Tablet Deduster Machine SZS200: Environment Condition & Installation

Environment condition

temperature: (18-24) ℃

relative humidity: 40%-50%

environment: anti-corrosion dust-proof

Installation

Opening

Check for damage on packaging when received. If there are, please open the package immediately, and check for damage on the machine and for missing parts. After everything is checked and appeared to be in order, please sign the conformation signature with the shipping company.

Installation

- Check whether the right model is received: SZS230 Uphill Deduster.

- Check whether everything on the packing list is in the package

- Place the machine on level ground

- Carefully clean off the protective oil on the machine’s surface

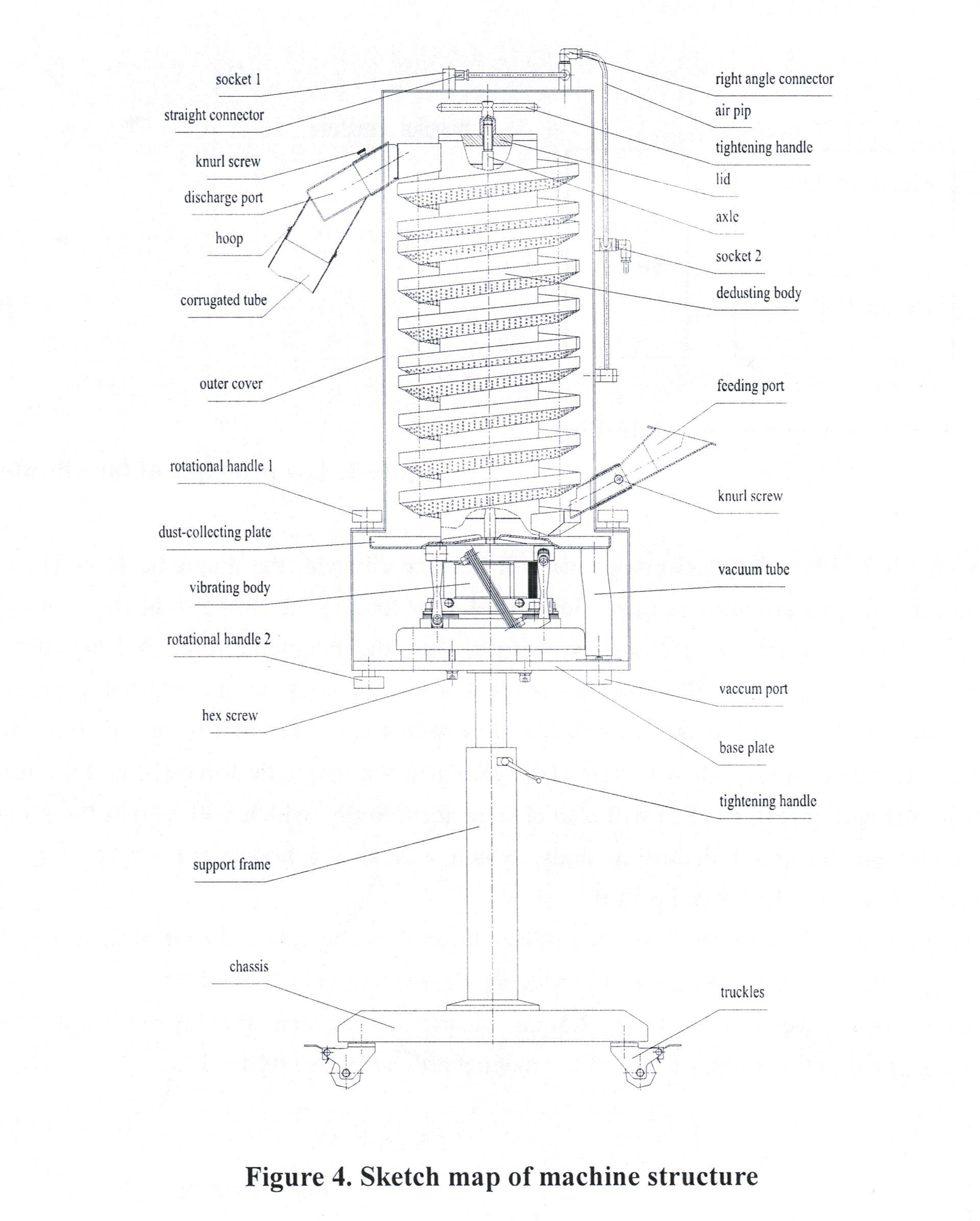

- Make sure to remove the three hex-screws mounted on lower plate, refer to figure 4 if necessary

- Check for loosen parts

- Plug in and test run the machine, check for any abnormity

Operation

When in need of disassembling, please refer to figure 4 and carefully remove machine parts. Especially be careful not to damage removed parts.

Please refer to the following order when disassembling: discharging port, feeding port, rotational handle 1, circular cover, rotational handle 2, square cover, tightening handle, lid, dedusting body, axis, dust-collecting plate, and vacuum tube.

Romove the three hex-screws used to secure dedusting body and main machine during shipping, which are also used to connect the base of the vibrating body and the mobile operating platform. These screws are not needed during reassembling or production. If the vibrating body also needs to be removed, then please first remove its cable from socket, then remove the vibrating body.

Assembling

The Assembling process is exactly the opposite sequence of the disassembling process, however, watch for the following:

- Do not screw the three hex-screw back on, they are for shipping purpose only.

- The socket for cables needs to be near the cable locking tube (on mobile operating platform)

- make sure that the pin on the bottom of dust-collecting plate is matching the hole on the magnet armature

- make sure that all the tightening device are well tightened

- Make sure that the feeding port on the dedusting body matches the feeding port on the outer cover, the same goes for the discharge port.

Checking and Preparing

First, please check the following:

- Check for connections

- Check for plugs and power supplies, and protections around them

- Check for machine’s switch, which needs to be in the off position, and check the speed control knob, which needs to be at lowest vibration speed. For reference, please consult figure 5 control panel.

Then, please do the following preparation:

- Move this deduster next to the discharge port of the tablet compressing machine, and lock the truckles. Then loosen the tightening handle and adjust height to connect the feeding port of this machine with the discharge port of the tablet compressing machine

- Connect the vacuum tube and compressed air tube, then connect the vacuum cleaner and the compressed air supplier

- Prepare a container under the discharge port of this machine, and then plug in the power supply

Test run

Please note that the test run can only be initiated after all the preparation is properly done

- check for the power switch

- throw a few tablet into the feeding port and adjust the speed control knob, observe machine’s operating speed

- Inspect the machine for any abnormal noise and unstable condition

If there are no abnormalities, then adjust the speed control knob and increase operating time to continue the test run

When the test run is complete with out any problems, then the machine can go into full production mode

Operating and emergency stopping

When the test run is complete, the machine can begin its production

Adjust the speed control knob to match the dedusting speed with the production speed of the compressing machine

When the production task is done, first adjust the speed control knob to minimum production speed, then turn off the switch and unplug the machine

What abnormalities happen during production, turn off the switch immediately for emergency stopping of the machine

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche