Tablet Deduster Machine SZS200: Introduction & Principle

Before installation and use, please read this instruction carefully.

Product introduction

Tablet Deduster Machine SZS200 has utilized many advanced technologies in its creation. This top spin sieve machine is able to act as both elevating and dedusting machine, which made it an unusual combination with other tablet-compressing machine and metal detection machine, and also made it extremely applicable in the filed of pharmacy, chemical engineering, electronics, and food.

Its advantage includes long dedusting path, automatic tablet polish on all sides, and high quality dedusting without damage to the tablet itself. In addition, it can act as a delivering device for any shape of tablet that needs to be dedusted. Best of all, it correspond with the GMP standard.

The machine also used many new designs, to allow and to ensure a better and safer production process.

Principle

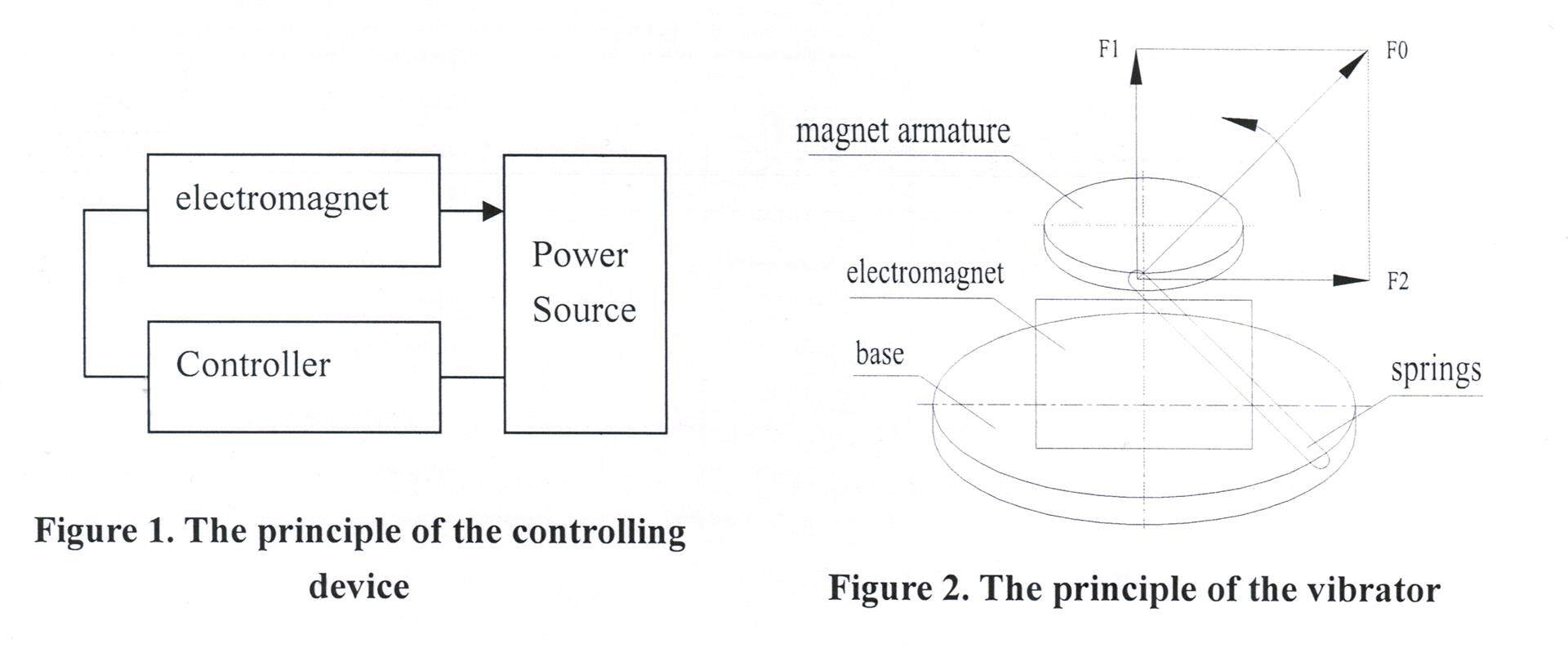

Tablet Deduster Machine SZS200 utilizes an electromagnetic vibrator to vibrate the spiral dedusting body, thus making the tablet to ascend while being polished an dedusted by the vibrating movement. Please see figure 1 and 2.

In Figure 2, when the electromagnetic coil is charged, the magnetic force (F) would cause the magnet armature to move downward, thus forcing the spring compressed. When the electromagnetic coil is not charged, the magnetic force disappears, and the spring would mover the magnet armature back to its original position. The vibrating motion the machine uses to polish and to dedust is the result from repetition of these movement. In other words, when current situation(I) changes, the magnetic force (F) and the restoring force from the spring (F0, F1, F2) would also change accordingly, which would adjusts the movement of the tablet on the spiral dedusting body, and also polish, dedust, and move the tablet upward.

There are also air powered dedusting device located on the side and roof of dedusting body’s outer cover, which serve the purpose of producing cleaner and smoother tablet.

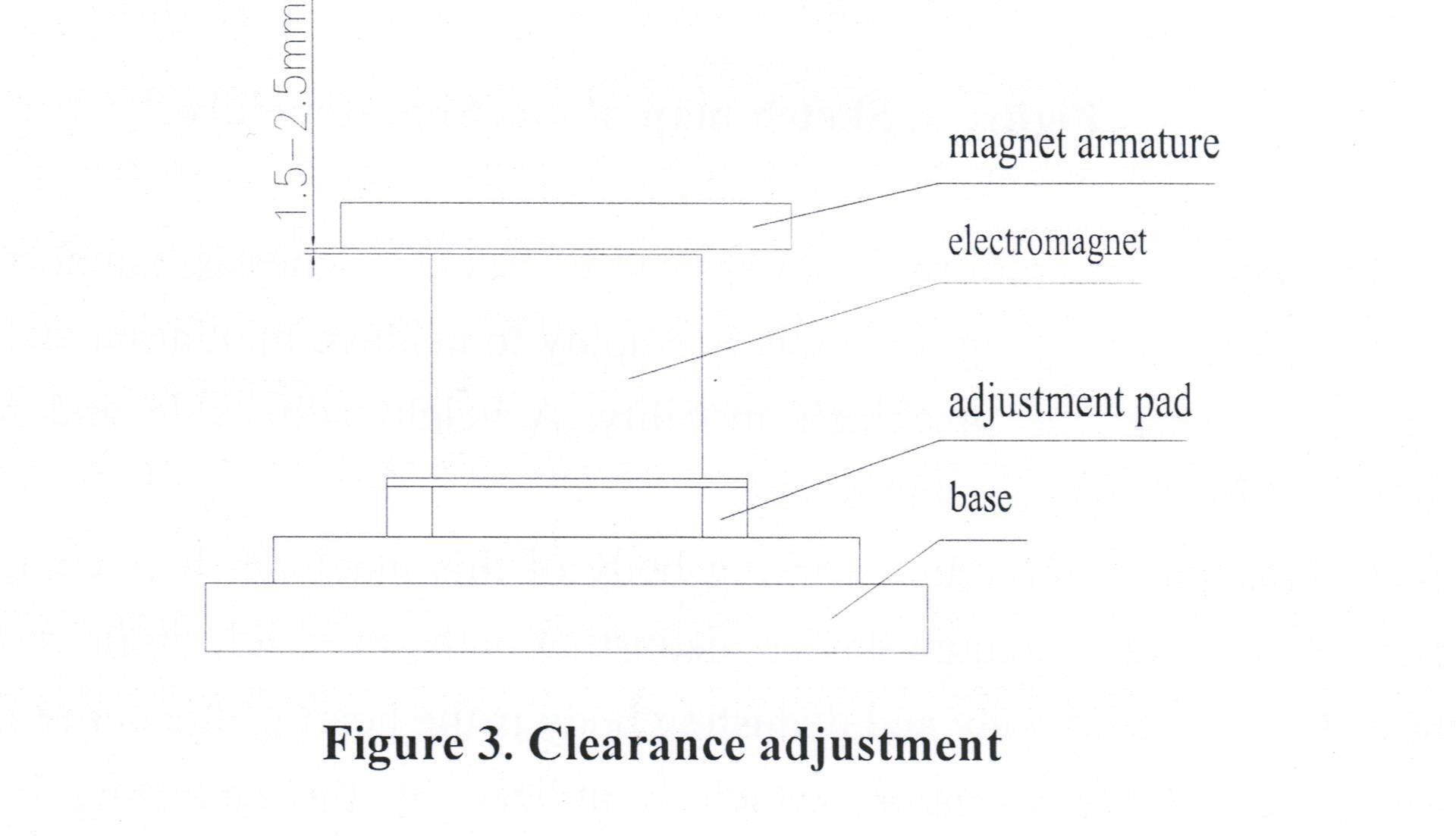

There are empty space, 1.5mm to 2.5mm, between the upper surface of electromagnetic and the lower surface of the magnet armature. See Figure 3.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche