VFFS Machines Explained: Bag Types, Buying Tips & Troubleshooting

If you want to stand out in the fierce market competition, exquisite packaging is a must. It can make your product more recognizable and more attractive to customers. Therefore, you’d better have a high-quality packing machine for your business. Currently, vertical packing machines are popular in the market. They can produce various bags and pouches, so many manufacturers select them as the first choice. If you’re not familiar with this machine, check the post for more valuable information.

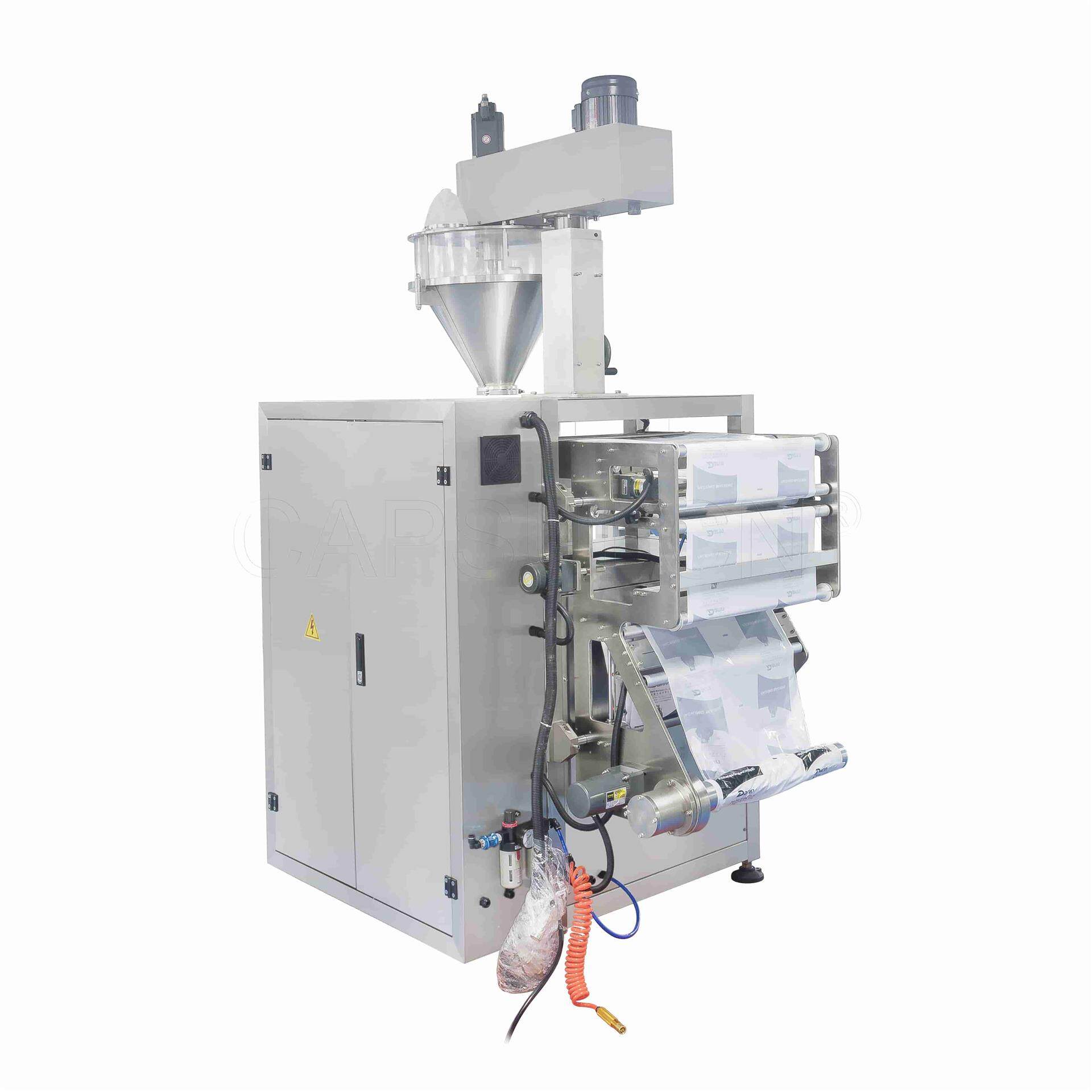

What is a Vertical Packaging Machine?

A vertical packing machine is also referred to as a vertical form fill machine (VFFS). it is used to create, fill, and seal packaging bags in a vertical orientation. The bags produced include many types, such as stand-up packing, 3-sided seal packing, pillow packing, etc. A VFFS machine can handle different packaging materials like plastic, paper, and foil. You can choose the most suitable one according to your production needs.

Now, most VFFS machines on the market are fully automatic models. They can automate the entire packaging process from bag forming to sealing. It significantly reduces the risk of manual labor and increases production speed. The machine also ensures each package is consistently filled and sealed. It helps maintain a uniform appearance and quality. In addition, compared to HFFS machines, VFFS machines occupy less floor space. If you don’t have a large workplace, VFFS machines are ideal for your production.

Applications of Vertical Packaging Machines

This machine could be used in many industries. Now let’s take a look.

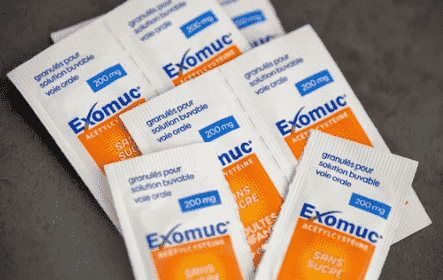

- Pharmaceuticals. They are used to pack tablets, capsules, powders, and other medicinal products. Their precise filling capabilities are crucial for maintaining correct dosages.

- Food industry. They are used for packaging snacks, coffee, sugar, grains, spices, etc. They ensure that food items are hygienically packed and preserved for longer shelf life.

- Cosmetics. Cosmetic products such as creams, powders, and gels are efficiently packed with VFFS machines.

- Chemical and industrial products. The machine mainly packs small hardware items, fertilizers, chemicals, and other industrial products, ensuring they are securely packed for transportation and storage.

How Does a VFFS Machine Work?

The working process of this machine is similar to that of HFFS machines. It also requires the film to unwind first, and then to form pouches. Before learning the detailed process, you can check the video to see how it works.

Step 1: film unwinding

After the film roll is placed on the unwinding reel, the film is pulled into the machine through a series of rollers. The rollers guide and tension the film to ensure smooth movement and proper alignment.

Step 2: bag forming and bottom sealing

The film is shaped into a cylindrical tube by a forming collar. The edges of the film overlap slightly. These edges are then sealed together by a vertical sealing bar. So a continuous tube is created. This vertical seam runs the length of the bag.

The tube is pulled downward by film pulling belts to form bags. The machine is equipped with many sensors or encoders. They measure the length of the bag to ensure consistent bag sizes. The bag length could be adjusted. It depends on your desired dimensions.

As the shape of the bag is finished, the bottom end of the tube is sealed horizontally by a pair of sealing jaws. This creates the bottom seal of the bag.

Step 3: bag filling

During the filling process, the product is measured and dispensed into the formed tube from the top. The machine will fill materials strictly according to the set weight. VFFS machines can handle various products, including granules, powders, liquids, and solids. The filling system may vary depending on the product type. For example, auger fillers are more suitable for powders while pump fillers for liquids.

Step 4: top sealing and discharge

Once the product is inside the bag, another set of horizontal sealing jaws creates the top seal of the bag. It helps completely seal the entire product to prevent leakage. Meanwhile, the cutting mechanism cuts the tube, separating the newly formed and filled bag from the rest of the film.

The finished bag is then discharged from the machine for further handling, such as labeling or boxing.

What Bags Can VFFS Machines Produce?

Vertical packing machines are highly versatile and can produce a variety of bag types to accommodate different packaging needs. Here are some common bag types for your reference.

Pillow Bags

Pillow bags are the most basic and common type of packaging. They feature a top seal, a bottom seal, and a vertical back seal. These bags are ideal for packaging a wide range of products, including snacks, chips, candies, and small hardware items. The primary advantage of pillow bags is their cost-effectiveness and simplicity. It makes them suitable for high-speed production lines. They offer efficient use of packaging material and are easy to produce and handle.

Gusseted Bags

Gusseted bags have expandable side folds or gussets. They allow the bag to expand and accommodate bulkier or larger volume products. These bags are commonly used for coffee, pet food, powdered goods, and other bulk items. These bags feature great capacity and stability. When filled, they can stand upright on shelves. It offers better display and storage options.

Block-Bottom Bags

Block-bottom bags are also known as flat-bottom or quad-seal bags. They have a rectangular base that allows them to stand upright. These bags can be stackable, and easy to store. They are often used for packaging nuts and other premium food products. These bags maximize shelf space and provide better packing efficiency.

Sachets

Sachets are small, flat packets. They are often used for single-serving products. They are ideal for packaging products like medicine, condiments, sauces, shampoos, etc. The main advantage of sachets is their convenience and portability. They are lightweight and easy to open. It makes them perfect for travel and on-the-go use. Sachets also allow for precise portion control, which is beneficial for both manufacturers and consumers. Moreover, sachets don’t require high manufacturing costs. Because the design is simple and the manufacturing process is also easy.

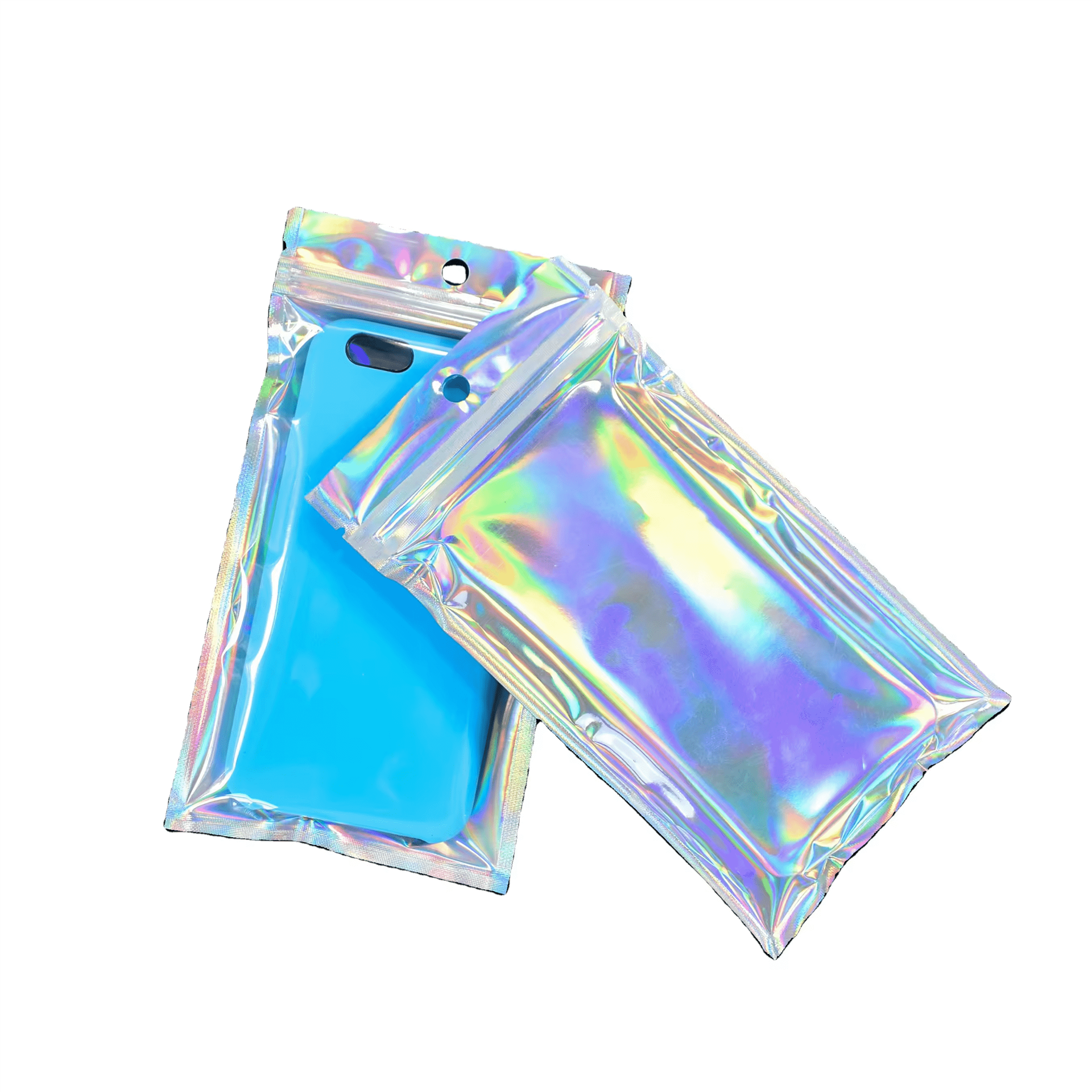

Three-Sided Seal Bags

As the name suggests, these bags are sealed on three sides with one side left open for filling. After filling, the fourth side is sealed to complete the package. This type of packaging offers a flat, flexible format. They are mainly used for packing larger quantities of powdered medications, tablets, capsules, and medical devices.

How to Choose a Vertical Packing Machine?

Product and Packaging Type

Different products may require specific filling mechanisms. So you should determine what product you want to pack first. If you need to package solids, choose the machine with a volumetric cup or scale filler. It ensures the products could be sealed tightly, and avoid leakage.

Packaging Size

Not all VFFS machines can handle all bag sizes. It is important to check whether the machine can deal with the specific dimensions you need. In addition, If your packaging sizes vary greatly, ensure the machine offers high flexibility. In this way, the equipment can handle this range without requiring extensive adjustments or retooling. This helps save much time and simplify the production process.

Film Properties

Different models of machines differ in handling specific material types, thicknesses, and widths. The equipment you choose should be compatible with the materials you plan to use. This can improve packaging efficiency, and ensure seal quality. For example, if your packaging material is mainly PE, make sure the VFFS machine could provide the right heat sealing temperature and pressure for PE. PE is flexible but sensitive to heat sealing temperature.

How to Troubleshoot the VFFS Machine?

During the operation, you may meet some problems. Actually, some minor issues can be easy to be solved by yourself. Take the machine DXD-80Y for example.

|

Problems |

Causes |

Solutions |

|

The heating plate does not |

The temperature is set incorrectly. |

Set correct temperature. |

|

The relay is damaged. |

Replace the relay. |

|

|

The wire drops or gets loose. |

Reconnect the wire. |

|

|

Bags are not pulled. |

The length value of bag pulling is wrongly set. |

Reset the length value of bag pulling. |

|

The drive part of the bag-pulling shaft is off or loose. |

Align and tighten the transmission shaft. |

|

|

The driver or the stepper motor is damaged. |

Replace them. |

|

|

The film feeding motor does not send out material. |

Feeding control photoelectricity is damaged. |

Replace it. |

|

Feeding control photoelectricity is too far away from photoelectric axis. |

Make them closer to each other. |

The End

A right vertical form fill seal machine is essential for optimizing your packaging process. It offers versatility and efficiency, making them a valuable asset in any packaging operation. By considering your specific needs, you can select a VFFS machine that will provide long-term benefits. This also causes a high return on investment.

At iPharMachine, we offer a wide range of VFFS machines for diverse packaging requirements. Our machines are equipped to handle various materials and bag types. You can use them efficiently to complete the packaging task. Whether you need a machine for powders, granules, or liquids, iPharMachine has the perfect solution for you. Explore our selection and find the ideal VFFS machine to enhance your packaging line.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche