Stick Pack vs Sachet: What's the Difference?

To manufacturers, selecting packaging depends on a range of factors. It's not just a pouch, box, or bottle to hold a product. For customers, it can even impact their buying decisions. So, choosing the right packaging type can be a challenging task. As we know, packaging works with various products. Today, let's focus on the product with a small amount or for a single use.

If you're handling this kind of product, there are two popular options out there—stick packs and sachets. Both are known for being small and easy to use. But they aren't completely the same. So, how do you choose between a stick pack and a sachet? In this blog post, we'll break down their differences and help you pick the perfect fit.

What Are Stick Packs?

Stick packs are slim, tube-shaped packages. They're typically used to contain single-serve products like instant coffee, drink mixes, single-dose medications and supplements, and sample-sized lotions or gels. The packaging is often made from laminated films and features three seals (one fin seal on the back and two horizontal seals on both ends). These allow it to effectively protect the contents inside and keep them fresh.

Stick packs are much longer than they are wide. For instance, if a packet is 1 to 2 cm wide, its length will range from 8-12 cm. The length-to-width ratio is approximately 3:1 to 5:1. Of course, the ratio can vary depending on the contents and their intended use. The unique design makes these packs easy to empty and carry around.

What Are Sachets?

Sachets are typically flat, rectangular packets. They also come compact for small portions of products for single use. You'll often see them in everyday items like sugar packets, instant teas, shampoos, facial masks, or pre-sorted medications. Crafted from materials like plastic, paper, or foil laminates, sachets are designed to be easy to open. Unlike stick packs, sachets come with 3- or 4-side seals to provide a higher degree of airtight protection for the contents inside.

Generally, sachets are more square compared to stick packs with an elongated shape. A typical width-to-length ratio for a sachet might range from 1:1 to 3:4. This shape provides ampler space for branding and product information than a stick pack does. Still, keep in mind that the exact dimensions can differ based on the manufacturer's design and the specific application.

Stick Pack vs Sachet: Pros and Cons

Now I guess you might be more curious about why some products come in sachets while others use stick packs. That's because they each have their own advantages and disadvantages. Let's check them out!

Pros of Stick Packs

- Lightweight and slim. Fit easily into your bag or pocket, perfect for on-the-go use. Can be stored in small compartments, keeping your environment neat and organized.

- Feature a narrow opening for easy dispensing whether you pour or squeeze.

- Often use less packaging material for the same product volume compared to traditional packaging. Cost-effective, minimal waste, and environmentally friendly.

- Typically made from laminated films that shield against moisture, oxygen, and light to help maintain product freshness and potency.

Cons of Stick Packs

- Offer less space for product information and branding.

- Can be more expensive for requiring specialized equipment.

- Not suitable for accommodating bulkier or irregularly shaped contents.

- May be tough to open if not designed properly.

Pros of Sachets

- Can pack a wide variety of products, including powders, liquids, gels, and small solids like capsules and tablets.

- Beneficial for marketing and compliance with more areas for logos, instructions, and legal information.

- Equipment for filling and sealing sachets is widely available. Easier to find more affordable options.

- Often designed with easy-open features like tear notches.

Cons of Sachets

- Can be less convenient to carry compared to a slim stick pack.

- May require more packaging material, increasing waste and material costs.

- Harder to pour or apply the contents neatly due to the wide opening, especially for liquids or fine powders.

Stick Pack vs Sachet: Comparing Manufacturing Processes

While stick packs and sachets serve similar purposes, their manufacturing processes have slight differences. Now, let's explore how each of them is created.

Manufacturing Steps of Stick Packs:

1. Material Preparation

– Stick packs use laminated films made of layers like plastic and aluminum foil.

– These films come in large rolls that can be easily used for high-speed production.

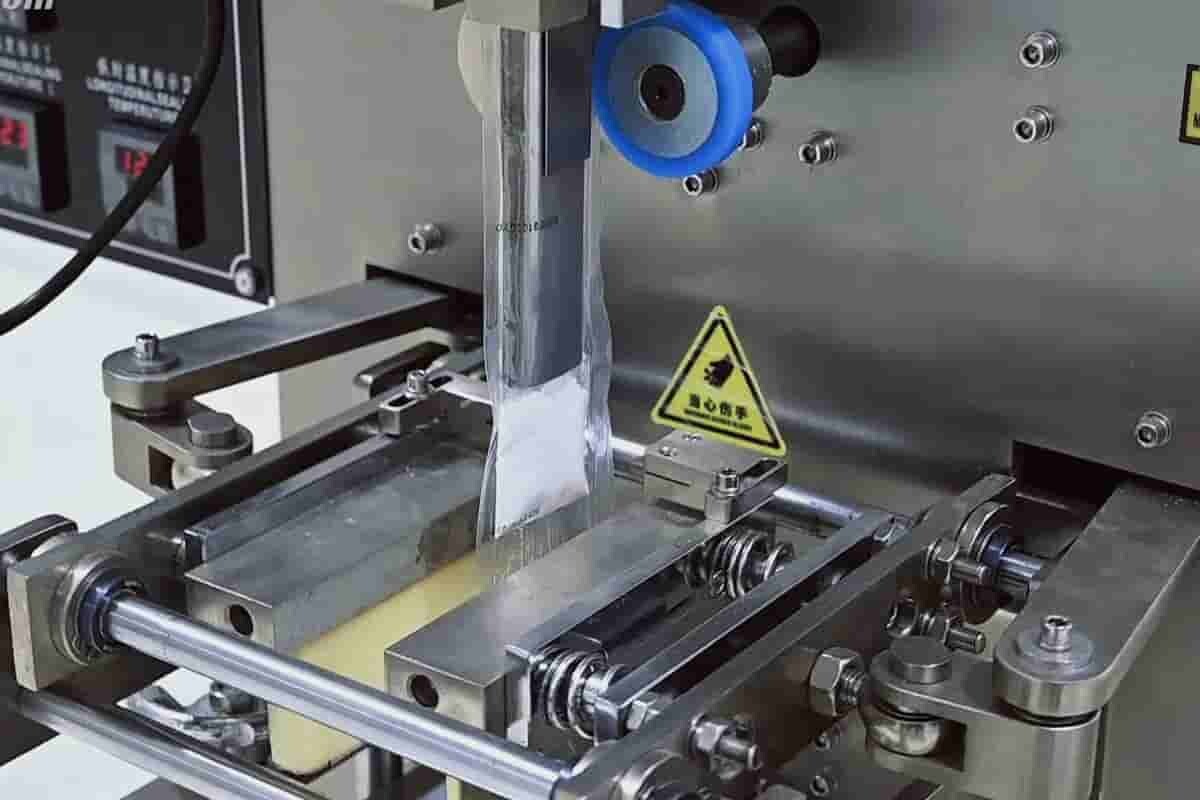

2. Forming the Tube

– Stick packs are made on Vertical Form-Fill-Seal (VFFS) machines specifically designed for narrow packaging.

– The film is shaped into a tube by feeding it over a collar, with the edges slightly overlapping.

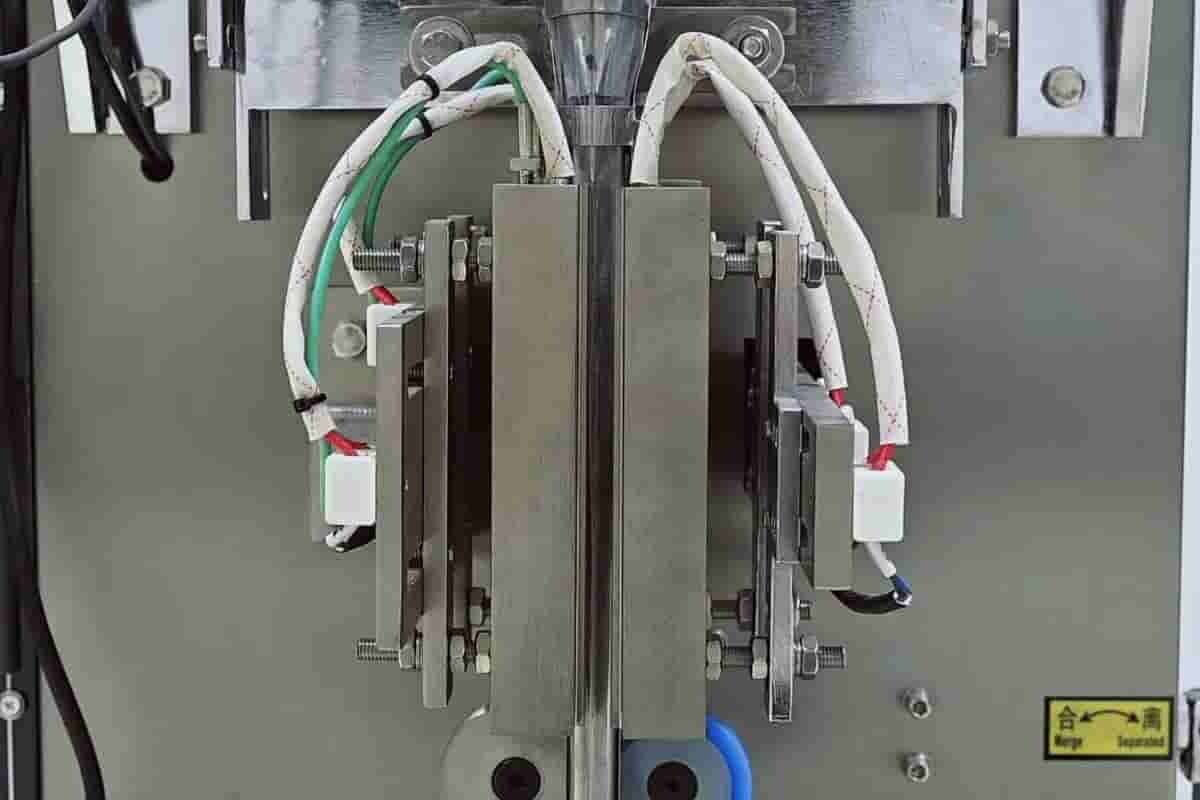

3. Longitudinal Sealing

– The edges are sealed along the length of the tube using heat or ultrasonic sealing, creating a continuous tube.

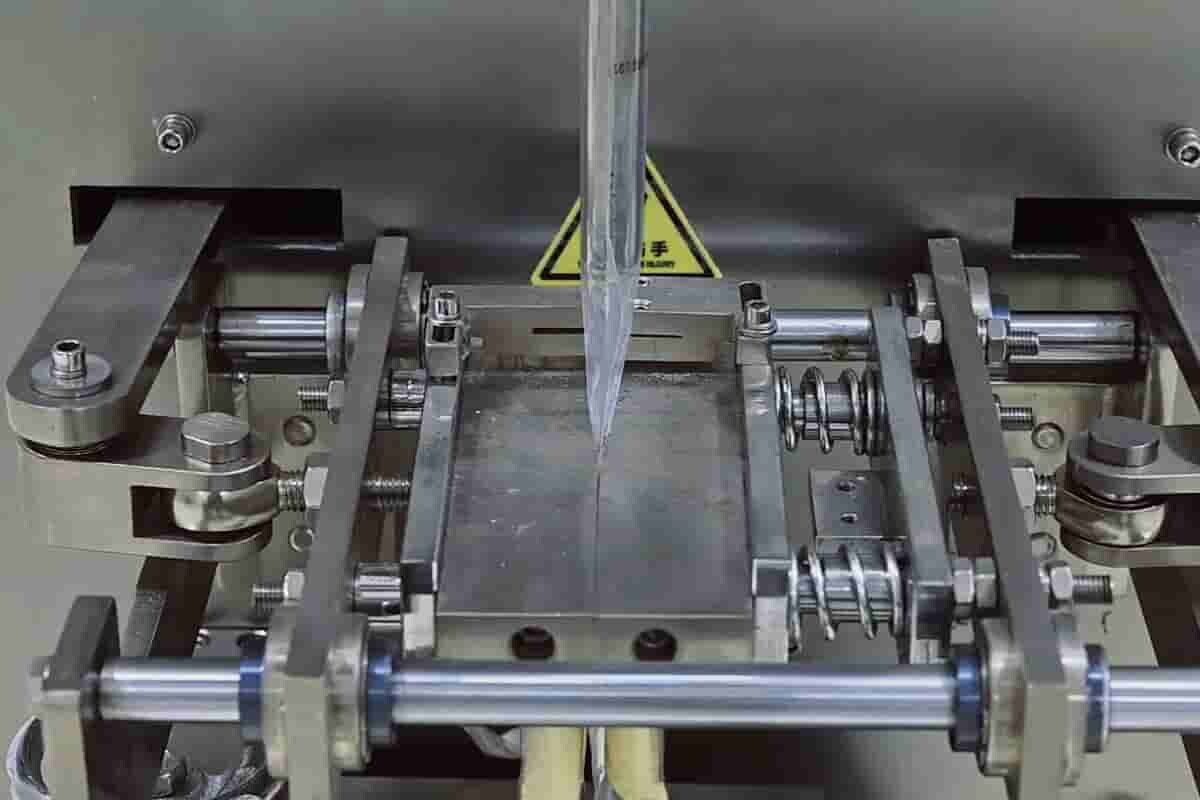

4. Bottom Sealing

– A horizontal seal at the tube's bottom forms the stick pack's base.

5. Filling

– The product is added from the top using a hopper or nozzle.

– Precise dosing ensures each stick pack has the exact required amount.

6. Top Sealing and Cutting

– After filling, the top end is sealed horizontally.

– The tube is then cut to separate each stick pack, with cuts made between the seals.

Key Characteristics:

- These machines often run multiple lanes at once for high output.

- The narrow packaging needs precise handling and sealing to maintain quality.

- Stick packs are best for free-flowing products that can pass through narrow filling tubes easily.

Manufacturing Steps of Sachets:

1. Material Preparation

– Like stick packs, sachets use laminated films and can include paper-based materials depending on product needs.

– Sachets are made from either a single roll folded to create three sides or two separate rolls for the front and back panels.

2. Forming the Pouch

– Sachets are produced on Vertical or Horizontal Form-Fill-Seal machines.

– VFFS: The film folds vertically, sealing the sides.

– HFFS: Two films meet horizontally to form the pouch.

3. Sealing Sides

– Vertical seals are added along the sides (when using two films) or along one side if the film is folded.

4. Bottom Sealing

– A horizontal seal is applied to create the bottom of the sachet.

5. Filling

– The product is filled from the top, with a larger opening.

– Accurate dosing ensures each sachet has a consistent amount.

6. Top Sealing and Cutting

– The top is sealed horizontally after filling.

– Sachets are cut or perforated for easy separation.

Key Characteristics:

- Can deal with different product types and sizes.

- Provides more surface area for branding.

- Works well with products of different viscosities and sizes.

Key Differences Between Stick Packs and Sachets

To give you a clearer understanding of "stick pack vs sachet," I've prepared a comparison table that summarizes and highlights their key distinctions.

|

Aspects |

Stick Pack |

Sachet |

|

Shape & Design |

Long, slender, tubular packaging; sealed on three sides with a side seam. |

Flat, rectangular or square; sealed on three or four sides. |

|

Feature |

Efficient material use, portable, consumer-friendly for single-dose use, compact design. |

Versatile, larger branding area, handles various product consistencies, suitable for a range of product types. |

|

Material Used |

Laminated films, often combining plastic and aluminum for moisture protection; uses up to 40% less material than sachets. |

Laminated films, sometimes includes paper-based materials; uses more material, offering extra branding space. |

|

Forming Method |

Single film shaped into a narrow tube, with longitudinal and transverse seals. |

Made from single (folded) or double films; formed vertically or horizontally. |

|

Filling |

Product inserted through a narrow top opening; best for free-flowing powders and granules. |

Product inserted through a larger top opening; suitable for various consistencies, including liquids, gels, and more. |

|

Machinery Used |

Specialized multi-lane VFFS machines for high-speed, narrow-width packaging. |

VFFS or HFFS machines, providing flexible solutions for diverse products. |

|

Limitations |

Limited to free-flowing products, requires precision in sealing and film handling to ensure quality. |

Uses more packaging material, bulkier, which may affect portability. |

|

Applications |

Ideal for single-use products like powdered beverages, pharmaceuticals, condiments, and supplements. |

Suitable for food, pharmaceutical, and personal care products in various forms (powders, gels, liquids, etc.). |

|

Consumer Experience |

Sleek, portable, and easy to open; designed for direct dispensing into the mouth or mixing with liquid. |

Has ample space for branding and product information; may include laser perforation for easy opening. |

Frequently Asked Questions (FAQs) about Stick Pack vs Sachet

Here are some FAQs to help you decide between stick packs and sachets for your packaging needs:

1. What products work best in stick packs?

Stick packs are perfect for powders, granules, and liquids that come in single doses. They're popular for items like energy drink powders, coffee, sugar, and supplements.

2. When should I choose a sachet instead?

If you need more space for labeling or your product requires a bigger package, sachets are a good choice. They're great for skincare samples, pharmaceuticals, and products that need more room.

3. Which one is more affordable?

Stick packs are often more budget-friendly because they use less material. But if you need a larger size, sachets might be more affordable because they can be made in various sizes.

4. Which is easier for on-the-go use?

Those slender stick packs are super convenient on the go. Sachets are also portable, but they're usually better for products that need a larger package.

5. Do both offer the same branding space?

Not quite. Stick packs have limited space, so they work well with a simple design, like a logo and essential details. Sachets give you more surface area, allowing for detailed information and eye-catching branding.

6. Which is more eco-friendly?

Stick packs usually use less material. Sachets can be made using recyclable material. So, it all depends.

7. Will stick packs or sachets keep my product fresh?

Yes! Both can use high-barrier materials to protect against moisture, light, and air. This helps keep your product fresh, as long as you choose quality materials.

8. Is the machinery used for stick packs and sachets different from each other?

Yes, stick packs often need specialized machines to handle their narrow shape. Sachets are more versatile and can usually be filled on a range of equipment, depending on the product.

9. Can I customize their shapes and sizes?

Sachets offer lots of flexibility in shape and size, making them great for different uses. Stick packs have a more standard, tubular shape but can vary in length.

10. How do I choose between stick pack vs sachet?

Think about your product type, the amount you want to package, your branding needs, and your budget.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche