Tablet Coating Process: A Fundamental Guide

Are you looking to make your tablets that not only look great but are also safe and effective? Then you need to gain a deeper understanding of one of the most important pharmaceutical techniques - the tablet coating process.

This crucial step in pharmaceutical manufacturing involves applying a thin layer of coating solution to tablet surfaces. This helps to protect your drug products from external factors and improve their appearance and taste. But that's not all - the tablet coating process can also significantly impact the safety and efficacy of your products.

This blog post will explore the basics of the tablet coating process, including its different types and critical parameters. If you're ready to take your business to the next level, don't miss out on this post to learn how it can benefit your manufacturing operations. Hopefully, the knowledge will help you find the tablet coating machine suit you most. And if you're looking for information about tablet coating defects, feel free to check this post:

Common Tablet Coating Defects and Remedies

Different Types of Tablet Coating Processes

Today, there are various types of tablet coating used in the pharmaceutical or nutraceutical industry. Selecting the tablet coating process that best suits you can help you produce high-quality, safe, and effective drugs. Here are some of the most common tablet coating processes:

Sugar Coating Process

This is the oldest and most traditional tablet coating technique. This process involves applying multiple layers of syrup-based coatings to the tablet until a smooth and shiny surface is achieved.

The sugar coating process involves several steps:

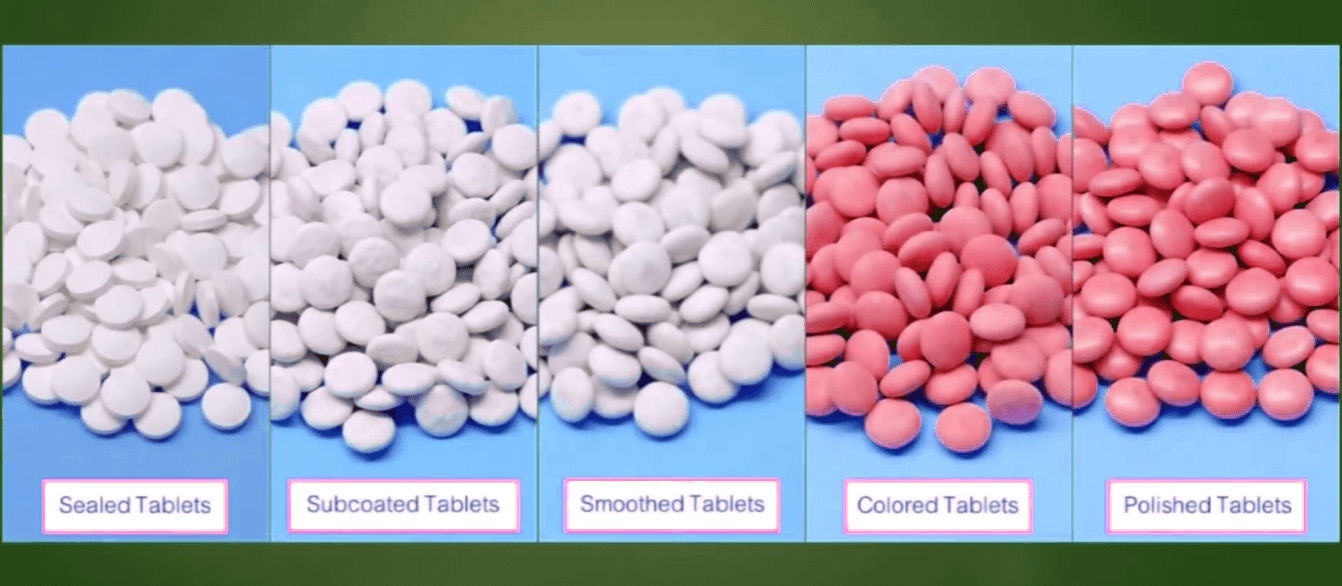

STEP 1: Sealing - Apply a seal coat to protect the tablet core from moisture and strengthen it.

STEP 2: Subcoating - Coat the tablet with sugar syrup to round edges and cover imperfections.

STEP 3:Smoothing - Apply syrup solution to smooth and increase tablet size.

STEP 4: Coloring - Apply color in several layers with water-insoluble pigments.

STEP 5: Polishing - Apply a wax mixture to give the tablet a shiny finish.

STEP 6:Printing (Optional) - Apply printed design or logo with edible ink.

The sugar coating process can provide an attractive appearance to the tablet and mask its unpleasant taste or odor. Yet, it is a time-consuming and labor-intensive process.

Film Coating Process

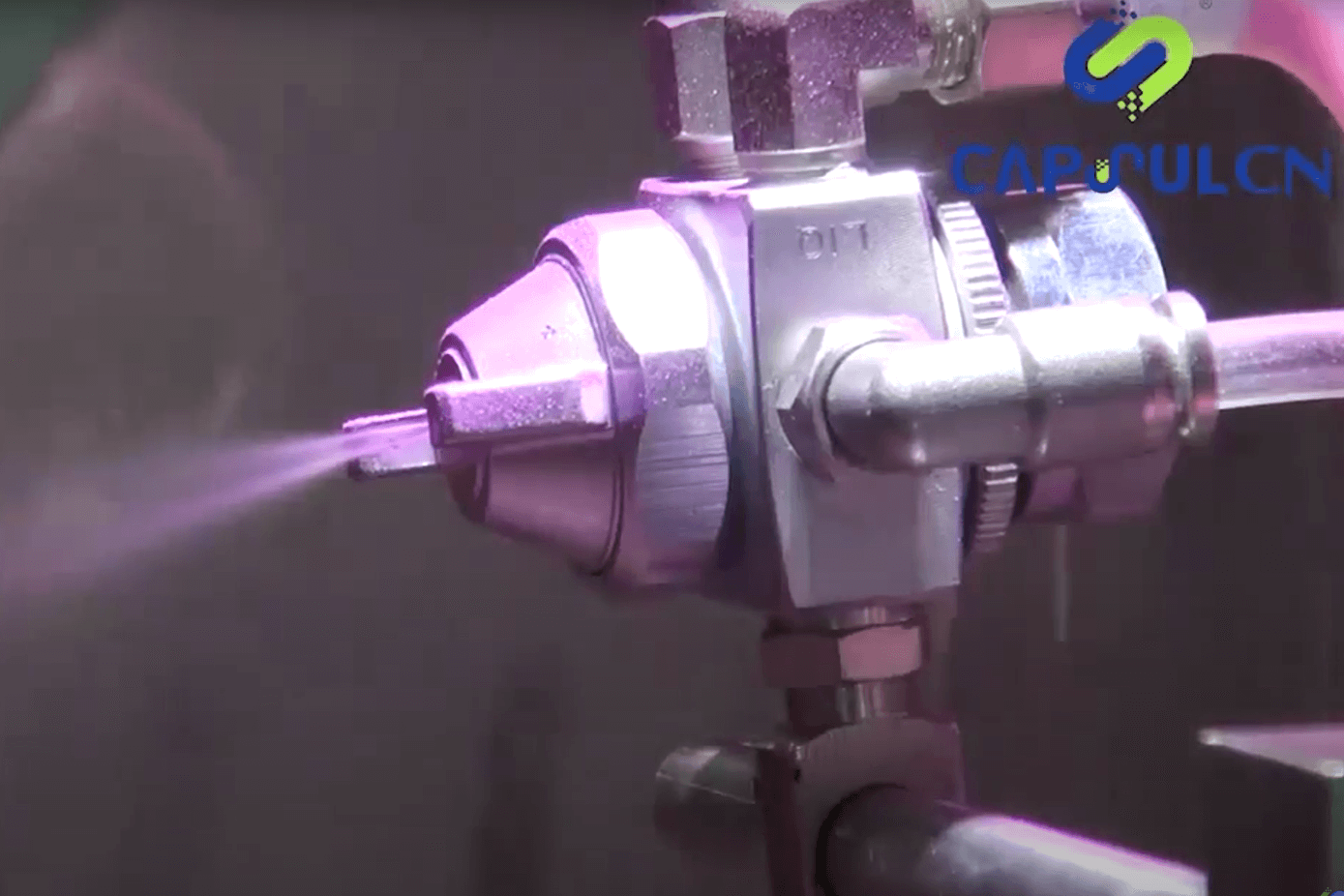

Film coating is a more modern and popular tablet coating process. It involves adding a thin layer of coating solution to the tablet surface using a spray gun. This process typically takes place in a coating pan where the heated air quickly dries the solution to form a transparent, protective film.

Film coating is deemed a single-stage process. To help you better understand this process, we break it down into multiple smaller steps.

STEP 1:Prepare the coating solution.

STEP 2:Load the tablets.

STEP 3:Apply the coating solution onto the tablets using a spray nozzle.

STEP 4:Dry the coating using heated air.

STEP 5:Inspect the film-coated tablets for uniformity and defects.

Film coating is more efficient and cost-effective than sugar coating. It can also provide improved drug release profiles. It is commonly used for tablets that are sensitive to moisture or light.

Read More:

8 Essential Tablet Coating Process Parameters You Should Know

There are several essential parameters that need to be monitored and controlled during the tablet coating process. These parameters help ensure the batch-to-batch quality and consistency of your tablets. Let's take a look! To have a better understanding of tablet coating euqipment, feel free to check the following guides:

What Is A Tablet Coating Machine: A 101 Guide

Types of Tabler Coating Machine: The Ultimate Guide

1. Coating Formulation

The coating formulation is the specific combination of syrup or polymers, plasticizers, colorants, and solvents used to create the coating solution. The proportions of each component in the coating formulation should be carefully controlled. The formulation must also be compatible with the tablet core and the tablet coating equipment.

2. Inlet Air Temperature and Relative Humidity

The inlet air is used to dry the coating solution after it is sprayed onto the tablets. So, its temperature should be high enough to evaporate the solvent and dry the coating quickly.

Relative humidity measures the amount of moisture present in the air. It is important because if the humidity is too high, the coating may not dry properly, and the tablets may stick together. If the humidity is too low, the coating may dry too quickly, causing it to crack or peel.

3. Spray Rate

The spray rate refers to the amount of coating solution sprayed onto the tablets per unit of time. If the spray rate is too low, the coating may be too thin, resulting in inadequate protection of the tablet core. On the other hand, if the spray rate is too high, the coating may be too thick, resulting in issues like tablet sticking or capping.

The spray rate can be optimized by adjusting the pump speed, the nozzle size, and the nozzle pressure. A well-controlled spray rate can lead to a high-quality coating, improving the shelf life, appearance, and taste of the tablet.

4. Spray Distance

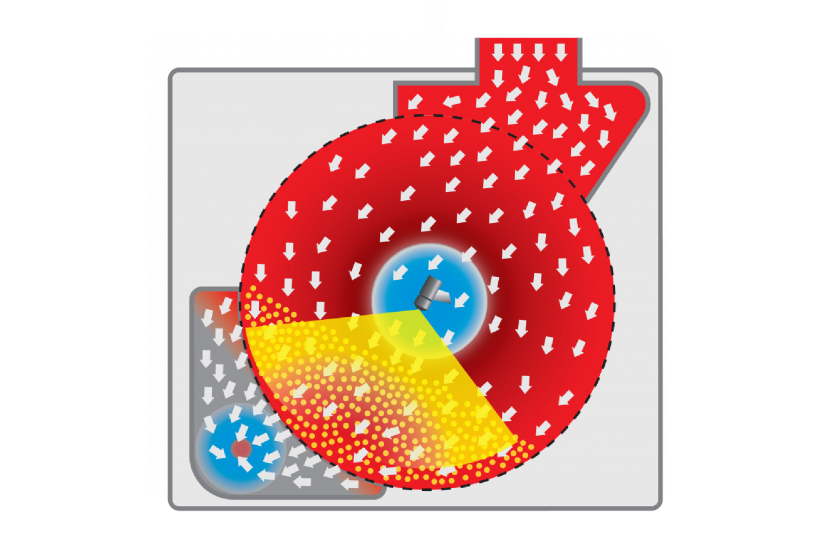

Here are two distance parameters needed to be monitored. One is the distance between the spray gun and the tablet bed. And the other is the distance between the spray guns.

(Image Source: L.B. BOHLE)

The first distance determines the spray pattern and the amount of overspray. This parameter must be adjusted to ensure the coating solution reaches the tablets uniformly without any pooling or uneven distribution.

The other distance relates to the spray gun overlap. It refers to the amount of overlap between the spray pattern of adjacent spray guns. This parameter needs to be optimized to ensure that the tablets are uniformly coated without defects.

5. Pan Speed

The pan speed refers to the rotation speed of the coating pan. It determines the efficiency of the tablet coating process. The ideal pan speed is determined by the tablet's size, shape, and density, the coating solution's viscosity, and the coating equipment's capacity.

A too-high or too-low pan speed can result in coating defects, such as mottling, streaking, or uneven coating thickness. If the pan speed is too high, the tablets may not receive enough coating solution, resulting in an uneven and thin coating. On the other hand, if the pan speed is too low, the tablets may get oversaturated with the coating solution, leading to thick and uneven coating.

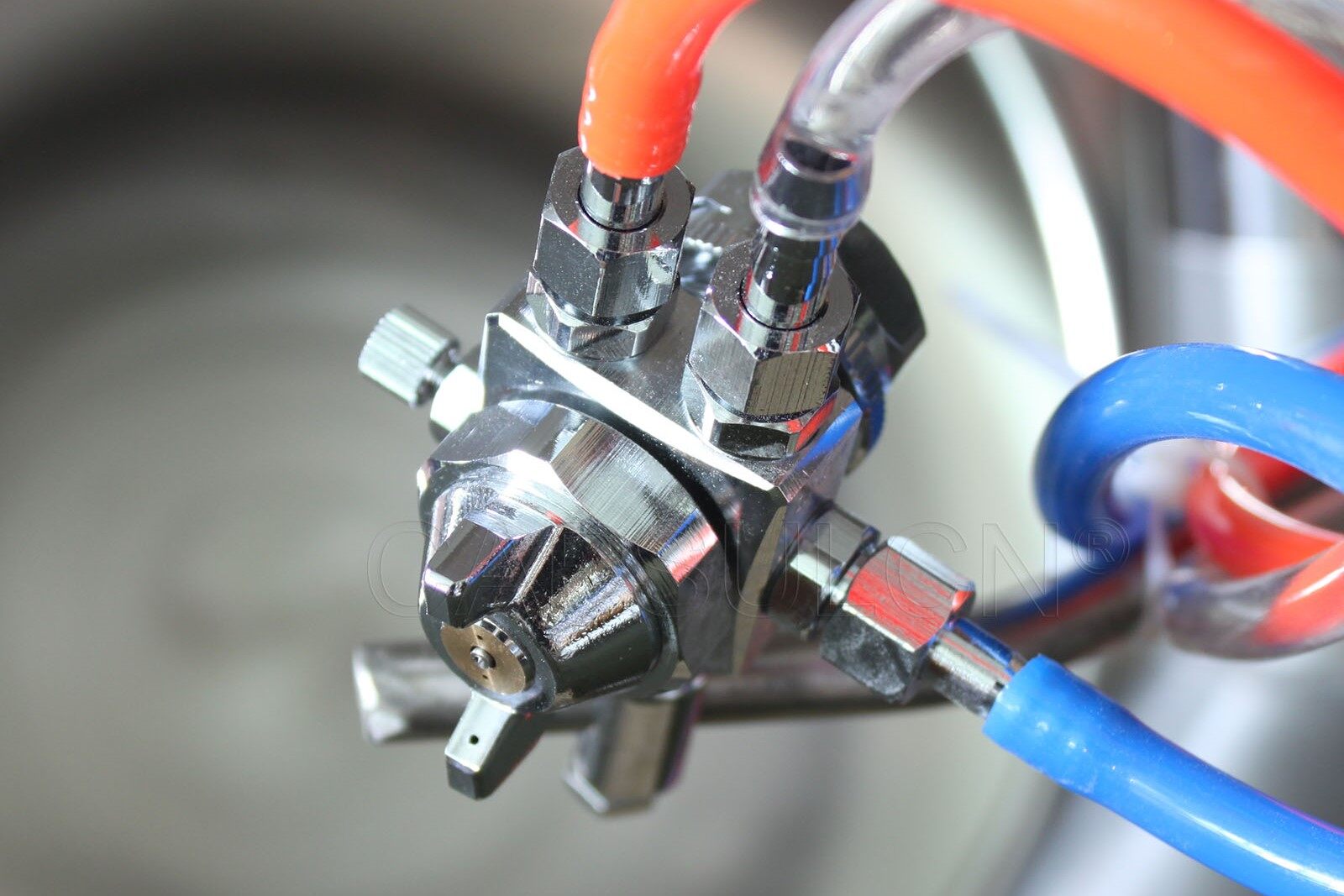

6. Atomization

This tablet coating process parameter directly affects the size and distribution of droplets the spray gun produces. Atomization is typically achieved by forcing the coating solution through a small orifice at high pressure, using either air or hydraulic pressure.

Factors that affect atomization include:

- The size and shape of the orifice.

- The pressure of the coating solution.

- The viscosity of the coating solution.

Careful control of these factors ensures that the coating solution is atomized evenly.

7. Drying Time

Drying time is a crucial parameter in the tablet coating process. It refers to the time required for the solvent to evaporate and the coating to dry completely. The drying time depends on the coating formulation, tablet size, pan speed, inlet air temperature, and relative humidity.

You can shorten the drying time by increasing the inlet air temperature, increasing the airflow rate, or reducing the tablet bed depth. On the other hand, it can be lengthened by lowering the inlet air temperature, slowing down the airflow rate, or increasing the tablet bed depth.

8. Exhaust Temperature and Airflow Rate

These two important parameters in the tablet coating process affect the drying time of uniformity of the coating.

(Image Source: Freund-Vector)

The exhaust temperature should be high enough to remove moisture from the coating. But it also needs to be low enough to prevent any defects that may occur during the tablet coating process.

The airflow rate helps to dry out the coating. If the airflow rate is too high, it may cause tablet movement, resulting in tablet damage or coating defects. On the other hand, if the airflow rate is too low, it may result in prolonged drying time, which can cause the coating to crack or peel off.

Conclusion

Tablet coating is a critical process in pharmaceutical manufacturing. It plays a significant role in improving drug efficacy, stability, and patient acceptability. Understanding the basics of tablet coating is essential for pharmaceutical manufacturers to produce safe and effective drugs that meet regulatory requirements and consumer needs.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche