How Does the Sugar Coating Process Work?

When it comes to pharmaceuticals, tablets are one of the most commonly used solid dosage forms. And there are various types of tablet coating methods, such as film coating, enteric coating. Yet, have you ever wondered why these small pills sometimes taste sweet? It's all thanks to the sugar coating process! Sugar coating is a technique used to improve the appearance and taste of tablets. It can also protect tablet ingredients from external factors.

In this blog post, we'll take a closer look at how the sugar coating process works. We'll explore the steps involved, as well as the pros and cons of using this technique. When you finish reading, you'll have a firmer grasp of how and why your medication gets its sweet shell. Alright, let's just jump into it!

What is Sugar Coating?

Sugar coating is a process used in the pharmaceutical or nutraceutical industry to make tablets look and taste better. It involves applying several layers of sugar syrup to a tablet. This creates a smooth and shiny outer layer.

This coating technique not only makes tablets look more attractive, but it also masks any unpleasant taste and odor of the medication inside. Additionally, the sugar coating can build a barrier for the pills from moisture, air, and other external factors. This can help to increase the shelf life of the medication.

Despite being a time-consuming and costly procedure, the sugar coating process is widely used in pharmaceutical and nutraceutical industries. Its popularity lies in its beneficial effects on the customer experience and the efficacy of tablets.

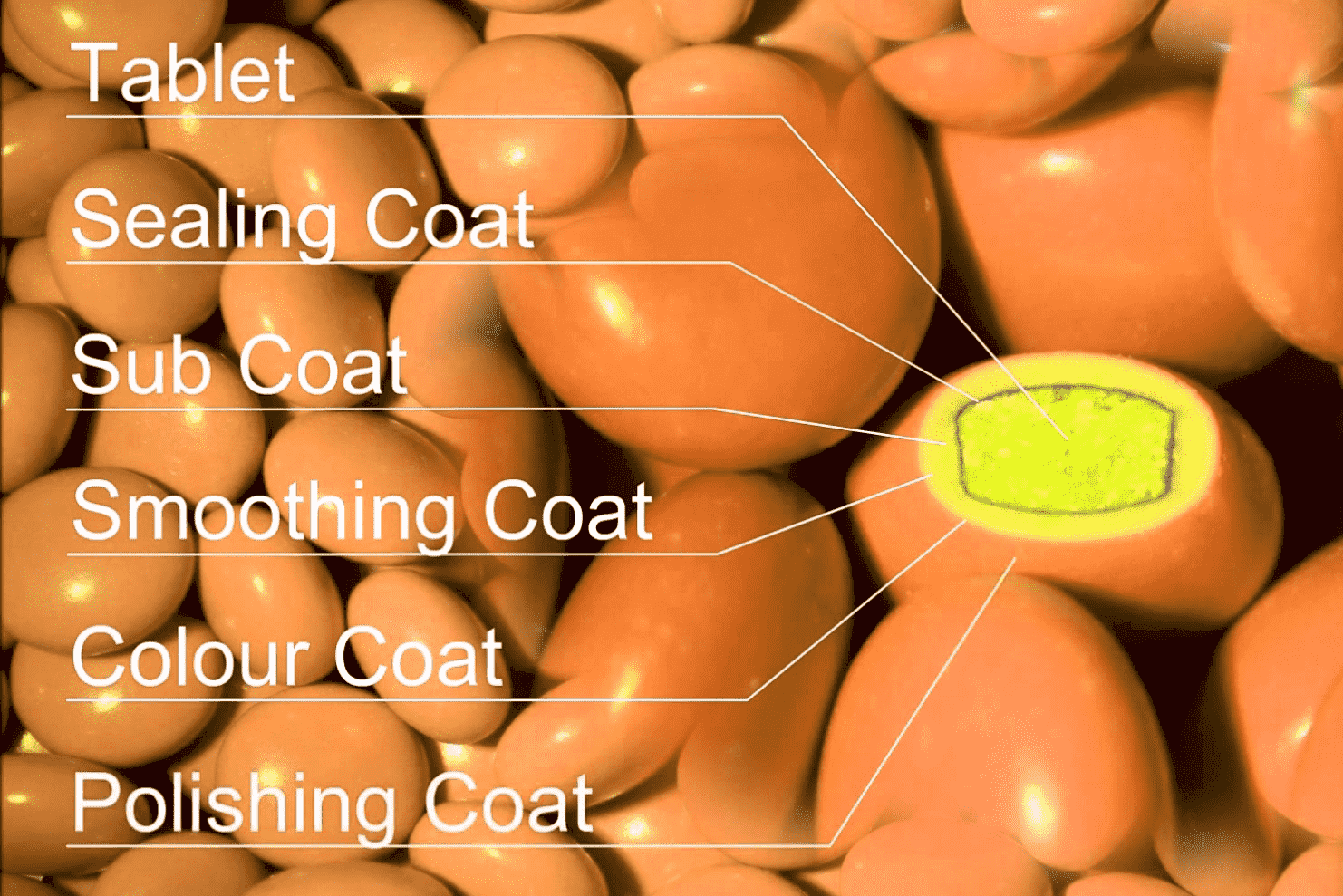

Steps Involved in Sugar Coating Process

In this section, we're going to break down the sugar coating process into 6 easy-to-follow steps. From sealing to polishing, each step plays a crucial role in making shiny and smooth sugar-coated tablets.

STEP 1: Sealing

The first step involves applying a thin layer of sealing material to the tablet. This seal coat serves three important purposes:

1. It helps to protect the tablet from moisture that might seep in during the sugar coating process.

2. It prevents the active ingredients from coming into contact with the sugar coating.

3. It can strengthen the core of the tablet.

There are many different materials used to create the seal coat. Shellac used to be the most commonly used sealing material. But today, cellulose acetate phthalate (CAP), polyvinyl acetate phthalate (PVAP), and zein (a corn protein derivative) are more popular because they don't have issues with polymerization.

The amount of seal coat material used depends on the batch size and the tablet's porosity. Getting the right amount of seal coat is important. This ensures the tablet core is properly protected.

STEP 2: Subcoating

After the seal coat is applied, the next step in the sugar coating process is subcoating. In this step, the tablet is coated with several sugar syrup layers. This helps round the edges of the tablet. It also helps to cover up any imperfections on the tablet's surface.

There are two methods used for subcoating: lamination and suspension.

Lamination: A mixture of sucrose and a binder solution (acacia or gelatin) is applied to the tablet surface. Then, a powder mixture containing calcium carbonate, titanium dioxide, calcium sulfate, and talc is added. The tablet is then dried with warm air to evaporate the water.

Suspension: This method involves applying a mixture of fillers in gum solution to the tablet surface, followed by a sucrose solution and drying. This method is good for automatic processes.

STEP 3: Smoothing

After the tablet edges are rounded in the subcoating process, they can be a little rough. That's why the next step is called smoothing. This step is important because it smooths the tablet's surface and increases its size.

To do this, a syrup solution is applied to the tablet. This syrup is usually made up of 60%–70% sugar, but sometimes it also contains other ingredients like acacia, gelatin, pigments, starch, or opacifier. The smoothing process is repeated many times (about 10 cycles) until the tablets are ready for the next step.

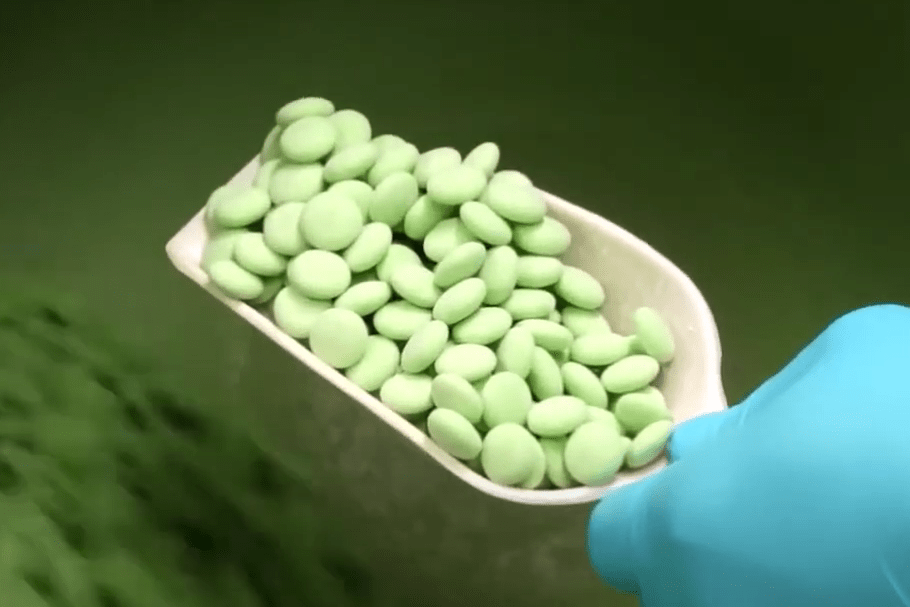

STEP 4: Coloring

The coloring phase of the sugar coating process is really important because it makes the tablet look attractive and stable. In this step, the color is applied in several layers until the desired shade is achieved.

The sugar-coating solution for coloring comprises 70% syrup and special coloring pigments. In the past, water-soluble dyes were used to color tablets, but they had some problems. The dyes would sometimes move around and get on the surface of the tablets when they were drying.

Now, we use something called water-insoluble pigment (lakes) instead. This helps keep the color even and ensures all the tablets in a batch look the same.

STEP 5: Polishing

After the coloring phase, sugar-coated tablets may look a bit dull. That's where polishing comes in! Polishing helps to give the tablets a shiny and elegant finish.

In this step, the tablets are placed in a polishing pan and applied to a mixture of beeswax, carnauba wax, and candelilla wax for the desired shine. Once the tablets have been polished, they're ready to be packaged and shipped off!

STEP 6: Printing (Optional)

Printing is an optional step in the sugar coating process. It involves applying a printed design or logo onto the surface of the sugar-coated tablet using edible ink. Printing can add an extra level of aesthetic appeal to tablets.

While printing is not a must in the sugar coating process, it can provide an additional layer of branding and marketing for pharmaceutical and nutraceutical companies.

Advantages and Disadvantages of the Sugar Coating Process

Pros:

Improving taste: Sugar coating can improve the taste and texture of tablets, making them easier to swallow.

Masking unpleasant odors: Sugar coating can also help mask unpleasant odors associated with certain ingredients.

Improving appearance: Sugar coating can make tablets look more appealing and distinguishable. This can help with brand recognition and patient compliance.

Low cost: Sugar coating is relatively inexpensive compared to other coating methods. It uses common materials such as sucrose and water.

Improving robustness: Sugar coating can make tablets less prone to breakage or damage during handling and transportation.

Enhancing mechanical strength: Sugar coating can also enhance the mechanical strength of the dosage form, improving its overall quality and effectiveness.

Protecting tablets: Sugar coating can protect tablets from moisture and other environmental factors. This helps to extend their shelf life.

Cons:

Increased cost: The sugar coating process can increase the cost of the final product because it requires specialized equipment and multiple steps.

Time-consuming: Sugar coating tablets is a time-consuming process, which can slow down production.

Tablet defects: Defects such as mottling, capping, chipping, and bridging can occur during the manufacturing process.

Decreased drug efficacy: In some cases, sugar coating can reduce the efficacy of the medication by delaying the release of the active ingredients.

Large size: Sugar coating can increase tablets' size, making them more difficult to swallow.

More difficult to break down: Sugar coating can make it more difficult for the tablet to break down in the digestive system. This can reduce absorption and delay the onset of action.

Skills required: The sugar coating procedure is tricky and needs to be handled by an experienced operator.

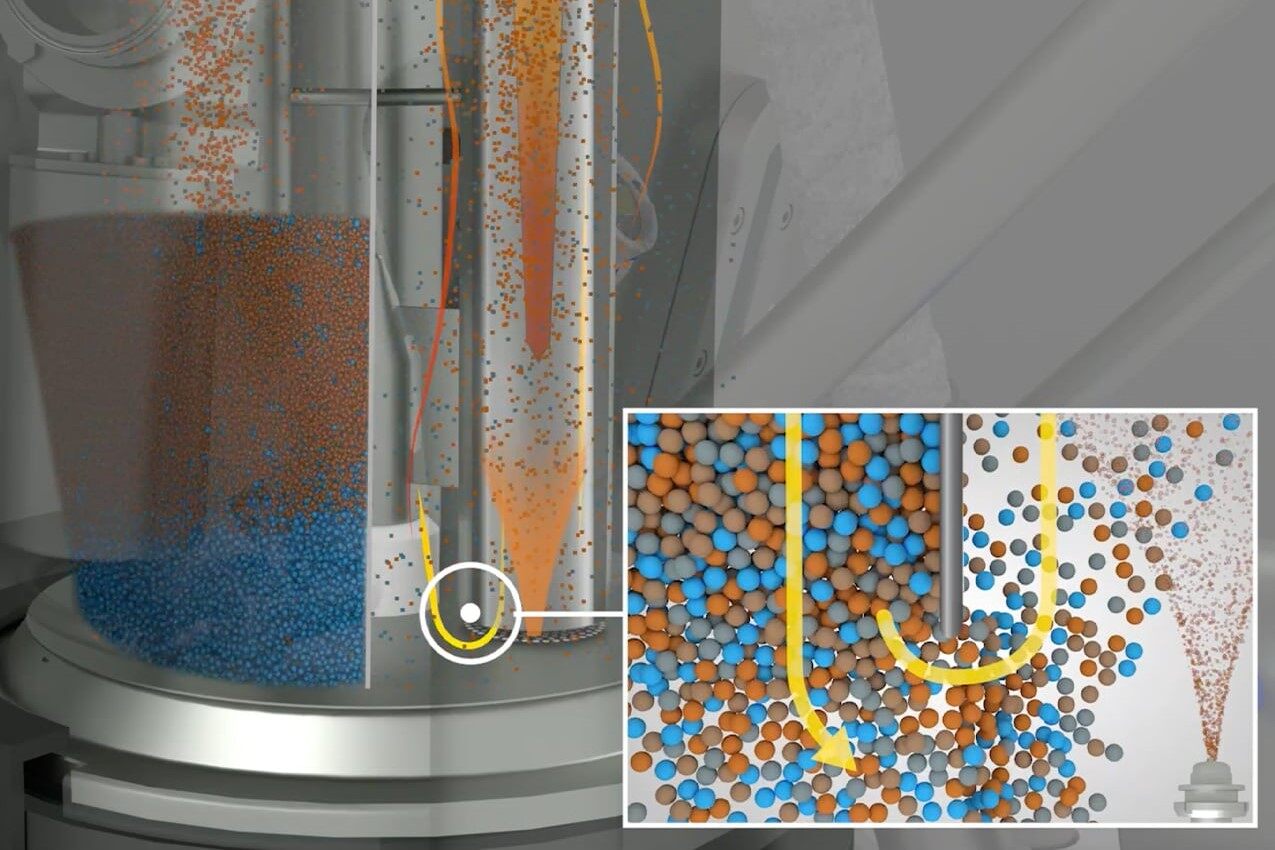

Machines Used for Sugar Coating Process

There are various types of tablet coating machines used to sugar coat tablets.

The most commonly used machinery is a standard coating pan. This machine holds tablets in a pan and uses a spray gun to apply the coating solution.

Another type is the perforated pan. The equipment is designed with a perforated drum to place tablets. The coating solution is then sprayed onto the tablets as the drum rotates.

Fluid bed coaters can also be used for sugar coating. In this machine, tablets are suspended in a stream of air and sprayed with the coating solution.

(Image Source: ROMACO)

The Bottom Line

Now you know how the sugar coating process works. It may seem like a simple process, but there are many steps involved that require specialized equipment and skilled operators. Overall, sugar coating is an important process in pharmaceutical and dietary supplement manufacturing that ensures the safety and efficacy of the drugs we take.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche