Understanding Different Types of Tablet Coating

Tablet coating is an essential process in the pharmaceutical and nutraceutical industries. It can enhance the appearance, protect from degradation, and optimize the performance of drug products. If you're looking to produce tablets that are of the highest quality, you've come to the right place!

In this blog post, we'll introduce you to the different types of tablet coating available, their advantages and disadvantages, and what equipment can be used for coating tablets efficiently. By the end of this article, you'll know how to take your pharma business to the next level by making good use of the tablet coating process! And if have met any tablet coating defects, you may check this guide: Common Tablet Coating Defects and Remedies.

How Many Different Types of Tablet Coating Are There?

The pharmaceutical industry employs three primary types of tablet coating for multiple reasons. These types include sugar coating, film coating, and enteric coating, each with its specific functions and applications.

1. Sugar Coating

Sugar coating has been used to cover tablets for a long time. It involves creating a hard, thick layer of sugar syrup around the tablet. The coating is dried and polished to deliver a smooth, shiny finish.

This coating is beneficial for three reasons:

A. It helps to hide the unpleasant taste of certain drugs that are bitter or unpalatable.

B. It provides protection against light and moisture, which can cause the drug to break down too quickly.

C. Sugar coating can enhance the appearance of the tablet and increase its shelf life.

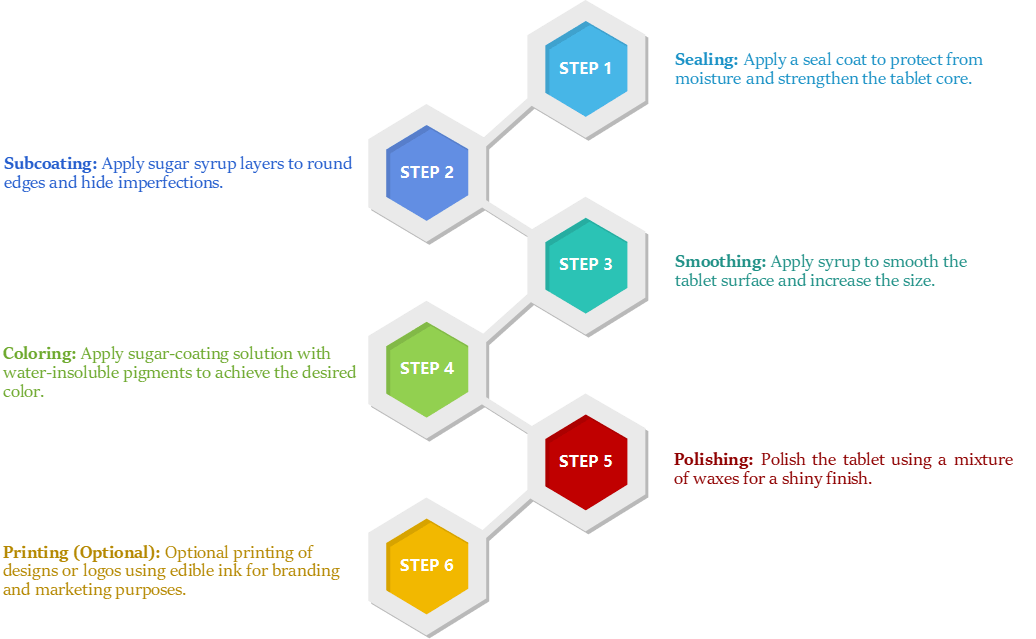

The sugar coating process can be divided into 6 steps:

2. Film Coating

While sugar coating was once a widely used method of tablet coating, drug manufacturers have largely switched to using the film coating process.

The film coating formulation is a mixture of multiple components, including:

- Polymers

- Plasticizers

- Colorants

- Solvents

This type of coating improves the tablet's appearance, masks the unpleasant taste or odor of the tablet's contents, controls the release of the active ingredients, and protects the tablet from moisture, light, and air.

Unlike sugar coating, film coating does not significantly affect how the drug is absorbed into the body. The film-coated tablet is smaller in size and easier to swallow. It also breaks down easily with agitation and moisture.

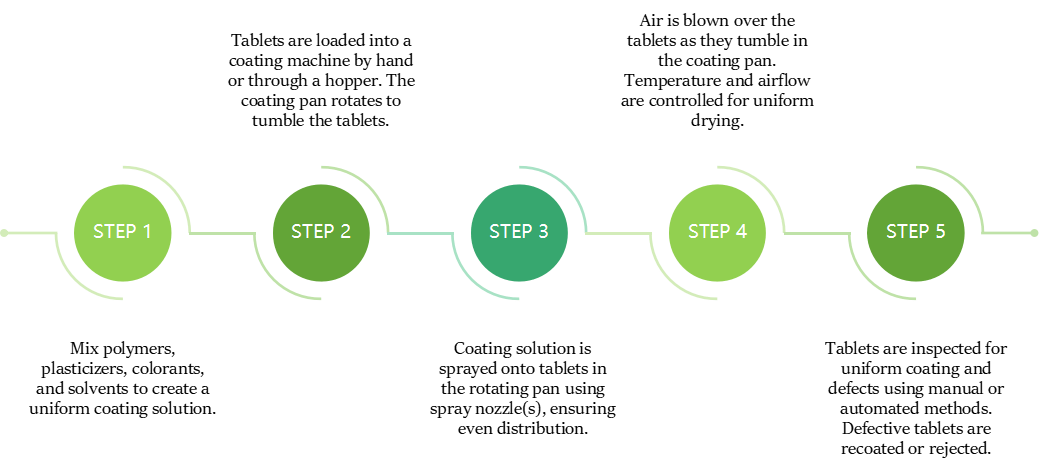

The process of film coating is performed in the following steps:

3. Enteric Coating

What is enteric coating? It is a specialized type of tablet coating. This coating is designed to protect the tablet's active ingredients from being dissolved in the acidic environment of the stomach. It holds the tablet in the stomach and only breaks down once the drug reaches the small intestine.

By doing so, the enteric coating allows the active ingredients to be released gradually and effectively into the bloodstream. This helps to enhance the therapeutic effect of the tablet. This type of coating is particularly useful for drugs sensitive to stomach acid.

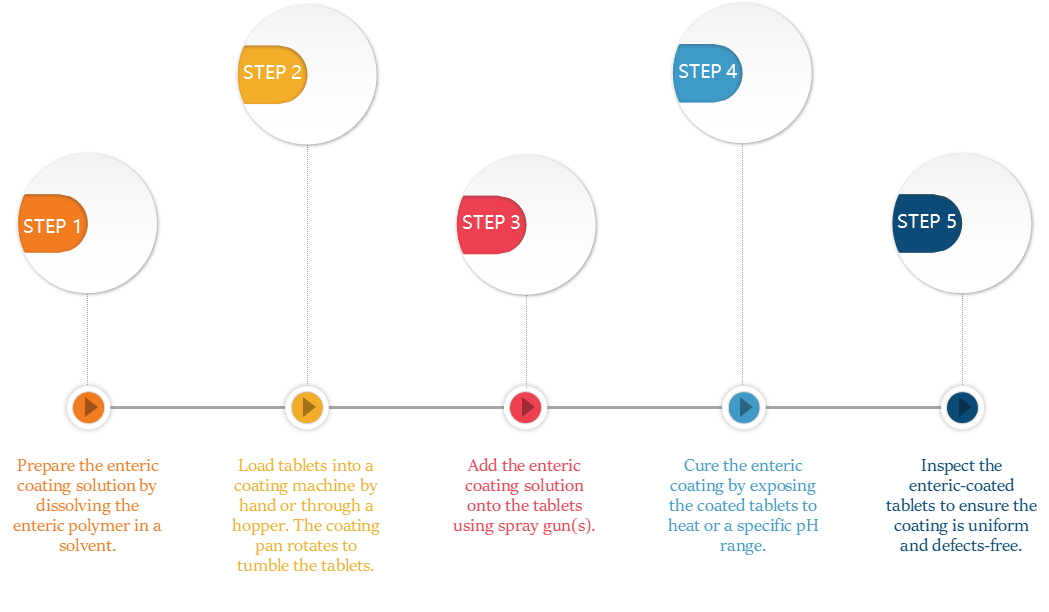

Here are the steps in the enteric coating process:

As you can see, the enteric coating process is similar to the film coating method. Yet, the former is formulated for the drug that needs to be released in specific areas of the intestine. So, the specific steps in the enteric coating may include different coating solutions, using specialized equipment to control pH and temperature, and additional testing to ensure the coating has the desired properties.

Read More:

Enteric-Coated VS Film-Coated Tablets: What's The Difference?

Film Coating VS Sugar Coating: What's The Difference

Advantages and Disadvantages of Different Types of Tablet Coating

Tablet coating is an important step in the manufacturing of pharmaceutical solids. Yet, each type of coating has its own advantages and disadvantages. Understanding the benefits and drawbacks of the three main types of tablet coating can help you choose the best coating method for your product. Let's take a look!

1. Sugar Coating

Sugar coating is the oldest and most traditional form of tablet coating. The process requires multiple layers of coating.

Advantages:

– Sugar-coated tablets are aesthetically appealing, as they are shiny and colorful.

– The sugar coating masks the taste and odor of specific drug ingredients, making the tablet easier to swallow.

– This coating can also build a barrier against moisture, light, and oxygen. This can help to extend the shelf life of the tablet.

Disadvantages:

– Sugar coating increases the tablet size, making swallowing difficult for some patients.

– Sugar coating can reduce drug efficacy as it may delay the release of active ingredients.

– The coating process is time-consuming and requires skilled labor. This can increase the cost of the final product.

2. Film Coating

Film coating is a more popular form of tablet coating. It's mixed with polymers, plasticizers, colorants, and solvents to form a film around the tablet.

Advantages:

– Film-coated tablets are smoother and more uniform in size. They are easier to swallow than sugar-coated tablets.

– Film coating can also provide a barrier to external factors, helping to extend the drug's shelf life.

– The process of film coating is more automated and cost-effective than sugar coating. This can reduce the cost of the final product.

Disadvantages:

– Film-coated tablets might not look as aesthetically appealing as sugar-coated ones as they are not as shiny or bright.

– The film coating can be prone to cracking or peeling. This can affect the appearance and stability of the tablet.

– Since the process is more automated, the filling coating equipment may cost more than conventional machines.

3. Enteric Coating

Enteric coating is a specialized form of tablet coating. It's designed to protect the drug from gastric acid but allows it to dissolve in the alkaline environment of the small intestine.

Advantages:

– Enteric-coated tablets can protect the drug from degradation in the acidic environment of the stomach. This can improve its bioavailability and efficacy.

– The coating can also help to reduce gastrointestinal side effects like stomach upset.

– Enteric coating can be used to deliver drugs sensitive to acidic environments, such as aspirin.

Disadvantages:

– Enteric coating is generally more expensive than sugar or film coating due to the additional materials required.

– Enteric-coated tablets can't be crushed before swallowing.

– The enteric coating may delay the release of the drug. This can impact the efficacy of time-sensitive medications.

Equipment Used For Tablet Coating

To end up with the above different types of coating reliably, you need an efficient piece of tablet coating equipment.

What is a tablet coating machine? It's an automated device designed to apply a thin layer of coating solution to the tablet. If you're in the market for such equipment, you'll find that there are mainly three types of tablet coating machines out there.

1. Standard Coating Pan

A standard coating pan is a circular or cylindrical vessel used in the pharmaceutical industry. It rotates on an axis at an angle between 30 and 45 degrees from the horizontal plane. This allows the tablets to tumble and move freely within the pan while the coating material is sprayed onto them.

Typically, there are three different methods to improve the drying performance of the standard coating pan. They are:

A. Pellegrini pan system

B. Immersion sword system

C. Immersion tube system

2. Perforated Pan

A perforated pan is a type of tablet-coating equipment widely used in the pharmaceutical industry. The machine consists of a fully perforated drum that rotates on a horizontal axis and a spray system applying the coating solution to the tablets inside the drum.

There are several different perforated pan systems available, each designed to optimize coating and drying.

A. Accela-cota

B. Hi-coater

C. Driacoater

D. Glatt coater

3. Fluidized Bed

A fluidized bed coater works by suspending the tablets in a stream of air, creating a fluid bed. The machine then applies the coating solutions to the solids as they move through the bed. The fluid bed provides an ideal environment for uniform and efficient coating of each tablet.

Conclusion

In summary, understanding tablet coating process in the pharmaceutical industry is essential for finding the best tablet coating machine manufacturers and best equipment. Each process has benefits and drawbacks, from sugar coating to film coating and enteric coating. By selecting the right type of coating, you can improve the efficacy and safety of your products.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche