5 Maintenance Tips and Solutions for V blenders

When buying a V blender, you must want to use it longer. So it is important to keep good maintenance. It ensures optimal performance and extends operational life. Proper maintenance includes many routines, you’d better know them well and operate them properly.

Five Tips for V Blender Maintenance

There are some common tips to make a better blender operation and use time.

Check the machine parts regularly

It is necessary to conduct regular maintenance for key machine parts. For those components used for rotation like shafts, you check it by manual operation. Rotate them manually and see if they can move smoothly without resistance. For those used for tightening, you should test whether they are tight and secure.

Also, you need to inspect the wiring and connections. Ensure that connections are secure and that there are no exposed wires. For safer operation, safety mechanisms should be checked. You can check if safety interlocks and emergency stop mechanisms can work well.

You can check these parts once a month. If you want to keep a closer eye on the machine, checking once a week is also good.

Replacement of worn-out parts

When checking parts, you might notice some are damaged or worn out. For example, seals and gaskets may have cracks or tears. Or bearings might be significantly worn or near the end of their lifespan. In such cases, you should replace these parts with new ones.

Lubrication

It is pretty useful to lubricate critical components such as bearings and joints. It guarantees the smooth operation and longevity of a V Blender. For lubricant selection, you’d better use the lubricant specified by the blender's manufacturer. This can usually be found in the user manual or maintenance guide.

Common lubricants include oils and greases. You can apply them with a clean brush. Please note that clean the bearings, joints, and surrounding areas before applying. It aims to remove any dust, debris, or old lubricant. So contaminants do not enter the moving parts and degrade the new lubricant.

For bearings, you should make sure that the lubricant penetrates the bearing surfaces. For joints, you need to apply evenly over the entire surface. In addition, you should avoid over-lubrication. It would attract dust and debris. Then they form abrasive particles that can damage moving parts.

Monitor the mixing process

During mixing, you can first check if all display panels and indicator lights are functioning correctly. Then you should pay attention to the operating sounds. If you hear any unusual noises, such as grinding, knocking, or squealing sounds. They may indicate mechanical issues. Common problems involve damaged gears, loose parts of the blender, insufficient lubrication, or belt issues.

In addition, you should observe the blender for any abnormal vibrations. It means imbalanced loads or mechanical faults. If you find the issue, inspect internal components such as bearings, and mounts for wear or damage.

Clean after mixing

There is an often overlooked detail. You need to clean the machine after it stops running. This helps the machine run smoothly next time. It mainly includes the following three steps.

- Internal cleaning - You use a vacuum or brush to clean out extra powders and granules. It can prevent contamination for the next batch.

- External cleaning - You can wipe down the exterior surfaces with a damp cloth. It helps remove dust and debris. If you want to use cleaning agents, make sure they do not damage the blender’s material.

- Disinfection - It is also necessary to disinfect the blender with approved sanitizers. It can maintain hygiene standards. This is especially important for pharmaceutical and food applications.

How to Troubleshoot Common V Blender Problems?

When you use a V blender, it is normal to encounter some issues. If you can deal with it yourself, there is no need to find a repairman. Then you can save some repair fees.

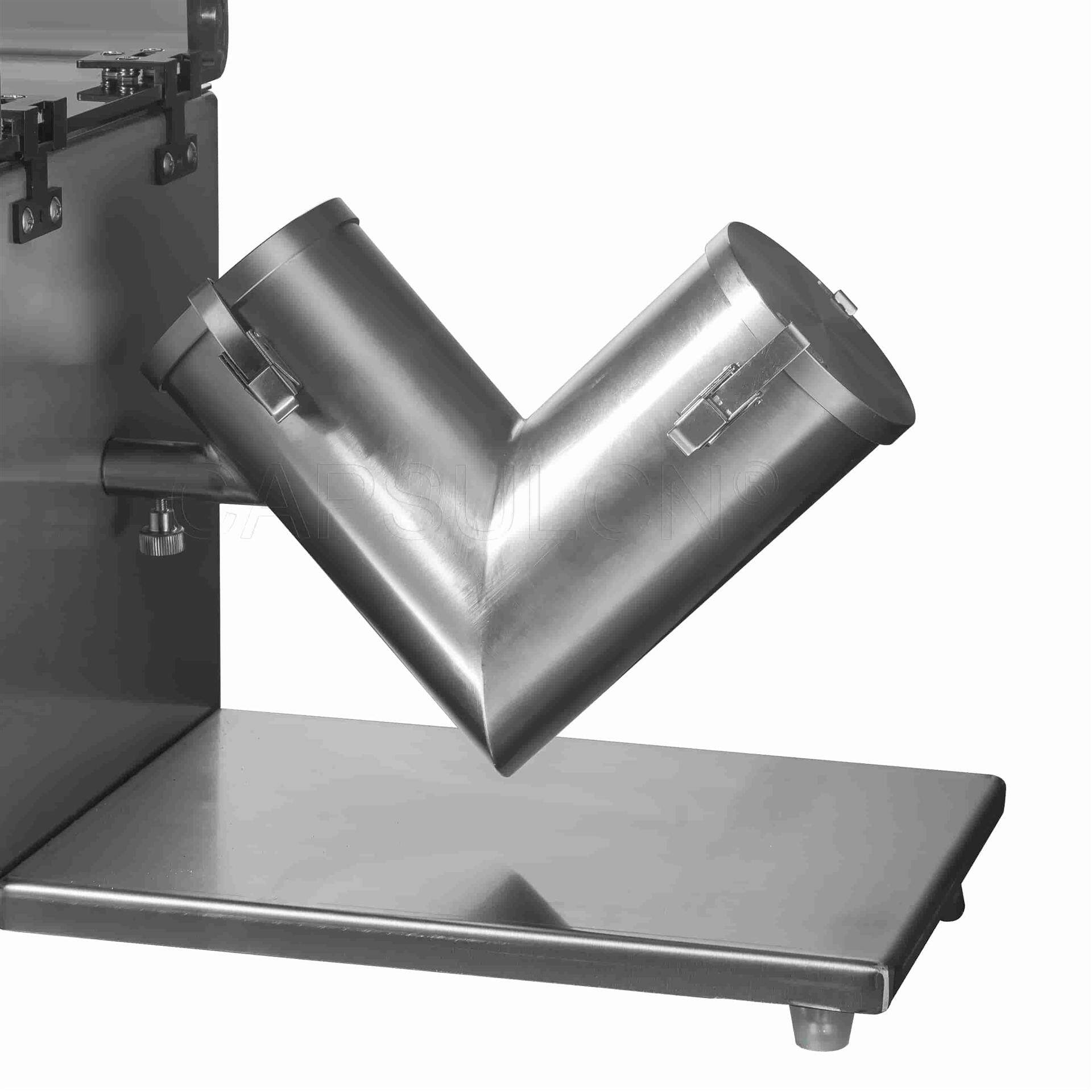

Take our powder mixer V1 for example. This machine is used for mixing dry powder and granulates in the pharmaceutical, chemical and food industries. The V-shaped cylinder makes materials mixed without dead angle, evenly and high efficiently. It is also easy to operate and clean. If you have problems when using it, here are some solutions for your reference.

|

Fault |

Cause |

Solution |

|

There is powder leak and dust at the outlet and inlet. |

The buckle at the outlet is not tight. |

Fix the position and then lock it. |

|

It is because of the ageing sealing ring. |

Replace the sealing ring. |

|

|

The V-shaped cylinder doesn’t work when the machine is started. |

The protective cover is not closed. |

The protective cover should be closed when starting the machine. |

|

The revolving speed is wrongly set. |

Increase the speed. |

|

|

The power is connected but the power switch is not on. |

Replace the fuse. |

|

|

The iron absorption stone of the protective cover falls down. |

Mount the iron absorption stone according to the N-S poles. |

|

|

There is abnormal vibration noise. |

The foot pads are uneven or missing. |

Adjust the machine to be level or add foot pad. |

|

The main shaft shakes. |

The screw of the motor is not fixed properly. |

|

|

The V-shaped cylinder does not rotate smoothly. |

The set screws are not tightened. |

|

|

The V-shaped cylinder falls down during working process. |

The set screws are not tightened properly. |

Reposition and tighten the set screws. |

The End

Good maintenance can prevent unexpected breakdowns, ensuring smooth operation. In addition to your knowledge of the machines, employee training is also necessary. Proper training can greatly improve working efficiency. Besides, you can record each maintenance and repair. It helps in identifying recurring issues and patterns of wear and tear. You then know if some parts require replacement.

Historical data also allows for predictive maintenance. Potential issues can be found before they lead to significant breakdowns. This approach minimizes downtime and extends the equipment's lifespan.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche