A Closer Look at the Types of Semisolid Dosage Forms

Struggling to find the right formulation for your skincare or medical needs? Semisolid dosage forms might be the answer. These versatile products make the application easy and convenient. They also deliver care or treatment effectively.

In this article, we'll take a look at the different types of semisolid dosage forms. By the end of reading, you'll know what sets each one apart and how they can be used to meet your specific needs. Whether you're into skincare or pharmaceuticals, this closer look will give you valuable insights. Let's explore!

What is a Semisolid Dosage Form?

Semisolid dosage forms are formulations that straddle the line between solids and liquids. They typically feature a creamy or gel-like texture that can be applied directly to the body, like your skin and mucous membranes. So, they're usually designed to be gentle.

According to the FDA, oil and water are the two phases of a semisolid dosage form. They combine to create a smooth, spreadable consistency. Because they're designed for targeted treatment, semisolid dosage forms can deliver active ingredients right where they're needed.

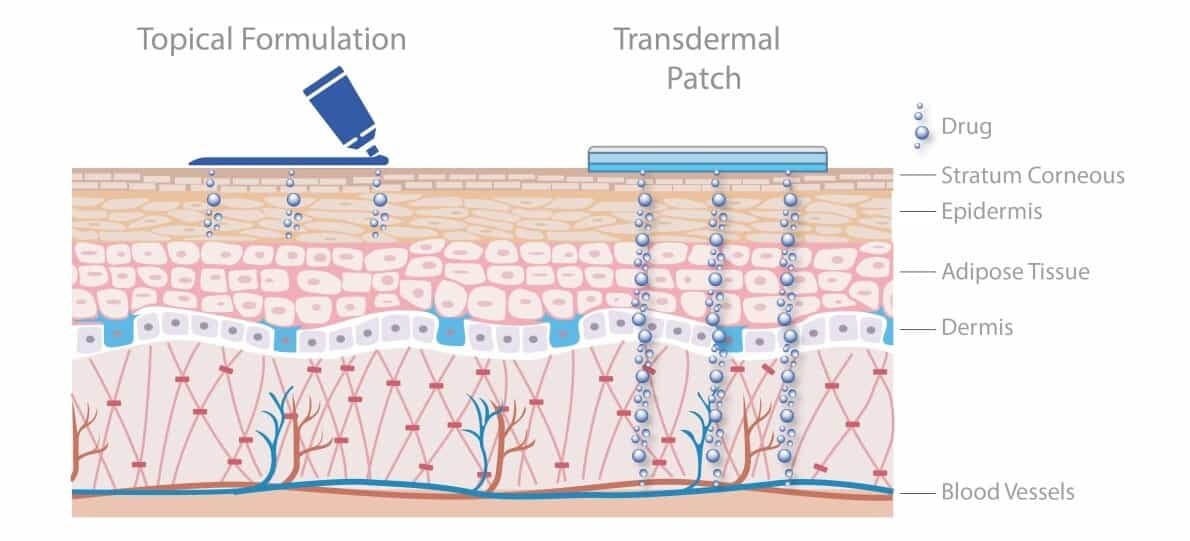

The release of active ingredients in semisolid dosage forms varies. Some stay on the surface of your skin to tackle issues like irritation, while others can pass through the skin layers and get into the bloodstream for continuous relief. No matter the approach, the goal is the same: deliver medicine in a form that's both effective and comfortable for everyday use.

You might've heard about the term "semi-liquid dosage form" when people talk about semisolid dosage forms. These terms are sometimes used interchangeably in the pharmaceutical world, but they differ slightly. "Semisolid" is actually more precise and widely accepted. If you're curious to learn more, keep reading—we'll discuss it later.

Types of Semisolid Dosage Forms

Different types of semisolid dosage forms cater to different needs. Since they're either topical or transdermal, these formulations can deliver protective, therapeutic, and cosmetic effects.

Based on that, there are many types of semisolid dosage forms out there. To help clarify, we'll also give you some examples of these types.

1. Ointments

Composition & Characteristics:

— Typically made with hydrocarbon (petrolatum), absorption bases (e.g., lanolin), or water-in-oil (w/o) emulsion bases.

— Have a high oil content, giving them a thick, greasy feel and making them slower to absorb.

— Act as occlusive barriers, trapping moisture and active ingredients against the skin.

Benefits & Uses:

— Excellent for very dry or cracked skin due to their occlusive nature, which helps prevent water loss.

— Used in treating chronic skin conditions like eczema or psoriasis, where deep moisturization is needed.

— Provide long-lasting contact with the skin, which can enhance medication absorption (though they can feel heavy).

Real-World Examples:

— Petrolatum (e.g., Vaseline) for minor cuts and dryness.

— Prescription steroid ointments to reduce inflammation in psoriasis.

2. Creams

Composition & Characteristics:

— Usually an oil-in-water (o/w) or water-in-oil (w/o) emulsion, but most commercially available creams are o/w.

— Lighter and less greasy than ointments, with a blend of oils, water, and emulsifiers that keep the mixture stable.

— Absorb more quickly than ointments, leaving less residue on the surface.

Benefits & Uses:

— Ideal for moderate hydration needs, especially on areas that might be prone to breakouts if occluded by heavier bases.

— Common in facial moisturizers, hand creams, and medicated treatments for mild rashes or fungal infections.

— Good option for patients who dislike the heaviness or shininess of ointments.

Real-World Examples:

— Hydrocortisone creams for itchy or irritated skin.

— OTC antifungal creams for athlete's foot or ringworm.

3. Gels

Composition & Characteristics:

— Made with water or aqueous/alcoholic solutions thickened by gelling agents.

— Often transparent or translucent, with a cool, non-greasy feel.

— Dry quickly once applied, which can be especially soothing on inflamed or hot skin.

Benefits & Uses:

— Popular for treating acne (due to the quick absorption and non-clogging texture).

— Great for cooling relief of conditions like sunburn, muscle aches, or minor burns.

— Can deliver medications (such as analgesics) without leaving an oily film.

Real-World Examples:

— Aloe vera gels for sunburn relief.

— Topical pain relief gels containing menthol or lidocaine.

4. Pastes

Composition & Characteristics:

— Thicker and more solid than ointments, typically containing a high percentage of powder (like zinc oxide or starch) in a fatty or aqueous base.

— Sit on the skin's surface to guard against external factors and absorb moisture or secretions.

— Less greasy than pure ointments but can still feel somewhat heavy.

Benefits & Uses:

— Form strong barriers against friction or irritation, making them ideal for diaper rash or bedsores.

— Useful for conditions where the skin needs extended contact with medication or a protective shield.

— Less prone to running or melting in warm conditions compared to creams or ointments.

Real-World Examples:

— Zinc oxide pastes for diaper rash or wound protection.

— Some dental pastes for canker sores or oral lesions.

5. Lotions

Composition & Characteristics:

— Thinner, pourable mixtures often in an oil-in-water emulsion.

— High water content makes them easy to spread and quick to absorb.

— Usually contain additional ingredients like humectants (glycerin) or mild surfactants.

Benefits & Uses:

— Perfect for covering larger or hair-covered skin areas without the residue of thicker forms.

— Commonly used for routine body moisturization, mild sunburn relief, and itch control.

— Won't leave a heavy film on the skin, making them a go-to for daily skincare routines.

Real-World Examples:

— Calamine lotion for itching or mild irritations.

— Over-the-counter body lotions with added vitamins or sunscreen.

6. Foams

Composition & Characteristics:

— Have a bubbly, light texture. Created when a solution (oil-in-water or water-in-oil) is aerated with a propellant or air.

— Stabilizers help the foam keep its shape and prevent collapse.

— Easy to apply over uneven or hard-to-reach areas.

Benefits & Uses:

— Great for scalp treatments, as they can spread through hair without leaving it matted or oily.

— Often used in rectal or vaginal applications where a more expansive and uniform coverage is needed.

— Can provide rapid absorption for certain active ingredients.

Real-World Examples:

— Foaming prescription steroids for scalp psoriasis.

— Rectal foam for ulcerative colitis treatments.

7. Suppositories

Composition & Characteristics:

— Typically use a fatty or water-soluble base that melts at body temperature.

— Shaped for rectal, vaginal, or urethral insertion.

— Deliver medication directly to the local area or allow for systemic absorption.

Benefits & Uses:

— Bypass the gastrointestinal tract and can avoid first-pass metabolism, making them useful for patients who can't swallow pills.

— Provide localized relief (like hemorrhoid treatments) or systemic effects (like nausea control or pain management).

— Remain in a stable, solid state at room temperature but soften or dissolve upon insertion.

Real-World Examples:

— Glycerin suppositories for constipation relief.

— Vaginal antifungal suppositories for yeast infections.

8. Plasters and Transdermal Patches

Composition & Characteristics:

— Adhesive-backed systems containing medication in a semisolid matrix or reservoir.

— Offer a sustained release of the drug over a prolonged timeframe.

— Designed to stick well but avoid causing skin irritation.

Benefits & Uses:

— Great for chronic conditions needing steady doses, such as pain management or nicotine replacement.

— Can simplify dosing schedules, since patients don't have to remember multiple daily doses.

— Bypass the digestive tract, reducing stomach-related side effects.

Real-World Examples:

— Fentanyl patches for severe chronic pain.

— Nicotine patches to curb smoking cravings.

9. Lipsticks and Balms

Composition & Characteristics:

— Wax-based formulations that soften at body temperature, combining oils, waxes, and sometimes color or active ingredients.

— Provide a semisolid "stick" form that can be easily applied to lips or other targeted areas.

— Can include medicated agents (e.g., sunscreens, analgesics) or simply moisturizing elements.

Benefits & Uses:

— Protect against dryness, cracking, and environmental damage.

— Some varieties offer therapeutic relief (like cold sore balms), while others focus on cosmetic appeal.

— Often include sunscreens and other protective ingredients to guard delicate lip skin.

Real-World Examples:

— Medicated lip balms with menthol or benzocaine for cold sore pain.

— Colored lipsticks with moisturizing properties and SPF.

Compare "Semisolid Dosage Form" and "Semi-Liquid Dosage Form"

Now, let's go back to talk about the two terms: semisolid and semi-liquid. We put together a concise comparison table highlighting their key differences.

|

Semisolid Dosage Forms |

Semi-Liquid Dosage Forms |

|

|

Formulations with consistency between solid and liquid, typically retaining their shape unless acted upon. |

Definition |

Formulations that are more fluid than solids but not completely liquid, often flowing more easily than semisolids. |

|

Thick, viscous, and spreadable. |

Typical Consistency |

Flowing, less viscous, can be pourable or sprayable. |

|

Ointments, creams, gels, pastes, suppositories, transdermal patches. |

Common Examples |

Emulsions, lotions, suspensions, sprays, foams. |

|

Primarily topical, transdermal, or mucosal. |

Primary Routes of Administration |

Often topical as well, but can include oral, nasal, or pulmonary routes. |

|

Ideal for prolonged contact with the skin or mucous membranes; can provide localized or systemic effects. |

Usage & Applications |

Good for ease of application, rapid absorption, or uniform coverage, depending on formulation. |

|

Often contains higher viscosity agents (e.g., waxes, fatty bases, thickening agents). |

Viscosity Control |

May require emulsifiers, stabilizers, or rheology modifiers to maintain fluidity and homogeneity. |

|

Typically in tubes, jars, or special dispensing containers (e.g., pumps for gels). |

Packaging |

Often in bottles, pumps, spray dispensers, or pressurized canisters (aerosols). |

|

Usually stable at room temperature; viscosity can be affected by temperature changes. |

Storage & Stability |

Can separate or sediment over time if not stabilized; may require shaking or specific storage conditions. |

Key Considerations in the Formulation of Semisolid Dosage Forms

When developing different types of semisolid dosage forms—whether it's a cream, ointment, gel, or foam—there are several important factors that guide how well the final product will work and how it feels to the user.

- Base Selection: The type of base (oil-in-water, water-in-oil, or hydrocarbon) determines how the product spreads, absorbs, and feels on the skin.

- Active Ingredient Solubility and Stability: Ensuring the drug remains potent and evenly distributed is vital for consistent, effective treatment.

- Rheological Properties: Thickness and flow behavior impact the application's ease, coverage, and how the medication is delivered to the skin.

- pH and Skin Compatibility: Stabilizing pH levels ensures the medication works effectively while also protecting the skin's natural barrier.

- Preservatives and Microbial Control: Semisolid products often contain water, which can encourage microbial growth unless properly preserved.

- Sensory Attributes and Patient Experience: Products that feel greasy or smell unpleasant may reduce user compliance, hindering treatment success.

- Packaging and Storage: Appropriate containers and storage conditions prevent contamination and maintain product integrity.

Equipment Used for Manufacturing Semisolid Dosage Forms

If you're making different types of semisolid dosage forms, you need to rely on a range of specialized equipment. Below are some of the most common types used during production and packaging of your semisolid products:

1. Mixing and Blending Equipment

- Planetary Mixers: Ideal for high-viscosity products; the blades rotate on their axis and orbit around the mixing bowl, ensuring thorough blending.

- High-Shear Mixers: Use intense shear forces to break down particles and form stable emulsions.

(CHL-50 High-Shear Mixer - CapsulCN)

- Propeller or Paddle Mixers: Suitable for moderate viscosities and straightforward mixing tasks.

2. Heating and Cooling Systems

- Jacketed Vessels: Allow heating or cooling fluids to circulate around the product, maintaining precise temperatures during melting or emulsification.

- Temperature Controllers: Keep the product within a specific temperature range to protect heat-sensitive ingredients.

3. Vacuum Systems

- Vacuum Homogenizers: Remove air bubbles and improve uniformity. This also helps maintain product stability.

- Vacuum Pumps: Generate the vacuum environment needed for deaeration and homogenization.

4. Milling or Particle-Size Reduction Equipment

- Colloid Mills: Use a high-shear rotor and stator to reduce particle size, enhancing smoothness and uniformity.

(JM-L65 Colloid Mill - CapsulCN)

- Triple Roller Mills: Press the semisolid product between three rollers, refining the texture and eliminating grittiness.

5. Filling and Packaging Machines

- Tube Fillers: Automatically fill and seal metal or plastic tubes, ideal for creams and ointments.

(CNF-80A Tube Filler & Sealer - CapsulCN)

- Jar Filling Systems: Deposit precise amounts of semisolid into jars or tubs.

- Sachet/Stick Pack Fillers: Package single-use doses of lotions or gels in individual packets.

6. Labeling and Sealing Equipment

- Label Applicators: Attach labels with dosage information and branding.

- Heat Sealers or Induction Sealers: Add protective seals to containers, preventing contamination or product leakage.

The Bottom Line

Now that you know more about different types of semisolid dosage forms, it's time to put this knowledge into action! If you're looking to enhance your semisolid formulations or have questions about the right approach, reach out to us at iPharMachine. We're here to help! Feel free to call us or get in touch through our website!

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche