How Labeling Machines for Vials Upgrade Your Business?

Vials are mainly used to store liquids and powders. They are particularly useful in pharma and laboratory research. So a clear label in these bottles is important. It tells people what's inside and if there are any warnings. If you need to put labels on your vials, you should know how to use a vial labeling machine. This post may help you further understand this machine.

What is vial labeling equipment?

This machine puts different labels on vials. Labels offer clear and key information about the content. For example, medicine labels tell you how much to take, how to use it, and what’s in it. Moreover, many government groups, like the FDA, have strict rules for labeling products. With a vial labeling machine, you can put labels on quickly and efficiently. This is really important for makers that manufacture medicine and health products.

Some advanced vial labeling machines can be adjusted to fit vials of different sizes. You can change the width or height for better labeling. This is useful if you need to frequently switch between different vial sizes. But if the vials are too big or too small for the machine to adjust to, you might need a custom machine.

Applications of vial labeling machines

Nearly every product requires precise and efficient labeling. It shows clearly about product details, such as product name, origin, expiration dates, etc. Here are some most common examples.

- Pharma industry. In this sector, vials are commonly used to hold medications and vaccines. Accurate labeling ensures products meet strict rules.

- Cosmetic industry. Common bottles in cosmetics include serum vials, essential oil vials, or fragrance bottles.

- Food and beverage industry. In this sector, vials are particularly useful for packaging condiments, oils, and drinks.

- Chemical industry. Small bottles are mainly used to store chemicals, reagents, and solvents.

How does a vial label applicator work?

Feed the bottles

You should put the bottles on a conveyor belt at first. The belt moves the bottles along for further processing. The machine can work with bottles of different sizes by changing how the bottles are guided.

Detect the bottles

As bottles move along the belt, a sensor helps track where they are. Then this sensor sends a signal to the control system. So the machine know when it should apply to the label. This makes sure each bottle gets a label in the right spot. And no bottle would overlap or miss labels.

Peel the label off the backing paper

The labels are kept in a roll on the label tray. The machine pulls the backing paper using a motor. As the paper moves, it goes over a plate that helps peel the label off. The label then gets ready to stick to the bottle.

Apply the label to the bottle

The peeled label is then applied to the bottle as it passes through the labeling station. This step is really important to make sure the label looks clean and neat.

Secure the label

After the label is put on the bottle, a roller presses it down tightly. This helps the label stick well without any air bubbles or wrinkles. The roller uses even pressure to make the label stick better. You can change the pressure if the bottles are different shapes or sizes.

Collect the backing paper

After the labels are peeled off, the leftover paper is rolled up neatly. So it doesn't make a mess. This helps keep the workspace clean and makes sure nothing gets in the way of the machine. Then, the labeled bottles keep moving and they are gathered at the end. If the machine is part of a bigger production line, the bottles can go to other machines for futher processing, like packaging.

Five common types of labeling equipment for small bottles

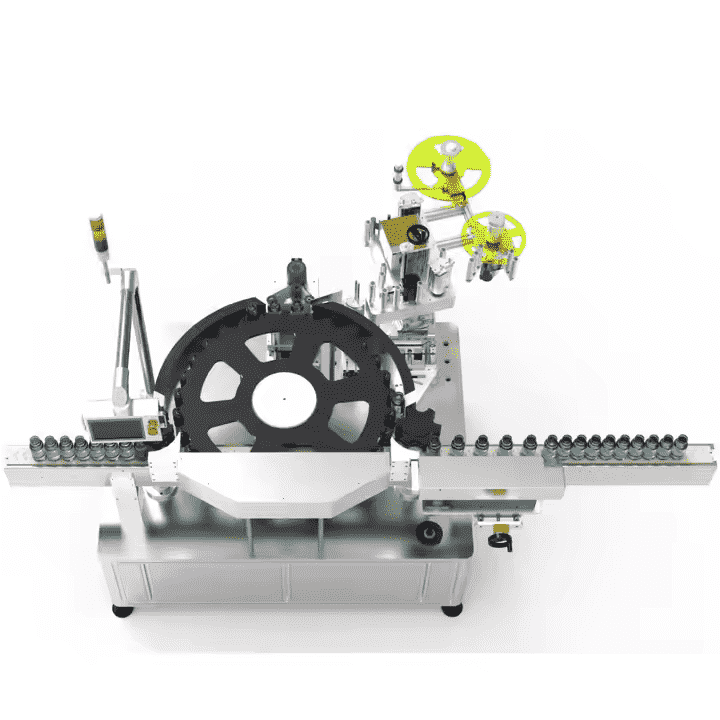

Wrap-around labeling machines

These machines label vials by wrapping the label completely around the vial’s surface. They work best with round, cylindrical vials and ensure the label stays secure. Wrap-around labeling is usually used in industries like pharmaceuticals and cosmetics. The machine applies the label accurately and it is suitable for vials of different sizes. This type is ideal for products like medicine vials, essential oil bottles, or flavoring agents.

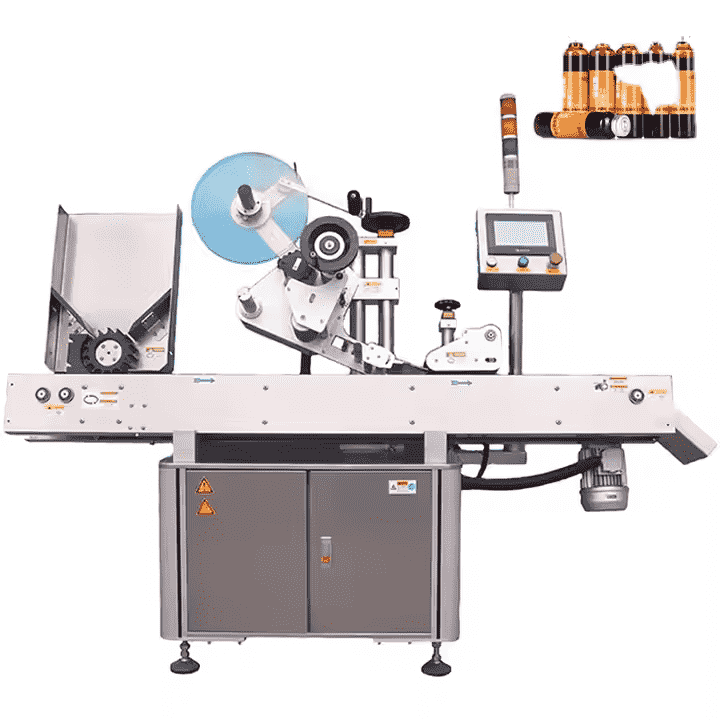

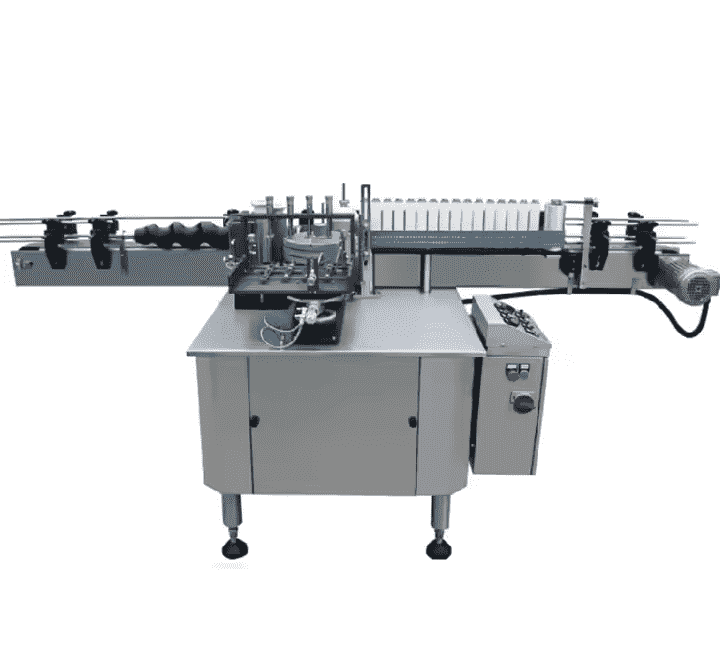

Horizontal labeling machines

Horizontal labeling machines lay vials flat on a conveyor belt for sticker labeling. This method works well for small, lightweight vials that could fall over during process. The machines are fast and precise, making them perfect for mass production. They are often used in pharmaceutical and lab settings for vials containing medicine, vaccines, or test samples. Their compact size makes them easy to fit into production lines.

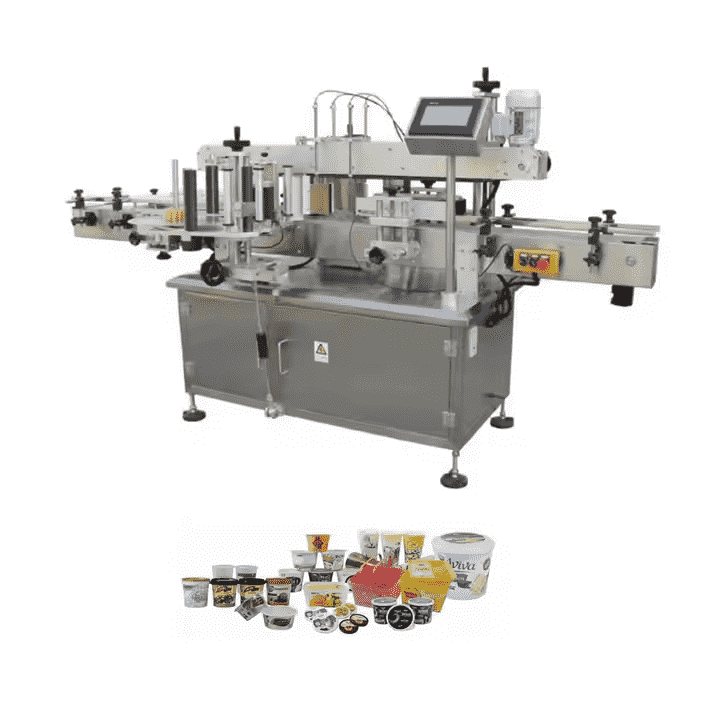

Vertical labeling equipment

These machines label vials that stand upright during the process. They are great for vials that are larger. Vertical vial labeling machines often include sensors to detect vial positions for precise label placement. They are commonly used in lab and cosmetic factories, such as for perfumes or serums.

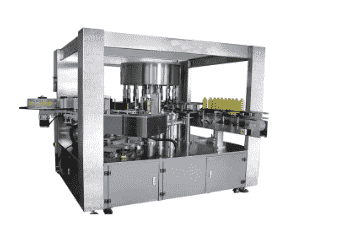

Rotary labeling machines

Rotary machines use a spinning platform to label vials quickly and precisely. They are ideal for large-scale operations, handling many vials in a short time. These machines can apply various label types, such as full wraps or partial labels. They are mainly used in industries like pharmaceuticals or cosmetics. Rotary labeling machines are a good choice when speed and accuracy are critical for production.

Cold glue labeling equipment

These machines use cold glue to stick labels onto vials instead of adhesive-backed labels. They are cost-effective for bulk production and are often used in traditional industries like food or beverages. These machines are ideal for products where adhesive labels might not work well, such as oils or certain cosmetics.

How do you choose a vial labeling machine?

A suitable labeling equipment is highly related to your production efficiency. So a careful selection is necessary.

Consider types of vials

You should be clear about what vials you want to use at first, especially considering shapes. Round vials for injectable medicines usually need a wrap-around labeling machine. Small, lightweight vials, such as sample containers, often work better with horizontal labeling machines. Because these machines can stabilize the vials during labeling. If your vials are heavy or have unique shapes, you may need a custom solution. You can directly find iPharMachine to help or find a supplier in Alibaba. The more detailed the information you provide, such as size, material, and weight, the more precise the options we can offer.

Labeling requirement

You should also consider the type of labels you need to apply. Standard labels with product names and barcodes can be applied by basic labeling applicators. However, if your labels need special features like tamper evidence or security seals, you’ll need a specialized machine. In addition, if you need to print variable data like batch numbers, a print-and-apply machine equipped with a printer will be necessary.

Production volume

Your production speed will influence the type of machine you choose. For large factories with mass production, a fully automatic labeling machine is essential. These machines can label vials quickly and consistently without constant human intervention. However, if you are a small business or a lab producing smaller batches, a semi-automatic machine is more practical. It costs less and still allows you to label vials efficiently, though at a slower pace.

The end

Vial labeling machines ensure products are accurately identified and meet industry standards. Whether you are a small business or a large-scale manufacturer, a proper machine can make a significant difference in your business. If you don’t know which type suits your product, contact iPharMachine. We have a professional technical team to help you choose the most suitable one and arrange shipping if you need it.

Leave your comment

Also Offers

Containment Automatic Capsule Filling Machine SFK-703

Fully Automatic Dosator Capsule Filling Machine CZ-40

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche