Delve into the Types of Blister Packaging

In a world where products demand attention on crowded shelves and online marketplaces, blister packaging emerges as a superhero, shielding our products with its protective embrace. Whether daily vitamins or flashy electronics, blister packaging comes in various forms, each boasting unique characteristics and functionalities.

In this blog post, we unveil the different types of blister packaging, bringing you closer to understanding the artistry behind this vital solution. So, get ready to dive into the world of blister packaging!

What Are the Most Common Types of Blister Packaging?

Blister packaging seems to come in a great variety of shapes and styles. Ultimately, it can be classified into four common types depending on the materials used.

1. Plastic-Paperboard Blister Packaging

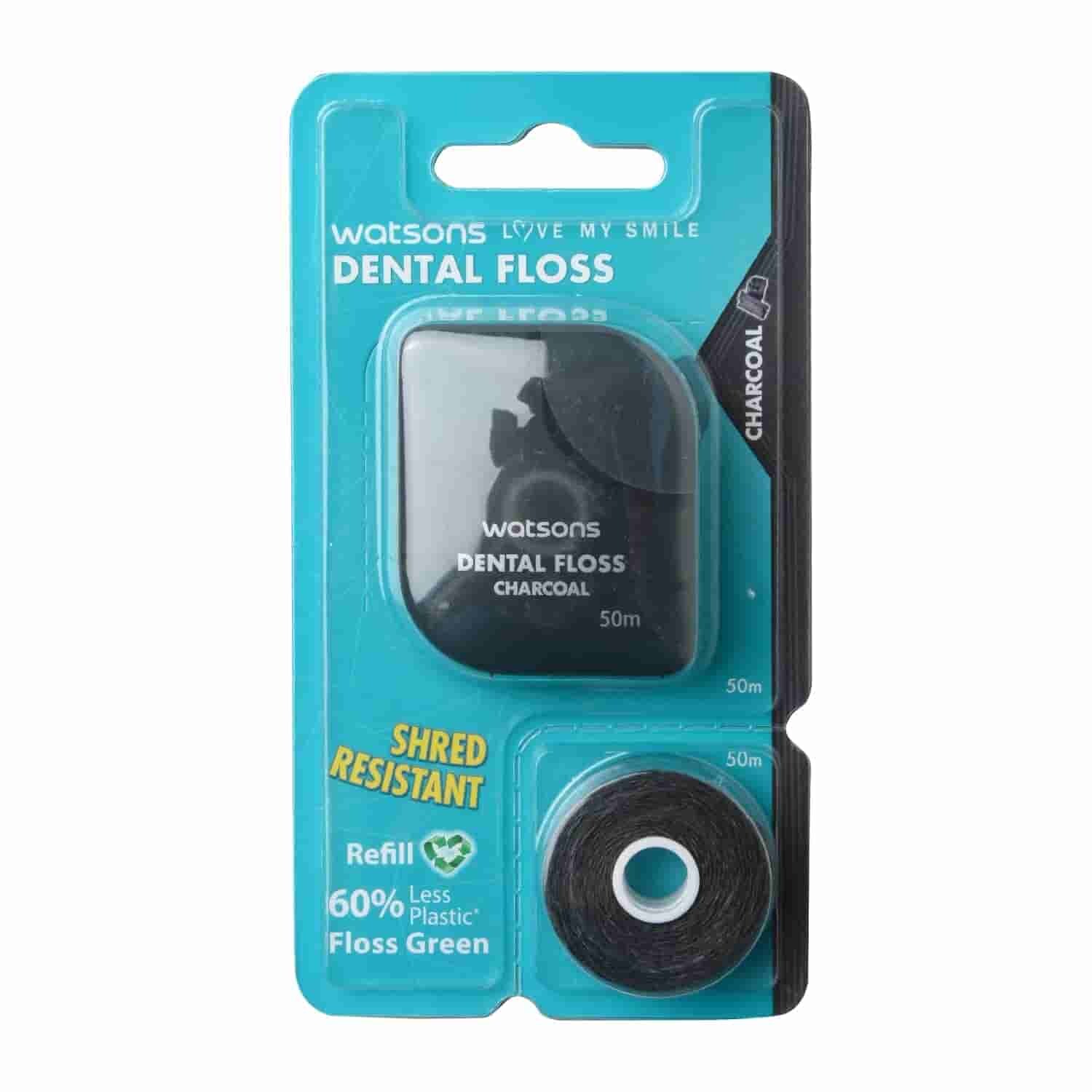

This type of blister packaging is the most common packaging method used in the retail market. It has a range of variations to cater to specific product needs. Each type possesses distinct features that make it suitable for different applications. This offers manufacturers flexibility and consumers an array of packaging options to choose from.

A. Face Seal Blister

The face seal blister is widely used, particularly for small, lightweight products manufactured in high volumes.

This cost-effective packaging is produced by molding a plastic blister around the product to ensure a snug fit. The plastic material used for the blister is typically transparent, allowing consumers to see the product inside. Once the product is placed in the blister, the blister is heat-sealed to a paperboard backing.

In the face seal blister, the seal is only on the flange. It is the edge of the blister that surrounds the product. The rest of the paperboard remains uncovered, allowing easy product access.

B. Full-Face Seal Blister

The full-face seal blister provides stronger protection and improved aesthetics compared to the standard face seal blister.

In a full-face seal blister, the plastic is also heat-sealed directly to the paperboard backing. Unlike the stand face seal blister, this packaging solution extends the plastic to cover the product and the paperboard backing completely.

This design adds extra strength and durability to the edge of the card. Covering the entire face prevents bent corners and reinforces the hang hole. This type of blister packaging is ideal for products that require a more robust and visually appealing presentation.

Yet, the full-face seal blister is generally more expensive than the standard face seal blister due to the increased amount of plastic material.

C. Full Card Blister

The full card blister is similar to the full-face seal blister. The plastic extends to hold the product and covers the entire card. The main difference lies in how the plastic is attached to the paperboard backing.

As the name implies, this type of blister packaging is not attached to the paperboard by heat sealing. Instead, it is assembled by inserting the card into the plastic blister. The plastic in the full card blister is designed with flanges that wrap around the edges of the paperboard to hold it n place.

By the way, in some cases, the paperboard backing may also be secured with a staple for added stability.

D. Trapped Blister

This type of blister packaging involves sandwiching the plastic blister between either a single folded paperboard or two cards sealed together.

In a trapped blister, there is a piece of paperboard in front of the plastic. This front paperboard piece is die-cut to fit around the blister. The plastic blister is then placed between the two pieces of paperboard. This packaging style provides increased stability and protection to the product inside.

Unlike other types of blister packaging, a trapped blister does not require heat sealing. This makes it a more cost-effective packaging option. The plastic covered by the front paperboard gives the packaging a clean, polished look.

2. Plastic-Plastic Blister Packaging

It is a type of blister packaging that does not include paperboard backing. Instead, it uses a plastic back that is divided into two halves by a hinge. The hinge can be located either at the base or the side of the blister pack. Further, the packaging features button snaps, allowing the two halves to be closed shut.

Clamshell packaging is a typical type of plastic-plastic blister packaging. As its name suggests, it is designed like a container allowed to open and close, like a clamshell.

The clamshell packaging is ideal for heavy products due to its strength and robustness. It can be designed to stand upright on the shelves or with a hang hole for easy showcasing. It's worth mentioning that the clamshell blister pack often requires knives, scissors, or trauma shears to open.

Regarding the production cost, since the tooling design and manufacturing process are complex, the clamshell packaging is usually more expensive than other blister pack styles.

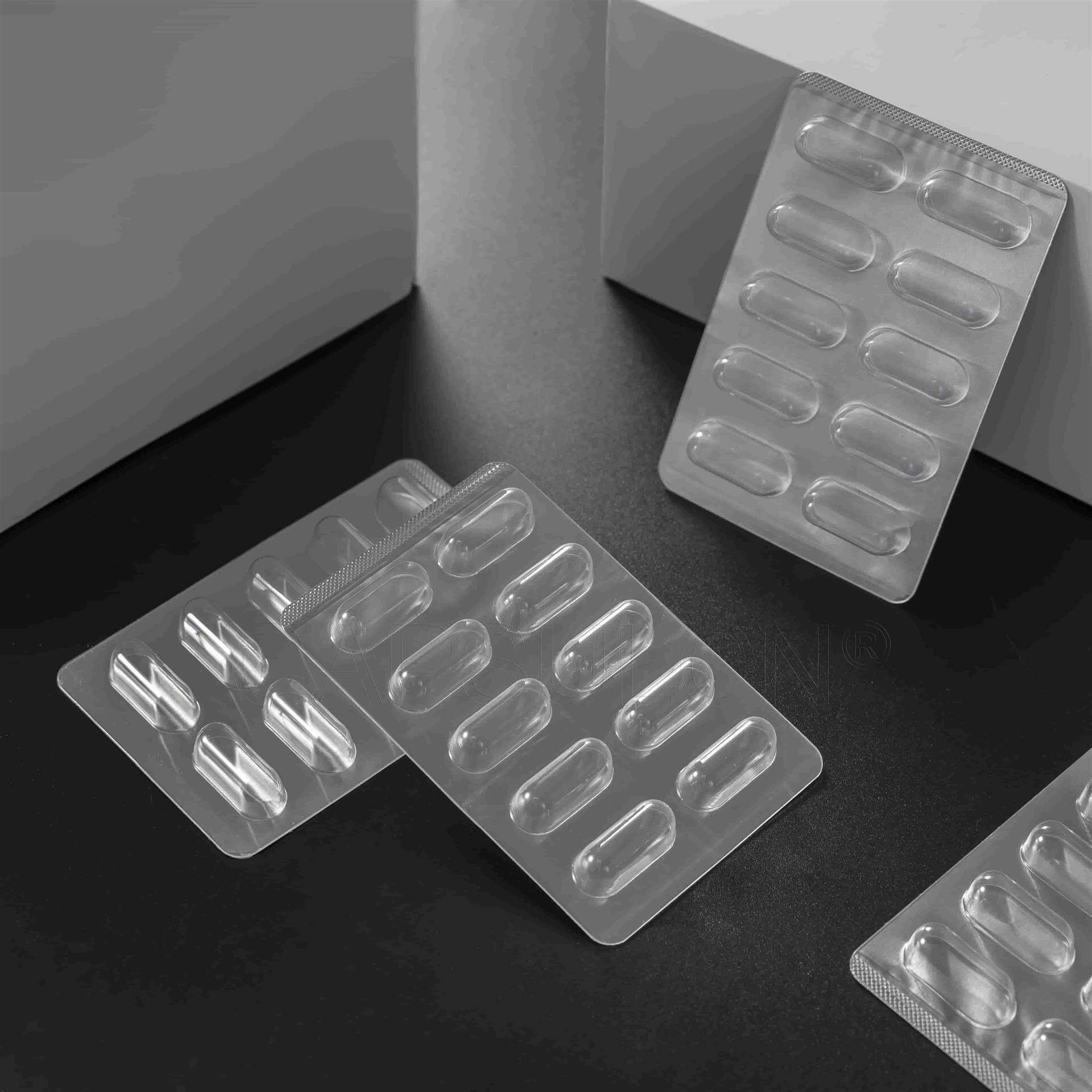

3. Aluminum-Plastic Blister Packaging

If you're working in the pharmaceutical industry, you must be no stranger to Alu-PVC blister packaging. In this term, Alu refers to aluminum foil, while PVC stands for Polyvinyl Chloride, a widely used synthetic plastic polymer.

Aluminum foil is often used for blister packaging because it is an effective barrier against moisture, light, and oxygen. Additionally, the material is flexible and can be easily formed into the desired shape for packaging.

As one of the most popular types of blister packaging in the pharmaceutical industry, an Alu-PVC blister pack consists of a plastic cavity pre-formed from PVC and a backing made of aluminum foil.

The Alu-PVC blister manufacturing process involves several steps. First, the PVC film is heated and molded to create the blister cavity. Then, the aluminum foil is bonded to the PVC blister by heat sealing. This sealing process prevents contamination and tampering, ensuring the effectiveness and quality of the packaged medication.

Compared to the Alu-Alu blister we will discuss later, Alu-PVC blister packaging provides better product visibility since the PVC blister is transparent. Further, the Alu-PVC blister packs are relatively budget-friendly than the Alu-Alu ones.

4. Aluminum-Aluminum Blister Packaging

Aluminum-Aluminum packaging is another popular type of blister packaging in the pharmaceutical industry. The term can be shortened to Alu-Alu. This type of blister packaging consists of a lidding and base, both made from aluminum-based films. The aluminum foils serve as a powerful shield, protecting medication from moisture, oxidization, and UV rays.

The Alu-Alu blister manufacturing process involves cold forming. During the process, the blister foil is pressed into a die without heat by a stamp, creating precise cavities. The pack is then sealed with an aluminum lid.

This packaging is ideal for sensitive drugs, such as effervescent tablets, requiring optimal protection. However, the Alu-Alu blister packs come at a higher cost than traditional PVC-based ones due to the special materials and larger packaging size.

The Bottom Line

There are various types of blister packaging available. Each has its own benefits, such as visibility, durability, and convenience. Whether you're a manufacturer trying to find the best packaging solution or a consumer curious about the bodyguard for products, understanding the different types of blister packaging can help you make informed decisions.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche