Getting to Know Different Types of Counting Machines

Imagine a tool that streamlines your tablet manufacturing process and ensures flawless pill counting - that's where tablet counters come to play. Mechanical devices often come in a variety of types to meet specific needs. So do the tablet counting machines. If you're searching for your first tablet counter or looking to optimize your operations, we're here to help.

This blog post will explore the main types of tablet counting machines. Also, it will provide you with a head-to-head comparison of these machines to guide your choice. And that's not all - we will explore iPharMachine's cutting-edge tablet counting machine specifications in different categories. So, you can have a rough idea of what types of tablet counting machines suit you best. Let's get started!

Different Types of Tablet Counting Machines

Based on the automation degrees, tablet counters can be classified into three types. They include manual, semi-automatic, and fully automatic. Each has its own advantages and limitations.

1. Manual Tablet Counters

Manual tablet counters are the simplest tablet counting equipment. They are more of a handy tool for tablet counting. These pill counters are designed in the form of counting trays made of either plastic or stainless steel.

|

|

Some pill counting trays come in a flat plate, while some feature a set number of evenly spaced holes. The former requires counting by a human operator using a spatula. The latter is more convenient since the operator only needs to count the pills sitting in the holes.

Manual tablet counters are suitable when a hands-on approach is preferred. While they require more manual effort and time, they can be cost-effective for businesses with lower production volumes.

Advantages of Manual Tablet Counters

- Affordable for start-ups and even individuals

- Suitable for small batches when automated devices are not available

- Allows for visual confirmation of the pill count

Limitations of Manual Tablet Counters

- Time-consuming counting process, especially when larger quantities are required

- Prone to human error

- Not practical for large-scale production

2. Semi-Automatic Tablet Counting Machines

As the name suggests, semi-automatic tablet counting machines feature a certain level of automation but still require manual operations. These machines are often available as a tabletop version. They can be a standalone device or integrated into an existing tablet production line.

|

|

When using a semi-automatic machine, you need to load tablets and place bottles in position manually. In terms of automated operations, these machines boast photoelectric sensors to perform counting. This speeds up the process compared to manual counting.

Semi-automatic tablet counting machines can significantly improve counting accuracy and efficiency. These machines are adjustable and adaptable to various medication shapes, sizes, and formulations. They are popular choices for small to mid-sized pharmaceutical operations.

Advantages of Semi-Automatic Tablet Counting Machines

- Faster counting and packaging compared to manual tablet counters

- Reduced risk of human error

- Cost-effective solution for increasing productivity

- Can handle different sizes and shapes of tablets

Limitations of Semi-Automatic Tablet Counting Machines

- Higher initial investment than manual methods

- Not fully automated, requiring a certain level of human intervention

- Requires operator training to ensure proper monitoring and troubleshooting

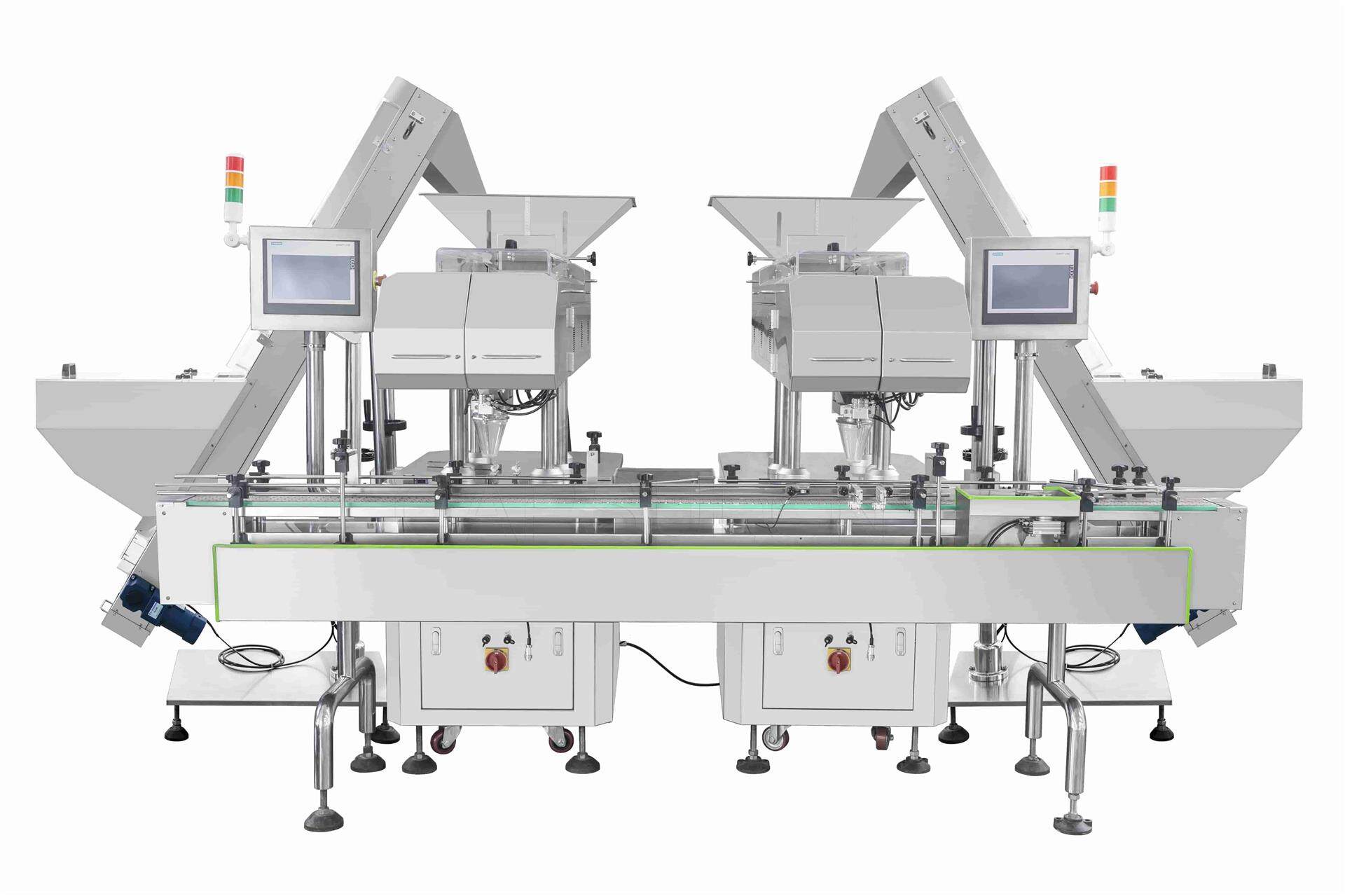

3. Automatic Tablet Counting Machines

Fully automatic tablet counting machines are advanced devices. They are equipped with photoelectric sensors, conveyors, and other automated systems. These components ensure precise counts while minimizing errors.

|

|

An automatic tablet counting machine typically includes an easy-to-use touchscreen interface. This feature enables operators to set the counting parameters, monitor the counting process, and make adjustments as needed.

Automatic tablet counting machines are designed to handle the entire process, from tablet feeding and counting to bottle filling. The high automation level allows for counting and filling large quantities of tablets in a short time. So, they are ideal for high-volume pharmaceutical manufacturing.

Advantages of Automatic Tablet Counting Machines

- High-speed counting and packaging for large production volumes

- Exceptional counting accuracy and consistency

- Minimal operator intervention required

- Adaptable and compatible with different tablet sizes and shapes

Limitations of Automatic Tablet Counting Machines

- Higher purchase and maintenance costs

- Requires trained operators for setup, monitoring, and regular maintenance

- More floor space is required to accommodate the machine

A Comparison of Three Types of Tablet Counting Machines

Here's a detailed comparison table for manual, semi-automatic, and automatic tablet counting machines.

|

Item |

Manual Tablet Counter |

Semi-Automatic Tablet Counting Machine |

Automatic Tablet Counting Machine |

|

Initial Investment |

Low initial cost |

Moderate initial investment |

Higher initial investment for advanced technology |

|

Output |

Limited output due to manual process |

Moderate output for small to medium batches |

High throughput for large-scale production |

|

Production Efficiency |

Low |

Moderate |

High |

|

Counting Accuracy |

Moderate accuracy, prone to human error |

High accuracy due to automated counting |

Very high accuracy with advanced technology |

|

Operator Involvement |

Requires significant operator involvement |

Requires operator interaction for setup and monitoring |

Minimal operator involvement |

|

Human Error Potential |

High potential for human errors in counting |

Moderate potential for operator errors |

Very low potential for errors due to automation |

|

Counting Method |

Visual counting by operators |

Automated counting by using photoelectric sensors |

Advanced automated counting mechanisms |

|

Process Complexity |

Simple and straightforward |

Moderate complexity due to human intervention |

High complexity due to advanced automation |

|

Quality Control |

Dependent on the operator's skills |

Dependent on manual monitoring and checks |

Built-in quality-control mechanisms |

|

Flexibility |

Limited to specific tablet sizes and shapes |

Moderate flexibility for various tablet types |

High flexibility for different tablets |

|

Packaging Integration |

Manual transfer of counted tablets to packaging |

Automatic dispensing into bottles |

Fully automated dispensing, packaging, and conveying |

|

Maintenance |

Low maintenance requirements |

Moderate maintenance due to moving parts |

Moderate maintenance due to advanced systems |

Specifications of Different Types of Tablet Counting Machines

If you clearly understand the types of tablet counting machines, there is one more important thing - the equipment specifications - to consider before making a purchase. By comprehending these details, you can confidently choose the right machine.

At iPharMachine, we offer diverse tablet counting solutions that can cover all your needs. Let's take a closer look at the specifications of these machines to help you make an informed decision.

Semi-Automatic Tablet Counting Machine Specifications

|

Model |

CDR-3A |

CDR-5A |

YL-4 |

YL-4B |

|

Output |

800-1200 pcs/min |

300-1500 pcs/min |

2000-4000 pcs/min |

1000-4000 pcs/min |

|

Tablet Size |

Ф5mm-25mm |

Ф3mm-13mm |

Ф6mm-23mm |

Ф5.5mm-18mm |

|

Capsule Size |

#00-#5 |

#00-#5 |

#00-#4 |

#00-#5 |

|

Container Size |

15-500ML |

15-500ML |

15-500ML |

15-500ML |

|

Weight |

55kg |

22kg |

75kg |

65kg |

|

Dimensions |

830x820x350mm |

400x360x550mm |

980x790x930mm |

920x780x930mm |

Automatic Tablet Counting Machine Specifications

|

Model |

PBDS-8 |

PBDS-12 |

PBDS-16 |

PBDS-24 |

|

Output |

10-50 bottles/min |

20-55 bottles/min |

60-100 bottles/min |

80-150 bottles/min |

|

Tablet Size |

Ф5.5mm-22mm |

Ф5.5mm-22mm |

Ф5.5mm-22mm |

Ф5.5mm-22mm |

|

Capsule Size |

#00-#4 |

#00-#4 |

#00-#4 |

#00-#4 |

|

Container Size |

Dia.: 20-100mm |

Dia.: 20-100mm |

Dia.: 20-100mm |

Dia.: 20-100mm |

|

Weight |

280kg |

300kg |

360kg |

580kg |

|

Dimensions |

1600x1500x1600mm |

1600x1500x1600mm |

2600x1600x1600mm |

4200x1800x1600mm |

The Bottom Line

Different types of tablet counting machines will offer you a wide range of options for accurate counting and efficient production. Whether you're a medicine maker or a supplement producer, there will be one that suits your needs. Don't miss out on the benefits these machines bring. Choose the right one for your business and streamline your counting process today!

Leave your comment

Comments

Thanks for sharing about the tablet manufacturing process. Tablet manufacturing is critical for companies dealing with vitamins and pharmaceuticals. You can also check out about <a>pharma manufacturer in india for capsules</a> <a href=”#https://www.ikonremedies.com/product-category/pharma/?wpf=pharma&wpf_cols=3&wpf_page=1&wpf_dosage-form=capsules”>here.

From: Ikonremedies | Created on: 10/16/2023 6:37 AM

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche