Common Tablet Coating Defects and Remedies

Are you running a pharmaceutical business? How many machines do you deal with daily for effective production? We know the answer would be many. But the most challenging part is when the product comes out differently than expected. It is common to see some defects in tablet coating with tablets you manufacture daily. Knowing about them and the solutions that can fix them is better.

In this post, you will get to explore the most common defects that can occur with tablet coating. Besides, practical troubleshooting ways are also included. So, let's learn about tablet coating troubleshooting and more without delay!

Understanding Tablet Coating & Its Importance

What is Tablet Coating?

Tablet coating can be defined as:

"The implementation of the different coating composition on tablets' moving beds. It involves the simultaneous use of heated air for effective solvent evaporation. Besides, proper coating distribution will be completed by the tablet movement. It would be perpendicular to the application of coating composition."

Types of Coating Techniques and Applications

Several types of coating methods are available that are helpful for production in the pharmaceutical industry. Before learning about defects in tablet coating, the following are some common tablet coating types that many companies are using:

Sugar coating

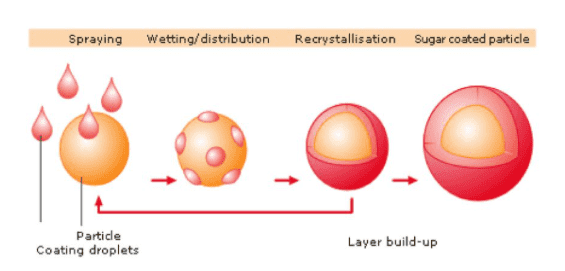

The first tablet coating type is sugar coating which is a traditional method. However, it is still successfully applied in many pharma companies. Generally, the steps involved in the sugar coating process are sealing, sub-coating, syrup coating, coloring, and polishing. So, the tablet will be coated with a sugar syrup layer and then dried. After proper drying, the tablet gets polished, and the outcome possesses a smoother and shiny surface.

Film coating

As sugar coating is time-consuming, film coating is another designed tablet coating technique. The film coating method includes the spray of polymer solution, pigments, and plasticizers. All these are performed on a tablet bed that rotates to create a thin and consistent film on the surface. Moreover, the absolute film coating should have some features like:

- Provide an elegant coating.

- Stability under light, heat, and moisture.

- Compatibility with coating additives.

- Solubility in the solvent of preferred choice.

Undoubtedly, many tablet film coating defects can also be seen in pharmaceutical companies.

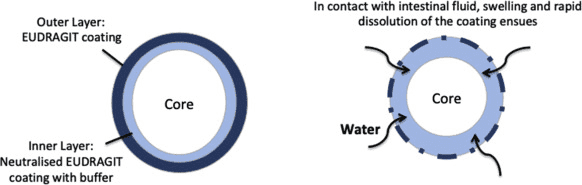

Enteric coating

Enteric coating means they are created with innovative science to hold the tablet together in the stomach. These tablets are also popularly known as gastro-resistant. A common reason behind enteric tablet coating involves protecting the stomach from the drug. Therefore, there are benefits to this coating, and tablets with enteric coating should never be crushed before consumption.

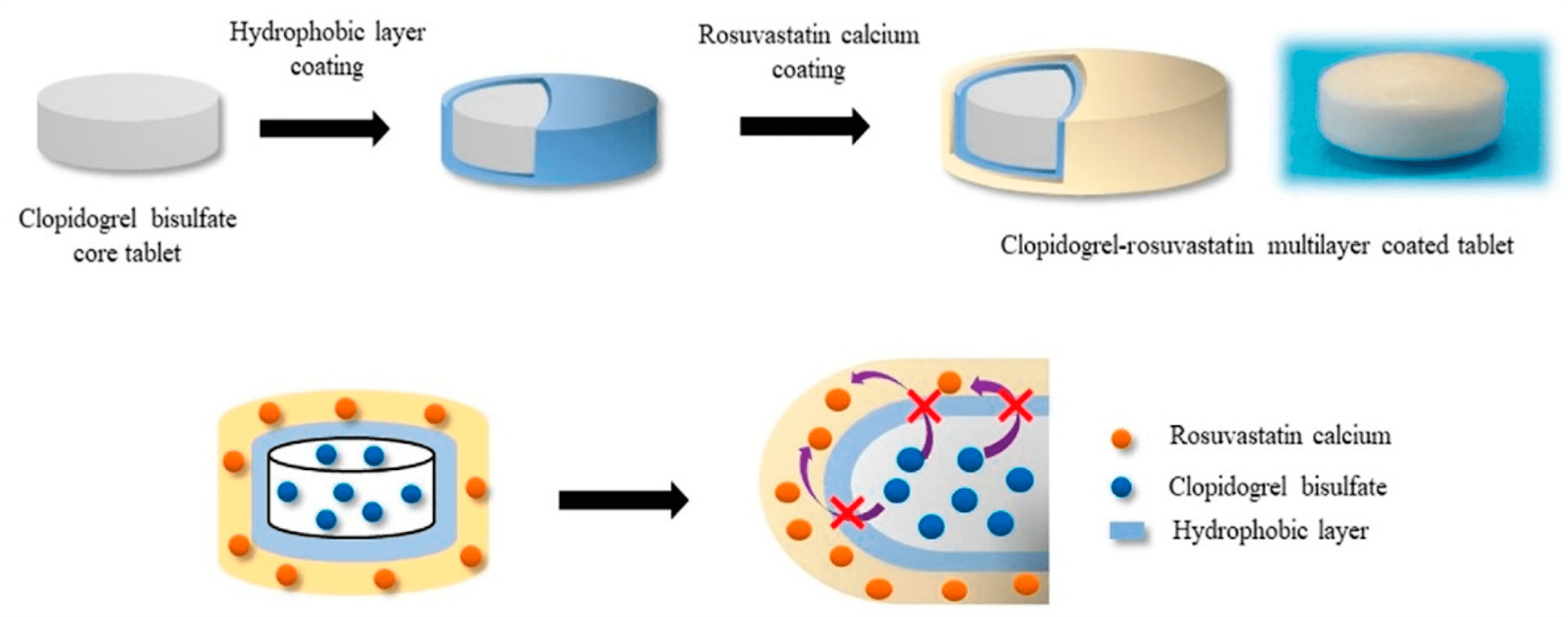

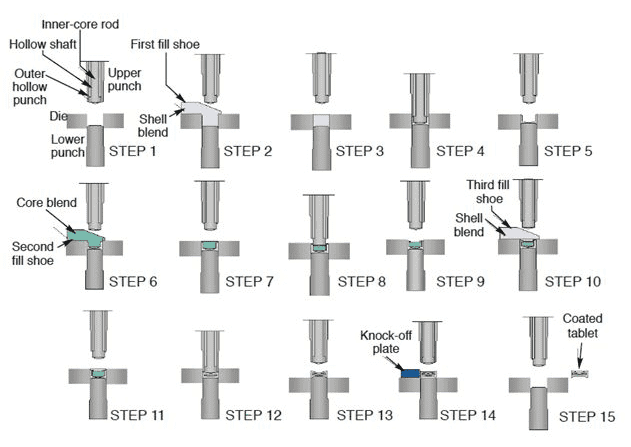

Press coating

Press coating is a type of tablet coating that compacts granular materials. And the compaction is done in the surrounding of a preformed tablet core. For effective press coating, specially designed equipment gets used. Press coating is a dry process companies use to separate incompatible chemical materials.

Common Tablet Coating Problems

Check out some tablet coating defects with pictures. These will give you clarity about different defect types:

Cracking or Splitting

Cracking is an issue that occurs with the film coating. You can see it visibly on the crown area of the tablet, where the splits are present around the edges. Generally, the cause of this issue is the internal stress of the film. It can increase and go beyond the film's strength. It results in the tablet coating cracking.

Chipping or Peeling

Chipping is also known as peeling. A problem with the tablets happens when the tablet becomes dented. You can see it clearly on the tablet's edges. One of the leading causes of this defect is the deformity of the table. Usually, it occurs when the rotation speed of the machine decreases when the coating is under process. There are also some other causes of this defect, like poor polymer, inappropriate plasticizer amount, etc.

Cratering

The following defect that occurs in the tablet coating is cratering. It is a defect of tablet coating that you can notice the craters on the tablet, which can lead to exposure to the tablet's surface. Besides, the reason behind the issue is improper drying duration for the film sealing. Another cause behind it is the coating solution with high-volume applied. In such conditions, there is a possibility of penetration of the tablet surface by excess polymer solution.

Orange Peel or Roughness

The orange peel defect of tablet coating is about a tablet having a rough surface. It means the tablet has a matt appearance rather than a glossy texture. Usually, the problem of roughness occurs because of the poor tablet composition, which can soften the tablet. One more reason to cause this defect is the high spray pressure along with the faster spray rate. It can result in an uneven tablet coating.

Color Variation

When you can see the difference in one batch of tablets, it can be the defect of tablet coating. There are many causes behind this issue with tablet products. During the preparation, there can be insufficient coating, poor mixing, or uneven spray patterns by the machine, resulting in color variation. Furthermore, soluble dyes-plasticizers or some additive's migration during drying can also lead to this defect.

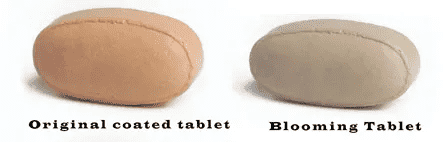

Blooming

Blooming defects in tablet coating are last on the list. It usually happens because of the change in the tablet's coating color. The color can turn dull when the tablets are stored at a higher temperature. The main cause behind this defect is the collection of pills on the surface of ingredients with low molecular weight.

Well-Known Causes of the Tablet Coating Defects

There are many reasons that result in the previously mentioned defects in coating. Below are some situations that can cause the issue with the tablet coating:

- Very little application of the coating.

- During coating, there is an inappropriate mix of tablets.

- When the spray guns are adjusted too close to the tablet bed.

- The mechanical strength of the machine is low.

- Drying conditions for the tablets that are not suitable.

- When the coating liquid is not distributed evenly.

Some Solutions for Tablet Coating Defects

Several solutions can lead to resolving the problems with your tablet coating. Check out some of them below:

- Maintain an adequate pan speed.

- Choose the formulation that has better mechanical strength.

- A proper environment should be created for the effective drying of tablets.

- Try to keep a calculated distance between every component.

- Check the position of the spray gun. It should provide ideal coverage to the tablet bed.

Tablet Coating Machines by iPharmachine

A high-quality tablet coating machine is a necessity for the perfect tablet coatings. As for tablet coating machine manufacturers, iPharmachine is one of the recognized brands that deals with providing pharmaceutical equipment to reputed pharma companies. Check out some exceptional solutions for coated tablet defects by iPharmachine. Below are some table coating machines:

BYC-1000 Tablet Coating Machine

BYC-1000 is equipment provided by iPharmachine that is effective for the tablet coating of Chinese and Western medicines. The machine brilliantly incorporates strong and weak current, hydraulic pressure, and pneumatics to offer the expected functionality.

Features

Some significant characteristics of the machine are:

- The integrated sprayer of high atomization.

- The room-temperature hot air is controllable in a coating pot for drying.

- Appropriately covers tablets with a sturdy, complete, and smooth coating.

Benefits

Below are some benefits that BYC-1000 provides:

- Easy machine operations.

- Feasible machine maintenance.

- Auxiliary materials get saved by using this machine.

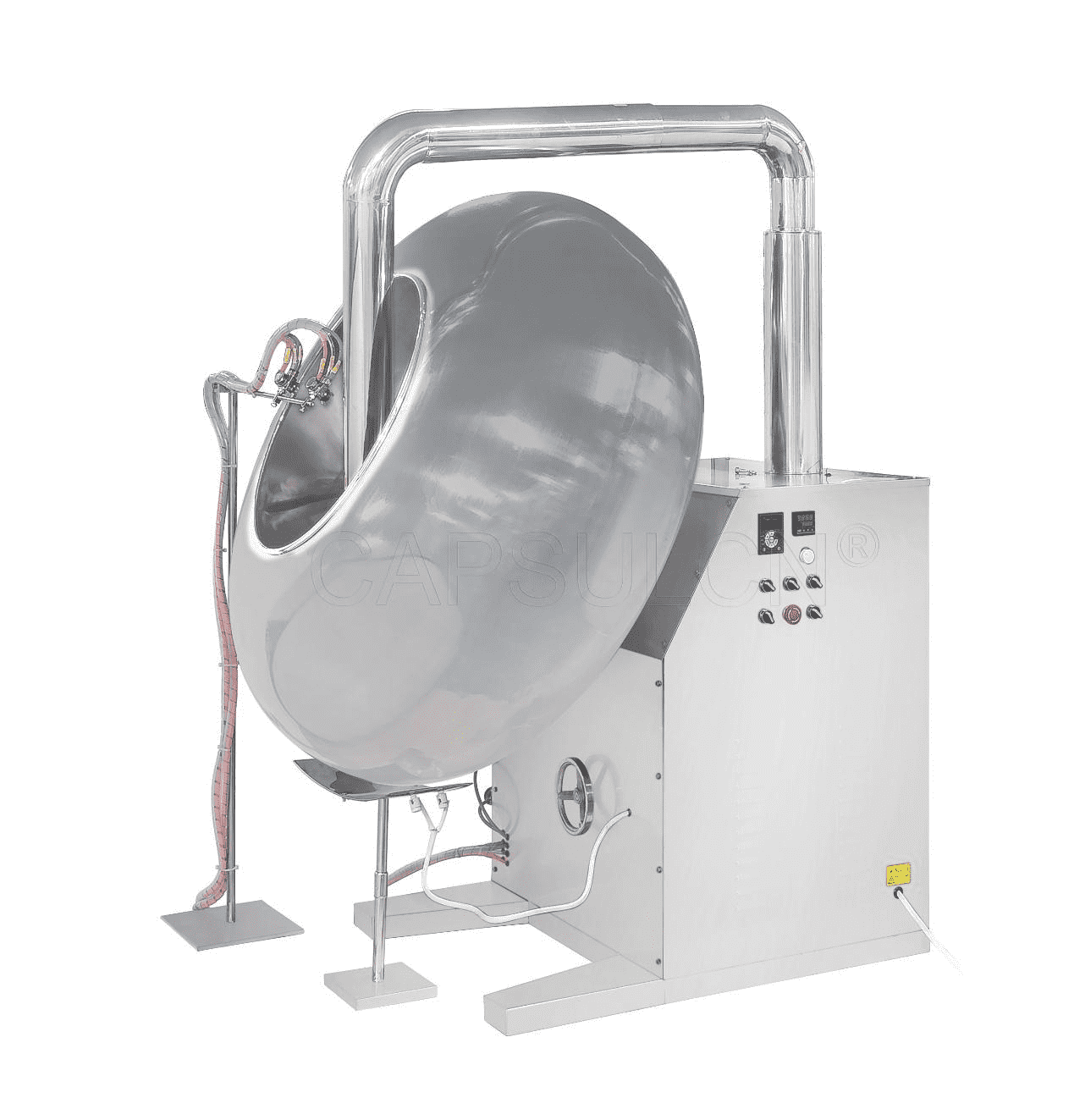

BYC-1250 Tablet Coating Machine

BYC-1250 is another best tablet coating machine by iPharmachine for resolving coating tablet defects. It also incorporates different aspects like BYC-1000, including hydraulic pressure, pneumatics, and strong and weak current. The primary device that BYC-1250 is composed of is the original sugar-coating machine.

Features

Below are some excellent features of the machine BYC-1250:

- The controlled room-temperature hot air system.

- Integration of automatic liquid and air feeding spray system.

- Effectively covers tablets with a solid layer that is fine, complete, and smooth.

Benefits

A few advantages of BYC-1250 for pharmaceutical companies are:

- The machine is simple to operate.

- Maintenance of the machine is easy.

- It provides smoother and bright surfaces for coated tablets.

- The machine also saves the auxiliary materials.

Conclusion & Recommendations

In the end section, tablet coating defects are common in every pharmaceutical business. But the main thing is to pay attention and apply the solution. However, a good tablet coating machine can protect your medicines from defects. So, iPharmachine is a top manufacturer of pharmaceutical equipment. You can choose our tablet coating machines and keep your tablet products free from significant defects.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche