Guide to V Blender Parts, Diagram and Design

When it comes to process manufacturing, tumble blenders are one of the must-have tools. These blenders are best known for their low-impact mechanism.

A V blender, one of the most popular tumble blenders, is widely used in the pharmaceutical, nutraceutical, food, chemical, cosmetics, plastics, and biotechnology industries.

What is a V blender? How does a V blender work? This machine relies on diffusion mixing, doing a great job in processing abrasive or fragile solids. It is also capable of making precise mixtures formulated with trace elements or ingredients that are very different in size and density.

The V blender typically consists of a variety of parts. These parts work together to make sure that every blend comes out precisely and homogeneously. With the help of this guide, you will become familiar with the V blender parts that help your mixing process run efficiently.

Read more:

V Mixer VS Ribbon Blender: Know the Difference

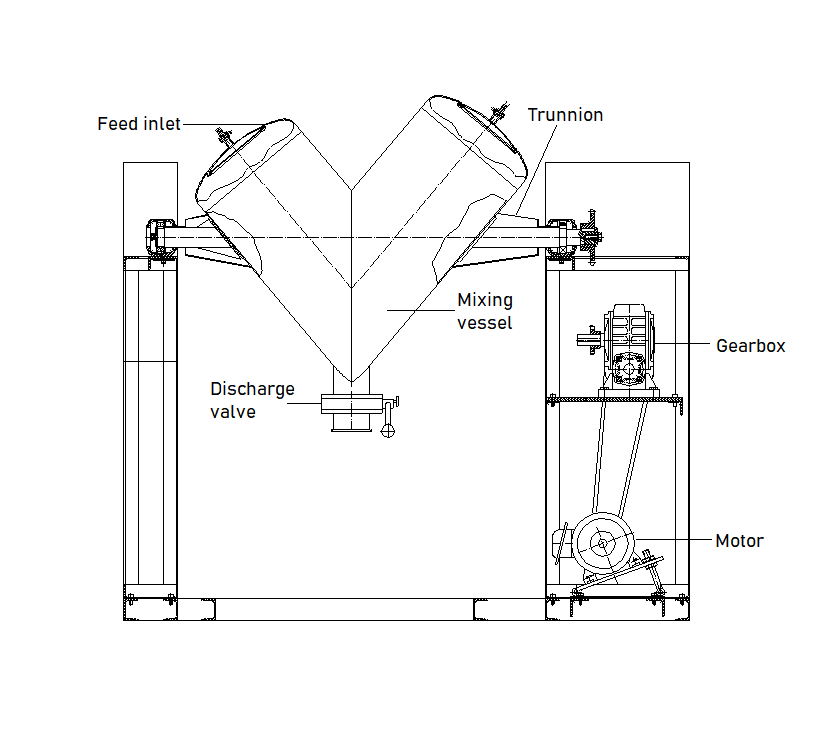

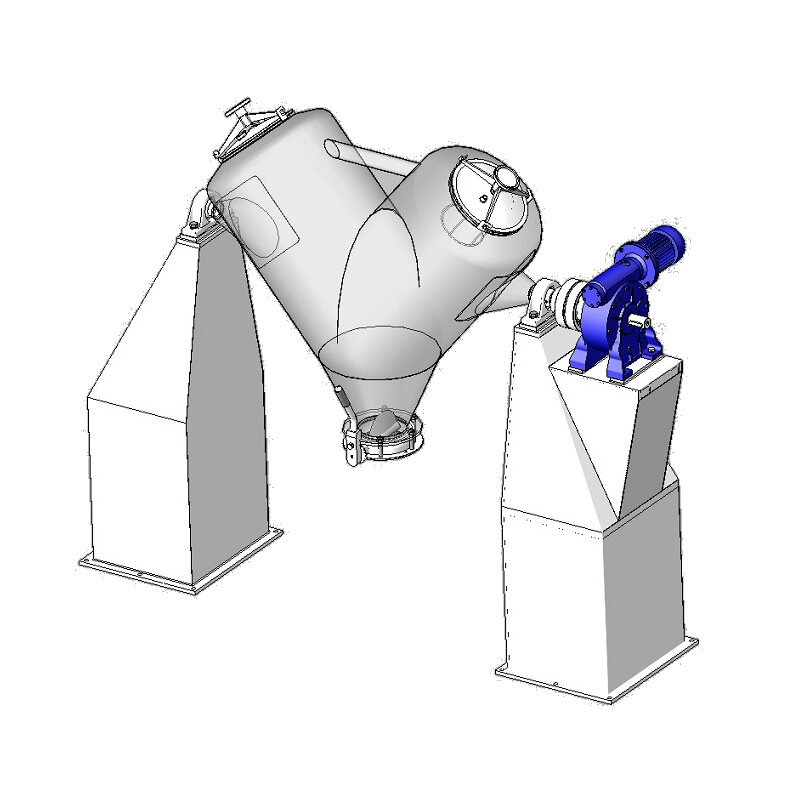

V Blender Diagram

Before diving into the V blender parts, let's take a closer look at the drawing shown below. This V blender diagram will help you understand the machine parts in a simpler, more intuitive way.

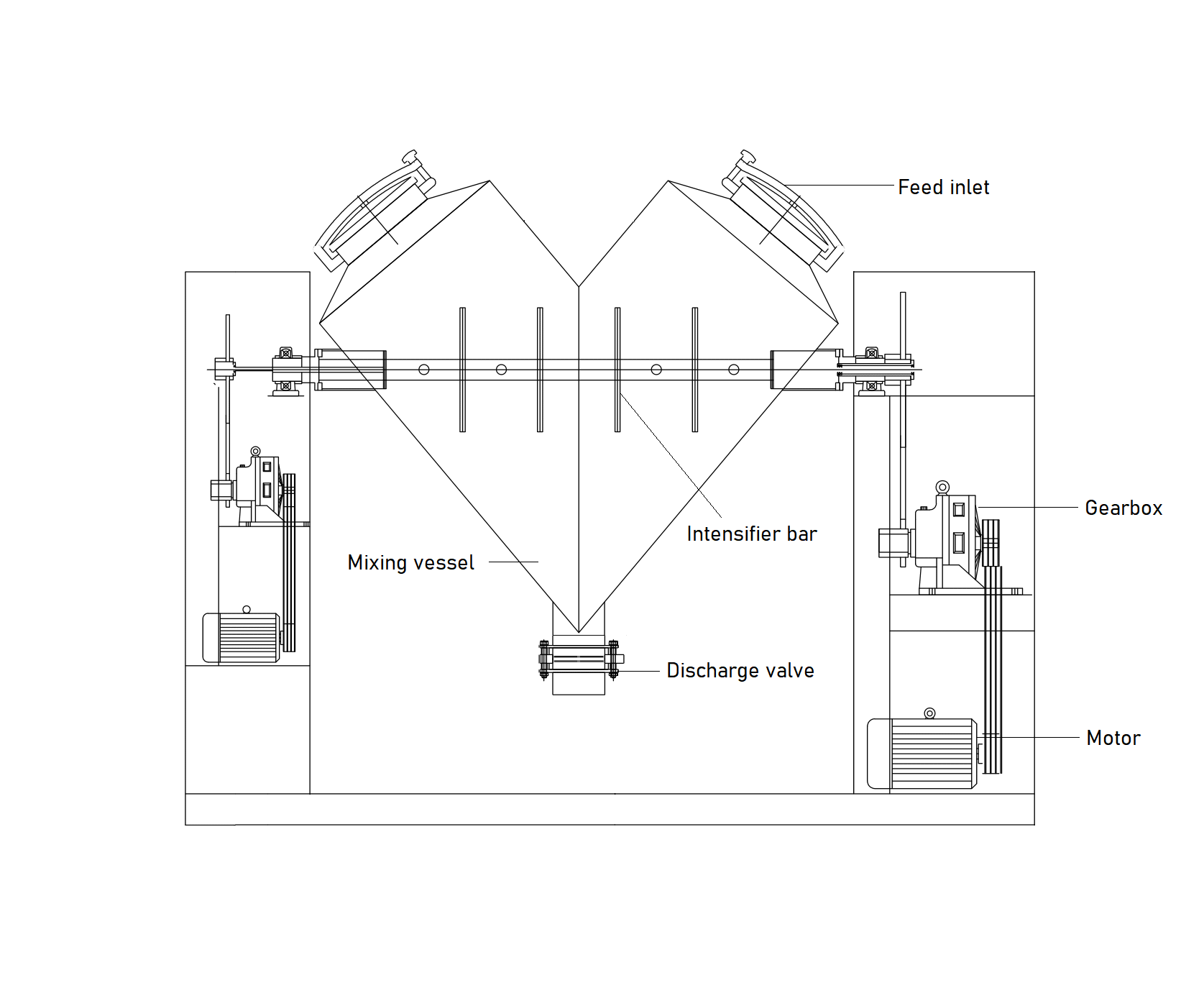

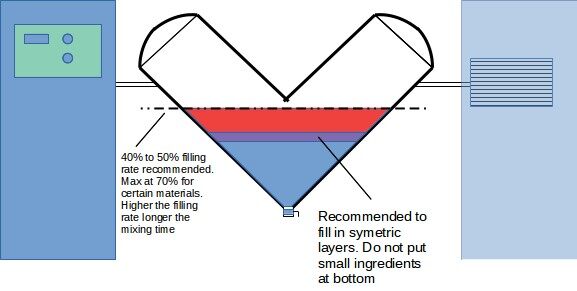

Below is another V blender diagram. As you can see, the biggest difference between these two drawings is the construction of the mixing vessel. The component going through the vessel is called an intensifier bar. It plays a big part in improving mixing efficiency, and we'll explore it later.

6 Important V Blender Parts

Now let's look at the critical parts of a V blender.

1. Feed inlet

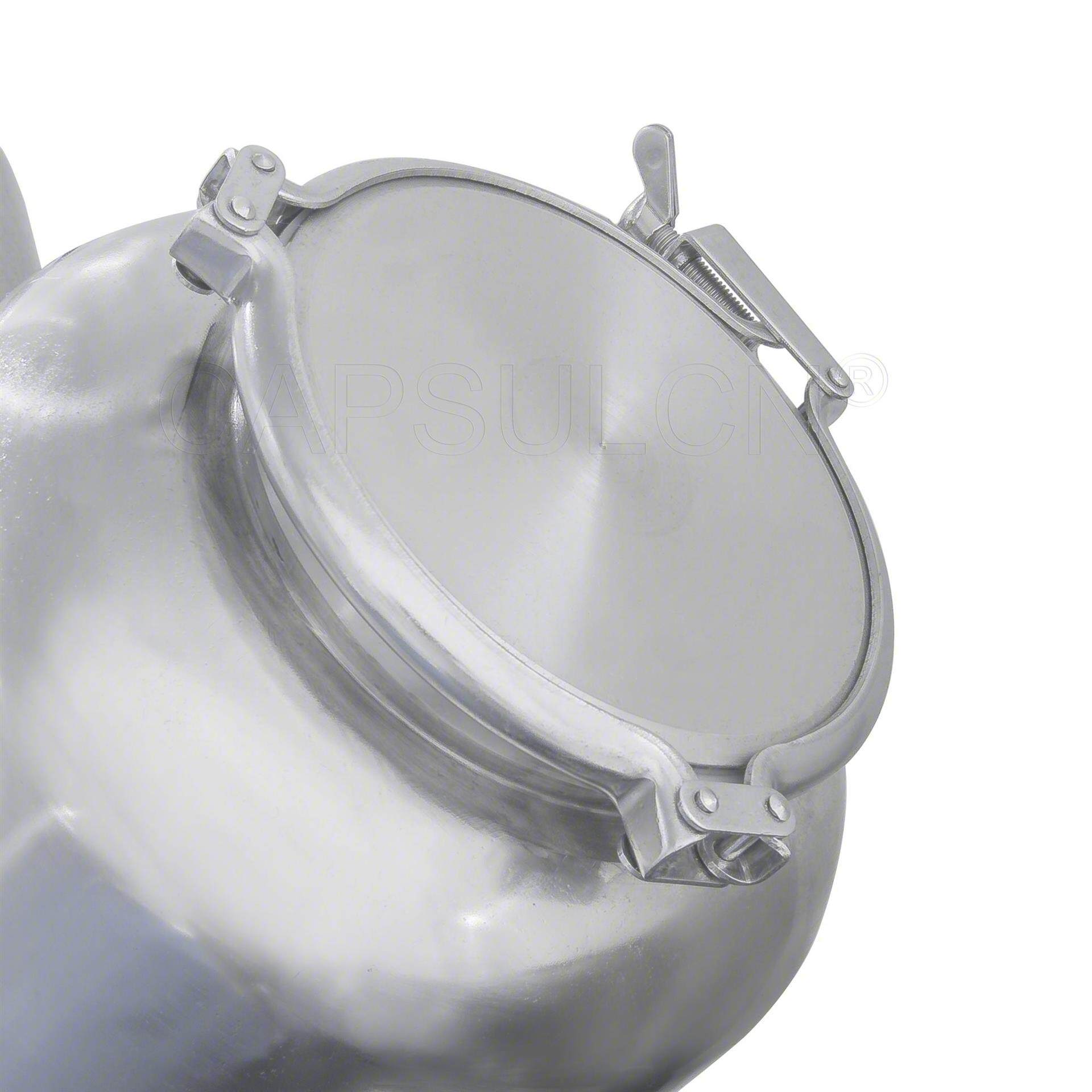

The feed inlet is where the materials to be processed are introduced into the blender. A V blender comes with two feed inlets at the top of the V shape. Equipped with detachable covers, these inlets allow for the manual feeding of ingredients and provide access to cleaning the inside of your V blender.

Depending on your needs, the feed inlet cover can be designed in multiple styles, including the one locked by a safety pin and the one secured by a clamp ring. The inlets typically boast a seal ring to keep the blender dust-tight.

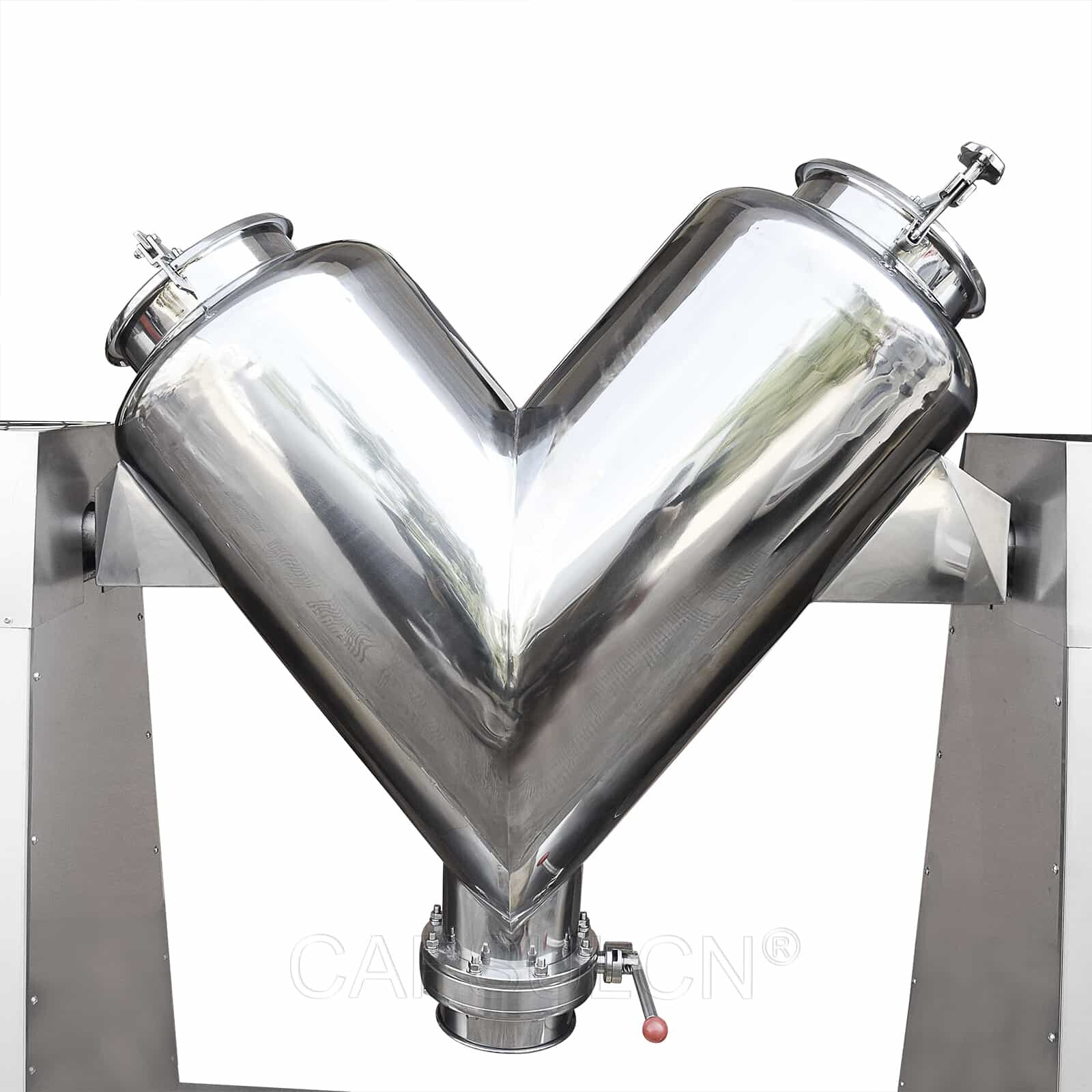

2. Mixing vessel

This V-shaped vessel is one of the most crucial V blender parts since it's where the blending process takes place. As the vessel rotates on its horizontal axis, the ingredients cascade down, dispersing particles throughout a newly exposed surface.

The mixing vessel is fully welded and polished to a smooth, sanitary finish, enabling efficient blending and easy cleaning. This component is typically constructed from 304 stainless steel to satisfy the requirements of cGMP or GMP regulations.

To meet various mixing applications, you can equip the vessel with a variety of optional design considerations:

- An intensifier bar for deagglomeration;

- Spray nozzles for coating or solid-liquid mixing;

- Jackets for heating or cooling;

- A vacuum system for material drying.

3. Intensifier bar

The intensifier bar is one of the optional V blender parts. It's mounted along the axis of rotation of the blender. If you want to break up tough lumps or large agglomerations in the batch, an intensifier bar is a go-to. This device is designed to provide sufficient shear for specific applications that require the reduction of lumps.

As mentioned above, the V blender is best for mixing solid ingredients. Actually, it also can be used to produce a homogeneous solid-liquid blend. If the liquid is a small part of the blend, it can be constantly sprayed over the solids while the blender is rotating. To do this, you can choose the intensifier bar incorporated with spray nozzles.

4. Discharge valve

The discharge port is where the mixture exits the machine. This component has a butterfly valve that is hermetically sealed for optimal performance.

Depending on your preferences, the valve can be constructed to open either manually, through pneumatic control, or automatically.

5. Motor and gearbox

The V blender is propelled using an explosion-proof electric motor that is paired with a gearbox. The overall speed of the blending process is kept under control thanks to the job done by this assembly.

6. Control panel

The control panel of a V blender typically provides the functions to start, stop and jog the machine. Besides, it allows you to set up the mixing time and regulate the rotating speed.

Among them, the variable frequency drives work to adjust the rotational speed, enabling the ingredients to slide down the mixing vessel in a controlled way.

Design of V Blender

Thanks to its shape, the V blender is also known as a twin shell blender or V-cone blender. The blender is made up of two different hollow cylindrical shells. The two shells are joined to one another in the shape of a V at an angle varying from 75 to 90 degrees.

There are three separate openings in the construction of a V blender. Two openings are located at the top of the V-shaped mixing vessel. They are used as inlets for the material feed. And the third opening at the bottom of the vessel comes with a butterfly discharge valve, allowing the mixed product to leave the equipment in a controlled manner.

The tumble blenders all work by rotating about a horizontal axis, and the twin shell blender has no exception. It features trunnions on both sides of the mixing vessel.

Aside from functioning as a support, the trunnions allow an intensifier bar to travel through them into the vessel, helping with deagglomeration as and when needed. Also, the intensifier bar can be provided with a spray system for the coating or liquid-solid mixing process, depending on your production needs.

Success Factors for Effective Blending

To achieve a homogeneous blend within a short circle time, we come up with 3 success factors that help you get the most out of your blending operation.

1. Material Loading

It's important to load a twin shell blender in a symmetrical fashion. It's best to load in layers and put small ingredients in the middle of the bigger ones. If the level is higher than where the two shells meet, you should put the same amount of ingredients in both of them to get the best cycle time.

2. V Blender Capacity

A long mixing time or failure to get a homogeneous blend is caused by overfilling the blender.

The mixing duration for twin shell blenders is normally between 10 and 15 minutes.

When a V blender is rotating, it is essential to leave some space in the mixing vessel. The solid ingredients need room to tumble, so the volume of the solids should not be too high. Typically, 40%-70% of the container's total volume will ensure adequate material diffusion in the twin shell blender.

3. Mixing Speed

Depending on the device's size, the normal mixing speed for V blenders (500-2000L) is between 10 and 25 revolutions per minute. V blenders have a critical speed where the centrifugal force equals the force of gravity. The best mixing speed is said to be between 50% and 80% of the critical speed.

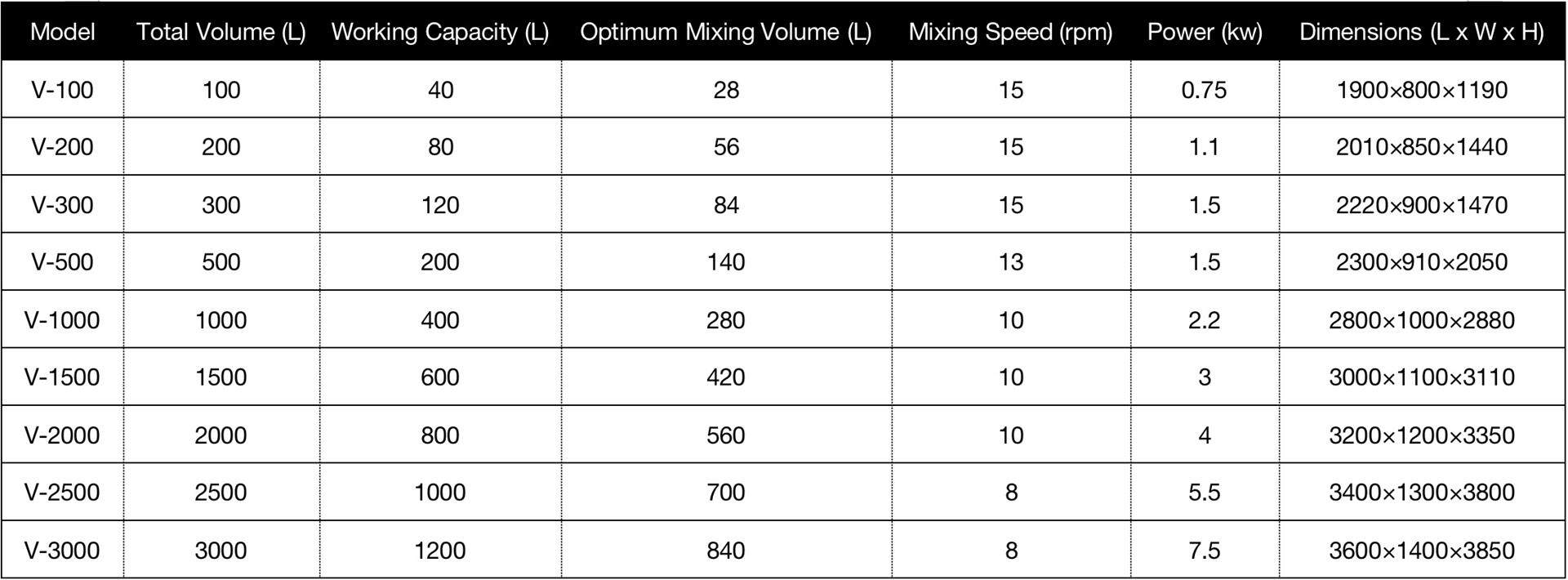

Specifications for V Blenders

Below is a specification chart of v blenders supplied by iPharMachine. This chart covers the V blender capacity, optimum mixing volume, total volume, and many other technical parameters that help you to find the right equipment.

As you see in the above specification chart, at iPharMachine, each piece of V blender is fabricated by following the above 3 success factors for reliable and efficient mixing. If you're looking for a quality V-cone blender, contact us today!

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche