The Ultimate Guide to Buying a Tablet Counting Line in 2024

Tablet counting is always essential to the success of a pharma business. The demand for faster, more accurate, and higher-quality pill counting has reached new heights in recent years. So, how do you get this job done right in 2024? Go for a dependable tablet counting line!

Do not know where to start? Fret not. We've put together this guide to help you make savvy investments. Whether it's your first-ever tablet counting line or you're eyeing an upgrade, come along with us to unravel the essential factors you should have in your playbook. Let's get started!

What Is A Tablet Counting Line?

A tablet counting line is also known as a tablet counting and bottling line. Although it comes with the keyword COUNTING, the line is an automated system that can manage multiple jobs. It is suitable for various companies ranging from small-size to large-scale operations. If you're going to produce a significant volume of tablets or capsules, investing in such a counting line can greatly boost your production efficiency.

A tablet counting line typically comprises an array of machinery and equipment. These machines are designed to work together to perform counting, filling, capping, sealing, and labeling operations. They can also communicate with each other during the entire process.

What Are The Components Of A Tablet Counting Line?

A tablet packaging line is designed to perform multiple tasks. It consists of a group of machinery and equipment interlinked to complete the packaging process. Typically, machines included in a standard tablet counting line are:

1. Bottle Unscrambler

|

|

A bottle unscrambler is the starting point of a tablet counting line. This vital component is used to efficiently arrange and feed empty bottles onto the counting line. It helps ensure a continuous and organized bottle infeed to the next station.

2. Bottle Air Rinser

|

After the bottle unscrambler organizes the bottles, they are transferred by a conveyor to the cleaning station. That's where a bottle air rinser steps in. The rinser uses compressed air to remove dust, debris, and any contaminants inside the bottles. This crucial step ensures that each bottle is clean and ready to be filled with tablets or capsules.

3. Desiccant Inserter

Next, we have the desiccant inserter. This specialized machine plays a crucial role in the pharmaceutical and packaging industries. It inserts desiccant packets into the bottles after they are conveyed out of the cleaning station.

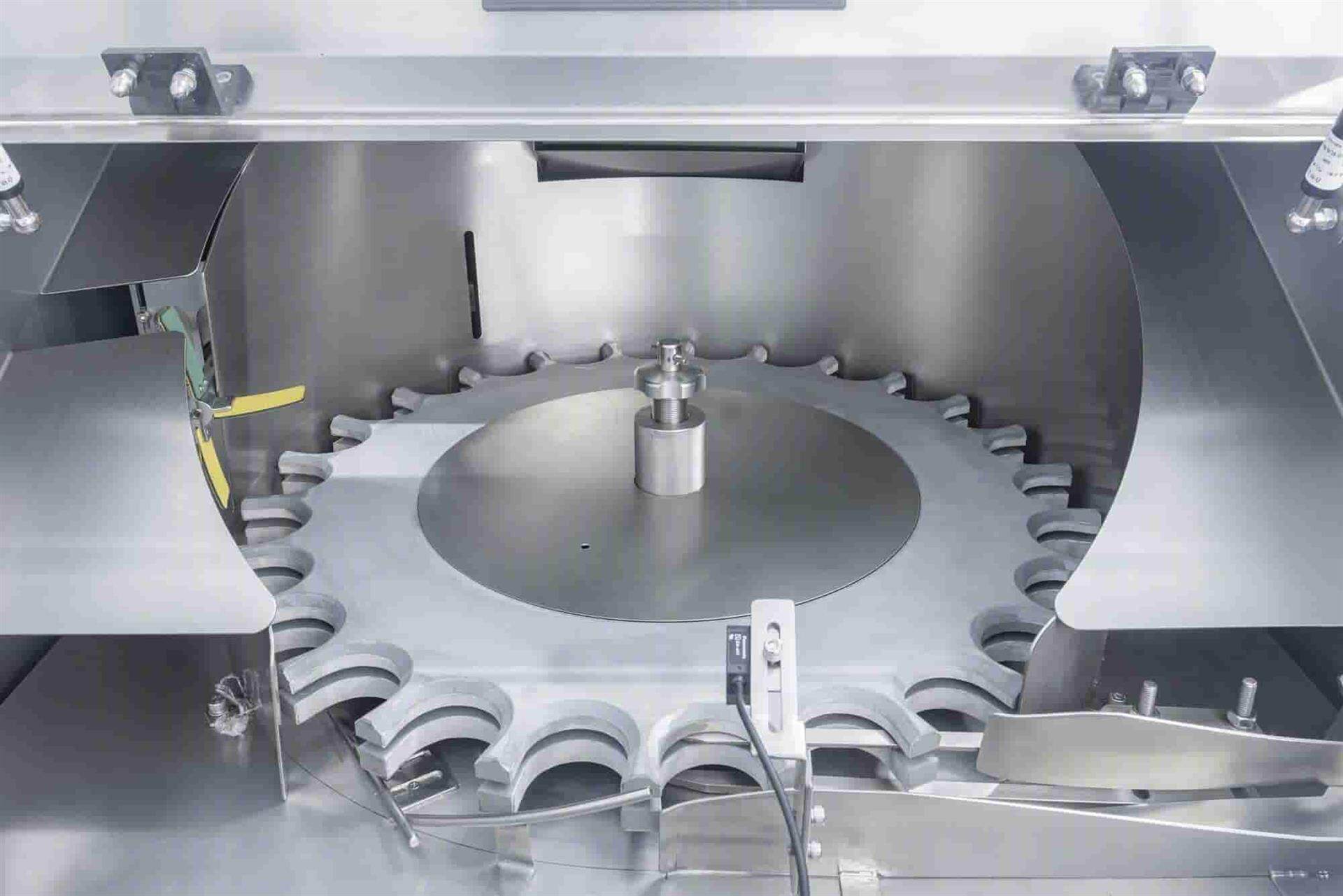

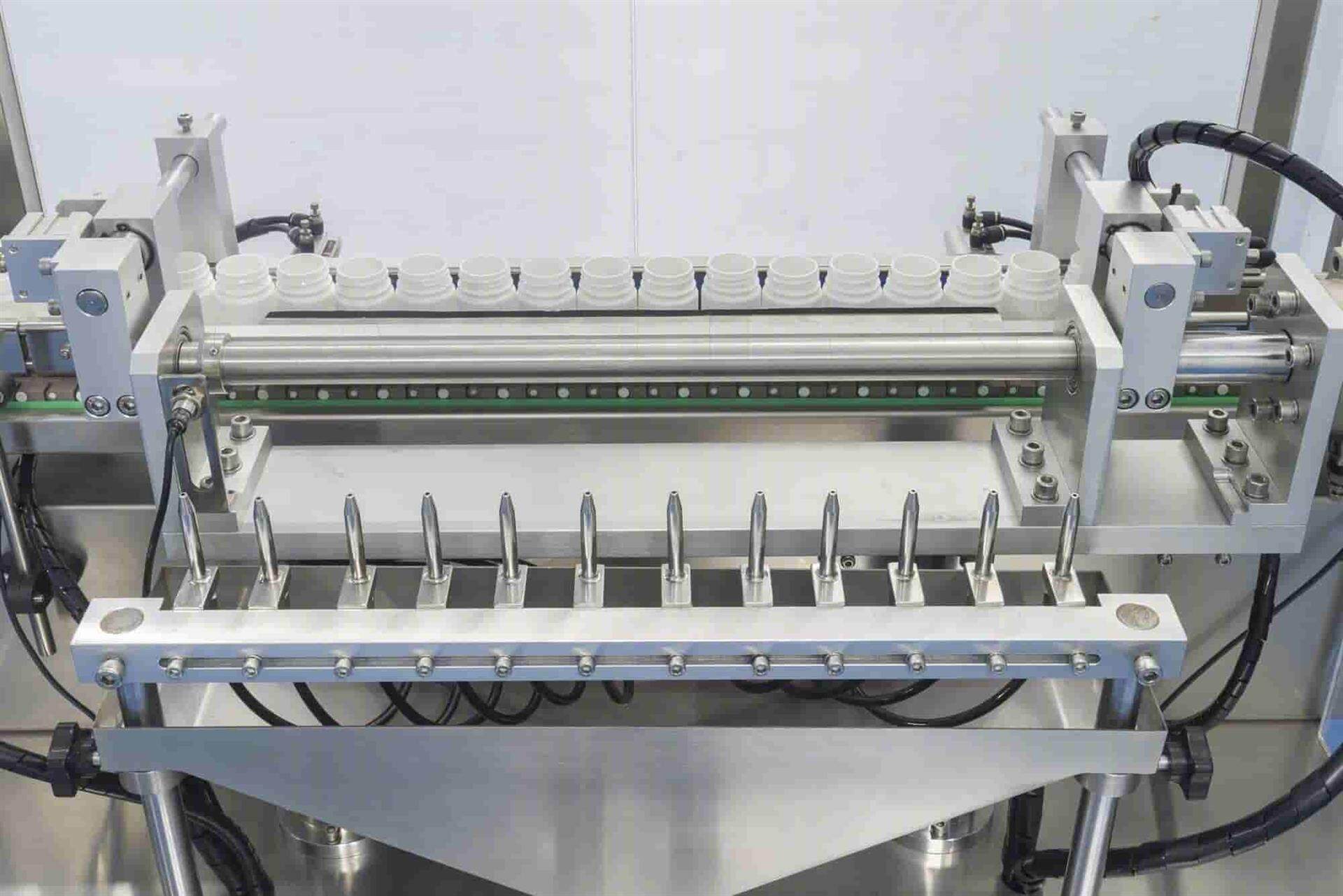

4. Tablet Counting Machine

Now, here comes the most important component - a tablet counting and filling machine. This automated device uses advanced photoelectric sensors to accurately count tablets or capsules. It also comes with the functionality of filling these oral solids into the bottles at a high speed. The tablet counting and filling machine minimizes manual counting errors and maintains the product's consistency.

5. Inline Capper

The filled bottles then travel to an inline capper via the conveyor. The inline capper is an indispensable piece of equipment in the counting line. It's designed to securely seal the bottles with threaded caps. This vital component provides a tight, tamper-evident closure, preventing the product from contamination.

6. Induction Sealer

Moving along the tablet counting line, we encounter the induction sealer. This specialized device uses electromagnetic induction to produce heat and create a hermetic seal on the capped bottles. This machine further ensures the safety and integrity of the pharmaceutical or supplement product.

7. Labeling Machine

|

A labeling machine is another essential component of the counting line. It applies labels to the sealed bottles. The machine ensures that each bottle is labeled correctly to enhance product identification.

8. Accumulation Table

|

|

The accumulation table is often positioned at the end of the line. It functions as a buffer zone to prevent bottlenecks in production. The device also helps ensure a smooth flow of finished bottles for further packaging.

10 Things To Consider When Buying A Counting Line

Purchasing a counting line can be a simple or complex game. This depends on how much homework you've done. To ensure you find the right machines for your production needs, there are several key things to always keep in mind.

1. Cost

Investing in a tablet counting line is a big deal since you need to buy multiple pieces of equipment rather than a single machine. So, it's essential to consider the initial purchase price, installation costs, ongoing maintenance, and operational expenses.

2. Compatibility

Finding a single machine that fits your production needs might be easy. Yet, ensuring each piece of equipment on a counting line is compatible with your product can be challenging. So, be sure to do your homework before buying. Choose machines that work well with your tablets or capsules to be counted and packaged.

3. Production Capacity

Carefully evaluating your manufacturing needs before buying a tablet counting line is important. If the line is incapable of counting and packaging tablets on demand, it will cause production delays and even revenue loss. On the other hand, if the line is over-capacity, it can be a waste of resources.

4. Flexibility

If you're now in the market for a counting line, you definitely intend to produce more than one solid dosage form. Look for equipment that features simple, fast changeover. They can adjust to different bottle sizes, tablet shapes, and packaging requirements. A flexible packaging line can improve overall efficiency and reduce the cost in the long run.

5. Integration

Smooth coordination between different devices on a counting line is critical. Ensure the upstream and downstream machines, such as the tablet counting machine, inline capper, and labeling machine, are seamlessly connected. Integration can optimize the overall workflow and minimize the risk of errors.

6. Safety Features

A tablet packaging line comprises a group of mechanical devices, which means operators have to be exposed to a working environment with many more electrical components and moving parts. This may double and even triple the potential hazards to operators. So, ensure that each piece of equipment has necessary safety features in place, including safety guards, interlocks, and emergency stop buttons.

7. Regulatory Compliance

Ensure each piece of equipment on the tablet counting line meets your local regulatory requirements, such as GMP, cGMP, 21 CFR Part 11, and more. Look for machines that meet the necessary standards to ensure the safety and efficacy of your product.

8. Maintenance and Technical Support

Ask suppliers for maintenance and support packages for each machine on the tablet counting line. These services should be specifically designed for your counting line.

9. Energy Efficiency

Sustainability is a hot topic in today's pharmaceutical industry. Using energy-efficient equipment can reduce carbon footprint, helping protect the earth. Inquire about the energy consumption of the counting line and its impact on your overall production costs and environment.

10. Future Expansion

Counting lines that are designed with future expansion in mind can easily adapt to changing business needs. They are built to accommodate increased capacity or integrate new equipment. Choosing a scalable counting line is also a cost-effective move if you have long-term growth plans.

Applications Of A Counting Line

A counting line is used for counting and packaging tablets, capsules, pills, and other solids in an automated manner. The machines included in the line are responsible for smooth processes such as counting, filling, capping, and labeling. This type of counting line is commonly used in a wide spectrum of industries:

- Pharmaceuticals

- Nutraceuticals

- Dietary Supplements

- Food

- Cosmetics

- Agriculture

- Chemicals

Let's Get Started With The Best Tablet Counting Line Today!

If you don't know where to start, iPharMachine is here for all your tablet counting and bottling needs. At iPharMachine, we offer a wide array of tablet packaging solutions. They vary in terms of production speed, capacity, and levels of automation.

All these lines can be customized to serve your specific needs. Based on your business size, our dedicated sales team will recommend the solution that suits you best.

Automatic Capsule/Tablet Counting and Bottling Line

This counting line has a series of stations linked together to perform multiple tasks automatically. It completes processes from bottle unscrambling, cleaning, capsule/tablet counting and bottling, capping, labeling, and cartoning to overwrapping.

The PBDS series tablet counting machines play a key role in this line. These automatic counters count and fill capsules or tablets into bottles at high speed. This capsule/tablet counting and filling line can significantly increase the overall efficiency while reducing labor costs.

Semi-Automatic Capsule Counting and Filling Line

Compared to the automatic counting line, this semi-automatic capsule counting and filling line is provided with different types of equipment. These stations work in sync to complete the tasks such as capsule filling, polishing, inspection, counting, bottling, capping, sealing, and labeling.

This capsule counting and filling line utilizes the CDR-3A Capsule/Tablet Counting Machine as the key component. This machine can count 1000-1200 tablets/capsules per minute, making the counting line suitable for small to medium-scale production. The downside? This counting line requires human intervention during the process. So, we suggest you consider the labor costs before deciding to add this line to your facility.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche