Basic Tablet Counting Machine Parts You Should Know

When you're in the market for an efficient tablet counting solution, you'll find a wide range of machines with diverse looks. While these tablet counting machines vary in terms of designs, they share the same basic parts.

Understanding the basic tablet counting machine parts is an essential skill for beginners to master. Even if you're an experienced player in the tablet counting world, you will benefit from a refresher now and then. Taking your time to get familiar with tablet counting machine parts and their functions will make you confident in pharmaceutical manufacturing in the long run.

This post will help you familiarize yourself with the tablet counting machine parts. After the reading, you will know how to work with them and safely troubleshoot tablet counting issues.

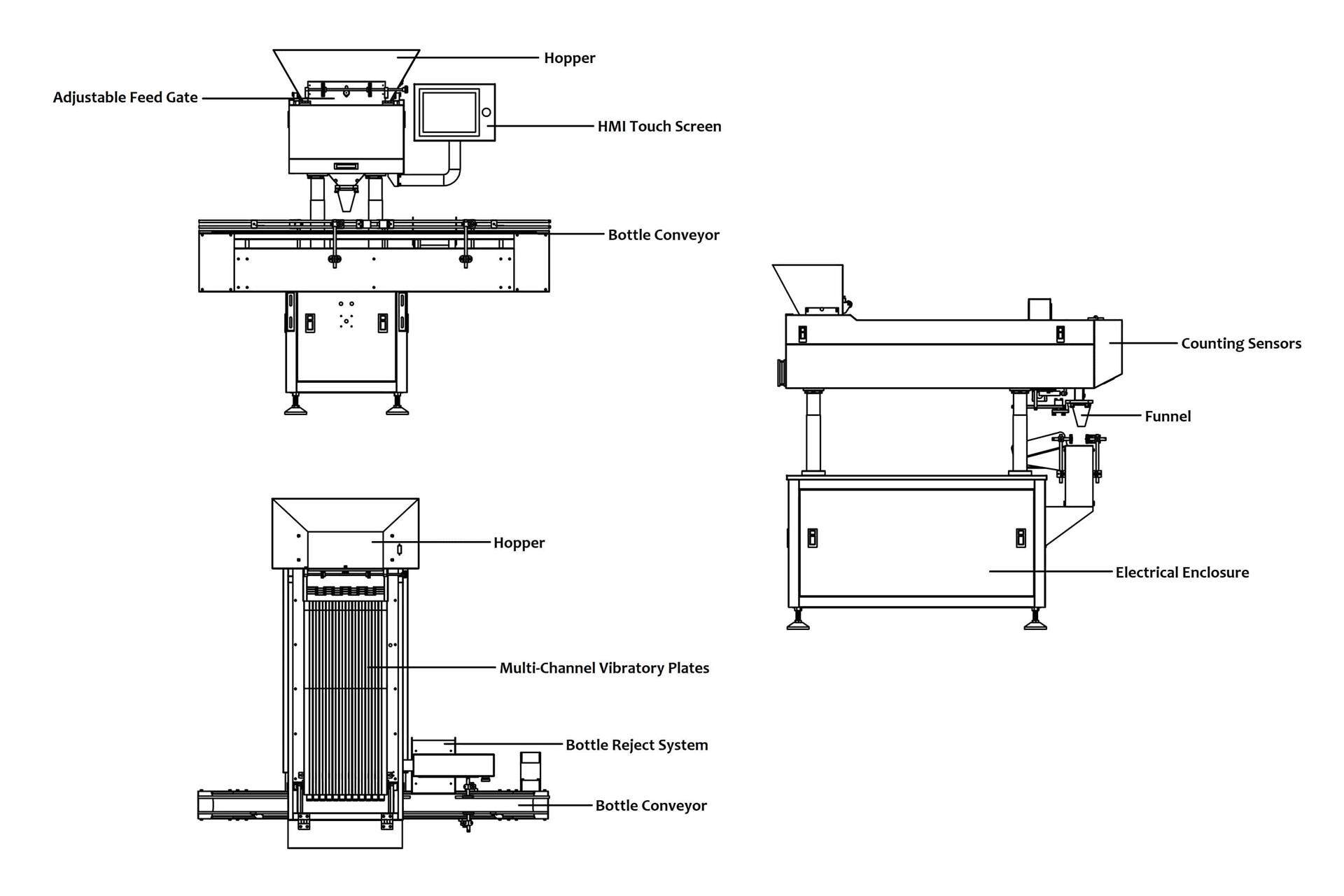

Tablet Counting Machine Diagram

Visualizing how a tablet counting machine works can make understanding its components and functions even easier. Below, we've provided a simplified three-view diagram of the machine. This drawing outlines the essential tablet counting machine parts. These elements come together to create a seamless counting process. Let's take a closer look!

What Are the Essential Tablet Counting Machine Parts?

Continuing from our previous discussion about the tablet counting machine diagram, let's now dive into a detailed exploration of the essential components. Understanding each part's features lets you know how these elements make the machine operate. Also, you'll be better equipped to evaluate different tablet counting machines on the market. So, without further delay, let's explore the basic counting machine parts:

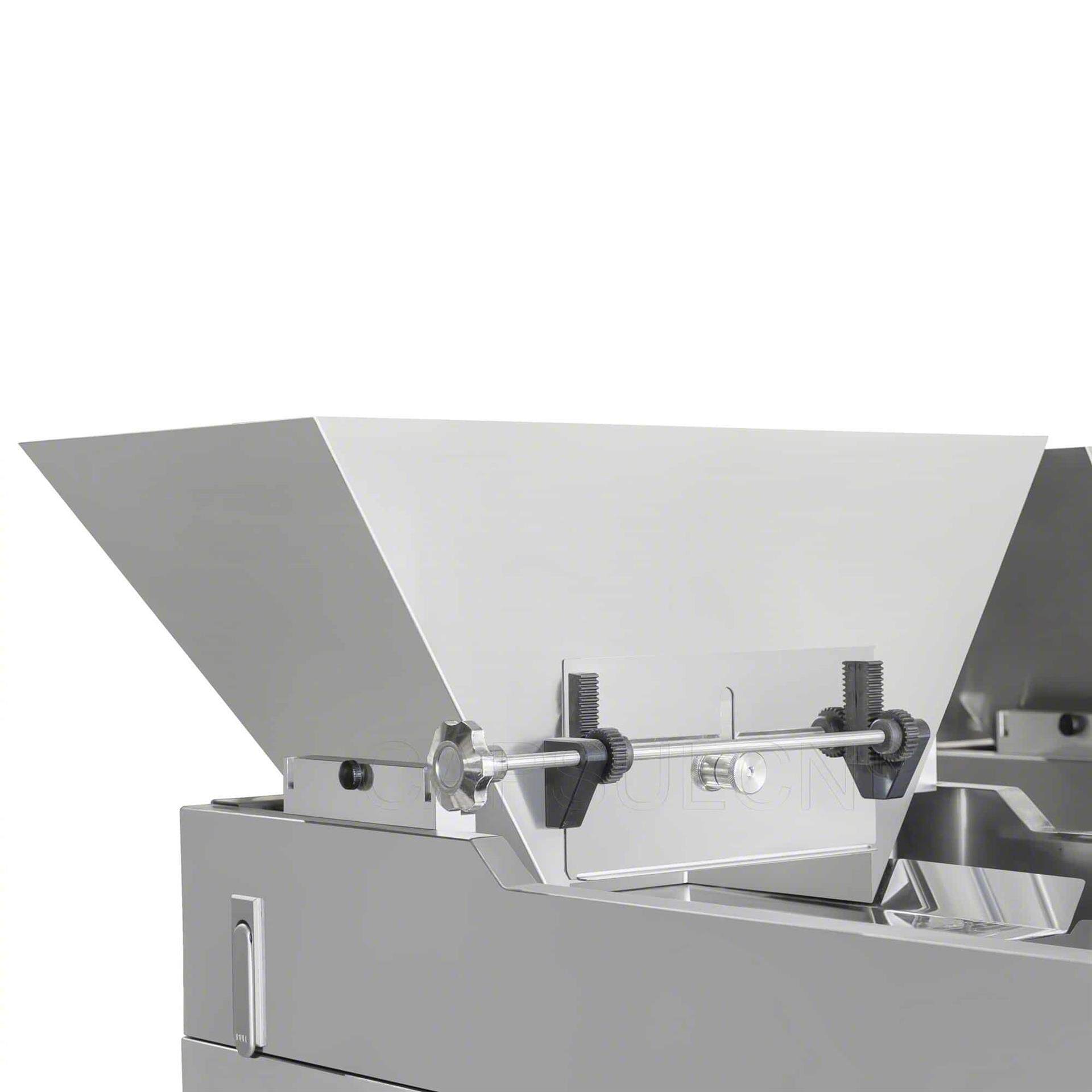

1. Hopper: Feeding the Tablets

A hopper in a tablet counting machine stores and feeds the tablet to be counted into the machine. The component is where the tablet counting process begins. The tablets can be loaded into the hopper manually or using an automatic loading device.

The hopper features a vibration-feeding design. This ensures a continuous and controlled supply of tablets for counting. The design also prevents jams and provides a smooth flow of tablets to the next stage. In some advanced models, the hopper is equipped with a level sensor to detect the level of tablets inside it.

2. Adjustable Feed Gate: Precise Tablet Flow

An adjustable feed gate is an essential part of the hopper. It's positioned at the bottom of the hopper. As the name suggests, the gate's position can be manually raised or lowered to adjust the opening for tablets to leave the hopper.

The adjustable feed gate is designed to ensure a steady tablet feed. This component regulates the tablet flow from the hopper to the vibratory plates. Adjusting the opening can control the number of tablets entering the machine. It facilitates optimal tablet feeding and prevents overloading.

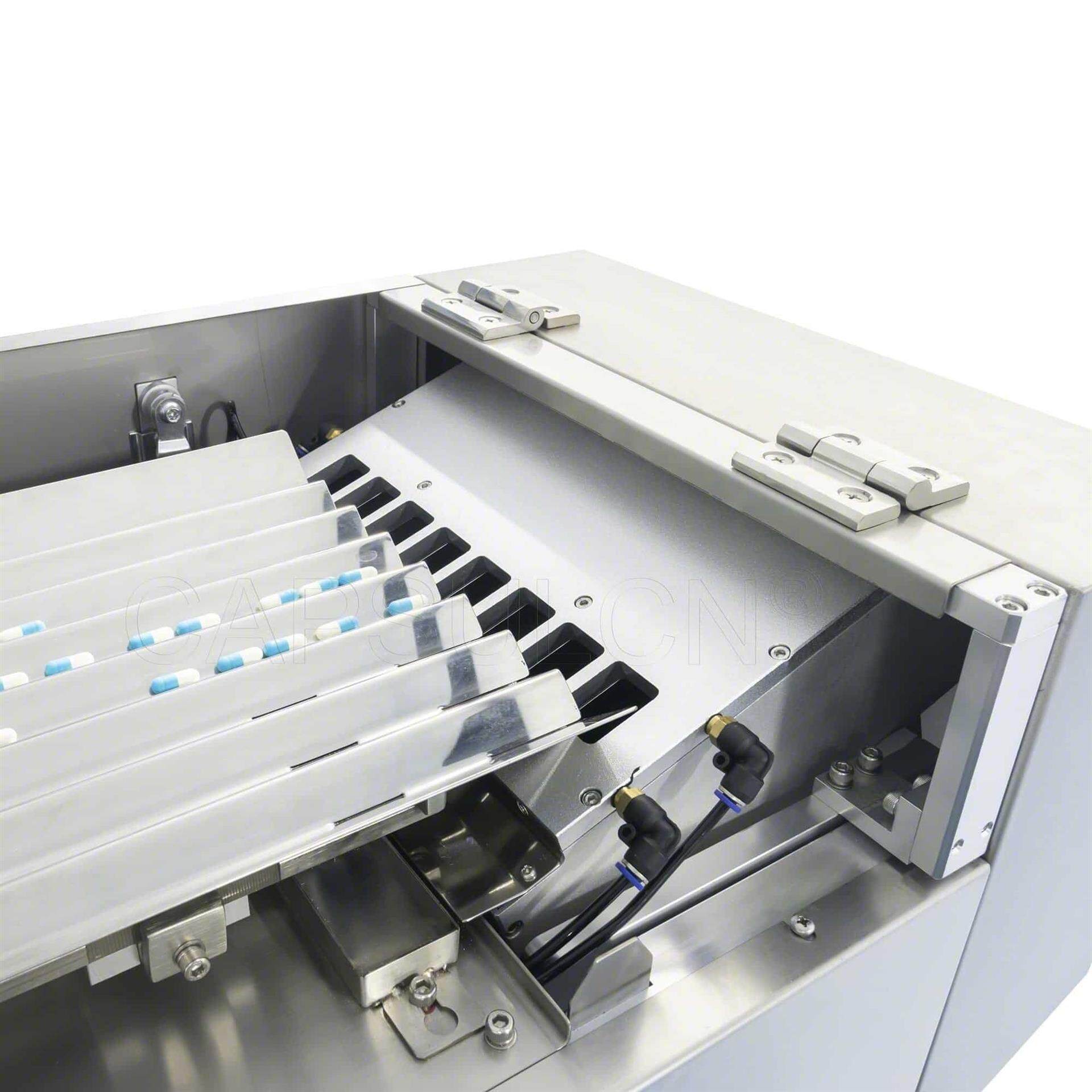

3. Vibratory Plates: Organizing the Tablets

Vibratory plates are one of the critical counting machine parts. They're installed beneath the adjustable feed gate. Vibratory plates are typically designed with multiple channels to hold and separate the tablets entering from the hopper.

These plates work on the principle of vibration to keep the tablets organized and separated from each other. This ensures tablets are not stacked together, which is crucial for accurate counting. The plates use controlled vibrations to transfer the tablets to the counting mechanism.

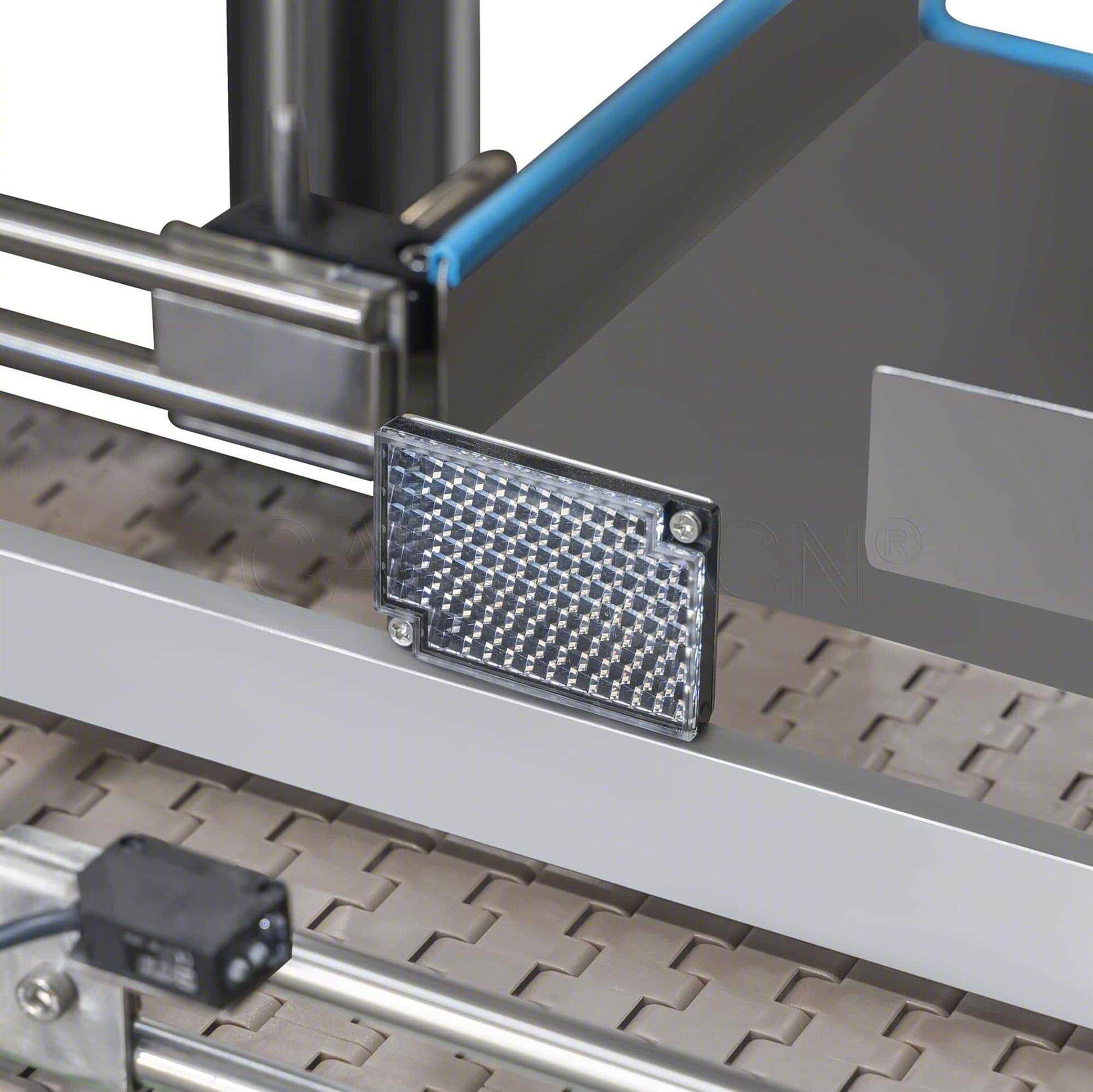

4. Counting Sensor Heads: Accurate Detection

Counting sensors lie at the heart of tablet counting machine parts. These critical components are located in a row of square holes. These square holes are beneath the last vibratory plate and aligned to the channels of the plate. They are used to receive the dropped tablets for counting.

Photoelectric sensors are also referred to as photo eyes. They're responsible for detecting the presence and passage of each tablet falling into the square holes. This component ensures accurate tablet counting by "seeing" every tablet traveling through the counting mechanism.

5. Filling Funnel: Guiding Tablets

A funnel in the tablet counting machine acts as a filling nozzle. It guides the counted tablets to a bottle or other packaging container. The funnel aligns with the bottle neck finish to discharge the tablets.

The funnel may be made of plastic or stainless steel as required. Its mouth can be customized depending on the bottle neck finish size. This helps reduce the risk of spills and ensures every tablet is discharged into the bottle.

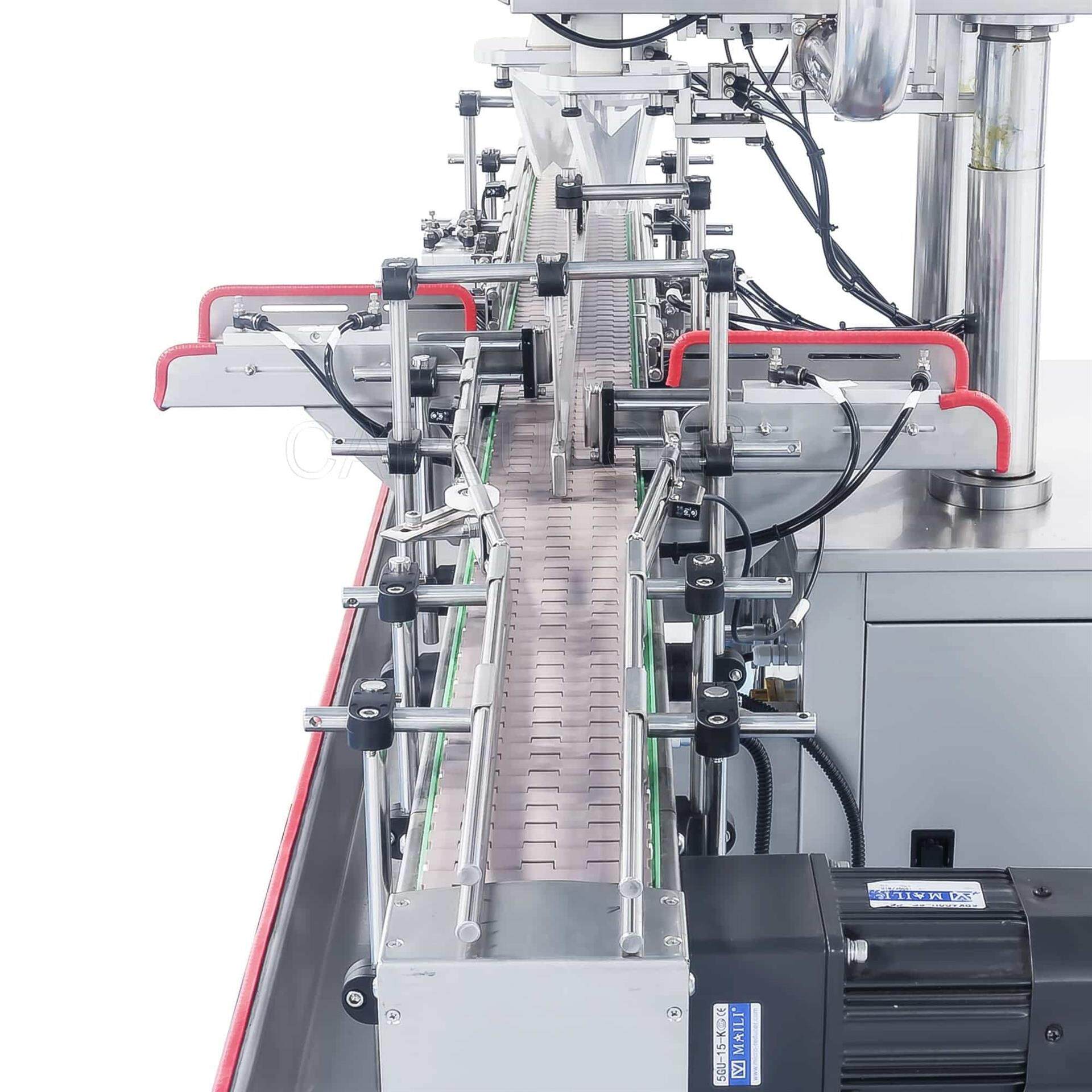

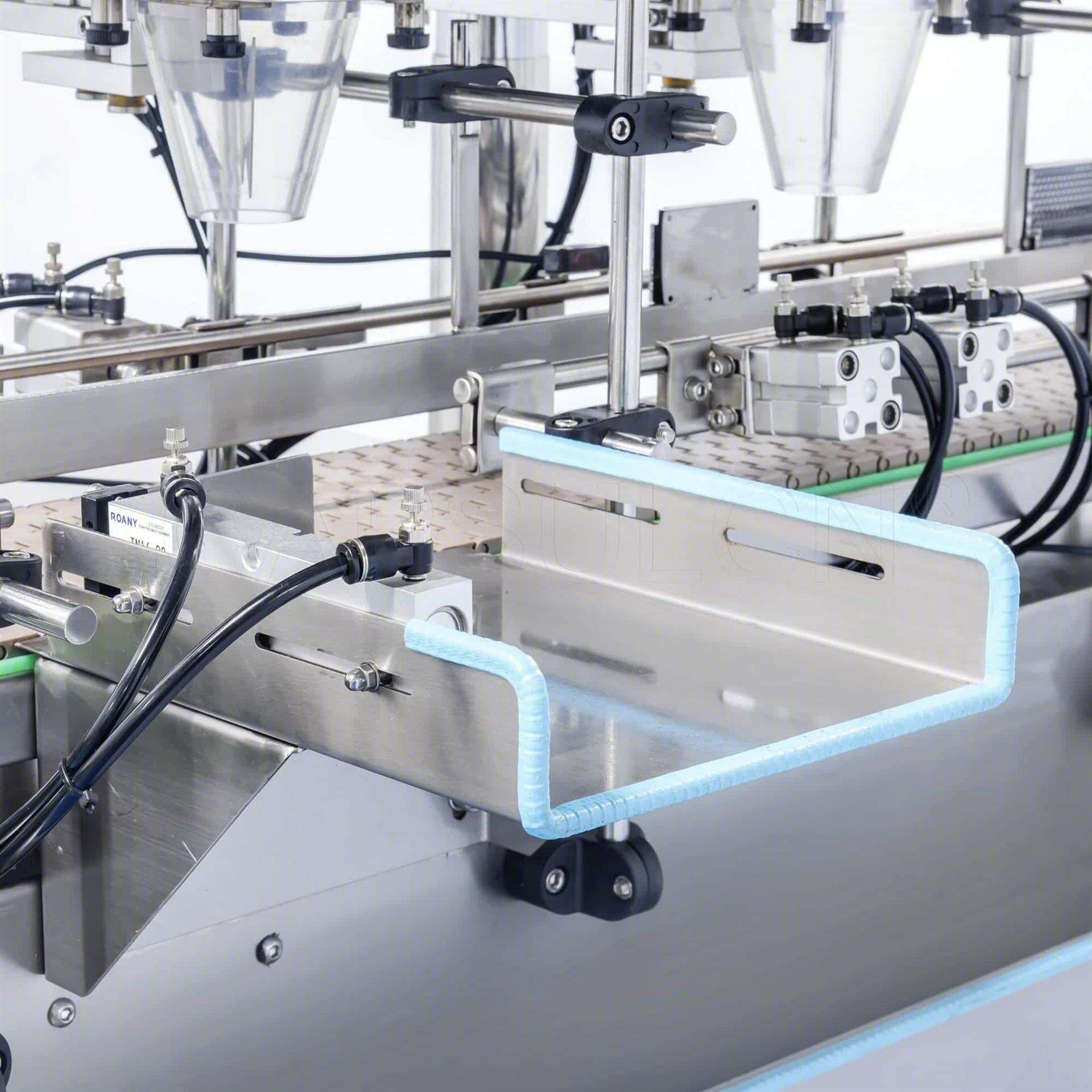

6. Bottle Conveyor: Controlled Movement

A bottle conveyor transports bottles or other packaging containers to be filled with tablets. The conveyor synchronizes with the counting process. This ensures the counted tablets drop into the correct containers at specific intervals.

7. Photoelectric Sensors: Verifying Presence of Bottles

These photoelectric sensors refer to the photo eyes installed along the bottle conveyor. They play a role in detecting the bottles' presence, position, and orientation on the conveyor. The sensors can identify upside-down bottles, fell bottles, and bottles with counting errors. They are used to ensure the efficiency of bottling operations.

8. Bottle Reject System: Ensuring Quality

To guarantee the accuracy of tablet counting and filling, you need a tablet counting machine equipped with a reject system. This system is generally incorporated with the bottle conveyor. When any upside-down bottles, fell bottles, or bottles with filling errors are identified, the reject system will remove these bottles from the conveyor. This step ensures product integrity and smooth running of the bottling line.

9. HMI Touchscreen: User-friendly Operation

An HMI (Human-Machine Interface) touchscreen is one of the essential counting machine parts. It provides a user-friendly interface for operators to monitor and control the tablet counting and filling process.

The PLC-based HMI displays process parameter settings and real-time machine status. It also provides alerts or warning signals when any error occurs. This component allows operators to quickly adjust settings and resolve issues during operation.

10. Electrical Enclosure: Safety and Protection

An electrical enclosure is used to house all electrical components of a tablet counting machine. It's responsible for safeguarding these components from external elements and protecting operators from electrical hazards. The enclosure is often lockable to prevent unauthorized access.

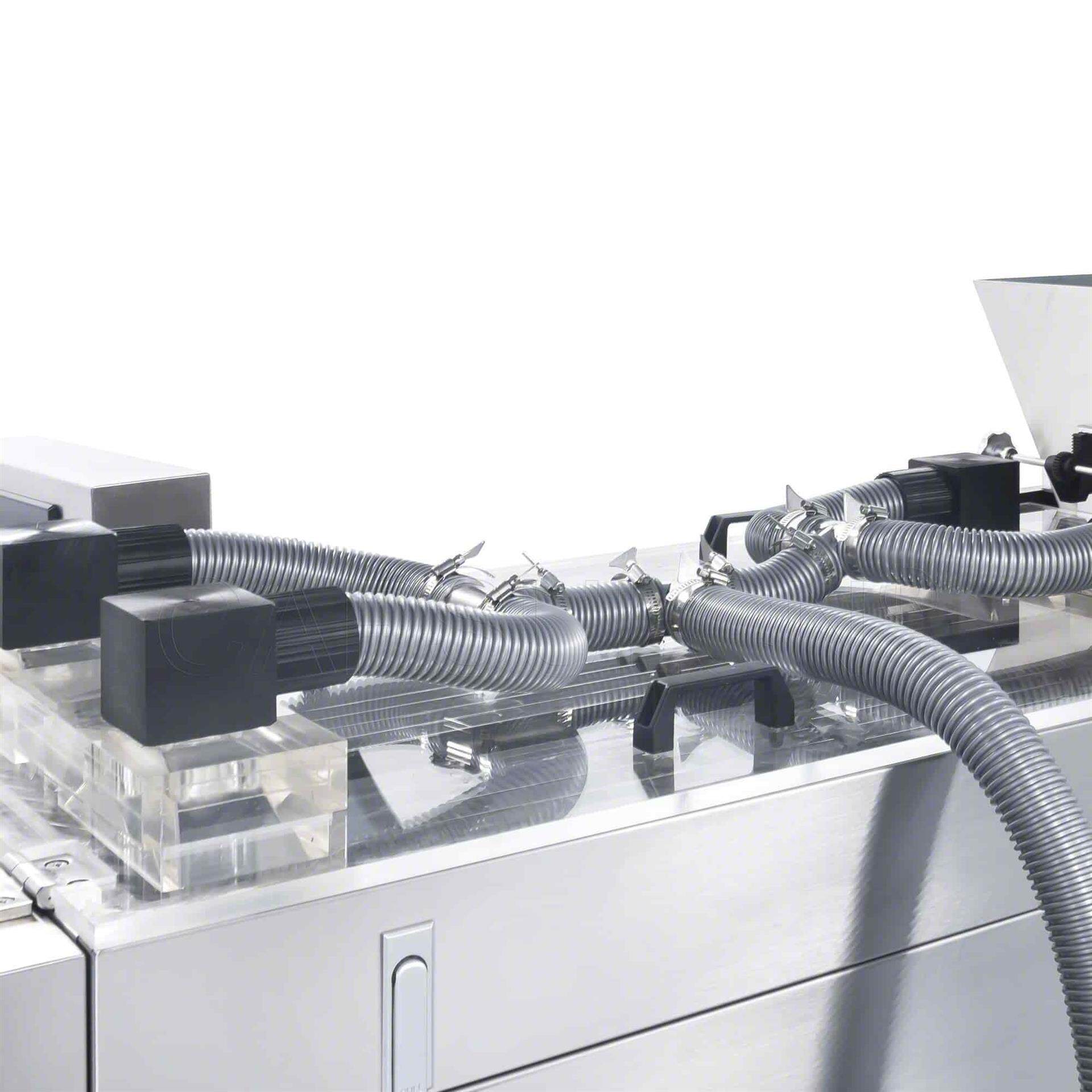

11. Dust Extraction Manifold: Maintaining Cleanliness

Pharmaceutical manufacturing processes may generate dust. The dust can expose operators to a harmful environment and contaminate the final product. So, a dust collection system is vital for keeping the manufacturing facility clean and safe.

The dust extraction manifold can effectively remove excess dust generated during tablet counting. This protects operators from potential chemical hazards and prevents cross-contamination. Additionally, it helps ensure the longevity of the components and parts of the counting machine.

12. Dust Cover: Further Containment

Another essential component to help create a dust-free working environment is a dust cover. This component is typically made of clear plastic, allowing operators to observe the flow of tablets. The dust cover is installed over the vibratory plates and counting sensors and encloses these areas. It works with the dust extraction manifold to further contain dust particles that might be generated throughout the tablet counting process.

The Bottom Line

Having a comprehensive understanding of the various tablet counting machine parts is crucial. With this understanding, you will know the function and importance of each component. This helps achieve optimal tablet counting efficiency. Additionally, the knowledge will empower you to make informed decisions when selecting a tablet counting machine based on your unique requirements.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche