Everything You Need to Know About Tube Filling Machine Parts

Are you struggling to find a tube filling machine for packaging your products efficiently? If you get to know the main parts, working principles and uses of such a machine, it will be easier for you to find the best tube filler for your products.

In this article, we will guide you through the most important parts and working principles of a tube filling machine. With this knowledge, you will end up making a more informed decision when choosing a tube filler for your business.

What is a Tube Filler?

A tube filler is an efficient machine for filling containers. It is usually used to fill various products into tubes.

According to your production scale, tube filling machines are usually available in manual, semi-automatic and fully automatic options.

What are the Important Parts of a Tube Filling Machine?

While there are many different types of tube filling machines on the market, they share the same important parts. By understanding the functions and roles of these parts, you will gain a more complete understanding of your tube filler.

Frame

The frame of a tube filling machine is usually made of sturdy stainless steel. It is the support system for the entire machine that holds all the other parts together.

Hopper

The hopper is where empty tubes are stored. When the tube filling machine starts running, the tubes in the hopper are fed onto the machine's rotary table. The entire tube filling process begins in the hopper.

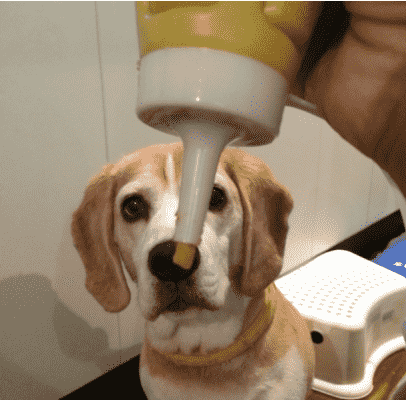

Filling Nozzle

The filling nozzle is the most critical component of a tube filling machine. This is because the filling nozzle will touch the container directly to do the main filling operation. Also, it can adjust to different shapes and sizes of containers. With it, your product can be precisely filled into the tube.

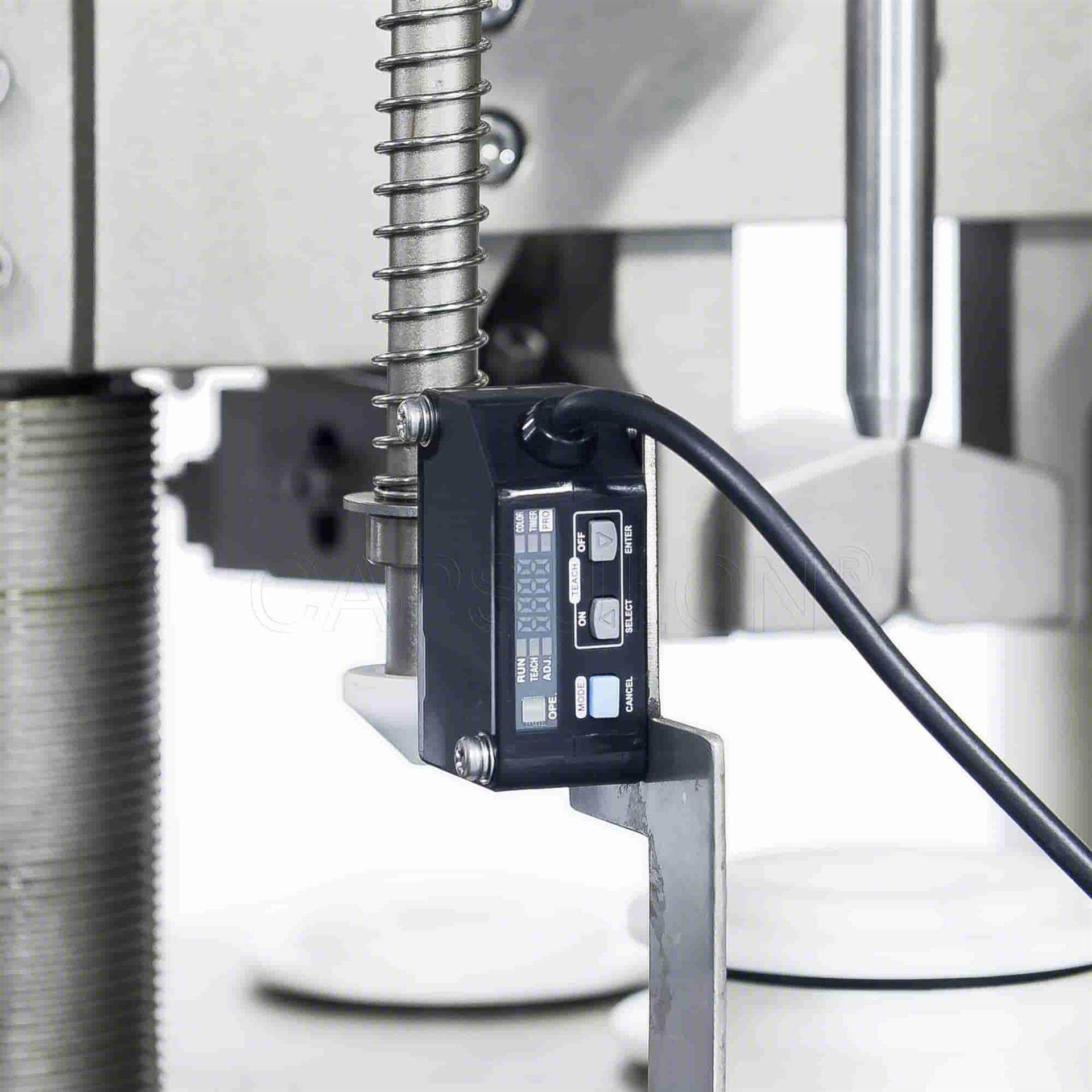

Sensor

The sensor is an important detection device of the tube filling machine. It accurately recognizes whether a tube has been filled correctly or not. It helps the machine to minimize tube filling errors.

Control Panel

The control panel allows the user to change various settings of the machine. With it, the user can adjust the speed and output of tube filling according to specific needs.

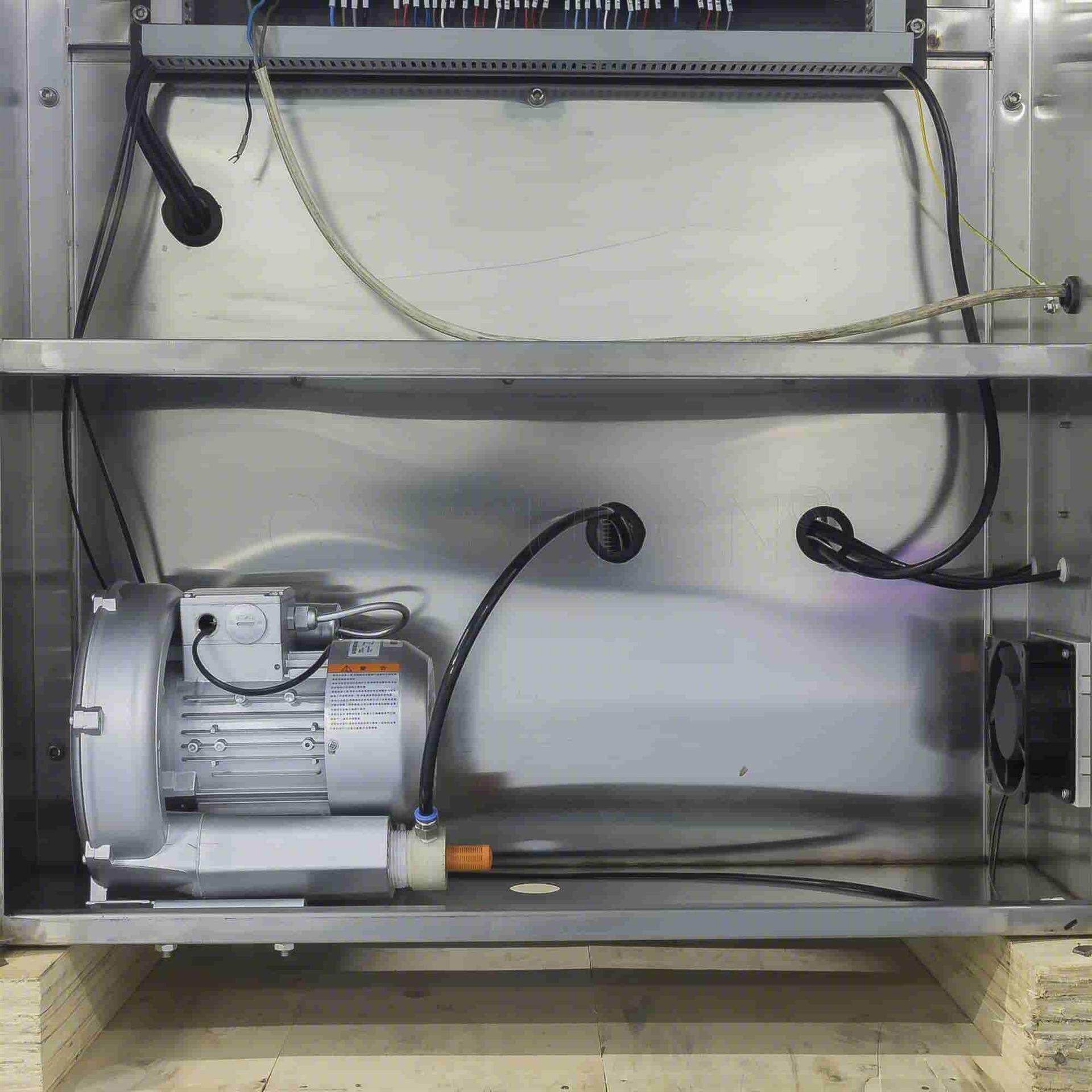

Motor

The motor serves as a constant source of power in the tube filler. Without it, the machine can’t keep running smoothly.

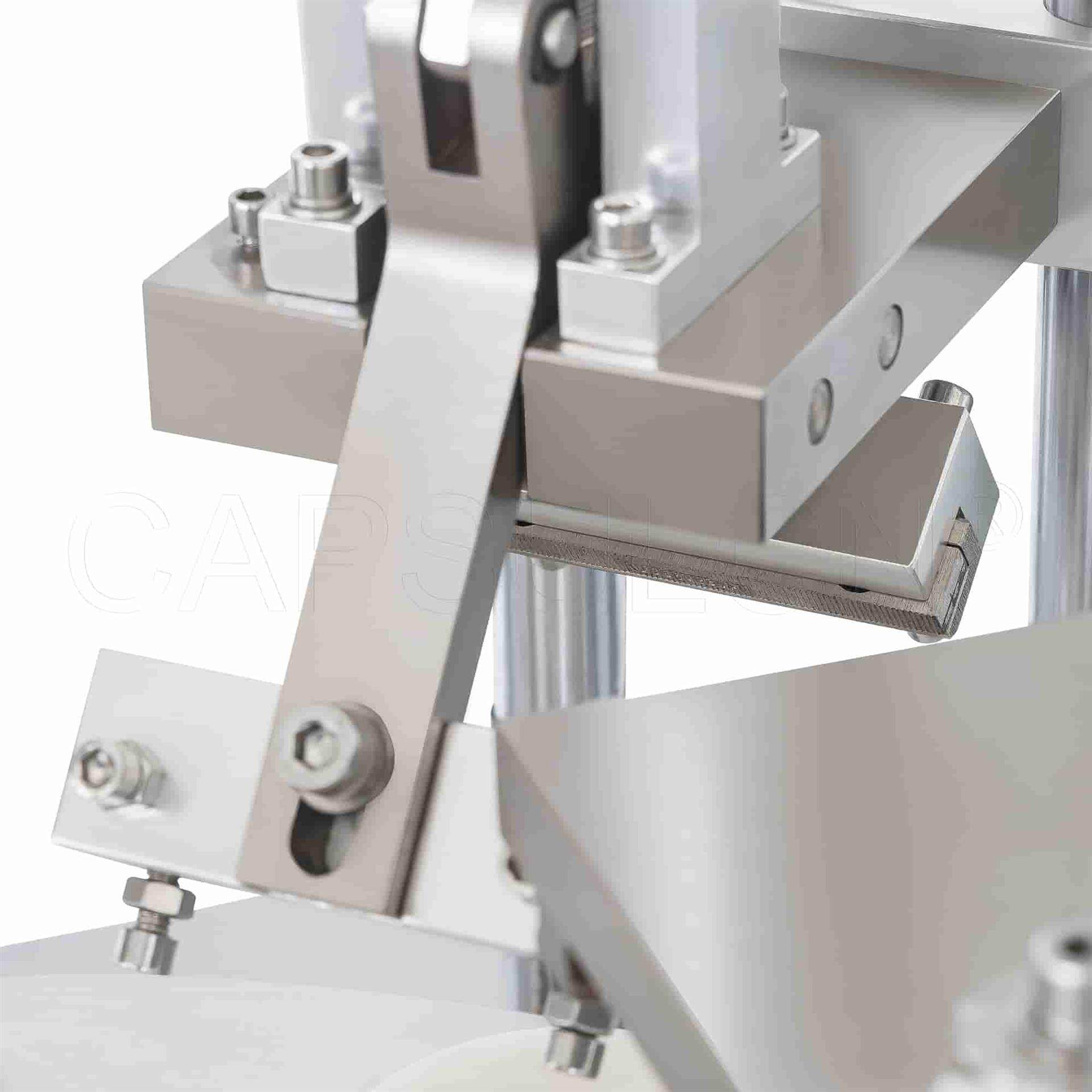

Tail Cutter

After the tube is sealed, its tail is not always flat. At this point, the tail cutter will trim the tube's tail to make it look neat and nice.

Coding Device

The coding device is responsible for the finishing touches in the tube packaging process. It prints important information like product shelf life on the filled tubes.

Sealer

After the product is filled into the tube, the sealer will come to seal this tube. It helps to prevent product leakage and keep the product fresh.

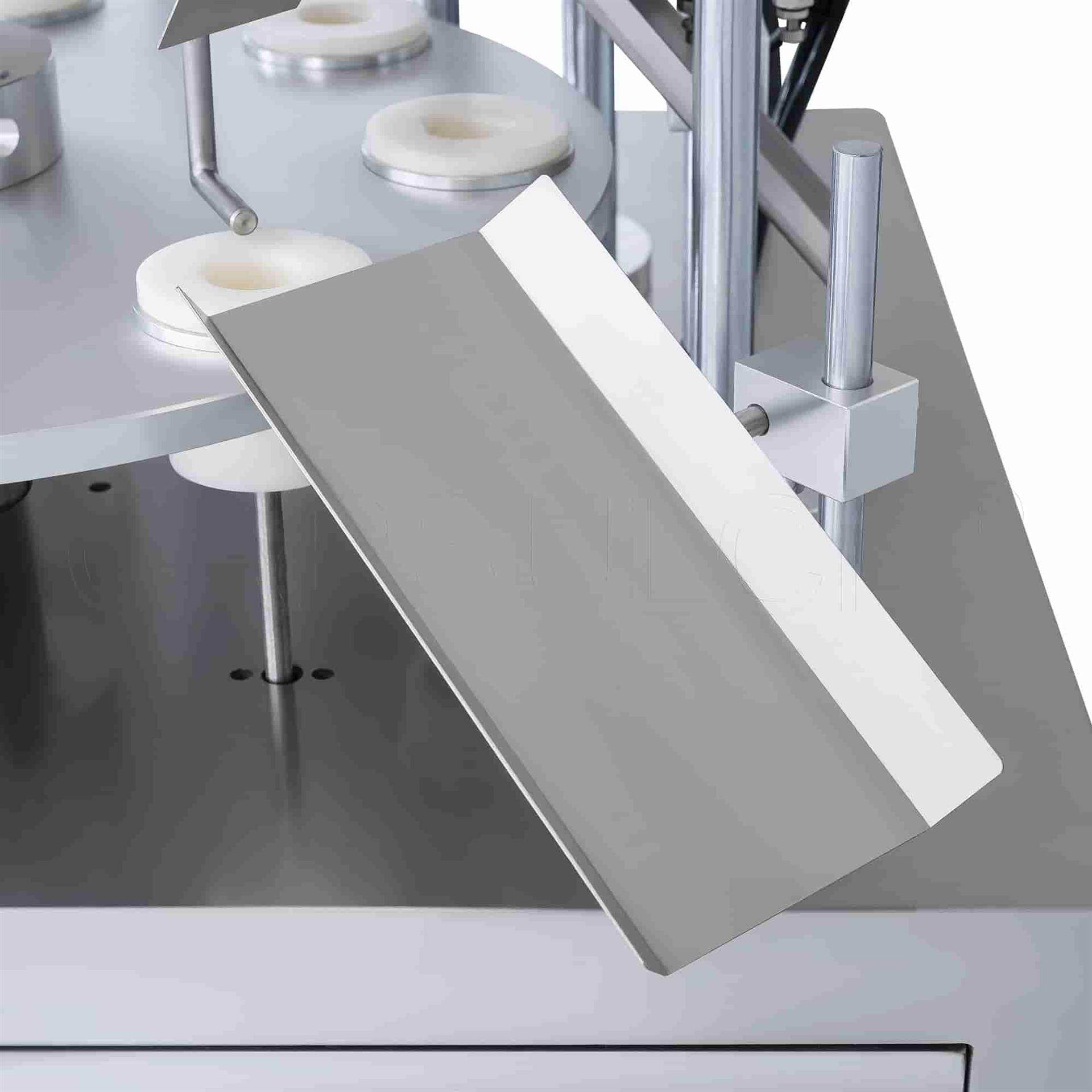

Discharge Device

The discharge device of a tube filling machine collects the finished tubes and usually has the shape of an inclined hopper. When the machine has completed the full process of filling and sealing, the finished tubes will slide into this discharge device.

Tube Filling Machine Working Principle

Now that we've learned about the most important parts of a tube filling machine, you might be wondering how this machine works with these parts. Let's take a look.

Step1: First, the empty tubes stored in the hopper are fed into the machine, and then they move to the rotary table.

Step2: As the tube passes over the filling nozzle, the sensor will detect whether the tube mouth is exactly aligned with the filling nozzle. If not, the machine will automatically reposition the tube. This helps to ensure accurate filling.

Step3: Next, the filling nozzle is driven to reach into the tube and fill it with the prepared product. For piston tube fillers, the filling nozzle is usually actuated by a cylinder.

Step4: When the filling nozzle has filled the product, the rotary table will move the tube to the sealing station. The mechanical clamp above this station will immediately clamp the tube for sealing.

Step5: After the machine seals the tube, it will fold its end again. This step is to make the seal of the tube more solid and durable.

Step6: The final step in the tube filling process involves coding the tubes. Vital information about the product such as production date and expiration date will be printed on the tubes.

Step7: After all packaging steps are over, the sealed tubes will go to the discharge unit.

This is how the tube filling machine works step by step.

What Products Can Tube Filling Machine Fill?

The tube filler is a multi-purpose device. It can be used to fill many products from a wide range of industries. Here are some of the hottest products that can be filled by a tube filler.

Personal Care Products

A tube filling machine can be used to fill personal care products. It helps ensure the hygiene and safety of these products. Therefore, consumers can use them with peace of mind. The most common products include:

- Toothpaste

- Shampoo

- Body lotion

- Hand cream

Pharmaceutical Products

The tube filling machine can also be applied in pharmaceutical sector. It can perfectly package various pharmaceutical pastes so that they can ultimately meet strict hygiene requirements. The following are some of the products filled with a tube filler:

- Burn ointment

- Anti-allergic lotions

- Syrups

- Pain relief creams

Food Products

Tube filling machines are very popular in the food industry. Most of the sauces in your kitchen are filled by this equipment. They help in keeping these food products hygienic and fresh. It can fill any sauce you can think of, for example:

- Tomato sauce

- Mustard

- Mayonnaise

- Salad dressings

Pet Products

To make it easier for you to feed your pet, Pet food and medications are usually packaged in tubular containers. This makes tube filling machines ideal for the pet industry. Common products include:

- Pet nutrition

- Pet skin ointment

- Pet snacks

Stationery Products

Tube filling machines are also used for filling stationery products.

- Glue

- Oil paint

- Watercolor

The bottom line

After learning about the components and usefulness of a tube filling machine, you will surely recognize what an efficient and useful packaging tool it can be for your products.

There are many various tube filling machine configurations on the market, so picking the best one for your business can be tricky. If you need high-quality equipment for your production needs, please contact ipharmachine, an experienced tube filling machine manufacturer. Plus, we can provide custom solutions to improve your tube filling line's efficiency.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche