How Does a Tablet Counting Machine Work

Tablet counting always plays a vital role in pharmaceutical manufacturing. But how do those tiny medicine bottles get filled with the exact number of pills every time? To count pills accurately and quickly, tablet counting machines are an efficient tool you should have. Whether you're new to the game or want to streamline your production process, knowing how a tablet counting machine works is essential.

This blog post will break down the counting process into steps. So you will better understand the tablet counting machine principle. Read on to discover how these machines can be game-changing for your tablet packaging needs. Let's dive right in!

What Is A Tablet Counting Machine?

What is a tablet counting machine? A tablet counting machine is a specialized device. It is designed to accurately count and dispense a preset number of pills into various packaging containers.

Tablet counting machines on the market fall into three levels of automation: manual, semi-automatic, and fully automatic. Different types of tablet counting machines feature unique designs and cater to specific needs. Manual counters are suitable for smaller operations. Semi-automatic and fully automatic machines enhance efficiency and accuracy for larger production needs.

Tablet counting machines are primarily used in the pharmaceutical and nutraceutical sectors. Additionally, they are occasionally employed in industries such as food, cosmetics, and small consumer goods.

Tablet Counting Machine Principle

As mentioned above, tablet counting machines are available in three types. Each has its own way of working. Here, we will discuss the tablet counting machine principle in greater detail.

How Does A Manual Tablet Counter Work?

Manual tablet counters come in various designs. Some require a spatula to perform counting, while some only need a few shakes of the counting tray. No matter the type, the operation of a manual tablet counter relies on human intervention.

This section will focus on the manual tablet counter featuring holes. The holes represent the desired tablet count. Here's a detailed breakdown of the tablet counting machine principle:

Step 1: Tablet Loading onto the Flat Tray

To begin the counting process, operators manually pour the tablets onto a flat tray of the manual tablet counter. The tray provides a visible surface for tablets to be spread out. This facilitates an organized counting process.

Step 2: Shaking to Filling the Holes

The tray boasts small holes or openings that correspond to the desired tablet count. After tablets are placed on the tray, operators gently shake the tray back and forth. This motion helps the tablets settle into these holes. Each hole accommodates a single tablet.

Step 3: Continuous Shaking to Remove the Excess Tablets

Operators continue shaking the tray. This action helps to remove any excess pills that might be present on the tray's surface.

Step 4: Releasing Tablets into the Chute

Once the holes are filled with tablets, operators squeeze a handle or lever connected to the tray. This action triggers the release of tablets from the holes and guides them into a chute.

Step 5: Dispensing into a Bottle

To complete the counting process, operators tilt the tray slightly. This action allows the tablets released to slide down the chute and fall into a waiting bottle.

How Does A Semi-Automatic Tablet Counting Machine Work?

Semi-automatic tablet counting machines represent a harmonious blend of manual and automated processes. Compared to the manual method, they optimize accuracy and efficiency in the tablet counting and packaging journey. The tablet counting machine principle is as follows:

Step 1: Manual Tablet Loading into the Feeding Hopper

The counting process begins with operators manually pouring tablets into a specially designed feeding hopper. This hopper serves as the entry point for the tablets into the machine. The hopper's design includes a vibration mechanism. This component gently agitates the tablets to prevent clustering and ensure an even flow.

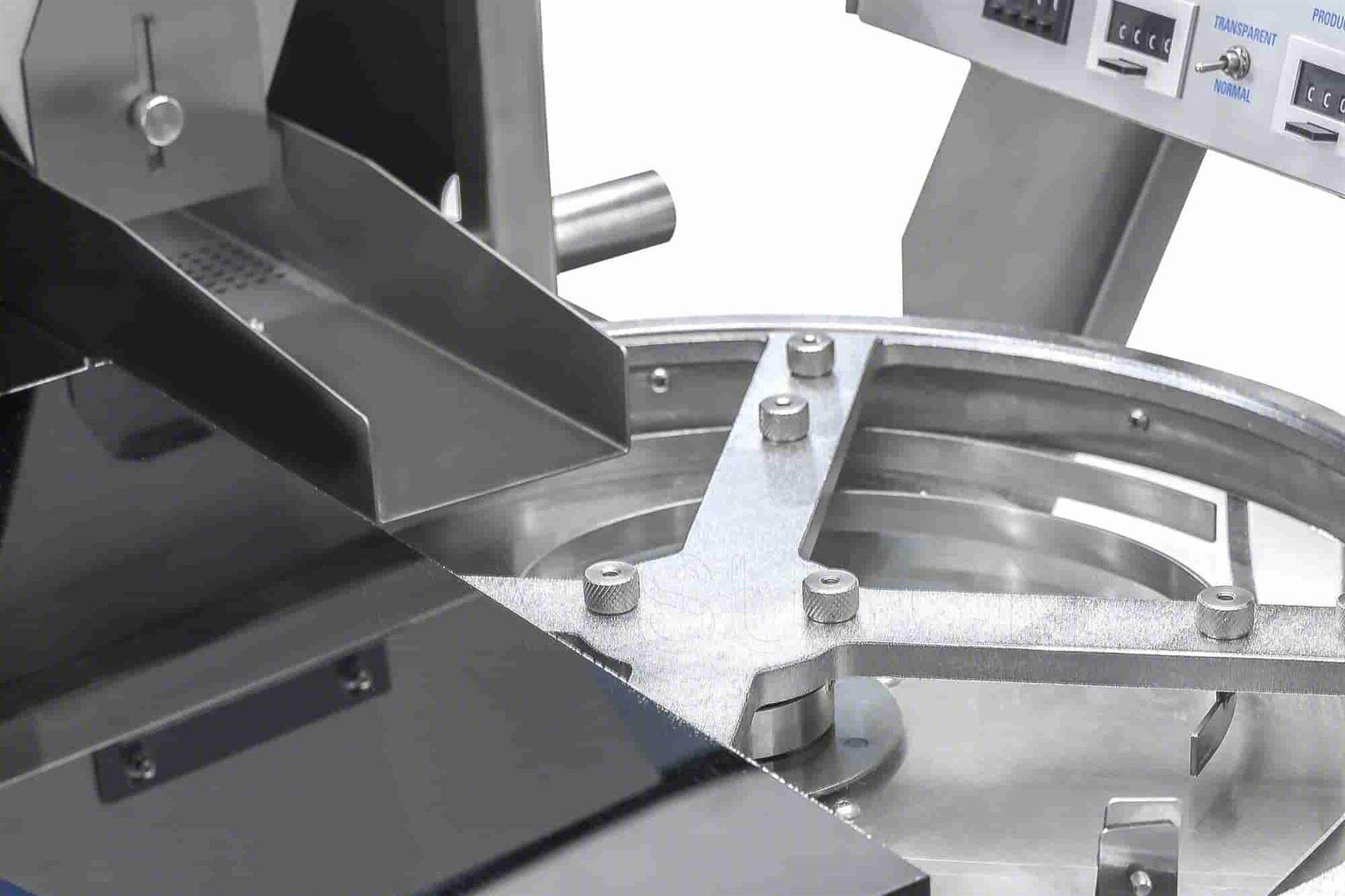

Step 2: Tablet Transfer onto the Turntable

Tablets from the feeding hopper are directed onto a turntable. This turntable acts as a rotating platform. It efficiently carries the tablets through the counting process. The turntable is equipped with a photoelectric sensor. This sensor detects each tablet's presence as it passes by, ensuring precise tracking.

Step 3: Tablet Transfer to Discharge Funnels

As the turntable continues to rotate, it carefully transfers the tablets to individual discharge funnels. These funnels are positioned around the turntable's periphery. Just above each discharge funnel is another sensor. The sensors meticulously detect the tablets as they are guided into these funnels.

Step 4: Accurate Counting and Bottling

Tablets gathered in the discharge funnels are now ready for counting. The sensors above each funnel monitor the passage of tablets, ensuring accurate tablet counts. Once the desired count is achieved, the tablets cascade from the discharge funnels into waiting bottles.

How Does An Automatic Tablet Counting Machine Work?

Automatic tablet counting machines represent the pinnacle of efficiency and accuracy in tablet packaging. They can handle large-scale production volumes with minimal human intervention.

These machines consist of multiple sensors, vibratory plates, and dust extraction systems. All parts and components ensure a precise and streamlined counting process. Here's an intricate exploration of the tablet counting machine principle:

Step 1: Loading Tablets into the Feeding Hopper

In an automatic tablet counting machine, tablets can be manually loaded into the feeding hopper or using a specialized device. This hopper is also packed with a vibrating mechanism to feed tablets into the machine.

Step 2: Tablets Transition to Multiple-Channel Vibratory Plates

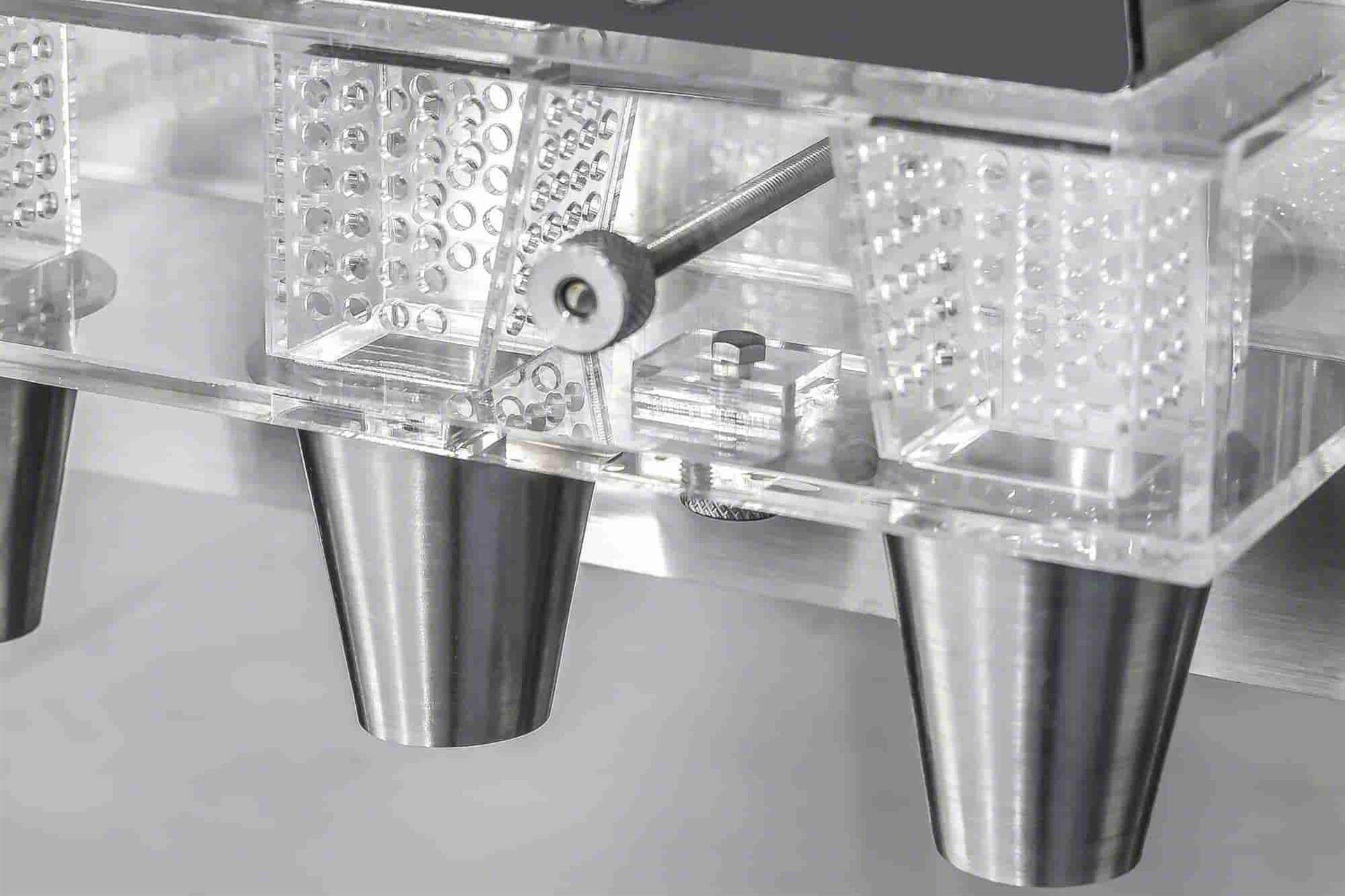

The feeding hopper facilitates the controlled release of tablets onto multiple-channel vibratory plates. These plates engage in rhythmic vibrations that serve a dual purpose: separating tablets that might adhere to each other and aligning them for precise counting.

Step 3: Guiding Tablets to the Discharge Chute

Tablets, now separated and aligned, journey through the multiple-channel vibratory plates. The vibrations guide them along the designated paths to the discharge chute for further processing.

Step 4: Counting and Dispensing Tablets with Sensor Heads

Positioned atop each discharge funnel is a sensor head. This is a critical component responsible for tablet counting. As tablets cascade down the discharge chute, the sensor head accurately detects their passage and makes counts. The sophisticated sensor technology delivers precise counting, thereby guaranteeing that the desired number of tablets is dispensed.

Step 5: Bottling and Conveyor Transfer

With the accurate count confirmed, the sensor-controlled mechanism orchestrates the release of tablets. The desired number of tablets fall into bottles awaiting under the discharge funnels. These bottles are transferred by a conveyor system. After filling, the bottles are conveyed to the next processing station, contributing to a seamless production workflow.

SOP For Operation Of Tablet Counting Machines

Unlike manual and semi-automatic machines, fully automatic tablet counting machines are more complex. They have more intricate mechanisms that require specialized knowledge and training to operate.

With the understanding of the tablet counting machine principle, an SOP will help you to use the machine more safely and correctly. And most importantly, you can get accurate tablet counts by following the SOP.

So let's take a closer look at the tablet counting machine SOP.

Objective: Using an automatic tablet counting machine to ensure accurate and efficient tablet counting.

Scope: This SOP outlines the step-by-step process for operating an automatic tablet counting machine.

Equipment and Materials:

- Automatic tablet counting machine

- Tablets for counting

- Packaging containers

- Necessary safety gear (gloves, safety goggles, etc.)

Procedure:

Preparation:

- Read through the machine's user manual and safety precautions.

- Ensure the automatic tablet counting machine is clean, calibrated, and properly working.

- Prepare the tablets to be counted and the required packaging containers.

Startup:

- Power on the machine according to the instructions.

- Ensure that all safety guards are in place.

Tablet Loading:

- Load the tablets into the feeding hopper. Adhere to the machine's loading capacity to prevent overloading.

Setting Parameters:

- Set the desired tablet count and other relevant parameters on the machine's control panel.

Initiating the Counting Process:

- Press the start button to begin the counting process. Follow the machine's operating procedures.

Monitoring:

- Observe the tablet flow through the feeding hopper. Ensure the tablets are properly separated and aligned on the multi-channel vibratory plates.

- Continuously monitor the counting process. Check for any blockages or errors. Address any issues promptly.

Quality Check:

- Periodically check a sample of counted tablets for accuracy against the set count. Adjust settings if necessary to ensure accuracy.

Dispensing into Packaging Containers:

- Once the desired count is achieved, tablets will be released into the discharge funnels.

- Ensure that the packaging containers are properly positioned under the funnels.

Completing Packaging:

- Observe as tablets are filled into the packaging containers. Ensure that the count is accurate and consistent.

Shutdown:

- After the counting and filling process, follow the instructions to shut down the machine safely.

- Clean any residual tablets from the machine and dispose of waste material properly.

Cleaning and Maintenance:

- Use an appropriate cleaning agent. Clean all parts and components as per the machine's user manual.

- Perform routine maintenance tasks according to the recommended schedule.

Documentation:

- Record the tablet counting process in the documentation or log, including batch number, tablet count, operator's name, and any issues.

Note:

- Always adhere to the operational instructions and safety precautions. In case of any technical issues or concerns, consult a qualified technician.

References:

- User manual for the automatic tablet counting machine

- Relevant safety regulations and guidelines

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche