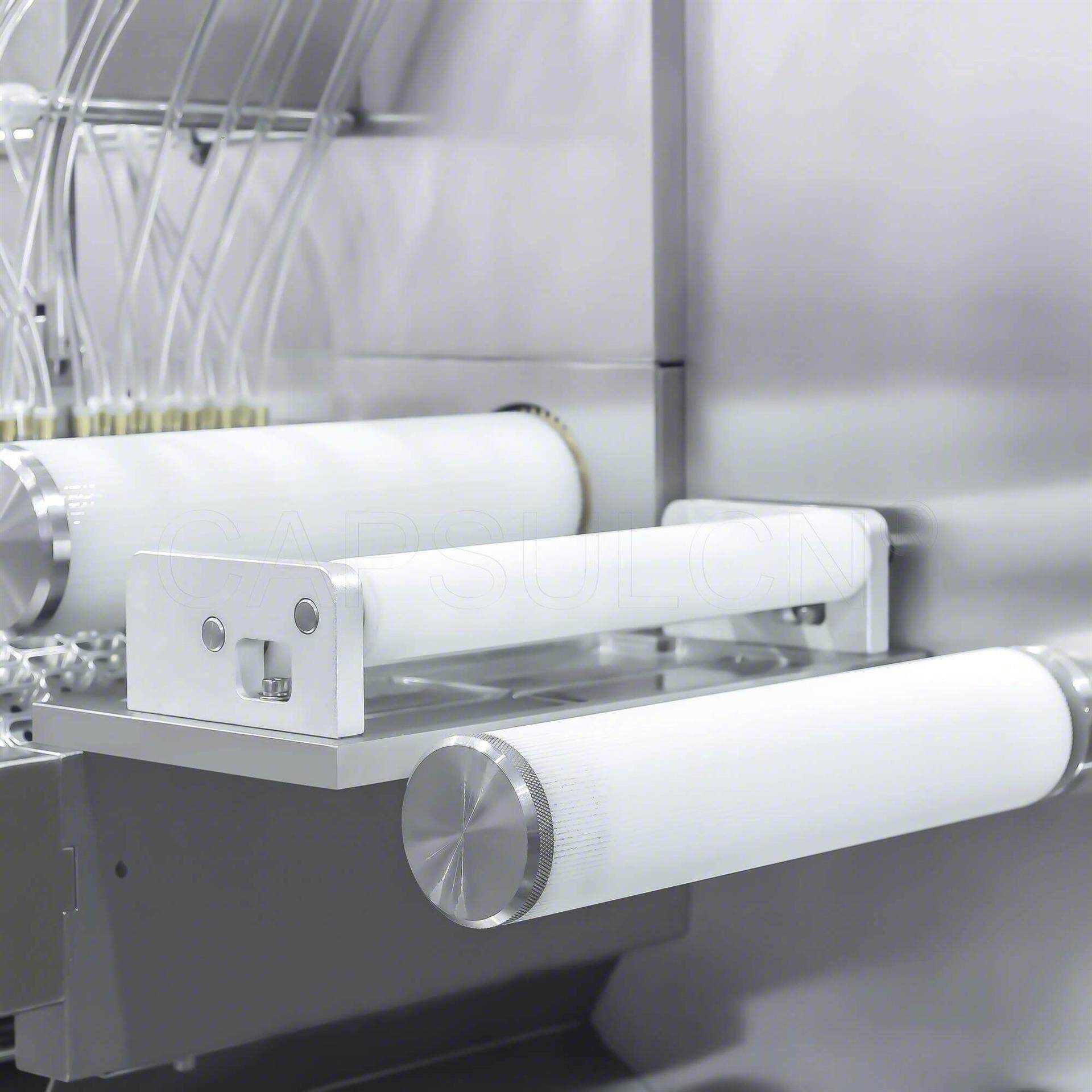

7. Lubrication Rollers

These rollers work in a group to feed the left and right ribbons through the die rolls. Made of porous material, they apply lubricant to both the upper and lower surfaces of the ribbons. This prevents the gelatin from sticking to the machinery and the final capsules from sticking together during the drying process.

8. Die Roll

The die roll is a piece of tooling used to form and seal a soft gelatin capsule. As one of the critical softgel encapsulation machine parts, this tooling is designed with a number of custom cavities. These cavities determine the shapes and sizes of soft gelatin capsules.

The tooling is typically made from a sanitary alloy in line with the GMP requirements. They come in pairs and need to be perfectly aligned to the same height for high-quality softgel manufacturing.

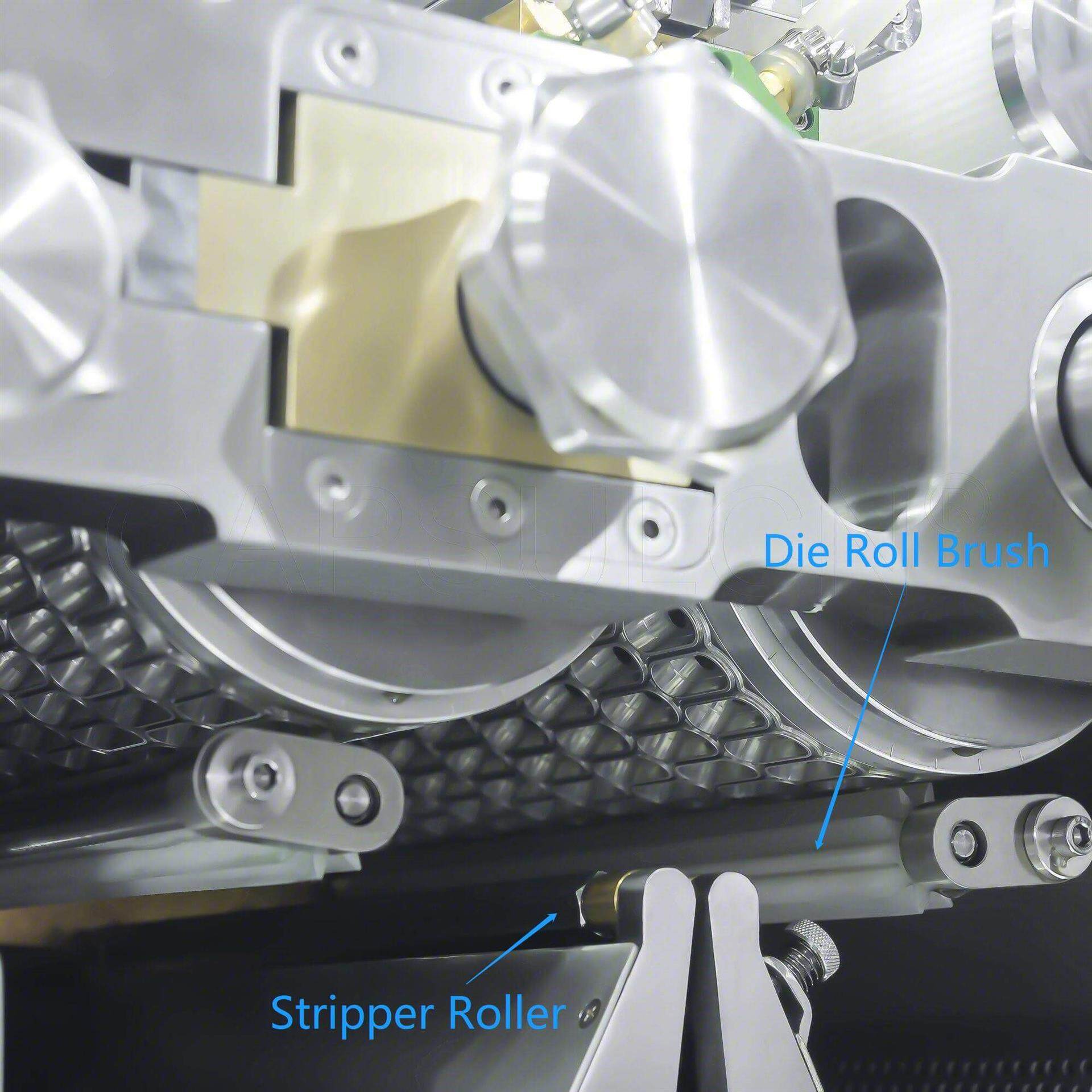

9. Die Roll Brush + Stripper Roller + Mangle Roller

There is a pair of brushes mounted under the die rolls. These brushes are used to remove any softgels stuck in the cavities of die rolls.

As with the brushes, stripper rollers are another pair of tooling to push the formed soft gelatin capsules out of the ribbon.

Mangle rollers are installed under the conveyor. After the capsules have been cut out of the ribbon, the remaining gelatin, called the netting, needs to be disposed of. So, these adjustable mangle rollers play the role of pulling the netting into a net collector.

10. Conveyor

This unit is designed to transfer the filled gelatin capsules to the drying process.

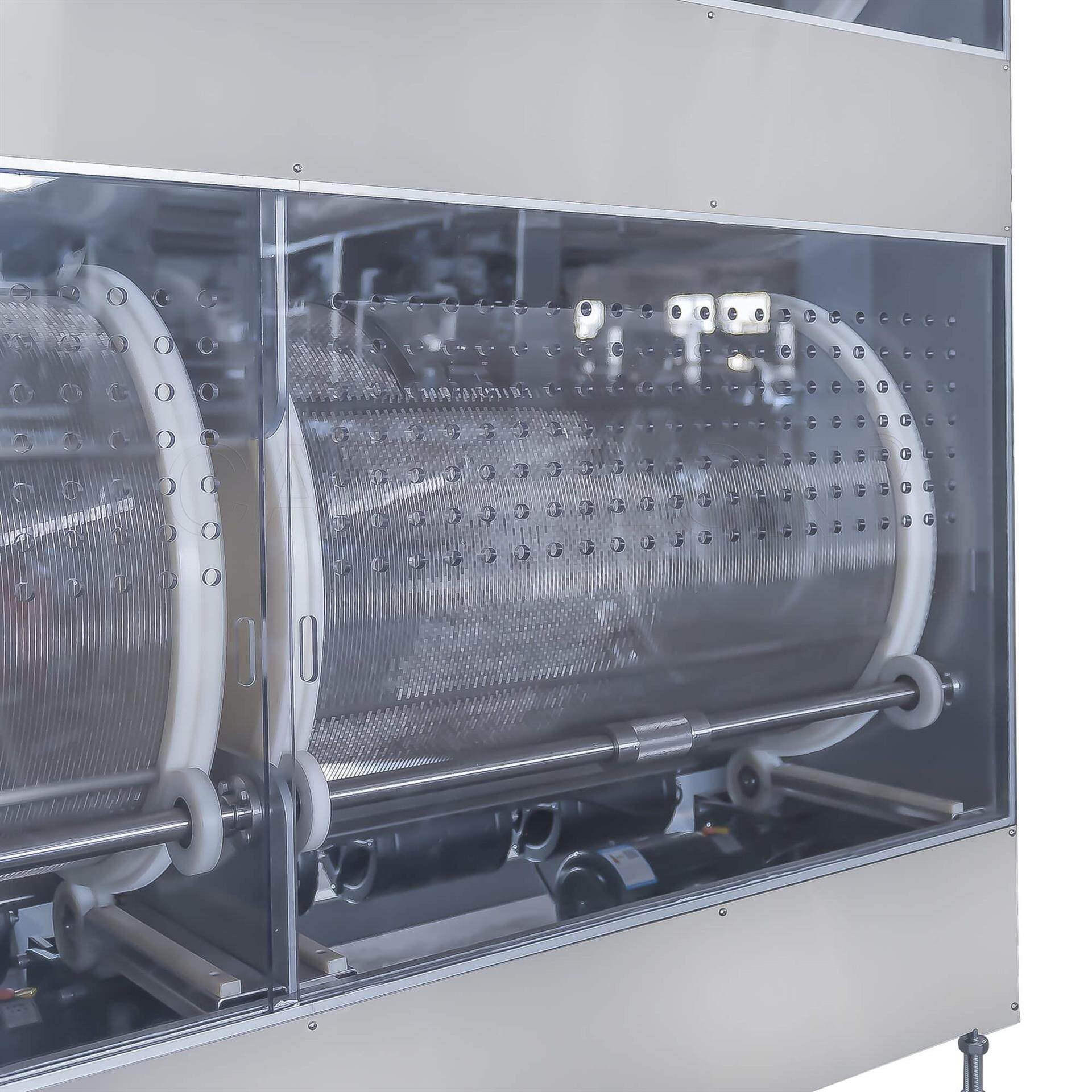

11. Tumble Dryer

As for the softgel drying process, the rumble dryer rotates in a controlled way to remove excess moisture from the finished softgels. Tumble drying is the most efficient way for the drying process. A well-designed tumble dryer can produce high-quality results in less time with little loss or damage to the capsules.

12. PLC Touch Screen

A PLC touch screen is one of the essential modern softgel encapsulation machine parts. The screen enables the operator to monitor and control every stage of softgel manufacturing, from production formulations to output speed.

The Bottom Line

If you've read this far into our guide to softgel encapsulation machine parts, you probably know more about this machine than most people do. Using the right machine parts will help your business to flourish in today's fiercely competitive pharmaceutical or nutraceutical market.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche