What Is A Tamping Pin Capsule Filling Machine And How Does It Work?

Generally, there three types of capsule fillers: manual, semi-automatic, and automatic. While speaking of automatic capsule filling machine, the tamp filling method is the most common technology.

Have you ever heard about the tamping pin capsule filling machine? This article will give you an intro to this versatile machine. Also, it will cover everything you need to know about its capsule filling process. Please scroll down to check them out!

Introduction to the Tamping Pin Capsule Filling Machine

The idea of tamping pin capsule filling was developed by Höfliger & Karg. Today, most automatic capsule fillers are powered by the tamp or dosing disc filling method. As the critical part of this machine, the tamp filling system typically consists of a powder bowl, tamping pins, tamping springs, a dosing disc, and a tamping ring.

The tamping pin capsule filling machine, also called the dosing disc-style filler, is designed to create and achieve uniform material plugs by using the above components. It can fill capsules of various sizes and with a broad range of solid dosage products, including powder, pellets, granules, micro-tablets, and more.

Now that you know what the dosing disc capsule filler is, you may be wondering how it works.

Dosing Disc Capsule Filling Principle

Before diving into the working principle of the tamping pin capsule filling machine, let's look at the structure of the dosing system. Here, we take powder as the fill material.

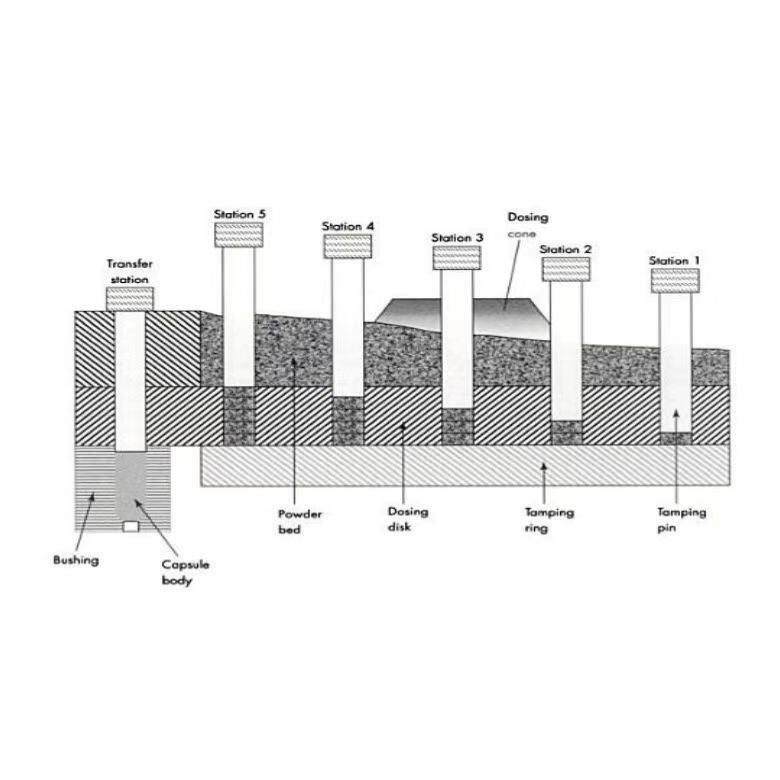

Typically, in the tamp filling machine, the powder is contained in a cylindrical powder bowl. A rotating dosing disc with six sets of dosing holes is mounted beneath the bowl. A fixed tamping ring is situated at the base of the dosing disc. The system consists of five tamping stations and one transfer station to complete the filling process.

First, the powder is fed to the dosing cone from a hopper. The dosing cone helps spread the powder evenly in the bowl and keeps a constant powder level. The rotating powder bowl stops at six stations, allowing the powder to flow into the holes of the dosing disc.

Next, the dosing disc indexes the holes underneath the tamping pins loaded with springs. The tamping pins compress the powder in the first set of holes to form a plug with a preset depth.

Then, the dosing disc continues to rotate, enabling the next set of tamping pins to align over the holes holding a powder plug. During the process, the powder keeps flowing into the holes and is retained by the tamping ring. The tamping is repeated another four times until the powder in the last set of holes is compressed to form a plug with the desired depth.

Finally, the dosing disc indexes the last set of holes over the empty capsule bodies. The powder plug is pushed into the capsule body by a set of pins at the transfer station.

Critical Process Variables of the Tamping Pin Capsule Filling Machine

To optimize a tamp filling process, you must know some critical variables, including the powder bed depth, dosing disc thickness, capsule filling speed, and tamping pressure.

Powder Bed Depth

Free-flowing powders allow the powder bed height to remain the same and the tamping pins at each station to stay immersed in the powder.

While for cohesive powders, the bed depth is often slanted with powder build-ups. It may result in the increase of powder bed depth over the fourth and fifth tamping stations. So, the earlier tamping stations can't be filled with enough powder to achieve the target depth and fill weight.

Aside from the target fill weight, the powder bed depth has an impact on the fill weight consistency. For free-flowing and cohesive powders, a higher bed depth helps achieve a more consistent fill weight. Of course, an increased powder bed height can produce larger ejection forces.

Dosing Disc Thickness

Choosing the right dosing disc is crucial to achieving target weight and dosage uniformity. The dosing disc thickness plays a big part in selecting capsule sizes for various applications.

If the cavity volume is too low for the target fill weight, generating the required pressure for powder compression will be challenging. If the volume is too high, the applied pressure may be not enough to form a stable plug for a smooth transfer to the capsule body.

Want to know how to select dosing disc for capsule filling? Check this article, and you will learn more about dosing disc thickness calculation.

Capsule Filling Speed

When the tamping pin capsule filling machine is running slow, higher fill weights and compression forces can be achieved. That's because more powder flows into the holes of the dosing disc before indexing between tamping stations.

So, for cohesive powders, slow filling speed may enable a higher fill weight and better fill weight consistency.

Tamping Pressure

If you're struggling with fill weight variation on your capsule filler, try increasing the tamping pressure. A higher tamping force can prevent powder loss during the ejection and transfer of plugs.

Yet, the downside is that the machine can't run for a long time, or the dosing disc drive will damage. To get around this problem, most modern machine manufacturers specify the maximum tamping force ranging from 50N to 150N.

Benefits of the Tamping Pin Capsule Filling Machine

If you've ever googled the most popular type of automatic capsule filler, you may have noticed that the tamping pin/dosing disc-style machines always show up on your page. Then why tamping pin capsule filling machines? Below are some of the top advantages.

Accurate and Flexible Dosing

This machine features a dosing disc that has control over the fill weight. The well-calculated dosing disc thickness helps perform extremely accurate filling and can handle various capsule sizes. It also ensures high-speed, reliable production as and when required.

Integration

It's constructed to allow a seamless integration into a production line to streamline processes, boost efficiency, level up automation, and reduce costs.

Production Scale-Up

Also, the tamping pin capsule filling machine can increase the number of dosing disc cavities and tamping pins to meet specific production needs. This machine can be upgraded without adding more equipment if you want to improve production capacity.

Comparison of Dosator and Tamping Pin Capsule Filling Machines

When it comes to automatic capsule fillers, dosator and dosing disc filling are the two most common technologies used in the pharmaceutical industry. So, what are the differences between dosator and tamping pin capsule fillers?

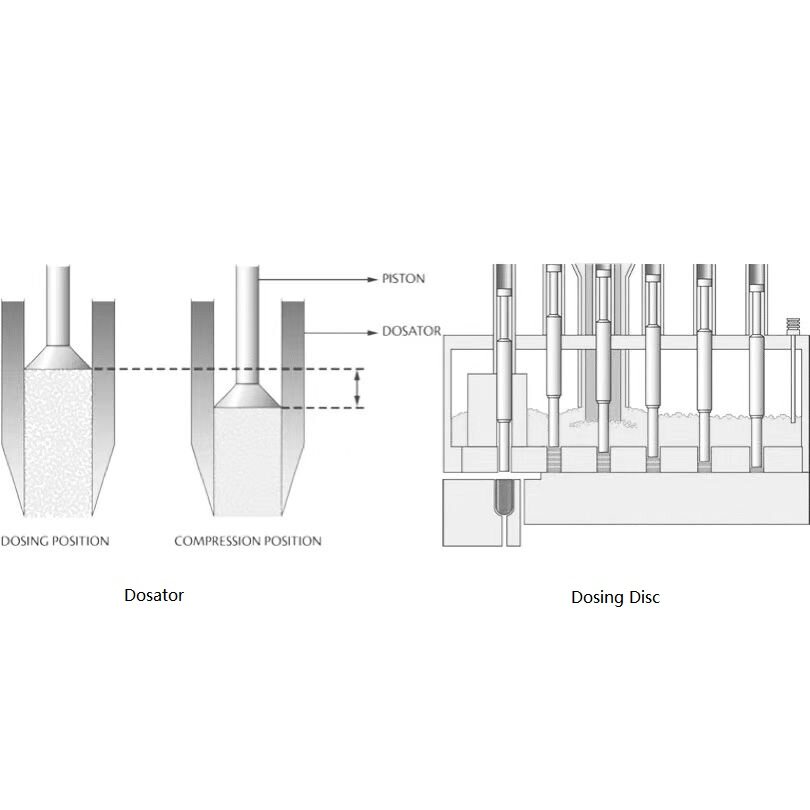

First of all, they work on different principles. The dosator forms a compressed powder plug by using a dosator tube with a piston inside. The dosing disc filler employs a rotating dosing disc and tamping pins for powder compaction.

Second, the filling applications. Both can handle various dosage formulations, including powder, pellets, granules, tablets, micro-tablets, and combinations. The dosator is even capable of the precise filling of low-dose dry powder for inhalers.

Conclusion

This article covers the introduction, working principle, advantages, and critical process parameters of the tamping pin capsule filling machine. The information will give you a rough idea of the most popular type of automatic encapsulation machine.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche