2024 Toothpaste Filling Machine Buyer's Guide

If this is your first time buying a toothpaste filling machine, you might be feeling overwhelmed. Yet, you don't have to be. Taking a few minutes to do some homework, for example, reading our Toothpaste Filling Machine Buyer's Guide, can help a lot. This guide will teach you everything you need to know about toothpaste filling machines, including how they work, the different types available, and their features. At the end of this post, we've also included some great examples that could fit your filling needs.

What Is a Toothpaste Filling Machine?

A toothpaste filling machine is a kind of tube filling equipment. It's used to fill a squeeze tube with a product and then seal the tube.

This machine is quite versatile. Beyond toothpaste, it's also capable of packing creams, gels, lotions, ointments, and condiments, as well as pastes and other semi-solid items. That's why, when you google "toothpaste filling machine," you will often come across terms like "tube filling machine" or "tube filling and sealing machine." They are exactly the same sorts of things.

How Does a Toothpaste Filling Machine Work?

Most toothpaste filling machines are created to automate the process of filling and sealing tubes. The working of these machines is typically straightforward, efficient, and hygienic. Here, we break down how they work step by step:

STEP 1: Prepare the toothpaste (or other semi-solid fills).

The toothpaste is stored in a hopper or reservoir within the machine. The hopper can be double-jacketed to control the temperature. It's also equipped with an agitator to stir the product gently.

STEP 2: Loading

Empty tubes to be filled have one open end and the other sealed with a cap. These empty tubes are loaded into the tube magazine by the operator.

STEP 3: Feeding

Most automatic toothpaste filling machines feature a cassette infeed system. This system automatically feeds tubes into the machine one after another. Each tube is picked up and placed in a designated holder.

STEP 4: Positioning

The tube is then transferred to a print registration device as the turntable rotates. This registration device features a mark sensor to detect the prints on the tube. This ensures each tube is correctly positioned and oriented.

STEP 5: Cleaning

The tube moves to the cleaning station, where an air nozzle blows off any dust inside the tube.

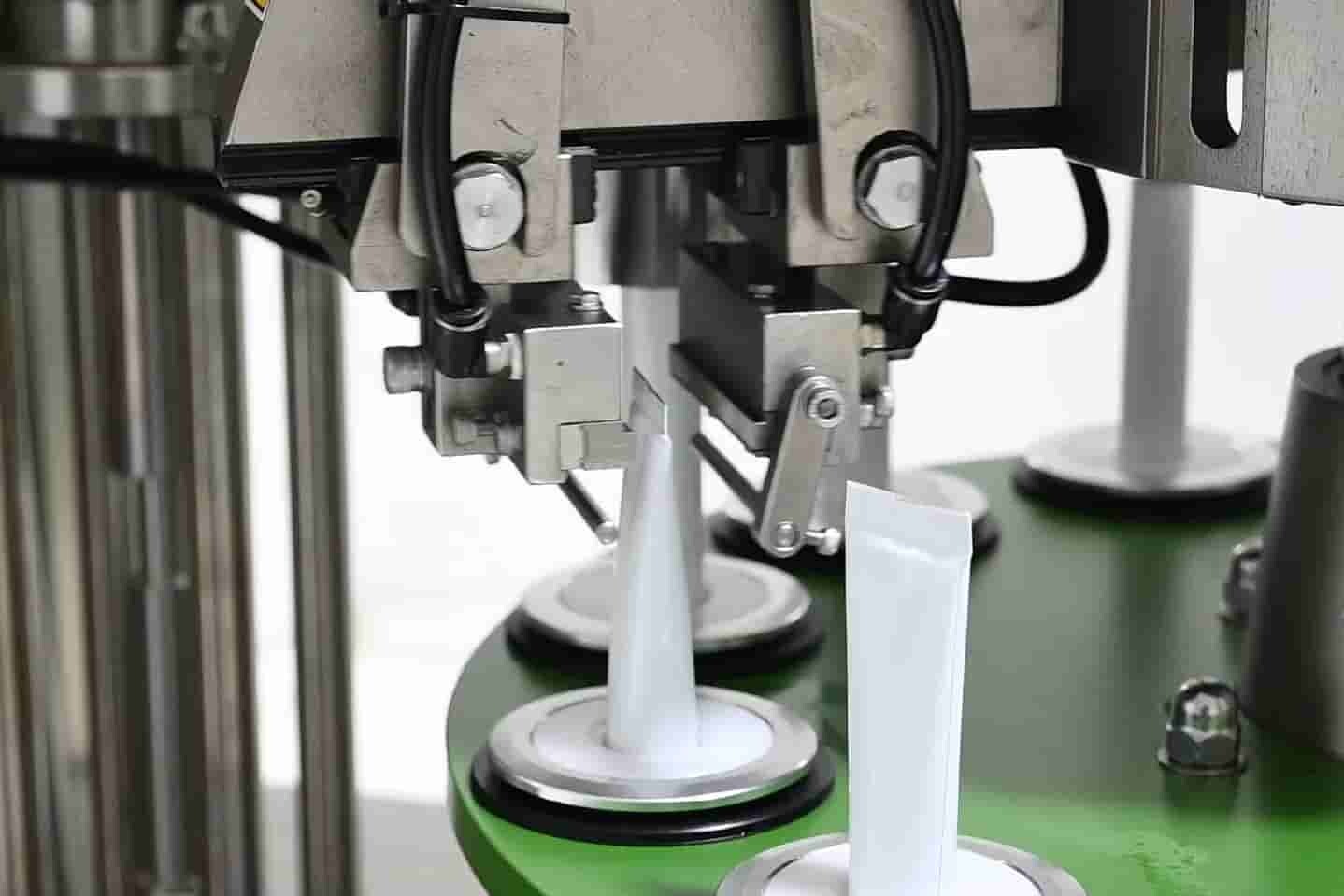

STEP 6: Filling

The machine uses a precise dosing system to dispense the exact amount into each tube at the filling station. The filling nozzle dives into the tube to prevent air pockets or spills, filling from the bottom up.

STEP 7: Sealing

After filling, the tube moves to the sealing station. Depending on the tube materials, the sealing methods vary:

– For plastic or laminated tubes: The machine heats the open end of the tube and presses it closed to create a tight seal.

– For metal tubes: The machine folds or crimps the open end to seal it mechanically.

Expiration dates or batch numbers can be embossed in the seal.

STEP 8: Trimming

When reaching the trimming station, excess material at the end of the tube is cut off for a neat look.

STEP 9: Discharge

The finished tubes are ejected from the machine. They may slide into a collection bin or move onto a conveyor belt, ready for further processing.

What Are the Types of Toothpaste Filling Machines?

Want to find the best fit for your production needs? Understanding the type of toothpaste filling machines can help. Here are the three main types of machines available on the market.

1. Manual Toothpaste Filling Machines

Manual tube fillers are the most basic type. You need to handle much of the process by hand. These machines can only fill one tube at a time.

How They Work:

– Tube Loading: Manually place an empty tube under the filling nozzle. Or, manually insert the nozzle tip into the open end of the tube.

– Filling: Use an adjustable screw to control the filling volume. Once set, pull the lever to fill.

– Sealing: Sealing can only be done using separate equipment.

Advantages:

- Portable and affordable

- Easy to use with minimal training required

- Adjustable for different tube sizes and products

Disadvantages:

- Requires significant manual effort

- Slow operation speeds and time-consuming

- Highly dependent on the operator's skills, with a greater chance for inconsistent fill levels or sealing quality

Best For:

– R&D labs

– Small-scale businesses or startups

– Budget-conscious operations

2. Semi-Automatic Toothpaste Filling Machines

In semi-automatic machines, the filling and sealing processes are almost automated. Still, they need some level of human involvement. Compared to manual options, they fill more accurately and efficiently.

How They Work:

– Tube Loading: Manually insert the tubes into their holders following the movement of the turntable.

– Tube Feeding: The tubes are fed into the machine automatically through a cassette infeed system.

– Tube Positioning: A mark sensor detects the position of the tubes. Once a tube is not oriented correctly, the orientation device comes into play.

– Filling: The machine automatically fills the tubes.

– Sealing: A pair of sealing jaws closes the open end of the tube for a secure seal.

– Trimming: Excess packaging materials on the seal are trimmed off.

Advantages:

- Faster than manual machines due to automated filling

- Provides more uniform filling volumes and better sealing

- Less manual effort

Disadvantages:

- More expensive than manual machines

- Requires operators to load empty tubes and keep an eye on the entire process

- Operators need to learn how to use and maintain the machine

Best For:

– Medium-sized businesses

– Businesses requiring increased production output

– Companies transitioning from manual to automated processes

3. Fully Automatic Toothpaste Filling Machines

Automatic machines manage the entire process with little to no human involvement. These machines can be integrated with multiple optional features.

How They Work:

– Tube Feeding: Automatically feed tubes with a cassette infeed system.

– Tube Orientation: The print registration device detects and corrects the positioning and orientation of the tubes.

– Cleaning: This function is optional. It removes any debris inside the tube by air blast.

– Filling: The filling nozzles dive into tubes and precisely fill them with the exact amount of the product.

– Sealing and Coding: Automatically seals the tubes using heat or crimping methods, depending on the tube material. Batch numbers or expiration dates are embossed while sealing happens.

– Trimming: A set of blades trims off excess material.

– Ejection: Finished tubes are automatically ejected.

Advantages:

- Capable of filling large quantities quickly and continuously

- Ensure uniform filling and sealing with minimal product waste

- Reduce manual labor involvement, lowering long-term labor costs

- Often include touch-screen controls and programmable settings

Disadvantages:

- Higher upfront costs compared to manual and semi-automatic machines

- Requires skilled personnel for operation and maintenance

- May require more workspace due to a larger footprint

Best For:

– Large-scale manufacturers

– Businesses requiring high efficiency and consistency

– Companies with the capital to invest in advanced machinery

Must-have Features to Look for in A Toothpaste Filling Machine

Are you in the market for a toothpaste tube filling machine? Check out these must-have features beforehand.

|

Feature |

Why It's Important |

What to Look For |

|

Robust Construction |

Increases longevity and reduces downtime. |

Quality materials; reputable manufacturer. |

|

Hygienic Design |

Prevents contamination and meets safety standards. |

Stainless steel construction; easy-to-clean components; compliance with GMP. |

|

User-Friendly Operation |

Enhances efficiency and reduces errors. |

Intuitive controls; programmable settings; multi-language interface. |

|

Easy Maintenance |

Minimizes downtime and reduces service costs. |

Accessible components; clear manuals; manufacturer support. |

|

Compatibility with Tube Types |

Allows flexibility with different tube materials and sizes. |

Adjustable holders; ability to handle plastic, laminated, and metal tubes. |

|

Product Compatibility |

Maintains product quality across various formulations. |

Viscosity handling; non-reactive materials. |

|

Accurate Filling Mechanism |

Ensures consistent product quantity and reduces waste. |

Precise dosing systems like piston fillers; adjustable fill volumes. |

|

Efficient Sealing Mechanism |

Maintains product integrity and extends shelf life. |

Appropriate sealing methods for tube materials; consistent seal quality. |

|

Production Speed and Capacity |

Meets production demands and allows for scalability. |

Adjustable speed settings; high output rates. |

|

Adjustability and Flexibility |

Accommodates different products and tube sizes. |

Tool-free adjustments; multi-product capability. |

|

Safety Features |

Protects operators and complies with regulations. |

Emergency stop buttons; protective guards; sensors and alarms. |

|

Regulatory Compliance |

Ensures legal operation and market access. |

Necessary certifications; available documentation. |

iPharMachine Tube Filling Solutions

iPharMachine has really made a name for itself worldwide when it comes to high-quality packaging equipment for pharmaceuticals and healthcare products.

We've got a fantastic range of tube filling machines. Each brings speed, efficiency, and safety to packing products like toothpaste, creams, gels, and more.

If you're aiming to cut costs, improve efficiency, or ramp up your production, our selection of tube filling machines could be just what you're looking for!

- Semi-automatic Tube Filling and Sealing Machine CNF-30A - A toothpaste tube filling machine can be custom-made for handling plastic, laminate, and aluminum tubes. Except for the manual loading of the tube, each step is automated.

- Automatic Aluminum Tube Filling and Sealing Machine NF-60Z - A highly efficient toothpaste filling machine that applies crimping techniques to create a neat, tamper-evident seal for each tube. This model can pack up to 3,000 tubes per hour, with a filling error of no more than ±1%.

- Automatic Tube Filling and Sealing Machine CNF-80A - This is the most cutting-edge model from our product range. This machine is designed to work with plastic, laminate, and metal tubes of various sizes. With a maximum production capacity of up to 4800 tubes per hour, it has a host of advanced features.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche